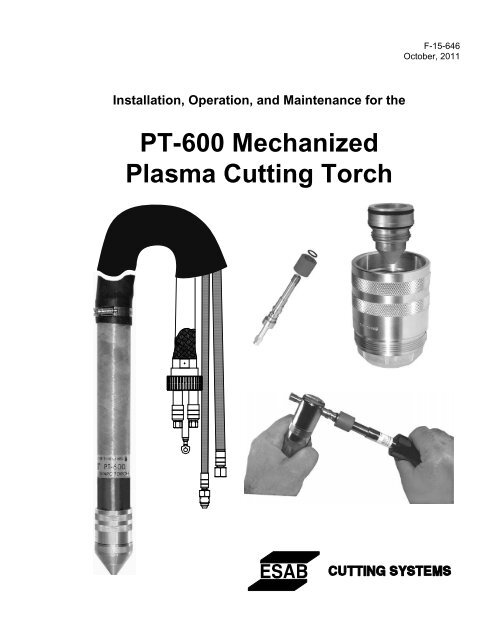

PT-600 Mechanized Plasma Cutting Torch

PT-600 Mechanized Plasma Cutting Torch

PT-600 Mechanized Plasma Cutting Torch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

F-15-646<br />

October, 2011<br />

Installation, Operation, and Maintenance for the<br />

<strong>PT</strong>-<strong>600</strong> <strong>Mechanized</strong><br />

<strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong>

The equipment described in this manual is<br />

potentially hazardous. Use caution when installing,<br />

operating and maintaining this equipment.<br />

Purchaser is solely responsible for the safe<br />

operation and use of all products purchased,<br />

including compliance with OSHA and other<br />

government standards. ESAB <strong>Cutting</strong><br />

Systems has no liability for personal injury or<br />

other damage arising out of the use of any<br />

product manufactured or sold be ESAB. See<br />

standard ESAB terms and conditions of sale<br />

for a specific statement of ESAB’s<br />

responsibilities and limitations on its liability.<br />

ESAB <strong>Cutting</strong> Systems first priority is total customer<br />

satisfaction. We constantly look for ways to<br />

improve our products, service and documentation.<br />

As a result, we make enhancements and/or design<br />

changes as required. ESAB makes every possible<br />

effort to ensure our documentation is current. We<br />

cannot guarantee that each piece of documentation<br />

received by our customers reflects the latest design<br />

enhancements. Therefore, the information<br />

contained in this document is subject to change<br />

without notice.<br />

This manual is ESAB Part Number F15646<br />

November 2001 updated spare parts<br />

June 2002 boot part number changed<br />

Dec 2002 Added no underwater cut with H-35 tp process data<br />

This manual is for the convenience and use of the<br />

cutting machine purchaser. It is not a contract or<br />

other obligation on the part of ESAB <strong>Cutting</strong><br />

Systems.<br />

© ESAB <strong>Cutting</strong> Systems, 2000<br />

Printed in U.S.A.

Type of equipment Materialslag<br />

DECLARATION OF CONFORMITY<br />

according to the EC Low Voltage Directive 73/23/EEC<br />

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE<br />

enligt lågspänningsdirektivet 73/23/EEG<br />

Fill in and put a cross in appropriate boxes Fyll i och kryssa tillämpliga rutor<br />

<strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong><br />

Brand name or trade mark Fabrikatnamn eller varumärke<br />

ESAB<br />

Type designation etc. Typbeteckning etc.<br />

<strong>PT</strong>-<strong>600</strong> AY, (8)0558001827, (8)0558001828, (8)0558001829, (8)0558001830, (8)0558001831,<br />

(8)0558001832, (8)0558001833,<br />

Manufacturer’s name, address, telephone No, telefax No: Tillverkarens namn, adress, telefon, telefax:<br />

ESAB Welding & <strong>Cutting</strong> Products<br />

411 South Ebenezer Road, Florence, South Carolina 29501, USA<br />

Phone: +1 843 669 4411, Fax: +1 843 664 4258<br />

Manufacturer’s authorised representative established within the EEA; Name, address, telephone No, telefax No:<br />

Tillverkarens representant inom EES; Namn, adress, telefon, telefax:<br />

ESAB AB<br />

Box 8004, 402 77 Göteborg, Sweden<br />

Phone: +46 31 50 90 00, Fax: +46 31 50 92 61<br />

The following harmonised standards or technical specifications (designations) which comply with good engineering<br />

practice in safety matters in force within the EEA have been used in the design:<br />

Följande harmoniserande standarder eller tekniska specifikationer (beteckningar) som uppfyller god säkerhetsteknisk<br />

praxis inom EES har använts i konstruktionen:<br />

EN 60 974-7<br />

Arc welding equipment - Part 7: <strong>Torch</strong>es<br />

1. The equipment conforms completely, with the above stated harmonised standards or technical<br />

specifications.<br />

Materielen överensstämmer helt med ovan angivna harmoniserade standarder eller tekniska specifikationer.<br />

OR ELLER<br />

2. The equipment conforms only partially with the above stated harmonised standards or technical<br />

specifications but complies with good engineering practice in safety matters in force within the EEA.<br />

Materielen överensstämmer endast delvis med ovan angivna harmoniserade standarder eller tekniska<br />

specifikationer men uppfyller god säkerhetsteknisk praxis inom EES.<br />

Additional information Övriga uppgifter<br />

By signing this document, the undersigned declares as manufacturer, or the manufacturer’s authorised<br />

representative established within the EEA, that the equipment in question complies with the safety requirements<br />

stated above.<br />

Genom att underteckna detta dokument försäkrar undertecknad såsom tillverkare, eller tillverkarens representant inom<br />

EES, att angiven materiel uppfyller säkerhetskraven angivna ovan.<br />

Manufacturer<br />

Tillverkare<br />

Date Datum<br />

Göteborg 2003-01-10<br />

Or<br />

eller<br />

Signature Underskrift<br />

Manufacturer’s authorised representative<br />

Tillverkarens representant<br />

Position Befattning<br />

Managing Director<br />

Clarification namnförtydligande<br />

Henry Selenius

<strong>PT</strong>-<strong>600</strong> <strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong><br />

Table of Contents<br />

Page<br />

Section 1 Safety<br />

1.1 Introduction 1<br />

1.2 Safety Notations And Symbols 1<br />

1.3 General Safety Information 2<br />

1.4 Electrical Grounding 3<br />

1.5 Operating A <strong>Plasma</strong> <strong>Cutting</strong> Machine 4<br />

1.6 Service Precautions 8<br />

1.7 Safety References 10<br />

Section 2 Description<br />

2.1 General 1<br />

2.2 Scope 1<br />

2.3 Package Options Available 1<br />

2.4 Technical Specifications<br />

2.4.1 <strong>Plasma</strong> Gas 2<br />

2.4.2 Start Gas 2<br />

2.4.3 Secondary Gas 2<br />

2.4.4 <strong>PT</strong>-<strong>600</strong> <strong>Torch</strong> 2<br />

2.5 Parts Kits<br />

2.5.1 Starter Kit 3<br />

2.5.2 Spare Parts Kit 4<br />

Section 3 Installation<br />

3.1 General 1<br />

3.2 Connection of Hose and Cable Bundle to <strong>Torch</strong> Body 1<br />

3.3 Disassembly of <strong>Torch</strong> Bundle from <strong>Torch</strong> Body 3<br />

3.4 <strong>Torch</strong> Mounting “Precaution” 4<br />

i

<strong>PT</strong>-<strong>600</strong> <strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong><br />

Table of Contents<br />

Page<br />

Section 4 Operation<br />

Safety Precautions 1<br />

4.1 Set Up 2<br />

4.1.1 Mirror <strong>Cutting</strong> Requirements 2<br />

4.2 Cut Quality 3<br />

4.2.1 Introduction 3<br />

4.2.2 Cut Angle 3<br />

4.2.3 Cut Flatness 4<br />

4.2.4 Surface Finish 5<br />

4.2.5 Dross 6<br />

4.2.6 Dimensional Accuracy 7<br />

4.3 <strong>Torch</strong> Flow Passages 8<br />

4.4 Influence of Gas Options on Cut Quality<br />

4.4.1 Introduction 9<br />

4.4.2 Aluminum 10<br />

4.4.3 Carbon Steel 11<br />

4.4.4 Stainless Steel 12<br />

4.5 Process Data<br />

4.5.1 Introduction 13<br />

4.5.2 Process Data Settings<br />

Carbon Steel 14<br />

Aluminum 34<br />

Stainless Steel 66<br />

Section 5 Maintenance<br />

5.1 Introduction 1<br />

5.2 <strong>Torch</strong> Body 1<br />

5.3 <strong>Torch</strong> Front End Disassembly 2<br />

5.4 Front End Assembly 5<br />

ii

<strong>PT</strong>-<strong>600</strong> <strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong><br />

Table of Contents<br />

Page<br />

Section 6 Troubleshooting<br />

6.1 Reduced Consumable Life 1<br />

6.2 No Pilot Arc 2<br />

6.3 No Arc Transfer 2<br />

6.4 No Preflow <strong>Plasma</strong> 2<br />

6.5 No Preflow Shield 2<br />

6.6 <strong>Torch</strong> Fails To Fire 3<br />

6.7 No High Frequency in <strong>Torch</strong> 3<br />

Section 7 Replacement Parts<br />

7.1 General 1<br />

7.2 Ordering 1<br />

7.3 <strong>PT</strong>-<strong>600</strong> <strong>Torch</strong> Front End 2<br />

7.4 Hoses and Cables 4<br />

7.5 Complete Assemblies and Tools 6<br />

7.6 Parts Kits 8<br />

Customer/Technical Information<br />

Back Manual Cover<br />

iii

<strong>PT</strong>-<strong>600</strong> <strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong><br />

Table of Contents<br />

This page intentionally left blank<br />

iv

SECTION 1<br />

1.1 Introduction<br />

1.2 Safety Notations And Symbols<br />

!<br />

SAFETY<br />

The process of cutting metals with plasma equipment<br />

provides industry with a valuable and versatile tool.<br />

ESAB cutting machines are designed to provide both<br />

operation safety and efficiency. However, as with any<br />

machine tool, sensible attention to operating<br />

procedures, precautions, and safe practices is<br />

necessary to achieve a full measure of usefulness.<br />

Whether an individual is involved with operation,<br />

servicing, or as an observer, compliance with<br />

established precautions and safe practices must be<br />

accomplished. Failure to observe certain precautions<br />

could result in serious personnel injury or severe<br />

equipment damage. The following precautions are<br />

general guidelines applicable when working with<br />

cutting machines. More explicit precautions pertaining<br />

to the basic machine and accessories are found in the<br />

instruction literature. For a wide scope of safety<br />

information on the field of cutting and welding<br />

apparatus, obtain and read the publications listed in<br />

the Recommended References.<br />

The following words and symbols are used throughout<br />

this manual. They indicate different levels of required<br />

safety involvement.<br />

ALERT or ATTENTION. Your safety is involved<br />

or potential equipment failure exists. Used in<br />

concurrence with other symbols and information.<br />

!<br />

!<br />

!<br />

DANGER<br />

WARNING<br />

CAUTION<br />

CAUTION<br />

NOTICE<br />

Used to call attention to immediate hazards<br />

which, if not avoided, will result in serious<br />

personal injury or loss of life.<br />

Used to call attention to potential hazards<br />

that could result in personal injury or loss of<br />

life.<br />

Used to call attention to hazards that could<br />

result in minor personal injury or equipment<br />

damage.<br />

Used to call attention to minor hazards to<br />

equipment.<br />

Used to call attention to important<br />

installation, operation or maintenance<br />

information not directly related to safety<br />

hazards.<br />

1-1

SECTION 1<br />

SAFETY<br />

1.3 General Safety Information<br />

!<br />

WARNING<br />

<strong>Cutting</strong> Machine starts automatically.<br />

This torch may be mounted on a mechanized cutting<br />

machine. This equipment moves in various directions<br />

and speeds and may start automatically.<br />

• Moving machinery can crush.<br />

• Only qualified personnel should operate or service<br />

equipment.<br />

• Keep all personnel, materials, and equipment not<br />

involved in production process clear of entire<br />

system area.<br />

• Keep gear racks and rails clear of debris or<br />

obstructions, such as tools or clothing.<br />

• Fence off entire work cell to prevent personnel<br />

from passing through area or standing in the<br />

working envelope of the equipment.<br />

• Post appropriate WARNING signs at every work<br />

cell entrance.<br />

• Follow lockout procedure before servicing.<br />

!<br />

WARNING<br />

Failure to follow operating instructions<br />

could result in death or serious injury.<br />

Read and understand this operator’s manual before<br />

using machine.<br />

• Read entire procedure before operating or<br />

performing any system maintenance.<br />

• Special attention must be given to all hazard<br />

warnings that provide essential information<br />

regarding personnel safety and/or possible<br />

equipment damage.<br />

• All safety precautions relevant to electrical<br />

equipment and process operations must be<br />

strictly observed by all having system<br />

responsibility or access.<br />

• Read all safety publications made available by<br />

your company.<br />

1-2

SECTION 1<br />

!<br />

WARNING<br />

SAFETY<br />

Failure to follow safety warning label<br />

instructions could result in death or<br />

serious injury.<br />

Read and understand all safety warning labels on<br />

machine.<br />

Refer to operator’s manual for additional safety<br />

information.<br />

1.4 Electrical Grounding<br />

Electrical grounding is imperative for proper machine<br />

operation and SAFETY. Refer to your power source<br />

manual’s Installation section for detailed grounding<br />

instructions.<br />

!<br />

WARNING<br />

Electric shock hazard.<br />

Improper grounding can cause severe injury or death.<br />

Machine must be properly grounded before put into<br />

service.<br />

!<br />

WARNING<br />

Improper grounding can damage machine<br />

and electrical components.<br />

• Machine must be properly grounded before put<br />

into service.<br />

• <strong>Cutting</strong> table must be properly grounded to a good<br />

earth ground rod.<br />

1-3

SECTION 1<br />

SAFETY<br />

1.5 Operating A <strong>Plasma</strong> <strong>Cutting</strong> Machine<br />

WARNING<br />

!<br />

Flying debris and loud noise hazards.<br />

• Hot spatter can burn and injure eyes. Wear<br />

goggles to protect eyes from burns and flying<br />

debris generated during operation.<br />

• Chipped slag may be hot and fly far. Bystanders<br />

should also wear goggles and safety glasses.<br />

• From plasma arc can damage hearing. Wear<br />

correct ear protection when cutting above water.<br />

! WARNING<br />

Burn hazard.<br />

Hot metal can burn.<br />

• Do not touch metal plate or parts immediately after<br />

cutting. Allow metal time to cool, or douse with<br />

water.<br />

• Do not touch plasma torch immediately after<br />

cutting. Allow torch time to cool.<br />

! WARNING<br />

Hazardous voltages. Electric shock<br />

can kill.<br />

• Do NOT touch plasma torch, cutting table or cable<br />

connections during plasma cutting process.<br />

• Always turn power off to plasma power supplies<br />

before touching or servicing plasma torch.<br />

• Always turn power off to plasma power supplies<br />

before opening or servicing plasma plumbing or<br />

flow control box.<br />

• Do not touch live electrical parts.<br />

• Keep all panels and covers in place when machine<br />

is connected to power source.<br />

• Insulate yourself from workpiece and electrical<br />

ground: wear insulating gloves, shoes and<br />

a<br />

clothing.<br />

• Keep gloves, shoes, clothing, work area, and<br />

equipment dry.<br />

1-4

SECTION 1<br />

! WARNING<br />

Pinch hazard.<br />

Moving vertical slides can crush or pinch.<br />

SAFETY<br />

Keep hands clear of torch and slide during operation.<br />

!<br />

WARNING<br />

Fume hazard.<br />

Fumes and gases generated by the plasma cutting<br />

process can be hazardous to your health.<br />

• Do NOT breathe fumes.<br />

• Do not operate plasma torch without fume removal<br />

system operating properly.<br />

• Use additional ventilation to remove fumes if<br />

necessary.<br />

• Use approved respirator if ventilation is not<br />

adequate.<br />

1-5

SECTION 1<br />

SAFETY<br />

!<br />

WARNING<br />

Radiation hazard.<br />

Arc rays can injure eyes and burn skin.<br />

• Wear correct eye and body protection.<br />

• Wear dark safety glasses or goggles with side<br />

shields. Refer to following chart for recommended<br />

lens shades for plasma cutting:<br />

Arc Current<br />

Lens Shade<br />

Up to 100 Amps Shade No. 8<br />

100-200 Amps Shade e No. 10<br />

200-400 Amps Shade No. 12<br />

Over 400 Amps Shade No. 14<br />

• Replace glasses/goggles when lenses are pitted or<br />

broken<br />

• Warn others in area not to look directly at the arc<br />

unless wearing appropriate safety glasses.<br />

• Prepare cutting area to reduce reflection n and<br />

transmission of ultraviolet light.<br />

• Paint walls and other surfaces with dark colors to<br />

reduce reflections.<br />

• Install protective screens or curtains to reduce<br />

ultraviolet transmission.<br />

!<br />

WARNING<br />

Ruptured Gas Cylinders Can Kill<br />

Mishandling gas cylinders can rupture and violently<br />

release gas.<br />

• Avoid rough handling of cylinders.<br />

• Keep cylinder valves closed when not in use.<br />

• Maintain hoses and fittings in good condition.<br />

• Always secure cylinders in an upright position by<br />

chain or strap to a suitable stable object not part of<br />

an electrical circuit.<br />

• Locate cylinders away from heat, sparks and<br />

flames. Never strike an arc on a cylinder.<br />

• Refer to CGA Standard P-1, P<br />

“Precautions for Safe<br />

Handling of Compressed Gases in Cylinders”,<br />

available from Compressed Gas Association.<br />

on.<br />

1-6

SECTION 1<br />

SAFETY<br />

! WARNING<br />

Spark hazard.<br />

Heat, spatter, and sparks cause fire and burns.<br />

• Do not cut near combustible material.<br />

• Do not cut containers that have held combustibles.<br />

• Do not have on your person any combustibles (e.g.<br />

butane lighter).<br />

• Pilot arc can cause burns. Keep torch nozzle<br />

away from yourself and others when activating<br />

plasma process.<br />

• Wear correct eye and body protection.<br />

• Wear gauntlet gloves, safety shoes and hat.<br />

• Wear flame-retardant clothing that covers all<br />

exposed areas.<br />

• Wear cuffless trousers to prevent entry of sparks<br />

and slag.<br />

! WARNING<br />

Explosion hazard.<br />

Certain molten aluminum-lithium lithium (Al-Li) alloys can<br />

cause explosions when plasma cut with water.<br />

Do not plasma cut the following Al-Li alloys with<br />

water:<br />

Alithlite (Alcoa)<br />

X8192 (Alcoa)<br />

Alithally (Alcoa)<br />

Navalite (US Navy)<br />

2090 Alloy (Alcoa) Lockalite (Lockheed)<br />

X8090A (Alcoa)<br />

Kalite (Kaiser)<br />

X8092 (Alcoa)<br />

8091 (Alcan)<br />

• These alloys should only be dry cut on a dry table.<br />

• DO NOT dry cut over water.<br />

• Contact your aluminum supplier for additional<br />

safety information regarding hazards associated<br />

with these alloys.<br />

1-7

SECTION 1<br />

!<br />

DANGER<br />

Hydrogen explosion hazard.<br />

SAFETY<br />

• Do not cut under water with Hydrogen gas!<br />

• Hydrogen explosions can cause personal<br />

injury or death.<br />

• Hydrogen can create explosive gas pockets<br />

in the water table. These pockets will<br />

explode when ignited by sparks or the<br />

plasma arc.<br />

• Before cutting, be aware of possible<br />

hydrogen sources in the water table –<br />

molten metal reaction, slow chemical<br />

reaction and some plasma gases.<br />

• Explosive gas pockets accumulate<br />

underneath the cutting plate and inside the<br />

water table.<br />

• Clean slag (especially fine particles) from<br />

bottom of table frequently. Refill table with<br />

clean water.<br />

• Do not leave plate on table overnight.<br />

• If water table has not been used for several<br />

hours, vibrate or jolt it to break up hydrogen<br />

pockets before laying plate on the table.<br />

• If possible, change water level between cuts<br />

to break up hydrogen pockets.<br />

• Maintain water pH level near 7 (neutral).<br />

• Programmed part spacing should be a<br />

minimum of twice the kerf width to ensure<br />

material is always under the kerf.<br />

1.6 Service Precautions<br />

CAUTION<br />

• When cutting above water, use fans to<br />

circulate air between plate and water<br />

surface.<br />

Establish and adhere to preventive maintenance. A<br />

composite program can be established from<br />

recommended schedules in the instruction literature.<br />

Avoid leaving test equipment or hand tools on<br />

machine. Severe electrical or mechanical damage<br />

could occur to equipment or machine.<br />

1-8

SECTION 1<br />

!<br />

CAUTION<br />

SAFETY<br />

Extreme caution should be used when probing<br />

circuitry with an oscilloscope or voltmeter. Integrated<br />

circuits are susceptible to over voltage damage.<br />

Power off before using test probes to prevent<br />

accidental shorting of components.<br />

All circuit boards securely seated in sockets, all cables<br />

properly connected, all cabinets closed and locked, all<br />

guards and covers replaced before power is turned<br />

on.<br />

Never plug or unplug a printed circuit board while<br />

machine power is on. Instantaneous surges of voltage<br />

and current can damage electronic components.<br />

1-9

SECTION 1<br />

1.7 Safety References<br />

SAFETY<br />

The following nationally recognized publications on safety in welding<br />

and cutting operations are recommended. These publications have<br />

been prepared to protect persons from injury or illness and to protect<br />

property from damage, which could result from unsafe practices.<br />

Although some of these publications are not related specifically to this<br />

type of industrial cutting apparatus, the principles of safety apply<br />

equally.<br />

• “Precautions and Safe Practices in Welding and <strong>Cutting</strong> with<br />

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB <strong>Cutting</strong><br />

Systems.<br />

• “Precautions and Safe Practices for Electric Welding and <strong>Cutting</strong>,”<br />

Form 52-529. ESAB <strong>Cutting</strong> Systems.<br />

• “Safety in Welding and <strong>Cutting</strong>” - ANSI Z 49.1, American Welding<br />

Society, 2501 NW 7th Street, Miami, Florida, 33125.<br />

• “Recommended Safe Practices for Shielded Gases for Welding and<br />

<strong>Plasma</strong> Arc <strong>Cutting</strong>” - AWS C5.10-94, American Welding Society.<br />

• “Recommended Practices for <strong>Plasma</strong> Arc Welding” - AWS C5.1,<br />

American Welding Society.<br />

• “Recommended Practices for Arc <strong>Cutting</strong>” - AWS C5.2, American<br />

Welding Society.<br />

• “Safe Practices” - AWS SP, American Welding Society.<br />

• “Standard for Fire Protection in Use of <strong>Cutting</strong> and Welding<br />

Procedures” - NFPA 51B, National Fire Protection Association, 60<br />

Batterymarch Street, Boston, Massachusetts, 02110.<br />

• “Standard for Installation and Operation of Oxygen - Fuel Gas<br />

Systems for Welding and <strong>Cutting</strong>” - NFPA 51, National Fire<br />

Protection Association.<br />

• “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon<br />

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB <strong>Cutting</strong><br />

Systems. Obtainable through your ESAB representative or local<br />

distributor.<br />

• "Design and Installation of Oxygen Piping Systems," Form 5110.<br />

ESAB <strong>Cutting</strong> Systems.<br />

• “Precautions for Safe Handling of Compressed Gases in<br />

Cylinders”, CGA Standard P-1, Compressed Gas Association.<br />

Literature applicable to safe practices in welding and cutting with<br />

gaseous materials is also available from the Compressed Gas<br />

Association, Inc., 500 Fifth Ave., New York, NY 10036.<br />

1-10

SECTION 2<br />

DESCRI<strong>PT</strong>ION<br />

2.1 General<br />

The <strong>PT</strong>-<strong>600</strong> <strong>Mechanized</strong> <strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong> is a plasma arc torch factory assembled to provide torch component concentricity<br />

and consistent cutting accuracy. For this reason, the torch body can not be rebuilt in the Only the torch front-end has<br />

replaceable parts.<br />

2.2 Scope<br />

The purpose of this manual is to provide the operator with all the information required to install and operate the <strong>PT</strong>-<strong>600</strong> <strong>Mechanized</strong><br />

<strong>Plasma</strong> <strong>Cutting</strong> <strong>Torch</strong>. Technical reference material is also provided to assist in troubleshooting the cutting package.<br />

2.3 Package Options Available<br />

<strong>PT</strong>-<strong>600</strong> package options available through your ESAB dealer, see section 7 for replacement component part numbers.<br />

<strong>Torch</strong> For Mini-Bevel Head 12 ft (3.7 m) lead 12 ft. (3.7 m) 0560935685<br />

<strong>Torch</strong> For Mini-Bevel Head 14 ft (4.3 m) lead 14 ft. (4.3 m) 0558005850<br />

<strong>Torch</strong> For Mini-Bevel Head 14 ft (4.3 m) lead 14 ft. (4.3 m) 0558007580<br />

( Karben - Replacement Parts 7.8 )<br />

<strong>Torch</strong> Assemblies 4.5 ft. (1,3 m) 0558001827<br />

6 ft. (1,8 m) 0558001828<br />

7.2 ft. (2,2 m) 0558004123<br />

12 ft. (3,7 m) 0558001829<br />

15 ft. (4,6 m) 0558001830<br />

17 ft. (5,2 m) 0558001831<br />

20 ft. (6,1 m) 0558001832<br />

25 ft. (7,6 m) 0558001833<br />

NOTES:<br />

• Control lead from the power source to customer CNC is supplied based on customer order.<br />

• See Replacement Parts for assembly components.<br />

• See Process Data Sheets for a list of front-end torch consumable parts.<br />

• See end of section or replacement parts for information on torch part kits.<br />

Technical Specifications<br />

2-1

SECTION 2<br />

DESCRI<strong>PT</strong>ION<br />

2.4 <strong>PT</strong>-<strong>600</strong> Technical Specifications<br />

2.4.1 <strong>Plasma</strong> Gas Technical Specifications<br />

Type O 2<br />

, N 2<br />

, Air, H-35<br />

Pressure<br />

100 to 125 psig (6,9 – 8,6 bars)<br />

250 cfh (118 l/min) max. at <strong>600</strong>A<br />

Flow<br />

(varies with application)<br />

O 2<br />

-99.5%<br />

N<br />

Purity Required*<br />

2<br />

-99.995%<br />

H-35 Specialty gas<br />

Air-clean, dry and oil free<br />

Recommended Liquid Cylinder Service Oxygen: R-76-150-540LC (P/N 19777)<br />

Regulators<br />

Inert gas: R-76-150-580LC (P/N 19977)<br />

Oxygen: R-77-150-540 (P/N 998337<br />

Hydrogen/Methane:R-77-150-350 (P/N<br />

Recommended Cylinder 2-Stage 998342)<br />

Regulators<br />

Nitrogen: R-77-150-580 (P/N 998344)<br />

Industrial Air: R-77150-590 (P/N<br />

998348)<br />

Recommended Heavy –Duty Hi-flow<br />

Oxygen: R-76-150-024 (P/N 19151)<br />

Station or Pipeline Regulators<br />

Recommended High-capacity Station<br />

R-6703 (P/N 22236)<br />

or Pipeline Regulators<br />

Gas Filter Required 25 micron w/bowl guard (P/N 56998133)<br />

2.4.2 Start Gas Technical Specifications<br />

Type N 2<br />

, Air, H-35<br />

Pressure<br />

100 to 125 psig (6,9 – 8,6 bars)<br />

Flow<br />

250 cfh (118 l/min) max @ <strong>600</strong>A<br />

(varies with application)<br />

Minimum Purity Required 99.995% clean, dry, oil free<br />

2.4.3 Secondary Gas Technical Specifications<br />

Type<br />

2-2<br />

N 2<br />

, Air<br />

Pressure<br />

100 to 125 psig (6.9 – 8,6 bars)<br />

Flow<br />

485 cfh (228,9 l/min) max (varies with<br />

application)<br />

Minimum Purity Required<br />

99.995% clean, dry, oil free (Same source as<br />

start gas)<br />

Gas Filter Required 25 micron w/bowl guard (P/N 56998133)<br />

2.4.4 <strong>PT</strong>-<strong>600</strong> <strong>Torch</strong> Technical Specifications<br />

Type<br />

Rating<br />

Dimensions<br />

Water-Cooled, Dual Gas<br />

<strong>600</strong> amps @ 100 % duty cycle<br />

See Package Options (2.3). This section.

SECTION 2<br />

DESCRI<strong>PT</strong>ION<br />

2.5 <strong>PT</strong>-<strong>600</strong> ACCESSORIES / KITS<br />

2.5.1 200A Startup Kits<br />

P/N 0558002478 and 0558004907<br />

0558002478 consisting of:<br />

QTY P/N DESCRI<strong>PT</strong>ION<br />

4 0558001624 Electrode O2<br />

1 17672 Lubricant<br />

1 37082 Nozzle Retaining Cup<br />

1 996568 Tool, Nut Driver<br />

1 0558004611 Tool, Electrode Holder<br />

4 0558002499 Electrode <strong>PT</strong>-19 <strong>600</strong>A Tungsten<br />

2 0558001881 Nozzle 50A<br />

2 0558001883 Nozzle 150A<br />

2 0558001884 Nozzle 200A<br />

2 0558001882 Nozzle 100A<br />

2 21795 Shield 50A<br />

1 21796 Diffuser 50A<br />

2 21802 Shield 100-250A<br />

2 21944 Diffuser 100-360A<br />

1 37081 Shield Retainer<br />

2 0558002533 Baffle, Gas Swirl<br />

4 639575 O-ring .364 ID x .070<br />

2 996528 O-ring 1.614 ID x .070<br />

1 0558003858 Contact Ring Assembly<br />

1 37073 Contact Ring Screw<br />

0558004907 consisting of:<br />

QTY P/N DESCRI<strong>PT</strong>ION<br />

5 0558001624UL Electrode, 02 (Ultra-life)<br />

1 17672 Lubricant<br />

1 37082 Nozzle, Retaining Cup<br />

1 996568 Tool, Nut Driver<br />

1 0558004611 Tool, Electrode Holder<br />

1 0558001628 Electrode Holder, <strong>PT</strong>-<strong>600</strong><br />

3 0558001624 Electrode, 250A, <strong>PT</strong>-<strong>600</strong><br />

2 0558002499 Electrode, <strong>600</strong>A, <strong>PT</strong>-<strong>600</strong><br />

5 0558005456 Nozzle, 50A, <strong>PT</strong>-<strong>600</strong><br />

5 0558001881 Nozzle, 50A, <strong>PT</strong>-<strong>600</strong><br />

5 0558001882 Nozzle, 100A<br />

5 0558001883 Nozzle, 150-200A<br />

5 0558001884 Nozzle, 200A, <strong>PT</strong>-<strong>600</strong><br />

2 21795 Shield, 50A, <strong>PT</strong>-19XL<br />

5 0558004678 Shield, 100-200A, EPP<br />

5 21802 Shield, 100-250A, <strong>PT</strong>-19XL<br />

2 0558005458 Shield, Dia. .120”, <strong>PT</strong>-<strong>600</strong><br />

1 37081 Shield Retainer<br />

2 21944 Diffuser, 100-360A<br />

1 21796 Diffuser, 50A, <strong>PT</strong>-19XL<br />

2 0558002533 Baffle, Gas Swirl, 4X032P<br />

2 0558005457 Baffle, Gas Swirl, 20-50A<br />

2 996528 O-ring 1.614” ID x .07” Dia.<br />

1 0558003858 Contact Ring Assembly<br />

1 37073 Contact Ring Screw<br />

2-3

SECTION 2<br />

DESCRI<strong>PT</strong>ION<br />

2.5.2 Spare Parts Kit<br />

P/N 0558002479<br />

Consisting of:<br />

QTY P/N DESCRI<strong>PT</strong>ION<br />

1 17672 Silicone Lubricant<br />

1 0558004611 Electrode Holder Tool<br />

1 996568 Electrode Tip Tool<br />

5 996528 O-rings<br />

2 0558002533 Baffle, 4 hole<br />

2 0558001625 Baffle, 8 hole<br />

1 0558002532 Baffle, 32 hole<br />

1 0558002534 Baffle, 4 hole reverse<br />

1 0558002530 Baffle, 8 hole reverse<br />

1 0558002531 Baffle, 32 hole reverse<br />

5 86W99 O-ring<br />

1 0558001621 Electrode Holder w/O-ring<br />

5 0558001624 Electrode 250 Amp<br />

2 0558002516 Electrode 360/400 Amp<br />

2 0558002499 Electrode, N2, H-35,<br />

5 181W89 Nozzle O-rings<br />

2 0558001881 Nozzle, 50 Amp<br />

2 0558001882 Nozzle, 100 Amp<br />

2 0558001883 Nozzle, 150 Amp<br />

5 0558001884 Nozzle, 200 Amp<br />

5 0558001623 Nozzle, 250 Amp<br />

5 0558001885 Nozzle, 360 Amp<br />

2 0558001886 Nozzle, 400 Amp<br />

2 0558001887 Nozzle, <strong>600</strong> Amp<br />

1 37082 Nozzle Retaining Clip<br />

1 21796 Gas Diffuser, 50 Amp<br />

1 21944 Gas Diffuser, 100 to 360 Amp<br />

1 22496 Gas Diffuser, 100 to 360 Amp reverse<br />

2 21795 Shield, 50 Amp<br />

5 21802 Shield, 260 Amp<br />

2 21945 Shield, 360 Amp<br />

1 37081 Shield Retainer<br />

1 0558003858 Contact Ring Assembly<br />

1 37073 Contact Ring Screw<br />

2-4

SECTION 3<br />

3.1 General<br />

INSTALLATION<br />

The <strong>PT</strong>-<strong>600</strong> <strong>Torch</strong> comes with the front-end<br />

completely assembled with 250A consumables.<br />

Pilot arc cable and hoses may have to be<br />

assembled.<br />

3.2 Connection of Hose and Cable Bundle to <strong>Torch</strong> Body<br />

1. Unscrew the <strong>PT</strong>-<strong>600</strong> torch sleeve and slide it on<br />

the torch bundle until the pilot arc connection<br />

point is exposed.<br />

Pilot arc<br />

connection<br />

exposed<br />

Cooling Water/<strong>Plasma</strong><br />

Current Connections<br />

Gas<br />

Connections<br />

<strong>Torch</strong><br />

Body<br />

<strong>Torch</strong> Bundle<br />

Pilot Arc<br />

Cable<br />

Sleeve slid up on<br />

torch bundle<br />

<strong>Torch</strong><br />

Insulator<br />

Sleeve<br />

NOTE: It will be necessary to slide the outer sleeve<br />

of the torch bundle toward the power source to<br />

expose the pilot arc connection.<br />

2. Connect the cooling water IN (left-hand threads)<br />

and cooling water OUT (right-hand threads)<br />

hoses to torch body. A 1/2" open end wrench<br />

is required.<br />

NOTE: Coolant hoses (IN and OUT) are the same<br />

part number. The assembly requires two. The<br />

hoses are designed with a right hand d threaded nut<br />

on one end and a left hand threaded nut on the<br />

other. Reverse one hose end-for<br />

for-end to make the<br />

proper connections.<br />

NOTE: The cooling water tubes are shorter than the<br />

gas tubes.<br />

3. Connect gas fittings. To prevent cross<br />

attachment, the cut gas fitting is smaller in<br />

diameter than the shield gas fitting. 7/16" and<br />

1/2" wrenches are needed.<br />

NOTE: It is possible to cross one of the water<br />

connections with one of the gas connections. Each<br />

water hose has a cable inside for carrying voltage.<br />

4. Insert exposed pilot arc cable into the copper<br />

high frequency connector (H.F.). Tighten set<br />

screws using a 1/16" internal hex wrench. (i.e.<br />

Allen Wrench)<br />

3-1

SECTION 3<br />

INSTALLATION<br />

<strong>Torch</strong><br />

5. Slide the 0.56" diameter PVC tubing down over<br />

the copper HF connector. Secure with PVC<br />

electrical tape by wrapping pilot arc cable<br />

enough times to prevent the PVC insulator from<br />

sliding up.<br />

<strong>Torch</strong> Sleeve<br />

Pilot Arc<br />

Connection<br />

Insulator<br />

<strong>Torch</strong> Body<br />

6. Slide torch sleeve down over pilot arc cable<br />

connection and hose fittings. Thread sleeve<br />

onto torch body.<br />

<strong>Torch</strong><br />

Bundle<br />

Tape Securing<br />

Braided Shield<br />

Note: If it was necessary to remove the black tape<br />

securing the metal braided shield for torch sleeve<br />

clearance, replace this tape with electrical grade<br />

PVC tape.<br />

3-2

SECTION 3<br />

INSTALLATION<br />

7. Slide the black rubber torch bundle sleeve down<br />

to the torch sleeve. Stretch the bundle sleeve<br />

over the end of the torch sleeve till an over-lap<br />

of 1" to 1½" (25mm to 38mm) is achieved.<br />

8. Secure with stainless hose clamp<br />

(1.56" I.D. x 2.5" O.D.)<br />

<strong>Torch</strong> Bundle<br />

Sleeve<br />

!<br />

DANGER<br />

Electric Shock Can Kill!<br />

Disconnect primary power source before<br />

servicing torch.<br />

Do not touch front-end torch parts (nozzle,<br />

shield retaining cup, etc.) without turning<br />

primary power off.<br />

3.3 Disassembly of <strong>Torch</strong> Bundle From <strong>Torch</strong> Body<br />

Reverse assembly order.<br />

1. Loosen hose clamp holding the bundle sleeve.<br />

2. Slide the bundle sleeve up the bundle. It may<br />

be necessary to unwrap electrical tape securing<br />

braided shield if it interferes with sliding the<br />

torch sleeve up the torch bundle.<br />

3. Unscrew torch sleeve and slide it up the torch<br />

bundle to expose the pilot arc connection point.<br />

4. Remove electrical tape securing pilot arc<br />

connection insulator.<br />

5. Slide pilot arc connection insulator up cable and<br />

loosen screws in HF connector.<br />

6. Disconnect hoses.<br />

3-3

SECTION 3<br />

INSTALLATION<br />

3.4 Mounting <strong>Torch</strong> to Machine<br />

Refer to machine manual.<br />

!<br />

WARNING<br />

Clamping on <strong>Torch</strong> Body May Cause<br />

Dangerous Current To Flow Through<br />

Machine Chassis.<br />

• Do not mount on stainless steel torch<br />

body.<br />

Mount torch on<br />

insulated sleeve<br />

here<br />

C<br />

DO NOT mount<br />

on steel torch<br />

body here<br />

AUTION: CLAMP TORCH ABOVE THIS LA<br />

<strong>PT</strong>-<strong>600</strong><br />

PLASMARC TORCH<br />

BEL<br />

• <strong>Torch</strong> body is electrically insulated,<br />

however high frequency start current may<br />

arc through to find a ground.<br />

• Clamping near torch body may result in<br />

arcing between body and machine.<br />

• When this arcing occurs, torch body may<br />

require non-warranty replacement.<br />

• Damage to machine components may<br />

result.<br />

• Clamp only on insulated torch sleeve not<br />

less than 1.25" (31.75mm) from the torch<br />

end of the sleeve.<br />

3-4

SECTION 4<br />

!<br />

DANGER<br />

Electric Shock Can Kill!<br />

OPERATION<br />

• Disconnect primary power source before<br />

making any adjustments.<br />

• Disconnect primary source before doing<br />

maintenance on system components.<br />

• Do not touch front-end torch parts (nozzle,<br />

retaining cup, etc.) without turning primary<br />

power off.<br />

!<br />

WARNING<br />

Radiation hazard.<br />

Arc rays can injure eyes and burn skin.<br />

• Wear correct eye and body protection.<br />

• Wear dark safety glasses or goggles with<br />

side shields. Refer to following chart for<br />

recommended lens shades for plasma<br />

cutting:<br />

Arc Current Lens Shade<br />

Up to 100 Amps Shade No. 8<br />

100-200 Amps Shade No. 10<br />

200-400 Amps Shade No. 12<br />

Over 400 Amps Shade No. 14<br />

• Replace glasses/goggles when lenses are<br />

pitted or broken<br />

• Warn others in area not to look directly at<br />

the arc unless wearing appropriate safety<br />

glasses.<br />

• Prepare cutting area to reduce reflection<br />

and transmission of ultraviolet light.<br />

• Paint walls and other surfaces with dark<br />

colors to reduce reflections.<br />

• Install protective screens or curtains to<br />

reduce ultraviolet transmission.<br />

4-1

SECTION 4<br />

!<br />

WARNING<br />

OPERATION<br />

Oil And Grease Can Burn Violently!<br />

• Never use oil or grease on this torch.<br />

• Handle torch clean hands only on clean<br />

surface.<br />

• Use silicone lubricant only where directed.<br />

• Oil and grease are easily ignited and burn<br />

violently in the presence of oxygen under<br />

pressure.<br />

4.1 Set Up<br />

• Select an appropriate condition from the<br />

process data (SDP File) and install<br />

recommended torch front-end parts (nozzle,<br />

electrode, etc.) See process data to identify<br />

parts and settings.<br />

• Position torch over material at desired start<br />

location.<br />

• See Power Source Manual for proper settings.<br />

• See Flow Control Manual for gas control<br />

procedures.<br />

• See Control and Machine Manuals for startup<br />

procedures.<br />

4.1.1 Mirror <strong>Cutting</strong><br />

When mirror cutting, a reverse swirl gas baffle and<br />

reverse diffuser are required. These reverse parts<br />

will “spin” the gas in the opposite direction,<br />

reversing the “good” side of the cut.<br />

Reverse 4 Hole Baffle 0558002534<br />

Reverse 8 Hole Baffle 0558002530<br />

Reverse 32 Hole Baffle 0558002531<br />

Reverse Diffuser 22496<br />

4-2

SECTION 4<br />

OPERATION<br />

4.2 Cut Quality<br />

4.2.1 Introduction<br />

Causes affecting cut quality are interdependent.<br />

Changing one variable affects all others. Determining a<br />

solution may be difficult. The following guide offers<br />

possible solutions to undesirable cutting results. To<br />

begin select the most prominent condition:<br />

4.2.2 Cut angle, negative or positive<br />

4.2.3 Cut not flat, rounded or undercut<br />

4.2.4 Surface roughness<br />

4.2.5 Dross<br />

Usually the recommended cutting parameters will give<br />

optimal cut quality. Occasionally conditions may vary<br />

and slight adjustments will be required. If so:<br />

• Make small incremental adjustments when making<br />

corrections.<br />

• Adjust arc voltage in one volt increments, up or<br />

down as required.<br />

Adjust cutting speed 5% or less as required, until<br />

conditions improve.<br />

NOTICE<br />

Before attempting ANY corrections, check cutting<br />

variables with the factory recommended<br />

settings/consumable part numbers listed in Process<br />

Data.<br />

4.2.2 Cut Angle<br />

Negative Cut Angle<br />

Top dimension is greater than the bottom.<br />

Part<br />

• Misaligned torch<br />

• Bent or warped material<br />

• Worn or damaged consumables<br />

• Standoff low (arc voltage)<br />

• <strong>Cutting</strong> speed slow (machine travel rate)<br />

Drop<br />

Part<br />

4-3

SECTION 4<br />

OPERATION<br />

Part<br />

Positive Cut Angle<br />

Top dimension is less than the bottom dimension.<br />

• Misaligned torch<br />

Drop<br />

Part<br />

• Bent or warped material<br />

• Worn or damaged consumables<br />

• High standoff high (arc voltage)<br />

• <strong>Cutting</strong> speed fast<br />

• Current high or low. (See process data for<br />

recommended current level for specific nozzles).<br />

• Wrong secondary gas flow.<br />

4.2.3 Cut Flatness<br />

Top And Bottom Rounded<br />

Condition usually occurs when material is 0.25" thick<br />

(6,4mm) or less.<br />

• High current for given material thickness (See<br />

process data for proper settings).<br />

Drop<br />

Part<br />

4-4

SECTION 4<br />

OPERATION<br />

Top Edge Undercut<br />

Standoff low (arc voltage)<br />

Drop<br />

Part<br />

4.2.4 Surface Finish<br />

Process Induced Roughness<br />

Cut face is consistently rough and may be confined to<br />

one axis.<br />

Top View<br />

• Incorrect shield gas mixture (See process data)<br />

• Worn or damaged consumables<br />

Cut Face<br />

Machine Induced Roughness<br />

Can be difficult to distinguish from process induced<br />

roughness and is often confined to one axis.<br />

Roughness is inconsistent.<br />

or<br />

Process<br />

Induced<br />

Roughness<br />

Machine<br />

Induced<br />

Roughness<br />

• Dirty rails, wheels and/or drive rack/pinion. (Refer<br />

to maintenance section in machine owner’s<br />

manual).<br />

• Carriage wheel adjustment<br />

4-5

SECTION 4<br />

OPERATION<br />

4.2.5 Dross<br />

Dross is a by-product of the cutting process. It is the<br />

undesirable material that remains attached to the part.<br />

In most cases, dross can be reduced or eliminated<br />

with proper torch and cutting parameter setup. Refer<br />

to Process Data.<br />

Cut Face<br />

Lag<br />

Lines<br />

Rollover<br />

High Speed Dross<br />

Material weld or rollover on bottom surface along kerf.<br />

Difficult to remove. May require grinding or chipping.<br />

“S” shaped lag lines.<br />

• Standoff high (arc voltage)<br />

• <strong>Cutting</strong> speed fast<br />

Side View<br />

Lag<br />

Lines<br />

Cut Face<br />

Globules<br />

Slow Speed Dross<br />

Forms as globules on bottom along kerf. Removes<br />

easily.<br />

• <strong>Cutting</strong> speed slow<br />

Side View<br />

4-6

SECTION 4<br />

OPERATION<br />

Side View<br />

Splatter<br />

Top Dross<br />

Appears as splatter on top of material. Usually<br />

removes easily.<br />

Cut Face<br />

• <strong>Cutting</strong> speed fast<br />

• Standoff high (arc voltage).<br />

Intermittent Dross<br />

Appears on top or bottom along kerf.<br />

Non-continuous. Can appear as any kind of dross<br />

4.2.6 Dimensional Accuracy<br />

NOTICE<br />

• Possible worn consumables<br />

Other Factors Affecting Dross:<br />

• Material temperature<br />

• Heavy mill scale or rust<br />

• High carbon alloys<br />

4-7<br />

Generally, using the slowest possible speed (within<br />

approved levels) will optimize part accuracy. Most<br />

material thickness overlap for different voltages.<br />

Select consumables to allow a lower arc voltage<br />

and slower cutting speed.<br />

Recommended cutting speed and arc voltage will<br />

give optimal cutting performance.<br />

Small incremental adjustments may be needed due<br />

to material quality, material temperature and specific<br />

alloy. The operator should remember that all<br />

cutting variables are interdependent. Changing one<br />

setting affects all others and cut quality could<br />

deteriorate. Always start at the recommended<br />

settings.<br />

Before attempting ANY corrections, check cutting<br />

variables with the factory recommended settings/<br />

consumable part numbers listed in the process<br />

data.

SECTION 4<br />

OPERATION<br />

4.3 <strong>Torch</strong> Flow Passages<br />

Gas Flow<br />

Coolant Water Flow<br />

<strong>Plasma</strong><br />

Gas<br />

Shield<br />

Gas<br />

Coolant<br />

Water IN<br />

Coolant<br />

Water OUT<br />

4-8

SECTION 4<br />

4.4 Influence of Gas Options Cut Quality<br />

OPERATION<br />

4.4.1 Introduction<br />

All gases are not suitable for all situations. Certain<br />

gases assist in cutting specific materials and<br />

thickness. The following explains why certain gases<br />

are selected and their influence on the finished part.<br />

Other influences such as arc voltage and gas<br />

flow/pressure are covered in the process data.<br />

!<br />

DANGER<br />

Hydrogen explosion hazard.<br />

• Do not cut under water with Hydrogen gas!<br />

• Hydrogen explosions can cause personal<br />

injury or death.<br />

• Hydrogen can create explosive gas pockets<br />

in the water table. These pockets will<br />

explode when ignited by sparks or the<br />

plasma arc.<br />

• Before cutting, be aware of possible<br />

hydrogen sources in the water table –<br />

molten metal reaction, slow chemical<br />

reaction and some plasma gases.<br />

• Explosive gas pockets accumulate<br />

underneath the cutting plate and inside the<br />

water table.<br />

• Clean slag (especially fine particles) from<br />

bottom of table frequently. Refill table with<br />

clean water.<br />

• Do not leave plate on table overnight.<br />

• If water table has not been used for several<br />

hours, vibrate or jolt it to break up hydrogen<br />

pockets before laying plate on the table.<br />

• If possible, change water level between cuts<br />

to break up hydrogen pockets.<br />

• Maintain water pH level near 7 (neutral).<br />

• Programmed part spacing should be a<br />

minimum of twice the kerf width to ensure<br />

material is always under the kerf.<br />

• When cutting above water, use fans to<br />

circulate air between plate and water<br />

surface.<br />

4-9

SECTION 4<br />

OPERATION<br />

4.4.2 Aluminum and Process Gases<br />

Material Thickness: .188 through 1.00 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

Air<br />

Air<br />

Air<br />

Discussion: Dark cut face, potential dross, good cut angles<br />

Material Thickness: .250 through 3.000 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

H-35<br />

N 2<br />

Discussion: Smooth cut face, virtually dross free up to 1.5 in. thick , cut angles slightly larger<br />

with top edge rounding<br />

Material Thickness: .625 through 1.000 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

H-35<br />

Air<br />

Discussion: Slightly darker cut Face, virtually dross, cut angles slightly larger with top edge<br />

rounding<br />

Material Thickness: .625 through 1.5<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

H-35<br />

H-35<br />

Air<br />

Discussion: Slightly darker cut Face, virtually dross, cut angles slightly larger with top edge<br />

rounding<br />

Material Thickness: .188 through 1.500 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

N 2<br />

Air<br />

Discussion: Darker cut face, dross could be formed above 1 in. material, good cut angles,<br />

slight top edge rounding.<br />

Material Thickness: .062 through 1.000 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

N 2<br />

N 2<br />

Discussion: Darker cut face, dross could be formed above .75 in. material, good cut angles,<br />

slight top edge rounding.<br />

4-10

SECTION 4<br />

OPERATION<br />

4.4.3 Carbon Steel<br />

Material Thickness:<br />

Cut Qualities:<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

Discussion:<br />

Material Thickness:<br />

Cut Qualities:<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

Discussion:<br />

.125 through 1.500 inches<br />

Excellent<br />

N 2<br />

O 2<br />

Air<br />

Smooth shiny cut face, virtually no dross, good cut angles, sharp top edge<br />

.062 through .250 inches<br />

Good<br />

Air<br />

Air<br />

Air<br />

Smooth gray cut face, virtually dross free, larger cut angles do to plate<br />

thickness, cut speed and cutting amperage.<br />

4-11

SECTION 4<br />

OPERATION<br />

4.4.4 Stainless Steel<br />

Material Thickness: .062 through .750 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

N 2<br />

N 2<br />

Discussion: Dark cut face, virtually dross free, good cut angles, Beveled on gauge material<br />

do to thickness, speed and amperage<br />

Material Thickness: .062 through 1.000 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

Air<br />

Air<br />

Air<br />

Discussion: Dark cut face, virtually dross free, good cut angles, beveled on gauge material<br />

do to thickness, speed and amperage<br />

Material Thickness: .250 through 3.000<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

N 2<br />

Air<br />

Discussion: Dark cut face, virtually dross free, good cut angles, slight top edge rounding<br />

Material Thickness: .500 through 3.000 inches<br />

Cut Qualities: Good<br />

Start Gas:<br />

<strong>Plasma</strong>:<br />

Shield:<br />

N 2<br />

H-35<br />

N 2<br />

Discussion: Shiny gold color cut face, virtually dross free up to 1.5 inch material, greater<br />

thickness may have dross, cut angle slightly larger do to H-35 plasma gas.<br />

4-12

SECTION 4<br />

OPERATION<br />

4.5 Process Data<br />

4.5.1 Introduction<br />

The following information is a result of many hours of<br />

testing and is a general guide for setting up and<br />

cutting with a <strong>PT</strong>-<strong>600</strong> <strong>Mechanized</strong> <strong>Plasma</strong> Arc <strong>Torch</strong>.<br />

The machine’s control manages gas flow using Smart<br />

Flow II, a proportional valve flow control system.<br />

In most cases these settings will provide a quality cut.<br />

The data contains values for:<br />

cutting aluminum, carbon and stainless steel<br />

arc voltage (standoff)<br />

cutting speed<br />

current (amperes)<br />

gas flow rates for plasma/shield gas combinations<br />

This same data is contained in SDP files. (See your<br />

machine and programming manuals for more<br />

information on SDP files.)<br />

Also included is information on consumable part<br />

numbers for all possible current settings.<br />

NOTICE<br />

Speed, voltage, kerf, and current can be<br />

used any time for a <strong>PT</strong>-<strong>600</strong> torch<br />

application.<br />

Process data was derived using the Smart Flow II, a<br />

programmable gas flow control. This same<br />

information is used in creating Vision CNC process<br />

control (SDP) files. Only gas flow rates are given for<br />

reference when using Smart Flow II. Speed, arc<br />

voltage, kerf, and current (amperes) remain<br />

applicable when cutting with manual gas<br />

regulation systems.<br />

NOTICE<br />

Underwater <strong>Cutting</strong> Speeds Must Slowed by<br />

10%.<br />

As a general rule, above water cutting speeds<br />

can be applied to underwater cutting by<br />

reducing speeds by 10%. There are two<br />

underwater examples offered for reference in<br />

the following data. (p4-31, p4-91)<br />

4-13

SECTION 4<br />

OPERATION<br />

<strong>PT</strong>-<strong>600</strong><br />

<strong>Plasma</strong> Arc <strong>Cutting</strong> <strong>Torch</strong><br />

Material: Carbon Steel<br />

Am p eres: 50<br />

Start Gas:<br />

Cut Gas:<br />

Shield Gas:<br />

Air* @ 100 psi / 6,9 Bar<br />

Air* @ 100 psi / 6,9 Bar<br />

Air* @ 60 psi / 4,1 Bar<br />

*Do not use shop Air. Use bottled/compressed.<br />

<strong>Torch</strong> Sleeve P/N 0558001626<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref.)<br />

2 EA. O-rings P/N 996528 (Ref.)<br />

Gas Baffle P/N 0558002533 “4<br />

Hole”<br />

O-ring Supplied with Electrode<br />

Holder P/N 86W99 (Ref.)<br />

Electrode Holder w/O-ring<br />

P/N 0558001621<br />

O-ring Supplied with Electrode<br />

P/N 86W99 (Ref.)<br />

Electrode P/N 0558001624 “250A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle P/N 0558001881 “50A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser<br />

P/N 21796 “50A”<br />

Shield P/N 21795 “50A”<br />

Shield Retainer P/N 37081<br />

4-14

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong> Process Data<br />

50 Amperes<br />

Carbon Steel<br />

OPERATION<br />

Except where noted, data is for above water<br />

cutting. Reduce speed approximately 10% when<br />

cutting under water.<br />

Start<br />

Gas<br />

Cut<br />

Gas<br />

Shield<br />

Gas<br />

Material Thickness Air Air Air<br />

Timers<br />

IN 0.063<br />

MM 1,6<br />

Rise On Pierce (sec.) 0<br />

Pierce Delay (sec.) 0<br />

Setup Parameters Pounds per Square Inch (PSI - Pressure)<br />

Height Readings<br />

Travel Speed<br />

Kerf Width<br />

<strong>Plasma</strong> Start Gas<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

Shield Cut Gas<br />

Initial Height<br />

PSI 40<br />

BAR 2,76<br />

PSI 50<br />

BAR 3,45<br />

PSI 10<br />

BAR 0,69<br />

PSI 10<br />

BAR 0,69<br />

IN. .375<br />

MM 9,5<br />

Arc Voltage (standoff) 113<br />

IPM 220<br />

MM/MIN 5588<br />

Inches .05<br />

Notes:<br />

Pilot Arc Set to Low<br />

Millimeters 1,3<br />

4-15

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong><br />

<strong>Plasma</strong> Arc <strong>Cutting</strong> <strong>Torch</strong><br />

Material: Carbon Steel<br />

Am p eres: 65<br />

Start Gas:<br />

Cut Gas:<br />

Shield Gas:<br />

Air* @ 100 psi / 6,9 Bar<br />

Air* @ 100 psi / 6,9 Bar<br />

Air* @ 60 psi / 4,1 Bar<br />

OPERATION<br />

*Do not use shop Air. Use bottled/compressed.<br />

<strong>Torch</strong> Sleeve P/N 0558001626<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref.)<br />

2 EA. O-rings P/N 996528 (Ref.)<br />

Gas Baffle P/N 0558002533 “4<br />

Hole”<br />

O-ring Supplied with Electrode<br />

Holder P/N 86W99 (Ref.)<br />

Electrode Holder w/O-ring<br />

P/N 0558001621<br />

O-ring Supplied with Electrode<br />

P/N 86W99 (Ref.)<br />

Electrode P/N 0558001624 “250A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle P/N 0558001881 “50A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser<br />

P/N 21796<br />

Shield P/N 21796 “50A”<br />

Shield Retainer P/N 37081<br />

4-16

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong> Process Data<br />

65 Amperes<br />

Carbon Steel<br />

OPERATION<br />

Except where noted, data is for above water<br />

cutting. Reduce speed approximately 10% when<br />

cutting under water.<br />

Start<br />

Gas<br />

Cut<br />

Gas<br />

Shield<br />

Gas<br />

Material Thickness Air Air Air<br />

Timers<br />

IN 0.125 0.188 0.250<br />

MM 3,2 4,7 6,4<br />

Rise On Pierce (sec.) 0 0 0.1<br />

Pierce Delay (sec.) 0 0 0.4<br />

Setup Parameters Pounds per Square Inch (PSI - Pressure)<br />

Height Readings<br />

Travel Speed<br />

Kerf Width<br />

<strong>Plasma</strong> Start Gas<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

Shield Cut Gas<br />

Initial Height<br />

PSI 40 40 40<br />

BAR 2,76 2,76 2,76<br />

PSI 50 50 50<br />

BAR 3,45 3,45 3,45<br />

PSI 10 10 10<br />

BAR 0,69 0,69 0,69<br />

PSI 10 10 10<br />

BAR 0,69 0,69 0,69<br />

IN. .375 .375 .375<br />

MM 9,5 9,5 9,5<br />

Arc Voltage (standoff) 115 118 130<br />

IPM 150 100 75<br />

MM/MIN 3810 2540 1905<br />

Inches .065 .075 .085<br />

Notes:<br />

Pilot Arc Set to Low<br />

Millimeters 1,7 1,9 2,2<br />

4-17

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong><br />

<strong>Plasma</strong> Arc <strong>Cutting</strong> <strong>Torch</strong><br />

Material: Carbon Steel<br />

Am p eres: 100<br />

Start Gas:<br />

Cut Gas:<br />

Shield Gas:<br />

Nitrogen (N 2<br />

) @ 100 psi / 6,9 Bar<br />

Oxygen (O 2<br />

) @ 100 psi / 6,9 Bar<br />

Air* @ 60 psi / 4,1 Bar<br />

OPERATION<br />

*Do not use shop Air. Use bottled/compressed.<br />

<strong>Torch</strong> Sleeve P/N 0558001626<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref.)<br />

2 EA. O-rings P/N 996528 (Ref.)<br />

Gas Baffle P/N 0558002533 “4<br />

Hole” (0558002534 “Reverse”)<br />

O-ring Supplied with Electrode<br />

Holder P/N 86W99 (Ref.)<br />

Electrode Holder w/O-ring<br />

P/N 0558001621<br />

O-ring Supplied with Electrode<br />

P/N 86W99 (Ref.)<br />

Electrode P/N 0558001624 “250A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle P/N 0558001882 “100A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser<br />

P/N 21944 (22496 “Reverse”)<br />

Shield P/N 21802 “100A to 250A”<br />

Shield Retainer P/N 37081<br />

4-18

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong> Process Data<br />

100 Amperes<br />

Carbon Steel<br />

OPERATION<br />

Except where noted, data is for above water<br />

cutting. Reduce speed approximately 10% when<br />

cutting under water.<br />

Start<br />

Gas<br />

Cut<br />

Gas<br />

Shield<br />

Gas<br />

Material Thickness N 2<br />

O 2<br />

Air<br />

Timers<br />

IN 0.125 0.188 0.250 0.313 0.375 0.500 0.625 0.750<br />

MM 3,2 4,7 6,4 7,9 9,5 12,7 15,9 19,1<br />

Rise On Pierce (sec.) 0 0 0 0 0.2 0.4 0.5 0.3<br />

Pierce Delay (sec.) 0 0 0 0 0.2 0.5 0.6 0.7<br />

Setup Parameters Pounds per Square Inch (PSI - Pressure)<br />

Height Readings<br />

Travel Speed<br />

Kerf Width<br />

<strong>Plasma</strong> Start Gas<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

Shield Cut Gas<br />

PSI 25 25 25 25 25 25 25 25<br />

BAR 1,7 1,7 1,7 1,7 1,7 1,7 1,7 1,7<br />

PSI 46 46 44 46 46 46 48 46<br />

BAR 3,2 3,2 3,0 3,2 3,2 3,2 3,3 3,2<br />

PSI 20 20 20 20 20 20 20 18<br />

BAR 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,2<br />

PSI 10 18 18 10 16 10 12 10<br />

BAR 0,7 1,2 1,2 0,7 1,1 0,7 0,8 0,7<br />

IN. .375 .375 .375 .375 .375 .500 .500 .500<br />

Initial Height<br />

MM 9,5 9,5 9,5 9,5 9,5 12,7 12,7 12,7<br />

Arc Voltage (standoff) 123 135 133 134 149 141 159 162<br />

IPM 190 150 120 100 80 60 38 20<br />

MM/MIN 4826 3810 3048 2540 2032 1524 965 508<br />

Inches .08 .075 .100 .085 .012 .100 .14 .145<br />

Notes:<br />

Pilot Arc Set to Low<br />

Millimeters 2,0 1,9 2,5 2,2 3,0 2,5 3,6 3,7<br />

4-19

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong><br />

<strong>Plasma</strong> Arc <strong>Cutting</strong> <strong>Torch</strong><br />

Material: Carbon Steel<br />

Am p eres: 150<br />

Start Gas:<br />

Cut Gas:<br />

Shield Gas:<br />

Nitrogen (N 2<br />

) @ 100 psi / 6,9 Bar<br />

Oxygen (O 2<br />

) @ 100 psi / 6,9 Bar<br />

Air* @ 60 psi / 4,1 Bar<br />

OPERATION<br />

*Do not use shop Air. Use bottled/compressed.<br />

<strong>Torch</strong> Sleeve P/N 0558001626<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref.)<br />

2 EA. O-rings P/N 996528 (Ref.)<br />

Gas Baffle P/N 0558002533 “4<br />

Hole” (0558002534 “Reverse”)<br />

O-ring Supplied with Electrode<br />

Holder P/N 86W99 (Ref.)<br />

Electrode Holder w/O-ring<br />

P/N 0558001621<br />

O-ring Supplied with Electrode<br />

P/N 86W99 (Ref.)<br />

Electrode P/N 0558001624 “250A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle P/N 0558001883 “150A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser<br />

P/N 21944 (22496 “Reverse”)<br />

Shield P/N 21802 “100A to 250A”<br />

Shield Retainer P/N 37081<br />

4-20

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong> Process Data<br />

150 Amperes<br />

Carbon Steel<br />

OPERATION<br />

Except where noted, data is for above water<br />

cutting. Reduce speed approximately 10% when<br />

cutting under water.<br />

Start<br />

Gas<br />

Cut<br />

Gas<br />

Shield<br />

Gas<br />

Material Thickness N 2<br />

O 2<br />

Air<br />

Timers<br />

IN 0.188 0.250 0.313 0.375 0.500 0.625 0.750 1.000<br />

MM 4,7 6,4 7,9 9,5 12,7 15,9 19,1 25,4<br />

Rise On Pierce (sec.) 0 0 0 0 0.2 0.2 0.2 0.3<br />

Pierce Delay (sec.) 0 0 0 0 0.4 0.5 0.8 1.0<br />

Setup Parameters Pounds per Square Inch (PSI - Pressure)<br />

<strong>Plasma</strong> Start Gas<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

Shield Cut Gas<br />

Height Readings<br />

Travel Speed<br />

Kerf Width<br />

Notes:<br />

Pilot Arc Set to High<br />

Initial Height<br />

PSI 20 20 20 20 20 20 20 20<br />

BAR 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,4<br />

PSI 37 37 37 37 37 44 37 37<br />

BAR 2,6 2,6 2,6 2,6 2,6 3,0 2,6 2,6<br />

PSI 20 20 20 20 20 21 18 18<br />

BAR 1,4 1,4 1,4 1,4 1,4 1,5 1,2 1,2<br />

PSI 18 18 18 18 16 18 10 16<br />

BAR 1,2 1,2 1,2 1,2 1,1 1,2 0,7 1,1<br />

IN. .375 .375 .375 .375 .500 .500 .500 .500<br />

MM 9,5 9,5 9,5 9,5 12,7 12,7 12,7 12,7<br />

Arc Voltage (standoff) 127 126 131 134 140 151 157 156<br />

IPM 160 150 120 90 75 55 45 25<br />

MM/MIN 4064 3810 3048 2286 1905 1397 1143 635<br />

Inches .085 .095 .095 .120 .105 .125 .150 .165<br />

Millimeters 2,2 2,4 2,4 3,0 2,7 3,2 3,8 4,2<br />

4-21

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong><br />

<strong>Plasma</strong> Arc <strong>Cutting</strong> <strong>Torch</strong><br />

Material: Carbon Steel<br />

Am p eres: 200<br />

Start Gas:<br />

Cut Gas:<br />

Shield Gas:<br />

Nitrogen (N 2<br />

) @ 100 psi / 6,9 Bar<br />

Oxygen (O 2<br />

) @ 100 psi / 6,9 Bar<br />

Air* @ 60 psi / 4,1 Bar<br />

OPERATION<br />

*Do not use shop Air. Use bottled/compressed.<br />

<strong>Torch</strong> Sleeve P/N 0558001626<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref.)<br />

2 EA. O-rings P/N 996528 (Ref.)<br />

Gas Baffle P/N 0558002533 “4<br />

Hole” (0558002534 “Reverse”)<br />

O-ring Supplied with Electrode<br />

Holder P/N 86W99 (Ref.)<br />

Electrode Holder w/O-ring<br />

P/N 0558001621<br />

O-ring Supplied with Electrode<br />

P/N 86W99 (Ref.)<br />

Electrode P/N 0558001624 “250A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle P/N 0558001884 “200A”<br />

O-ring Supplied w/Nozzle<br />

P/N 181W89 (Ref.)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser<br />

P/N 21944 (22496 “Reverse”)<br />

Shield P/N 21802 “100A to 250A”<br />

Shield Retainer P/N 37081<br />

4-22

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong> Process Data<br />

200 Amperes<br />

Carbon Steel<br />

OPERATION<br />

Except where noted, data is for above water<br />

cutting. Reduce speed approximately 10% when<br />

cutting under water.<br />

Start<br />

Gas<br />

Cut<br />

Gas<br />

Shield<br />

Gas<br />

Material Thickness N 2<br />

O 2<br />

Air<br />

Timers<br />

IN 0.250 0.313 0.375 0.500 0.625 0.750 1.000 1.250<br />

MM 6,4 7,9 9,5 12,7 15,9 19,1 25,4 31,8<br />

Rise On Pierce (sec.) 0 0 0 0.1 0.2 0.3 0.3 0.6<br />

Pierce Delay (sec.) 0 0.2 0 0.2 0.3 0.3 0.5 1.0<br />

Setup Parameters Pounds per Square Inch (PSI - Pressure)<br />

<strong>Plasma</strong> Start Gas<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

Shield Cut Gas<br />

Height Readings<br />

Travel Speed<br />

Kerf Width<br />

Notes:<br />

Pilot Arc Set to High<br />

Initial Height<br />

PSI 26 25 25 25 20 25 25 25<br />

BAR 1,8 1,7 1,7 1,7 1,4 1,7 1,7 1,7<br />

PSI 40 43 40 44 40 40 40 44<br />

BAR 2,8 3,0 2,8 3,0 2,8 2,8 2,8 3,0<br />

PSI 20 20 20 20 20 18 18 22<br />

BAR 1,4 1,4 1,4 1,4 1,4 1,2 1,2 1,5<br />

PSI 8 14 18 10 11 7 12 22<br />

BAR 0,6 1,0 1,2 0,7 0,8 0,5 0,8 1,5<br />

IN. .375 .375 .375 .500 .500 .500 .500 .500<br />

MM 9,5 9,5 9,5 12,7 12,7 12,7 12,7 12,7<br />

Arc Voltage (standoff) 124 129 132 129 139 142 153 164<br />

IPM 170 140 110 90 65 55 40 20<br />

MM/MIN 4318 3556 2794 2286 1651 1397 1016 508<br />

Inches .095 .105 .110 .136 .120 .150 .170 .190<br />

Millimeters 2,4 2,7 2,8 3,5 3,0 3,8 4,3 4,8<br />

4-23

SECTION 4<br />

OPERATION<br />

Material: Carbon Steel<br />

<strong>PT</strong>-<strong>600</strong> Amperes: 200<br />

PLASMARC <strong>Cutting</strong> <strong>Torch</strong> Stat Gas: Nitrogen (N 2<br />

) @ 125 psi/8.6 bar<br />

WITH Cut Gas: Oxygen (O 2<br />

) @ 125 psi/8.6 bar<br />

EPP-200<br />

Shield Gas 1:<br />

<strong>Plasma</strong> Power Console Shield Gas 2: Not used<br />

High Speed <strong>Cutting</strong><br />

Air @ 100psi/6.9 bar @ 95cfh<br />

<strong>Torch</strong> Sleeve<br />

P/N 0558001825<br />

<strong>Torch</strong> Body P/N 0558001825 (Ref)<br />

2 ea. O-Rings P/N 996528 (Ref)<br />

Gas Baffle 4 Hole<br />

(See note next page)<br />

O-Ring Supplied with Electrode Holder<br />

P/N 86W99 (Ref)<br />

Electrode Holder with O-Ring<br />

P/N 0558001621<br />

O-Ring Supplied with Electrode<br />

P/N 86W99 (Ref)<br />

Electrode 250 Amp<br />

P/N 0558001624UL<br />

O-Ring Supplied with Nozzle<br />

P/N 181W89 (Ref)<br />

Nozzle 200 PR 150 AMP<br />

P/N 0558001883<br />

O-Ring Supplied with Nozzle<br />

P/N 181W89 (Ref)<br />

Nozzle Retaining Cup<br />

P/N 37082<br />

Gas Diffuser P/N 21944<br />

Reverse Swirl P/N 22496<br />

Shield, .160 Ø<br />

P/N 0558004678<br />

Shield Retainer<br />

P/N 0558004616<br />

4-Insert

SECTION 4<br />

OPERATION<br />

<strong>PT</strong>-<strong>600</strong>/EPP 200 High Speed<br />

Process Data<br />

200 Amperes<br />

Carbon Steel<br />

Mat.<br />

Thick<br />

Timers<br />

(seconds)<br />

Start<br />

Gas<br />

Cut Gas<br />

Shield<br />

Gas1<br />

N 2 O 2 Air<br />

Shield<br />

Gas2<br />

Not<br />

used<br />

IN 0.250 0.375 0.500 0.750 1.000<br />

MM 6.4 9.5 12.7 19.1 25.4<br />

Rise On Pierce 0 0.1 0.1 0.3 0.3<br />

Pierce Delay 0 0.2 0.2 0.3 0.5<br />

Auto Height Delay 0.4 0.4 0.4 0.4 0.4<br />

22psi@ 140 cfh 22psi@ 140 cfh 22psi@ 140 cfh 22psi@ 140 cfh 22psi@ 140 cfh<br />

<strong>Plasma</strong> Start Gas<br />

1.5bar@ 4.0 cmh 1.5bar@ 4.0 cmh 1.5bar@ 4.0 cmh 1.5bar@ 4.0 cmh 1.5bar@ 4.0 cmh<br />

Setup Parameters<br />

Pressure @ Flow<br />

Height<br />

Readings<br />

Travel<br />

Speed<br />

<strong>Plasma</strong> Cut Gas<br />

Shield Start Gas<br />

49psi@ 66 cfh 49psi@ 66 cfh 49psi@ 66 cfh 49psi@ 66 cfh 49psi@ 66 cfh<br />

3.4bar@1.9 cmh 3.4bar@1.9 cmh 3.4bar@1.9 cmh 3.4bar@1.9 cmh 3.4bar@1.9 cmh<br />

13psi@ 190 cfh 13psi@ 190 cfh 14psi@ 220 cfh 12psi@ 180 cfh 13psi@ 190 cfh<br />

0.9bar@ 5.4 cmh 0.9bar@ 5.4 cmh 1.0bar@ 6.2 cmh 0.8bar@ 5.1 cmh 0.9bar@ 5.4 cmh<br />

Shield Cut Gas 1 - 13psi@ 190 cfh 13psi@ 190 cfh 19psi@ 220 cfh 12psi@180 cfh 13psi@ 180 cfh<br />

- Air 0.9bar@ 5.4 cmh 0.9bar@ 5.4 cmh 1.3bar@ 6.2 cmh 0.8bar@ 5.1 cmh 0.9bar@ 5.1 cmh<br />

Shield Cut Gas 2 –<br />

Not<br />

Used<br />

Initial IN. 0.375 0.375 0.500 0.500 0.500<br />

Height MM 9.5 9.5 12.7 12.7 12.7<br />

Arc Voltage<br />

(standoff)<br />

126 130 145 149 149<br />

IPM 250 155 121 76 51<br />

MM/MIN 6350 3937 3073 1930 1295<br />

Kerf<br />

Width<br />

Inches .06 .09 .10 .11 .13<br />

Millimeters 1.5 2.3 2.5 2.8 3.3<br />

Notes:<br />

Pilot Arc Set to LOW<br />

Use the 150 amp nozzle when cutting at 200 amp high speed, P/N 0558001883.<br />

Up to 1 inch thick material use Gas Baffle 4 Hole P/N 0558002533, Reverse 4 hole P/N 0558002534<br />

4-Insert

SECTION 4<br />

<strong>PT</strong>-<strong>600</strong><br />