Milling · Turning - Komet Group

Milling · Turning - Komet Group

Milling · Turning - Komet Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UniTurn ®<br />

Internal Cutting Tools<br />

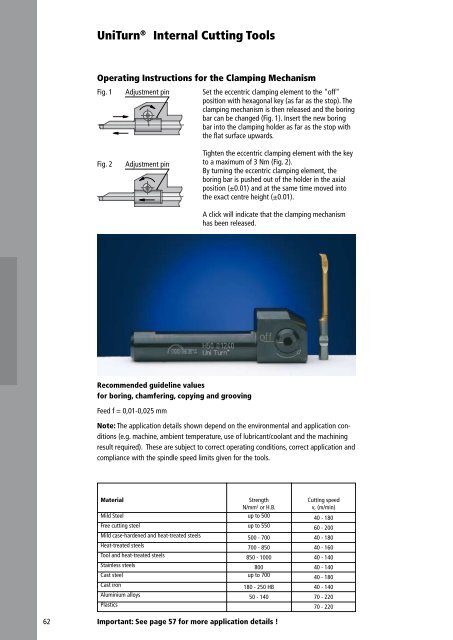

Operating Instructions for the Clamping Mechanism<br />

Fig. 1<br />

Adjustment pin<br />

Set the eccentric clamping element to the "off"<br />

position with hexagonal key (as far as the stop). The<br />

clamping mechanism is then released and the boring<br />

bar can be changed (Fig. 1). Insert the new boring<br />

bar into the clamping holder as far as the stop with<br />

the flat surface upwards.<br />

Fig. 2<br />

Adjustment pin<br />

Tighten the eccentric clamping element with the key<br />

to a maximum of 3 Nm (Fig. 2).<br />

By turning the eccentric clamping element, the<br />

boring bar is pushed out of the holder in the axial<br />

position (±0.01) and at the same time moved into<br />

the exact centre height (±0.01).<br />

A click will indicate that the clamping mechanism<br />

has been released.<br />

Recommended guideline values<br />

for boring, chamfering, copying and grooving<br />

Feed f = 0,01-0,025 mm<br />

Note: The application details shown depend on the environmental and application conditions<br />

(e.g. machine, ambient temperature, use of lubricant/coolant and the machining<br />

result required). These are subject to correct operating conditions, correct application and<br />

compliance with the spindle speed limits given for the tools.<br />

Material<br />

Mild Steel<br />

Free cutting steel<br />

Mild case-hardened and heat-treated steels<br />

Heat-treated steels<br />

Tool and heat-treated steels<br />

Stainless steels<br />

Cast steel<br />

Cast iron<br />

Aluminium alloys<br />

Plastics<br />

Strength<br />

N/mm 2 or H.B.<br />

up to 500<br />

up to 550<br />

500 - 700<br />

700 - 850<br />

850 - 1000<br />

800<br />

up to 700<br />

180 - 250 HB<br />

50 - 140<br />

Cutting speed<br />

v c (m/min)<br />

40 - 180<br />

60 - 200<br />

40 - 180<br />

40 - 160<br />

40 - 140<br />

40 - 140<br />

40 - 180<br />

40 - 140<br />

70 - 220<br />

70 - 220<br />

62<br />

Important: See page 57 for more application details !