EA New Homes Measures Guide - Earth Advantage

EA New Homes Measures Guide - Earth Advantage

EA New Homes Measures Guide - Earth Advantage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

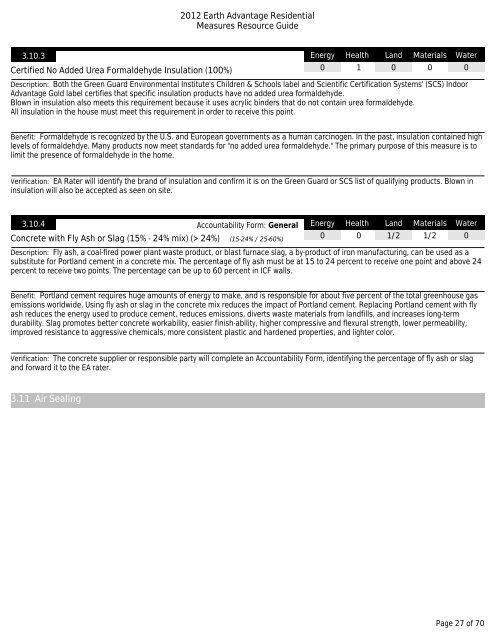

2012 <strong>Earth</strong> <strong>Advantage</strong> Residential<br />

<strong>Measures</strong> Resource <strong>Guide</strong><br />

3.10.3<br />

Certified No Added Urea Formaldehyde Insulation (100%)<br />

Energy<br />

Health<br />

Materials<br />

Water<br />

0 1 0 0 0<br />

Description: Both the Green Guard Environmental Institute's Children & Schools label and Scientific Certification Systems' (SCS) Indoor<br />

<strong>Advantage</strong> Gold label certifies that specific insulation products have no added urea formaldehyde. <br />

Blown in insulation also meets this requirement because it uses acrylic binders that do not contain urea formaldehyde. <br />

All insulation in the house must meet this requirement in order to receive this point.<br />

Land<br />

Benefit: Formaldehyde is recognized by the U.S. and European governments as a human carcinogen. In the past, insulation contained high<br />

levels of formaldehdye. Many products now meet standards for "no added urea formaldehyde." The primary purpose of this measure is to<br />

limit the presence of formaldehyde in the home.<br />

Verification: <strong>EA</strong> Rater will identify the brand of insulation and confirm it is on the Green Guard or SCS list of qualifying products. Blown in<br />

insulation will also be accepted as seen on site.<br />

3.10.4<br />

Accountability Form: General<br />

Concrete with Fly Ash or Slag (15% - 24% mix) (> 24%) (15-24% / 25-60%)<br />

Energy<br />

Materials<br />

Water<br />

0 0 1/2 1/2 0<br />

Description: Fly ash, a coal-fired power plant waste product, or blast furnace slag, a by-product of iron manufacturing, can be used as a<br />

substitute for Portland cement in a concrete mix. The percentage of fly ash must be at 15 to 24 percent to receive one point and above 24<br />

percent to receive two points. The percentage can be up to 60 percent in ICF walls.<br />

Health<br />

Land<br />

Benefit: Portland cement requires huge amounts of energy to make, and is responsible for about five percent of the total greenhouse gas<br />

emissions worldwide. Using fly ash or slag in the concrete mix reduces the impact of Portland cement. Replacing Portland cement with fly<br />

ash reduces the energy used to produce cement, reduces emissions, diverts waste materials from landfills, and increases long-term<br />

durability. Slag promotes better concrete workability, easier finish-ability, higher compressive and flexural strength, lower permeability,<br />

improved resistance to aggressive chemicals, more consistent plastic and hardened properties, and lighter color.<br />

Verification: The concrete supplier or responsible party will complete an Accountability Form, identifying the percentage of fly ash or slag<br />

and forward it to the <strong>EA</strong> rater.<br />

3.11 Air Sealing<br />

Page 27 of 70