Integrated system for safe and future-proof power distribution - Moeller

Integrated system for safe and future-proof power distribution - Moeller

Integrated system for safe and future-proof power distribution - Moeller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Integrated</strong> <strong>system</strong> <strong>for</strong> <strong>safe</strong> <strong>and</strong><br />

<strong>future</strong>-<strong>proof</strong> <strong>power</strong> <strong>distribution</strong><br />

With <strong>power</strong> requirements increasing all over the world <strong>and</strong> the<br />

continued increasing pressure to cut costs, there is an even<br />

greater need <strong>for</strong> secure investments through which efficient<br />

planning, assembly, installation <strong>and</strong> operation are ensured. To<br />

meet these requirements, cost-efficient <strong>and</strong> st<strong>and</strong>ardised <strong>power</strong><br />

<strong>distribution</strong> <strong>system</strong>s are needed that customers can adapt to the<br />

individual requirements of their projects. In short what is needed<br />

is maximum flexibility, economy <strong>and</strong> reliability.<br />

Extensive <strong>safe</strong>ty requirements <strong>and</strong><br />

special st<strong>and</strong>ards have to be observed in<br />

the <strong>power</strong> <strong>distribution</strong> sector. The consistent<br />

use of the extensive assembly<br />

<strong>and</strong> testing regulations as stipulated by<br />

DIN EN 60439-1 (VDE 0660 Part 500):<br />

2000-08 [1, 2] is there<strong>for</strong>e an important<br />

requirement <strong>for</strong> the reliable <strong>and</strong> <strong>safe</strong><br />

operation of a switchgear <strong>and</strong> controlgear<br />

assembly, i.e. a type-tested (TTA)<br />

<strong>and</strong> partially type-tested (PTTA) assembly<br />

<strong>for</strong> <strong>power</strong> <strong>and</strong> service <strong>distribution</strong><br />

boards (DIN EN 60439-3 (VDE 0660<br />

Part 504):2002-05 [3, 4]). In compliance<br />

with DIN EN 60204-1 (VDE 0113 Part<br />

1):1998-11 [5, 6] the switchgear <strong>and</strong><br />

controlgear assembly, or switchboard<br />

<strong>system</strong> <strong>for</strong> short, can likewise be used<br />

as a type-tested/partially low-voltage<br />

Jutta Zacharias is head of the<br />

Power Distribution business unit<br />

at <strong>Moeller</strong> GmbH in Bonn.<br />

e-mail: jutta.zacharias@moeller.net<br />

Dipl.-Ing. Heinrich Moog is head of<br />

xEnergy product management at<br />

<strong>Moeller</strong> GmbH in Bonn.<br />

e-mail: heinrich.moog@moeller.net<br />

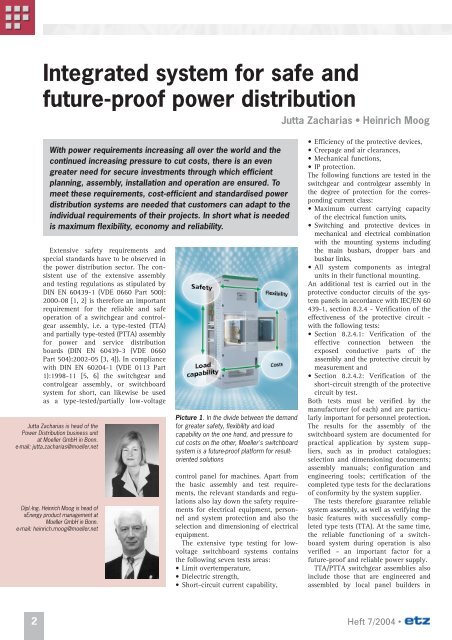

Picture 1. In the divide between the dem<strong>and</strong><br />

<strong>for</strong> greater <strong>safe</strong>ty, flexibility <strong>and</strong> load<br />

capability on the one h<strong>and</strong>, <strong>and</strong> pressure to<br />

cut costs on the other, <strong>Moeller</strong>'s switchboard<br />

<strong>system</strong> is a <strong>future</strong>-<strong>proof</strong> plat<strong>for</strong>m <strong>for</strong> resultoriented<br />

solutions<br />

control panel <strong>for</strong> machines. Apart from<br />

the basic assembly <strong>and</strong> test requirements,<br />

the relevant st<strong>and</strong>ards <strong>and</strong> regulations<br />

also lay down the <strong>safe</strong>ty requirements<br />

<strong>for</strong> electrical equipment, personnel<br />

<strong>and</strong> <strong>system</strong> protection <strong>and</strong> also the<br />

selection <strong>and</strong> dimensioning of electrical<br />

equipment.<br />

The extensive type testing <strong>for</strong> lowvoltage<br />

switchboard <strong>system</strong>s contains<br />

the following seven tests areas:<br />

• Limit overtemperature,<br />

• Dielectric strength,<br />

• Short-circuit current capability,<br />

Jutta Zacharias • Heinrich Moog<br />

• Efficiency of the protective devices,<br />

• Creepage <strong>and</strong> air clearances,<br />

• Mechanical functions,<br />

• IP protection.<br />

The following functions are tested in the<br />

switchgear <strong>and</strong> controlgear assembly in<br />

the degree of protection <strong>for</strong> the corresponding<br />

current class:<br />

• Maximum current carrying capacity<br />

of the electrical function units,<br />

• Switching <strong>and</strong> protective devices in<br />

mechanical <strong>and</strong> electrical combination<br />

with the mounting <strong>system</strong>s including<br />

the main busbars, dropper bars <strong>and</strong><br />

busbar links,<br />

• All <strong>system</strong> components as integral<br />

units in their functional mounting.<br />

An additional test is carried out in the<br />

protective conductor circuits of the <strong>system</strong><br />

panels in accordance with IEC/EN 60<br />

439-1, section 8.2.4 - Verification of the<br />

effectiveness of the protective circuit -<br />

with the following tests:<br />

• Section 8.2.4.1: Verification of the<br />

effective connection between the<br />

exposed conductive parts of the<br />

assembly <strong>and</strong> the protective circuit by<br />

measurement <strong>and</strong><br />

• Section 8.2.4.2: Verification of the<br />

short-circuit strength of the protective<br />

circuit by test.<br />

Both tests must be verified by the<br />

manufacturer (of each) <strong>and</strong> are particularly<br />

important <strong>for</strong> personnel protection.<br />

The results <strong>for</strong> the assembly of the<br />

switchboard <strong>system</strong> are documented <strong>for</strong><br />

practical application by <strong>system</strong> suppliers,<br />

such as in product catalogues;<br />

selection <strong>and</strong> dimensioning documents;<br />

assembly manuals; configuration <strong>and</strong><br />

engineering tools; certification of the<br />

completed type tests <strong>for</strong> the declarations<br />

of con<strong>for</strong>mity by the <strong>system</strong> supplier.<br />

The tests there<strong>for</strong>e guarantee reliable<br />

<strong>system</strong> assembly, as well as verifying the<br />

basic features with successfully completed<br />

type tests (TTA). At the same time,<br />

the reliable functioning of a switchboard<br />

<strong>system</strong> during operation is also<br />

verified – an important factor <strong>for</strong> a<br />

<strong>future</strong>-<strong>proof</strong> <strong>and</strong> reliable <strong>power</strong> supply.<br />

TTA/PTTA switchgear assemblies also<br />

include those that are engineered <strong>and</strong><br />

assembled by local panel builders in<br />

2 Heft 7/2004 •