Plastiline™ - Humes

Plastiline™ - Humes

Plastiline™ - Humes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6 Incorporation in spun concrete pipes<br />

6.1 The Plastiline shall be incorporated in the body of<br />

the concrete pipe by embedment of the locking keys in the<br />

concrete immediately following the manufacture of the<br />

pipe.<br />

6.2 The Plastiline blanket shall be so placed in the pipe<br />

that keys are circumferential in direction. This will allow a<br />

free escape to the unlined part of the pipe for any moisture<br />

or fluid which may accumulate between the lining and the<br />

pipe wall.<br />

6.3 The extent of the pipe circumference to be covered<br />

by the Plastiline shall be specified by the client. It is only<br />

necessary to line that area of concrete which is subject to<br />

corrosion (see page 6).<br />

6.4 Immediately upon completion of manufacture of the<br />

pipe the Plastiline is to be accurately positioned in the<br />

pipe and the locking keys fully embedded in the concrete in<br />

such fashion as to develop the pull-out strength stipulated<br />

in Clause 11.4.<br />

6.5 Keys adjacent to the ends of the pipe barrel shall not<br />

be closer than 13mm to the ends of the barrel and the<br />

maximum distance between keys on either side of a pipe<br />

joint, with an undeflected pipe fully ‘home’ shall not<br />

exceed 130mm for field welded pipes. For factory welded<br />

pipes incorporating spigot end caps and/or socket inserts,<br />

the distance of the first key from the pipe end shall not<br />

exceed 130mm.<br />

6.6 Embedment of Plastiline into concrete pipes can<br />

produce minor circumferential corrugations which will be<br />

more evident in smaller diameters. These corrugations<br />

shall be in addition to the tolerances allowed under<br />

Australian Standard AS 4058 and will have no significant<br />

effect on the carrying capacity of the pipes because of<br />

the smoothness of Plastiline and the smooth flow<br />

conditions.<br />

7 Incorporation in vertically cast pipes<br />

7.1 Plastiline sheet shall be so placed on the inner<br />

mould that keys are running in the longitudinal direction.<br />

A short length of each locking key shall be removed to<br />

provide weep channels at intervals of no more than 2.5m<br />

along assembled pipelines, to ensure that there is no<br />

build-up of hydrostatic pressure.<br />

7.2 The sheet shall be placed under slight tension and<br />

held firmly against the inner mould, to prevent leakage of<br />

mortar between blanket and mould. The sheet can be a<br />

pre-formed tube, or blanket held in place initially by metal<br />

or plastic straps and finally secured at the vertical edges<br />

under strips of rigid plastic, held by screws inserted from<br />

inside the mould.<br />

If the lining is a pre-formed tube, relief of hydrostatic<br />

presure is provided by leaving a short length of the<br />

circumference unwelded (at the invert) when the pipeline<br />

is assembled.<br />

7.3 Reinforcement shall be secured by plastic bar<br />

chairs or other method of support which will not damage<br />

the sheet.<br />

7.4 In large diameter vertically cast pipes, adjacent linings<br />

will normally be joined in the assembled pipeline by<br />

102mm joint strip as shown in the joint detail type P1<br />

(see page 11).<br />

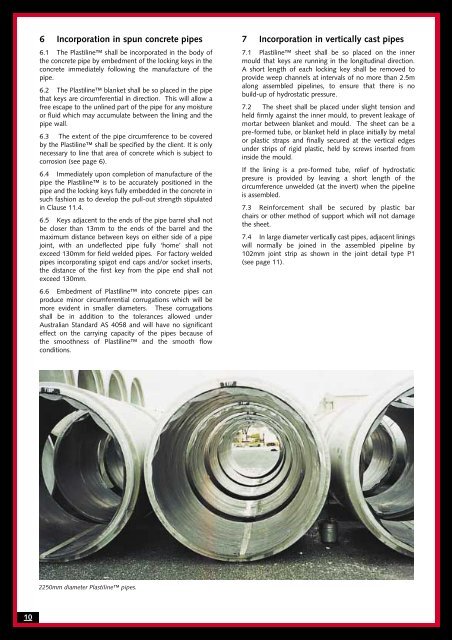

2250mm diameter Plastiline pipes.<br />

10