Lithography Lecture No. 1 - Foundation Coalition

Lithography Lecture No. 1 - Foundation Coalition

Lithography Lecture No. 1 - Foundation Coalition

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MEEN 489-500 Nanoscale<br />

Issues in Manufacturing<br />

<strong>Lithography</strong><br />

<strong>Lecture</strong> 1: The Lithographic<br />

Process<br />

1

Discuss Reading Assignment<br />

1 1 Introducing Nano<br />

2 2 Size Matters<br />

3 3 Interlude One-The Fundamental Science<br />

Behind Nanotechnology<br />

Electrons, Atoms, Ions, Molecules<br />

Metals, Ceramics, Polymers<br />

Biosystems<br />

Electrical Conduction and Ohm’s Law<br />

Quantum Effects<br />

Optics<br />

2

Nanofabrication - 2 principal<br />

approaches<br />

Top-Down<br />

Miniaturizing existing<br />

processes at the<br />

Macro/Microscale<br />

Traditional approach in<br />

industrial applications<br />

E.g. <strong>Lithography</strong>, backbone of<br />

computing systems<br />

Bottom-Up<br />

Assembling structures from<br />

the atomic/molecular level<br />

<strong>No</strong>vel approach, conceptually<br />

imitating nature<br />

E.g. chemical self-assembly<br />

3

<strong>Lithography</strong><br />

<strong>Lithography</strong> in Art<br />

How lithography works<br />

Materials used for lithography drawing<br />

Photolithography<br />

Photolithographic process<br />

4

<strong>Lithography</strong> in Art<br />

Invented by Alois Senefelder in 1798<br />

Used for book illustrations, artist's prints,<br />

packaging, posters etc.<br />

In 1825, Goya produced a series of lithographs.<br />

In the 20 th and 21 st century, become an<br />

important technique with unique expressive<br />

capabilities in the Art field<br />

5

How <strong>Lithography</strong> started<br />

<strong>Lithography</strong> (Greek for "stone<br />

drawing") relies on the fact that<br />

water and grease repel<br />

Draw a pattern onto a flat stone<br />

surface with a greasy substance<br />

Paint the printing ink onto the<br />

stone<br />

While the stone background<br />

absorbs water, the greasy<br />

substance retains wet ink on top<br />

Press paper against the stone to<br />

transfer the pattern<br />

Positive! Repeatable!<br />

6

Materials used for<br />

lithography drawing<br />

Litho crayons and<br />

pencils (containing<br />

wax, pigment, soap<br />

and shellac), conte<br />

crayons, pens and<br />

graphite pencils, etc.<br />

“Bulls of Bordeaux” by Goya<br />

7

<strong>Lithography</strong>, to date<br />

Miniaturized computing circuits require mass<br />

manufacturing of small features ⇒ push<br />

lithographic approach to new limits<br />

Some lithography approaches for manufacturing<br />

Optical lithography (including ultraviolet)<br />

X-Ray lithography<br />

Electron Beam lithography<br />

Ion Beam lithography<br />

“Dip-Pen” lithography<br />

…<br />

8

Optical/UV <strong>Lithography</strong><br />

Workhorse of current chip manufacturing<br />

processes<br />

Limited by wave length of light employed<br />

Smaller features ⇒ reduce wave length ⇒ UV<br />

light<br />

Here is how it works<br />

9

Photolithographic process<br />

Wafer cleaning<br />

Barrier layer formation<br />

Photoresist application<br />

Soft baking<br />

Mask alignment<br />

Exposure and development<br />

Hard-baking<br />

10

Wafer cleaning<br />

Cleans wafer chemically to remove particulate<br />

matter on the surface<br />

(traces of organic, ionic, and metallic impurities)<br />

11

Barrier layer formation<br />

After cleaning, silicon dioxide (a barrier<br />

layer) is deposited on the surface of<br />

the wafer<br />

12

Photoresist application<br />

After the formation of the SiO 2 layer, photoresist<br />

is applied to the surface of the wafer<br />

Spin coating produces a uniform thin film<br />

There are two types of photoresist: positive and<br />

negative<br />

13

(Photolitho_main_process.jpg)<br />

http://britneyspears.ac/physics/fabrication/photolithography.htm<br />

14

Soft baking<br />

During this stage, most of the solvents are<br />

removed from the photoresist coating<br />

The photoresist coatings become<br />

photosensitive (imageable) after softbaking<br />

15

Mask alignment<br />

Use a photomask - square glass plate with a<br />

patterned emulsion of metal film on one side<br />

The mask is aligned with the wafer to<br />

transfer the pattern onto the wafer surface.<br />

16

Exposure<br />

Photoresist<br />

- exposed through pattern on the<br />

mask with a high intensity ultraviolet light.<br />

Three primary exposure methods:<br />

- contact<br />

- proximity<br />

- projection<br />

17

(plithp2.gif)<br />

http://www.ece.gatech.edu/research/labs/vc/theory/photolith.html<br />

18

Development<br />

At low-exposure energies, the negative<br />

resist remains completely soluble in the<br />

developer solution…a a solvent mixture<br />

delivered the resist to the surface and the<br />

‘masked’ area did not chemically change.<br />

For positive resists, the resist solubility in its<br />

developer is finite even at zero-exposure<br />

exposure<br />

energy…the masked area did not chemically<br />

change, the exposed area must become<br />

MORE soluble.<br />

19

(plithp3.gif)<br />

http://www.ece.gatech.edu/research/labs/vc/theory/photolith.html<br />

20

Hard-baking<br />

The final step in photolithographic process<br />

Harden the photoresist and improve<br />

adhesion of the photoresist to the wafer<br />

surface<br />

21

References:<br />

http://www2.mmlc.nwu.edu/c303/levavy/lith1.html<br />

http://www.ece.gatech.edu/research/labs/vc/theory/pho<br />

tolith.html<br />

http://www.ece.gatech.edu/research/labs/vc/theory/pho<br />

tolith.html<br />

http://en.wikipedia.org/wiki/Photolithography<br />

http://britneyspears.ac/physics/fabrication/photolithogra<br />

phy.htm<br />

22

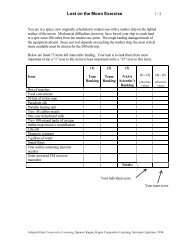

Assignment<br />

Review this PowerPoint set.<br />

23