Milling · Turning - Komet Group

Milling · Turning - Komet Group

Milling · Turning - Komet Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

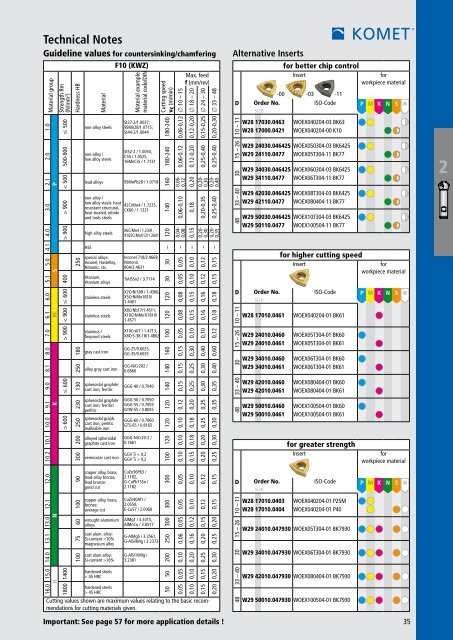

Technical Notes<br />

Guideline values for countersinking/chamfering<br />

Material group<br />

1.0<br />

2.0<br />

2.1<br />

P<br />

3.0<br />

4.0<br />

Strength Rm<br />

(N/mm 2 )<br />

# 500<br />

500-900<br />

< 500<br />

> 900<br />

> 900<br />

Hardness HB<br />

Material<br />

non-alloy steels<br />

non-alloy /<br />

low alloy steels<br />

lead alloys<br />

non alloy /<br />

low alloy steels: heat<br />

resostant structural,<br />

heat treated, nitride<br />

and tools steels<br />

high alloy steels<br />

F10 (KWZ)<br />

Material example<br />

material code/DIN<br />

St37-2/1.0037;<br />

9SMn28/1.0715;<br />

St44-2/1.0044<br />

St52-2 / 1.0050,<br />

C55 / 1.0525,<br />

16MnCr5 / 1.7131<br />

9SMnPb28 / 1.0718<br />

42CrMo4 / 1.7225,<br />

CK60 / 1.1221<br />

X6CrMo4 / 1.2341,<br />

X165CrMoV12/1.2601<br />

Cutting speed<br />

vc (m/min)<br />

180-240<br />

180-240<br />

160<br />

140<br />

120<br />

x 10 – 15<br />

0,06-0,12<br />

0,06-0,12<br />

0,06-<br />

0,12<br />

0,06-0,10<br />

0,04-<br />

0,08<br />

Max. feed<br />

f (mm/rev)<br />

x 18 – 20<br />

0,12-0,20<br />

0,12-0,20<br />

0,20<br />

0,18<br />

0,15<br />

x 24 – 30<br />

0,15-0,25<br />

0,25-0,40<br />

x 33 – 48<br />

0,20-0,30<br />

0,25-0,40<br />

0,20-<br />

0,30<br />

0,20-<br />

0,40<br />

0,20-0,35<br />

0,25-0,40<br />

0,20-<br />

0,30<br />

0,20-<br />

0,35<br />

Alternative Inserts<br />

-00 -03 -11<br />

D Order No.<br />

ISO-Code P M K N S H<br />

size<br />

10 – 11<br />

15 – 26<br />

30<br />

33 – 40<br />

48<br />

W28 17030.0463<br />

W28 17000.0421<br />

for better chip control<br />

Insert<br />

WOEX040204-03 BK63<br />

WOEX040204-00 K10<br />

W29 24030.046425 WOEX050304-03 BK6425<br />

W29 24110.0477 WOEX05T304-11 BK77<br />

W29 34030.046425 WOEX060304-03 BK6425<br />

W29 34110.0477 WOEX06T304-11 BK77<br />

W29 42030.046425 WOEX08T304-03 BK6425<br />

W29 42110.0477 WOEX080404-11 BK77<br />

W29 50030.046425 WOEX10T304-03 BK6425<br />

W29 50110.0477 WOEX100504-11 BK77<br />

for<br />

workpiece material<br />

§§<br />

§$<br />

$<br />

§§<br />

§$<br />

$<br />

§§<br />

§$<br />

$<br />

§§<br />

§$<br />

$<br />

§§<br />

§$<br />

$<br />

2<br />

5.1 5.0 4.1<br />

S<br />

400<br />

250<br />

HSS<br />

special alloys:<br />

Inconel, Hastelloy,<br />

Nimonic, stc.<br />

titanium,<br />

titanium alloys<br />

Inconel 718/2.4668,<br />

Nimonic<br />

80A/2.4631<br />

TiAl5Sn2 / 3.7114<br />

30 30 –<br />

0,05 0,05 –<br />

0,10 0,10 –<br />

0,12 0,12 –<br />

0,15 0,15 –<br />

for higher cutting speed<br />

Insert<br />

for<br />

workpiece material<br />

6.0<br />

# 600<br />

stainless steels<br />

X2CrNi189 / 1.4306,<br />

X5CrNiMo1810/<br />

1.4401<br />

120<br />

0,08<br />

0,15<br />

0,16<br />

0,18<br />

D Order No.<br />

ISO-Code P M K N S H<br />

size<br />

6.1<br />

M<br />

< 900<br />

stainless steels<br />

X8CrNb17/1.4511,<br />

X10CrNiMoTi1810/<br />

1.4571<br />

120<br />

0,08<br />

0,15<br />

0,16<br />

0,18<br />

10 – 11<br />

W28 17010.0461 WOEX040204-01 BK61 §<br />

7.0<br />

8.0<br />

8.1<br />

> 900<br />

180<br />

250<br />

stainless /<br />

fireproof steels<br />

gray cast iron<br />

alloy gray cast iron<br />

X10CrAl7 / 1.4713,<br />

X8CrS-38-18/1.4862<br />

GG-25/0.6025,<br />

GG-35/0.6035<br />

GG-NiCr202 /<br />

0.6660<br />

100<br />

160<br />

140<br />

0,05<br />

0,15<br />

0,15<br />

0,10<br />

0,30<br />

0,25<br />

0,10<br />

0,40<br />

0,30<br />

0,12<br />

0,60<br />

0,40<br />

15 – 26<br />

30<br />

W29 24010.0460<br />

W29 24010.0461<br />

W29 34010.0460<br />

W29 34010.0461<br />

WOEX05T304-01 BK60<br />

WOEX05T304-01 BK61<br />

WOEX06T304-01 BK60<br />

WOEX06T304-01 BK61<br />

§<br />

§<br />

§<br />

§<br />

9.0<br />

# 600<br />

130<br />

spheroidal graphite<br />

cast iron, ferritic<br />

GGG-40 / 0.7040<br />

140<br />

0,15<br />

0,25<br />

0,30<br />

0,35<br />

33 – 40<br />

W29 42010.0460<br />

W29 42010.0461<br />

WOEX080404-01 BK60<br />

WOEX080404-01 BK61<br />

§<br />

§<br />

10.0 9.1<br />

K<br />

> 600<br />

250 230<br />

spheroidal graphite<br />

cast iron, ferritic/<br />

perlitic<br />

spheroidal graph.<br />

cast iron, perlitic<br />

malleable iron<br />

GGG-50 / 0.7050<br />

GGG-55 / 0.7055<br />

GTW-55 / 0.8055<br />

GGG-60 / 0.7060<br />

GTS-65 / 0.8165<br />

120 120<br />

0,10 0,12<br />

0,18 0,20<br />

0,25 0,25<br />

0,30 0,35<br />

48<br />

W29 50010.0460<br />

W29 50010.0461<br />

WOEX100504-01 BK60<br />

WOEX100504-01 BK61<br />

§<br />

§<br />

10.2 10.1<br />

300 200<br />

alloyed spheroidal<br />

graphite cast iron<br />

vermicular cast iron<br />

GGG-NiCr20-2 /<br />

0.7661<br />

GGV Ti < 0,2<br />

GGV Ti > 0,2<br />

100 120<br />

0,10 0,10<br />

0,15 0,18<br />

0,20 0,20<br />

0,25 0,30<br />

for greater strength<br />

Insert<br />

for<br />

workpiece material<br />

12.0<br />

90<br />

copper alloy, brass,<br />

lead-alloy bronze,<br />

lead bronze:<br />

good cut<br />

CuZn36Pb3 /<br />

2.1182,<br />

G-CuPb15Sn /<br />

2.1182<br />

300<br />

0,05<br />

0,10<br />

0,12<br />

0,15<br />

D Order No.<br />

ISO-Code P M K N S H<br />

size<br />

12.1<br />

100<br />

copper alloy, brass,<br />

bronze:<br />

average cut<br />

CuZn40Al1 /<br />

2.0550,<br />

E-Cu57 / 2.0060<br />

300<br />

0,05<br />

0,10<br />

0,12<br />

0,15<br />

10 – 11<br />

W28 17010.0403<br />

W28 17010.0404<br />

WOEX040204-01 P25M<br />

WOEX040204-01 P40<br />

§§<br />

§ §§<br />

14.0 13.1 13.0<br />

N<br />

60<br />

75<br />

100<br />

wrought aluminium<br />

alloys<br />

cast alum. alloy:<br />

Si-content 10%<br />

AlMg1 / 3.3315,<br />

AlMnCu / 3.0517<br />

G-AlMg5 / 3.3561,<br />

G-AlSi9Mg / 3.2373<br />

G-AlSi10Mg /<br />

3.2381<br />

300<br />

250<br />

200<br />

0,05<br />

0,06<br />

0,10<br />

0,20 0,16 0,12<br />

0,25 0,20 0,15<br />

0,30 0,25 0,20<br />

15 – 26<br />

30<br />

W29 24010.047930 WOEX05T304-01 BK7930 §§§ §§<br />

W29 34010.047930 WOEX06T304-01 BK7930 §§§ §§<br />

15.0<br />

16.0<br />

H<br />

1400<br />

1800<br />

hardened steels<br />

< 45 HRC<br />

hardened steels<br />

> 45 HRC<br />

50<br />

50<br />

0,05<br />

0,05<br />

0,10<br />

0,10<br />

0,15<br />

0,15<br />

Cutting values shown are maximum values relating to the basic recommendations<br />

for cutting materials given.<br />

Important: See page 57 for more application details !<br />

0,20<br />

0,20<br />

33 – 40<br />

48<br />

W29 42010.047930 WOEX080404-01 BK7930 §§§ §§<br />

W29 50010.047930 WOEX100504-01 BK7930 §§§ §§<br />

35