Plastiline™ - Humes

Plastiline™ - Humes

Plastiline™ - Humes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

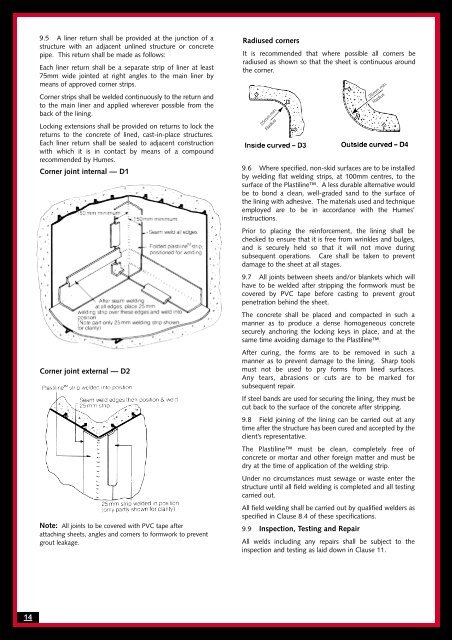

9.5 A liner return shall be provided at the junction of a<br />

structure with an adjacent unlined structure or concrete<br />

pipe. This return shall be made as follows:<br />

Each liner return shall be a separate strip of liner at least<br />

75mm wide jointed at right angles to the main liner by<br />

means of approved corner strips.<br />

Corner strips shall be welded continuously to the return and<br />

to the main liner and applied wherever possible from the<br />

back of the lining.<br />

Locking extensions shall be provided on returns to lock the<br />

returns to the concrete of lined, cast-in-place structures.<br />

Each liner return shall be sealed to adjacent construction<br />

with which it is in contact by means of a compound<br />

recommended by <strong>Humes</strong>.<br />

Corner joint internal — D1<br />

Corner joint external — D2<br />

Note: All joints to be covered with PVC tape after<br />

attaching sheets, angles and corners to formwork to prevent<br />

grout leakage.<br />

Radiused corners<br />

It is recommended that where possible all corners be<br />

radiused as shown so that the sheet is continuous around<br />

the corner.<br />

25mm min.<br />

Radius<br />

25mm min.<br />

Radius<br />

9.6 Where specified, non-skid surfaces are to be installed<br />

by welding flat welding strips, at 100mm centres, to the<br />

surface of the Plastiline. A less durable alternative would<br />

be to bond a clean, well-graded sand to the surface of<br />

the lining with adhesive. The materials used and technique<br />

employed are to be in accordance with the <strong>Humes</strong>’<br />

instructions.<br />

Prior to placing the reinforcement, the lining shall be<br />

checked to ensure that it is free from wrinkles and bulges,<br />

and is securely held so that it will not move during<br />

subsequent operations. Care shall be taken to prevent<br />

damage to the sheet at all stages.<br />

9.7 All joints between sheets and/or blankets which will<br />

have to be welded after stripping the formwork must be<br />

covered by PVC tape before casting to prevent grout<br />

penetration behind the sheet.<br />

The concrete shall be placed and compacted in such a<br />

manner as to produce a dense homogeneous concrete<br />

securely anchoring the locking keys in place, and at the<br />

same time avoiding damage to the Plastiline.<br />

After curing, the forms are to be removed in such a<br />

manner as to prevent damage to the lining. Sharp tools<br />

must not be used to pry forms from lined surfaces.<br />

Any tears, abrasions or cuts are to be marked for<br />

subsequent repair.<br />

If steel bands are used for securing the lining, they must be<br />

cut back to the surface of the concrete after stripping.<br />

9.8 Field joining of the lining can be carried out at any<br />

time after the structure has been cured and accepted by the<br />

client’s representative.<br />

The Plastiline must be clean, completely free of<br />

concrete or mortar and other foreign matter and must be<br />

dry at the time of application of the welding strip.<br />

Under no circumstances must sewage or waste enter the<br />

structure until all field welding is completed and all testing<br />

carried out.<br />

All field welding shall be carried out by qualified welders as<br />

specified in Clause 8.4 of these specifications.<br />

9.9 Inspection, Testing and Repair<br />

All welds including any repairs shall be subject to the<br />

inspection and testing as laid down in Clause 11.<br />

14