Plastiline™ - Humes

Plastiline™ - Humes

Plastiline™ - Humes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

UTILISATION<br />

1 Principal applications<br />

• Lining of spun pipes<br />

• Lining vertically cast pipes<br />

• Lining of cast insitu pipes<br />

• Lining of maintenance holes<br />

• Lining insitu structures such as<br />

pumping stations and treatment plants<br />

• Pile protection<br />

• Precast concrete component protection<br />

• Basement linings<br />

• Tank linings for chemical<br />

manufacturing plant<br />

2 Degree of lining required<br />

For minimum cost only those areas of the pipe surface which<br />

are likely to be attacked need to be lined. The area needing<br />

protection will vary with different service conditions. There are<br />

basically two conditions:<br />

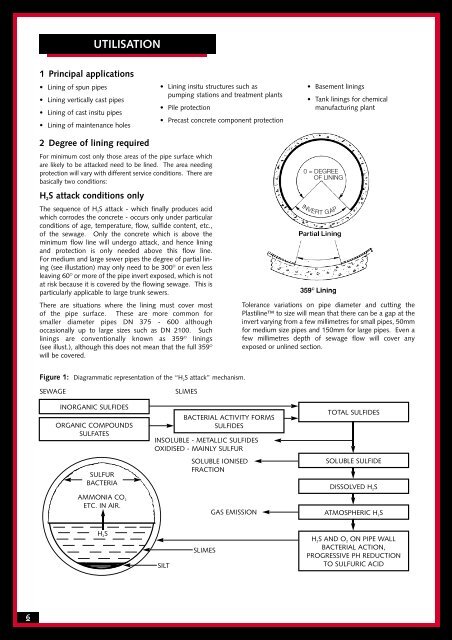

H 2 S attack conditions only<br />

The sequence of H 2 S attack - which finally produces acid<br />

which corrodes the concrete - occurs only under particular<br />

conditions of age, temperature, flow, sulfide content, etc.,<br />

of the sewage. Only the concrete which is above the<br />

minimum flow line will undergo attack, and hence lining<br />

and protection is only needed above this flow line.<br />

For medium and large sewer pipes the degree of partial lining<br />

(see illustation) may only need to be 300 O or even less<br />

leaving 60 O or more of the pipe invert exposed, which is not<br />

at risk because it is covered by the flowing sewage. This is<br />

particularly applicable to large trunk sewers.<br />

There are situations where the lining must cover most<br />

of the pipe surface. These are more common for<br />

smaller diameter pipes DN 375 - 600 although<br />

occasionally up to large sizes such as DN 2100. Such<br />

linings are conventionally known as 359 O linings<br />

(see illust.), although this does not mean that the full 359 O<br />

will be covered.<br />

0 = DEGREE<br />

OF LINING<br />

INVERT<br />

GAP<br />

Tolerance variations on pipe diameter and cutting the<br />

Plastiline to size will mean that there can be a gap at the<br />

invert varying from a few millimetres for small pipes, 50mm<br />

for medium size pipes and 150mm for large pipes. Even a<br />

few millimetres depth of sewage flow will cover any<br />

exposed or unlined section.<br />

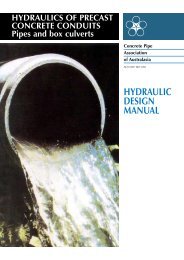

Figure 1: Diagrammatic representation of the “H 2<br />

S attack” mechanism.<br />

SEWAGE<br />

INORGANIC SULFIDES<br />

ORGANIC COMPOUNDS<br />

SULFATES<br />

SULFUR<br />

BACTERIA<br />

AMMONIA CO 2<br />

ETC. IN AIR.<br />

SLIMES<br />

BACTERIAL ACTIVITY FORMS<br />

SULFIDES<br />

INSOLUBLE - METALLIC SULFIDES<br />

OXIDISED - MAINLY SULFUR<br />

SOLUBLE IONISED<br />

FRACTION<br />

GAS EMISSION<br />

TOTAL SULFIDES<br />

SOLUBLE SULFIDE<br />

DISSOLVED H 2 S<br />

ATMOSPHERIC H 2 S<br />

H 2 S<br />

SILT<br />

SLIMES<br />

H 2 S AND O 2 ON PIPE WALL<br />

BACTERIAL ACTION,<br />

PROGRESSIVE PH REDUCTION<br />

TO SULFURIC ACID<br />

6