Plastiline™ - Humes

Plastiline™ - Humes

Plastiline™ - Humes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

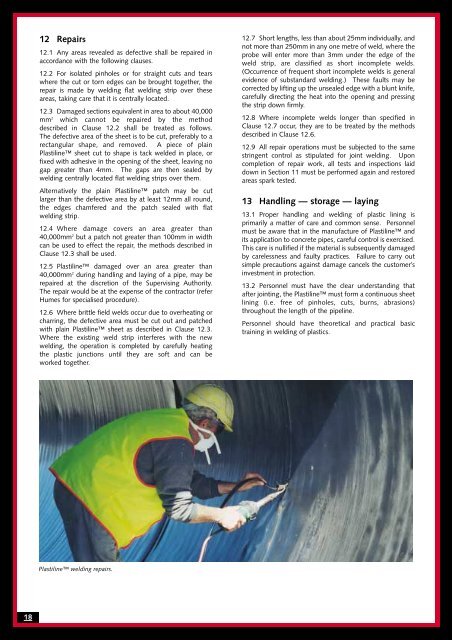

12 Repairs<br />

12.1 Any areas revealed as defective shall be repaired in<br />

accordance with the following clauses.<br />

12.2 For isolated pinholes or for straight cuts and tears<br />

where the cut or torn edges can be brought together, the<br />

repair is made by welding flat welding strip over these<br />

areas, taking care that it is centrally located.<br />

12.3 Damaged sections equivalent in area to about 40,000<br />

mm 2 which cannot be repaired by the method<br />

described in Clause 12.2 shall be treated as follows.<br />

The defective area of the sheet is to be cut, preferably to a<br />

rectangular shape, and removed. A piece of plain<br />

Plastiline sheet cut to shape is tack welded in place, or<br />

fixed with adhesive in the opening of the sheet, leaving no<br />

gap greater than 4mm. The gaps are then sealed by<br />

welding centrally located flat welding strips over them.<br />

Alternatively the plain Plastiline patch may be cut<br />

larger than the defective area by at least 12mm all round,<br />

the edges chamfered and the patch sealed with flat<br />

welding strip.<br />

12.4 Where damage covers an area greater than<br />

40,000mm 2 but a patch not greater than 100mm in width<br />

can be used to effect the repair, the methods described in<br />

Clause 12.3 shall be used.<br />

12.5 Plastiline damaged over an area greater than<br />

40,000mm 2 during handling and laying of a pipe, may be<br />

repaired at the discretion of the Supervising Authority.<br />

The repair would be at the expense of the contractor (refer<br />

<strong>Humes</strong> for specialised procedure).<br />

12.6 Where brittle field welds occur due to overheating or<br />

charring, the defective area must be cut out and patched<br />

with plain Plastiline sheet as described in Clause 12.3.<br />

Where the existing weld strip interferes with the new<br />

welding, the operation is completed by carefully heating<br />

the plastic junctions until they are soft and can be<br />

worked together.<br />

12.7 Short lengths, less than about 25mm individually, and<br />

not more than 250mm in any one metre of weld, where the<br />

probe will enter more than 3mm under the edge of the<br />

weld strip, are classified as short incomplete welds.<br />

(Occurrence of frequent short incomplete welds is general<br />

evidence of substandard welding.) These faults may be<br />

corrected by lifting up the unsealed edge with a blunt knife,<br />

carefully directing the heat into the opening and pressing<br />

the strip down firmly.<br />

12.8 Where incomplete welds longer than specified in<br />

Clause 12.7 occur, they are to be treated by the methods<br />

described in Clause 12.6.<br />

12.9 All repair operations must be subjected to the same<br />

stringent control as stipulated for joint welding. Upon<br />

completion of repair work, all tests and inspections laid<br />

down in Section 11 must be performed again and restored<br />

areas spark tested.<br />

13 Handling — storage — laying<br />

13.1 Proper handling and welding of plastic lining is<br />

primarily a matter of care and common sense. Personnel<br />

must be aware that in the manufacture of Plastiline and<br />

its application to concrete pipes, careful control is exercised.<br />

This care is nullified if the material is subsequently damaged<br />

by carelessness and faulty practices. Failure to carry out<br />

simple precautions against damage cancels the customer’s<br />

investment in protection.<br />

13.2 Personnel must have the clear understanding that<br />

after jointing, the Plastiline must form a continuous sheet<br />

lining (i.e. free of pinholes, cuts, burns, abrasions)<br />

throughout the length of the pipeline.<br />

Personnel should have theoretical and practical basic<br />

training in welding of plastics.<br />

Plastiline welding repairs.<br />

18