PackStak Pro - TOPS - Packaging Software

PackStak Pro - TOPS - Packaging Software

PackStak Pro - TOPS - Packaging Software

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

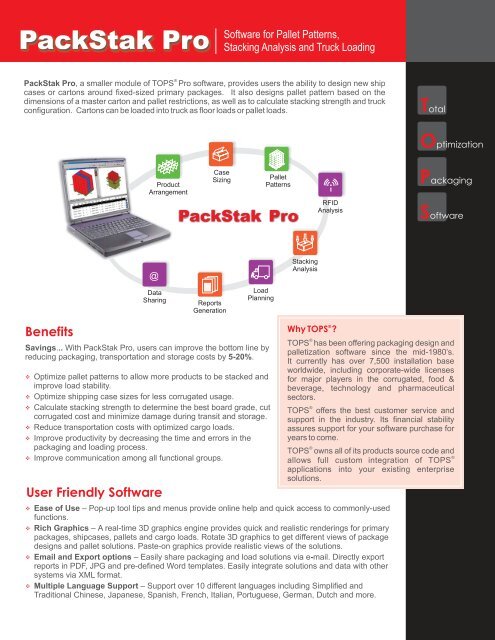

<strong>PackStak</strong> <strong>Pro</strong><br />

<strong>Software</strong> for Pallet Patterns,<br />

Stacking Analysis and Truck Loading<br />

®<br />

<strong>PackStak</strong> <strong>Pro</strong>, a smaller module of <strong>TOPS</strong> <strong>Pro</strong> software, provides users the ability to design new ship<br />

cases or cartons around fixed-sized primary packages. It also designs pallet pattern based on the<br />

dimensions of a master carton and pallet restrictions, as well as to calculate stacking strength and truck<br />

configuration. Cartons can be loaded into truck as floor loads or pallet loads.<br />

Total<br />

Optimization<br />

<strong>Pro</strong>duct<br />

Arrangement<br />

Case<br />

Sizing<br />

Pallet<br />

Patterns<br />

<strong>PackStak</strong> <strong>Pro</strong><br />

i<br />

RFID<br />

Analysis<br />

<strong>Packaging</strong><br />

<strong>Software</strong><br />

@<br />

Data<br />

Sharing<br />

Reports<br />

Generation<br />

Load<br />

Planning<br />

Stacking<br />

Analysis<br />

Benefits<br />

Savings ...<br />

With <strong>PackStak</strong> <strong>Pro</strong>, users can improve the bottom line by<br />

reducing packaging, transportation and storage costs by 5-20% .<br />

<br />

<br />

<br />

<br />

<br />

<br />

Optimize pallet patterns to allow more products to be stacked and<br />

improve load stability.<br />

Optimize shipping case sizes for less corrugated usage.<br />

Calculate stacking strength to determine the best board grade, cut<br />

corrugated cost and minimize damage during transit and storage.<br />

Reduce transportation costs with optimized cargo loads.<br />

Improve productivity by decreasing the time and errors in the<br />

packaging and loading process.<br />

Improve communication among all functional groups.<br />

User Friendly <strong>Software</strong><br />

<br />

<br />

<br />

<br />

Why <strong>TOPS</strong> ®<br />

?<br />

®<br />

<strong>TOPS</strong> has been offering packaging design and<br />

palletization software since the mid-1980’s.<br />

It currently has over 7,500 installation base<br />

worldwide, including corporate-wide licenses<br />

for major players in the corrugated, food &<br />

beverage, technology and pharmaceutical<br />

sectors.<br />

®<br />

<strong>TOPS</strong> offers the best customer service and<br />

support in the industry. Its financial stability<br />

assures support for your software purchase for<br />

years to come.<br />

®<br />

<strong>TOPS</strong> owns all of its products source code and<br />

®<br />

allows full custom integration of <strong>TOPS</strong><br />

applications into your existing enterprise<br />

solutions.<br />

Ease of Use – Pop-up tool tips and menus provide online help and quick access to commonly-used<br />

functions.<br />

Rich Graphics – A real-time 3D graphics engine provides quick and realistic renderings for primary<br />

packages, shipcases, pallets and cargo loads. Rotate 3D graphics to get different views of package<br />

designs and pallet solutions. Paste-on graphics provide realistic views of the solutions.<br />

Email and Export options – Easily share packaging and load solutions via e-mail. Directly export<br />

reports in PDF, JPG and pre-defined Word templates. Easily integrate solutions and data with other<br />

systems via XML format.<br />

Multiple Language Support – Support over 10 different languages including Simplified and<br />

Traditional Chinese, Japanese, Spanish, French, Italian, Portuguese, German, Dutch and more.

. . . . . . . .<br />

Corner Posts Package Design Dividers Pallet Patterns Case Size<br />

<strong>TOPS</strong> <strong>Pro</strong> Truck Loading RFID Intermediate Packa<br />

<strong>PackStak</strong> <strong>Pro</strong> Functions<br />

Primary Pack Sizing<br />

Determine the best size and arrangement to package a product.<br />

Support bottles, milk cartons, bags, tubs, stand-up pouches and blister<br />

packs.<br />

Apply graphics to create realistic packages.<br />

Simply enter the dimensions and apply graphics -a3Drendering of the<br />

product will come right on the screen within seconds.<br />

Pallet Building<br />

Automatically generate different pallet patterns for straight loads.<br />

Specify overhang and underhang.<br />

Use a slave pallet or add a raised platform for shipcases on the pallet.<br />

Restrict unitloads to certain pattern styles.<br />

Add labels, caps, pads, slip sheets, straps, corner posts and more.<br />

Primary package in different shapes<br />

and arrangements<br />

Pallets column stacked, pin-wheeled and loaded<br />

with alternating layer with secondary pattern on top.<br />

Combining Pallet Patterns<br />

<strong>PackStak</strong> <strong>Pro</strong> automatically generates different pallet patterns for straight loads. Users can<br />

pick the one that best meets their needs, be it for cubic efficiency, for store displays,<br />

for load stability or for inventory keeping. Simply point and click on the pallet pattern<br />

editor and the software will automatically change the pattern. Users can also combine<br />

two pallet patterns in the same unit load to meet their specific needs.<br />

Unit load with<br />

slave pallets (left)<br />

and raised<br />

platform (right).<br />

Compression and Stacking Strength Analysis<br />

<strong>PackStak</strong> <strong>Pro</strong> offers a host of mechanical and environment analyses to ensure savings<br />

in corrugated costs and minimize damage during transit and storage. It uses the McKee<br />

formula along with other factors to calculate stacking strength results based on Edge Crush,<br />

Ring Crush, or Kellicut results. Users can enter their own paper and board values as<br />

well as to filter out values for quick reference. Stacking strength is also available<br />

for non-RSC boxes as a relative percentage of RSC strength.<br />

Vehicle Loading<br />

Load a single product directly as floor loads or as pallet loads.<br />

Allow pallet loads and loose-filled items at the same time to maximize cube<br />

yield.<br />

Quickly visualize the best way to maximize floor space and cubic efficiency.<br />

Choose from an extensive database of trucks, railcars and sea containers or define your<br />

own transit vehicle.<br />

RFID Analysis<br />

The RFID location optimizer helps users find the best shipcase location for RFID tag<br />

placement for maximum readability. Users can also specify the shipcase face and position to<br />

place tags. (Feature to be released in third quarter 2007.)<br />

Floor loaded (middle), palletized (right) or<br />

combination loads with unit loads and loose<br />

items (left) into different vehicle types.<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

RFID<br />

Automatically place<br />

RFID tags for<br />

maximum readability<br />

Versatile Reports<br />

Create reports with different layouts.<br />

Realistic 3D views of primary pack, shipper, unitload and vehicle.<br />

Statistics for unitloads and vehicle loads.<br />

Comparison reports between load solutions or analyses.<br />

Save reports in XML, JPG, PDF, ASCII formats and more.<br />

Send reports via e-mail or share over a network.<br />

Share Specifications over Company Network or World Wide Web<br />

<strong>PackStak</strong> <strong>Pro</strong>’s web publisher allows users to convert packaging specifications into web pages<br />

for the Internet or a company’s Intranet to share among colleagues and customers.

. . . . . . . . .<br />

ge Stacking Analysis <strong>TOPS</strong> <strong>Pro</strong> Shrink Wrap Mixed Pallet Case Size<br />

<strong>TOPS</strong> <strong>Pro</strong> RFID Slip Sheets Container Loading<br />

The <strong>PackStak</strong> <strong>Pro</strong> Design <strong>Pro</strong>cess<br />

1.<br />

2.<br />

Define Parameters for each Specified Step<br />

Control Panel:<br />

Specify the design sequence for the analysis<br />

Click on the graphic icon to add respective step<br />

Choose from sequence to include primary pack,<br />

shipcase, pallet and transit vehicle<br />

Primary Pack: Select the primary package and enter the dimensions, weight and other<br />

parameters, if available for that shape. Users can specify the unit measure as well as<br />

the orientation of the package when placed inside the shipcase.<br />

:<br />

<strong>PackStak</strong> <strong>Pro</strong> Saves<br />

<strong>Packaging</strong> and<br />

Freight Costs<br />

8-15%<br />

Shipcase Parameters:<br />

<strong>PackStak</strong> will determine the dimension of the shipcase for the<br />

selected primary package. Users can specify primary pack quantity,<br />

unit of measure, orientation of the shipcase when loading onto<br />

pallets by checking the corresponding boxes under “Vert”, that is, to<br />

check off the dimensions that are allowed vertical during loading.<br />

UnitLoad: Select the pallet to be used from the <strong>PackStak</strong> database or create a custom<br />

pallet as desired. With unit load, users can:<br />

Specify its maximum height in actual value or by limiting the number of stacked layers<br />

Set the maximum weight for the unit load<br />

Specify the amount of overhang or underhang allowed<br />

Use of slave pallet or a raised platform<br />

Add labels, straps, corner posts and more<br />

Vehicle Parameters: Select the vehicle to be used from the <strong>PackStak</strong> database or create<br />

a custom sea container or trailer as needed. Users can:<br />

Load loose items to fill the void space not used by the unit loads<br />

Allow <strong>PackStak</strong> to use different unit load heights to cube out the vehicle<br />

Limit the style of loading patterns<br />

Specify how the loads will align inside the vehicle<br />

3.<br />

pallet pattern and how the unitloads will be<br />

Solutions:<br />

<strong>PackStak</strong> provides different solutions on<br />

primary pack arrangement which determines<br />

the shipcase size. Users can also pick the<br />

loaded into the transit vehicles for the<br />

analysis.<br />

4.<br />

Reports:<br />

<strong>PackStak</strong> provides a versatile report<br />

format where users can define what<br />

graphics and statistics to be included.

How to Save Money with <strong>PackStak</strong> <strong>Pro</strong><br />

Reduces Corrugated Use by<br />

Optimizing Shipcase Sizes<br />

By picking an alternate shipcase for<br />

the primary pack, board area is cut<br />

down by 17.15% while retaining the<br />

same cubic efficiency.<br />

Ln:<br />

Wd:<br />

Ht:<br />

Net:<br />

Grs:<br />

Cube:<br />

RSC (FEFCO 0201) 16.3125x12.3125x7.6250<br />

Can/Cylinder<br />

(OD)<br />

4.0000 in<br />

4.0000 in<br />

7.0000 in<br />

0.0000 oz<br />

0.0000 oz<br />

87.96 in3<br />

Height Vertical<br />

Shipper<br />

(ID)<br />

16.0000 in<br />

12.0000 in<br />

7.0000 in<br />

0.7778 ft3<br />

Shipper<br />

(OD)<br />

16.3125 in<br />

12.3125 in<br />

7.6250 in<br />

0.000 lb<br />

0.793 lb<br />

0.8863 ft3<br />

Height Vertical<br />

Can/Cylinder: 12<br />

Area Efficiency 78.54%<br />

Cubic Efficiency 78.54%<br />

Pattern:<br />

4x3x1<br />

RSC Area: 7.93 ft2<br />

Ln:<br />

Wd:<br />

Ht:<br />

Net:<br />

Grs:<br />

Cube:<br />

RSC (FEFCO 0201) 12.3125x8.3125x14.6250<br />

Can/Cylinder<br />

(OD)<br />

4.0000 in<br />

4.0000 in<br />

7.0000 in<br />

0.0000 oz<br />

0.0000 oz<br />

87.96 in3<br />

Height Vertical<br />

Shipper<br />

(ID)<br />

12.0000 in<br />

8.0000 in<br />

14.0000 in<br />

0.7778 ft3<br />

Shipper<br />

(OD)<br />

12.3125 in<br />

8.3125 in<br />

14.6250 in<br />

0.000 lb<br />

0.657 lb<br />

0.8662 ft3<br />

Height Vertical<br />

Can/Cylinder: 12<br />

Area Efficiency 78.54%<br />

Cubic Efficiency 78.54%<br />

Pattern:<br />

3x2x2<br />

RSC Area: 6.57 ft2<br />

Ships More <strong>Pro</strong>ducts by<br />

Optimizing Pallet Pattern<br />

Improvements made by using a<br />

different pallet pattern include:<br />

<br />

<br />

<br />

<br />

One more shipper per layer<br />

Five more shippers per pallet<br />

Area efficiency up by 10.45%<br />

Cubic efficiency up by 10.34%<br />

Ln:<br />

Wd:<br />

Ht:<br />

Grs:<br />

Cube:<br />

GMA (Notched) 48.000x40.000x5.000<br />

Shipper<br />

(ID)<br />

17.9375 in<br />

10.6875 in<br />

9.0630 in<br />

1.0055 ft3<br />

Shipper:<br />

Area Efficiency:<br />

Cubic Efficiency:<br />

Layers/load:<br />

Pattern:<br />

RSC Area:<br />

Shipper<br />

(OD)<br />

18.2500 in<br />

11.0000 in<br />

9.6880 in<br />

12.500 lb<br />

1.1255 ft3<br />

Height Vertical<br />

0.00 %<br />

0.00 %<br />

8.40 ft2<br />

Unitload<br />

(Incl. Pal)<br />

44.000 in<br />

36.500 in<br />

53.440 in<br />

565.000 lb<br />

49.6670 ft3<br />

40<br />

83.65 %<br />

82.69 %<br />

8<br />

5<br />

Column<br />

336 ft2<br />

Unitload<br />

(Incl. Pal)<br />

47.500 in<br />

40.250 in<br />

53.440 in<br />

627.500 lb<br />

59.1265 ft3<br />

45<br />

94.10 %<br />

93.03 %<br />

9<br />

5<br />

Diagonal<br />

378 ft2<br />

Saves Shipping Costs with<br />

Container Optimization<br />

<strong>Pro</strong>vides up to 50 different plans for<br />

straight loads. An optimal plan can<br />

load more shippers with the same<br />

resources.<br />

Ln:<br />

Wd:<br />

Ht:<br />

Grs:<br />

Cube:<br />

476.00x98.00x110.00<br />

Shipper<br />

(ID)<br />

24.6875 in<br />

12.9375 in<br />

11.3750 in<br />

2.1025 ft3<br />

Shipper:<br />

Area Efficiency:<br />

Cubic Efficiency:<br />

Cases per layer:<br />

Layers/load:<br />

Pattern:<br />

RSC Area:<br />

Density (gr/cc):<br />

Shipper<br />

(OD)<br />

25.0000 in<br />

13.2500 in<br />

12.0000 in<br />

0.000 lb<br />

2.3003 ft3<br />

Height Vertical<br />

0.00 %<br />

0.00 %<br />

13.41 ft2<br />

0.0000<br />

Vehicle<br />

Load<br />

475.000 in<br />

92.75 in<br />

108.00 in<br />

0lb<br />

2753.52 ft3<br />

1179<br />

93.02 %<br />

91.33 %<br />

131<br />

9<br />

Triblock<br />

15815 ft2<br />

0.0000<br />

Ln:<br />

Wd:<br />

Ht:<br />

Grs:<br />

Cube:<br />

476.00x98.00x110.00<br />

Shipper<br />

(ID)<br />

24.6875 in<br />

12.9375 in<br />

11.3750 in<br />

2.1025 ft3<br />

Shipper:<br />

Area Efficiency:<br />

Cubic Efficiency:<br />

Cases per layer:<br />

Layers/load:<br />

Pattern:<br />

RSC Area:<br />

Density (gr/cc):<br />

Shipper<br />

(OD)<br />

25.0000 in<br />

13.2500 in<br />

12.0000 in<br />

0.000 lb<br />

2.3003 ft3<br />

Height Vertical<br />

0.00 %<br />

0.00 %<br />

13.41 ft2<br />

0.0000<br />

Vehicle<br />

Load<br />

475.000 in<br />

92.75 in<br />

108.00 in<br />

0lb<br />

2753.52 ft3<br />

1188<br />

93.73 %<br />

92.03 %<br />

132<br />

9<br />

Triblock<br />

15936 ft2<br />

0.0000<br />

System Requirements<br />

Platform<br />

Network<br />

<strong>Pro</strong>cessor<br />

Hard Drive Space<br />

RAM Required<br />

Code<br />

Compiler<br />

Framework<br />

Database Format<br />

Import/Export<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

.....<br />

Windows 95, 98, NT, 2000, XP and 2003<br />

Any (Need only a file server)<br />

Pentium 400 Mhz or faster<br />

40 MB minimum<br />

128 MB, 256MB recommended<br />

32-bit<br />

Microsoft Visual C++ 6.0<br />

32-bit XVT 5.0 and Microsoft Foundation Classes<br />

32-bit C-Tree<br />

Uses ASCII comma delimited text files<br />

Compatible with most document management<br />

systems, spreadsheets, databases and<br />

mainframes. Include Excel, Access, Paradox,<br />

AS400 and Unix platforms<br />

<strong>Software</strong> Maintenance and Support<br />

®<br />

<strong>TOPS</strong> has an expert team to provide outstanding technical<br />

support and services including:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Unlimited technical assistance.<br />

Free software upgrades for the one year subscription.<br />

® .<br />

Toll-free access (USA only) during <strong>TOPS</strong> office hours<br />

One full day of free training set at customer’s convenience*<br />

or web based training.<br />

® .<br />

Access to <strong>TOPS</strong> flash-based software tutorial series<br />

Newsletters with the latest news and improvements in<br />

®<br />

<strong>TOPS</strong> software and tips on how to get the most out of your<br />

.<br />

software investment<br />

*Travel & living expenses are responsibility of customers<br />

T O P S<br />

275 West Campbell Road, Suite 600<br />

Richardson, Texas 75080 USA<br />

voice: 972-739-8677 fax: 972-739-9478<br />

www.topseng.com info@topseng.com<br />

For more details, call 972-739-8677<br />

or visit our web site at<br />

www.topseng.com