VOL 71 No4 - Navy League of Australia

VOL 71 No4 - Navy League of Australia

VOL 71 No4 - Navy League of Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESIGN AND DEMONSTRATION<br />

R1, commonly but un<strong>of</strong>ficially known as 'Mayfly', was designed in the<br />

late autumn and winter <strong>of</strong> 1908/9 before the Treasury had agreed<br />

to its funding and before Vickers had a contract for its construction.<br />

The design team included Captain Bacon and the newly appointed<br />

Inspecting Captain <strong>of</strong> Airships, Captain Murray Sueter, one <strong>of</strong> a group <strong>of</strong><br />

submarine experts who had worked with him for some years as well as<br />

other naval <strong>of</strong>ficers and a team from Vickers supervised by Sir James<br />

McKechnie the managing director <strong>of</strong> the naval construction works at<br />

Barrow-in-Furness, Cumbria. Under him were Charles Robertson the<br />

chief engineer, B Comyn the manager <strong>of</strong> the Cavendish Dock, James<br />

Watson the works manager and S W Hunt the chief draughtsman. The<br />

whole team drew heavily on their experience with submarine design<br />

and what little information they were able to obtain from Zeppelin<br />

construction in Germany. Captain Bacon helped with the latter as he was<br />

a German speaker and was able to translate a number <strong>of</strong> documents.<br />

The state-<strong>of</strong>-the-art was far from mature and this small group that<br />

would be known today as an 'integrated project team' was asked to<br />

design and construct an experimental airship that was to be the largest<br />

flying machine ever built as quickly as possible. This 'cutting-edge'<br />

project encountered problems that would be all too familiar to project<br />

managers today.<br />

The Admiralty Specification called for an experimental aerial<br />

scout capable <strong>of</strong> sustaining 40 knots , roughly twice the speed <strong>of</strong> a<br />

contemporary battleship, for 24 hours. It was to be able to land on the<br />

sea, float and be moored by an attachment on its nose to a warship<br />

or mast set up for the purpose. It was to carry powerful wireless<br />

equipment and to have an operational ceil ing <strong>of</strong> 1 ,500 feet or more.<br />

The normal crew was to be 20 accommodated in "reasonab le comfort".<br />

At 512 feet long and 48 feet in diameter she was only a few feet shorter<br />

than the new battleship DREADNOUGHT and was to carry a great deal<br />

<strong>of</strong> naval equipment that appears odd to a later generation <strong>of</strong> aviators.<br />

These included an anchor and cable, a capstan, hawsers and even a<br />

lightweight sea-boat! The ship was to be experimental and, therefore,<br />

to be built "as cheaply as possible". In order to meet the specification<br />

she had to be big because the total lift <strong>of</strong> a rigid airship increases as the<br />

cube <strong>of</strong> the dimensions whi lst the drag or resistance to forward motion<br />

only increases as the square. Numerous shapes were considered but<br />

the one chosen was designed by the American pr<strong>of</strong>essor Zahm. This<br />

comprised a parallel sided hull with a bow curve <strong>of</strong> twice the curvature<br />

<strong>of</strong> the hull and a stern <strong>of</strong> nine times the curvature. This was calculated<br />

to have only two-fifths the air resistance <strong>of</strong> the hull form used on<br />

Zeppelins to that date. The hull was not cylindrical but twelve-sided for<br />

ease <strong>of</strong> construction. R1 was the first airship in the world to be fitted<br />

with bow-mooring gear as standard equipment and it was to prove one<br />

<strong>of</strong> the most successful features <strong>of</strong> the design.<br />

Material for the construction <strong>of</strong> the airship was ordered in May 1909<br />

while contractors began work on the shed in which it was to be built.<br />

One side <strong>of</strong> it rested on the wall <strong>of</strong> the Cavendish Dock and the other<br />

was to rest on piles driven into the dock bed. Trouble was experienced<br />

with these and completion was delayed from the original planning<br />

assumption <strong>of</strong> August 1909 to June 1910. A wooden 'floor' was built<br />

over the water in the shed on which a cradle was built on which the<br />

airship framework was assembled. At this stage there was considerable<br />

discussion about the actual material from which the 'skeleton '<br />

framework <strong>of</strong> R1 was to be constructed. Vickers recommended wood<br />

but Captain Bacon insisted that, given the experimental nature <strong>of</strong> the<br />

ship, metal was necessary to give the most data for future construction.<br />

A trial section thirty-seven and a half feet long was built in the boiler<br />

shop to a design prepared by one <strong>of</strong> Vickers' foremen. One end was <strong>of</strong><br />

hollow wood spars, the middle was half wood and half aluminium and<br />

the other end all aluminium. Wood proved by far the best and wires<br />

made <strong>of</strong> extruded aluminium proved useless. The metal itself proved<br />

weaker than tests had indicated when supplies arrived from September.<br />

In November 1909 however, Vickers' metallurgists heard <strong>of</strong> an alloy<br />

called Duralumin. This was made in Germany but it appeared to be<br />

perfect for the application and the firm bought the Patent for the British<br />

Empire. It comprised 94% aluminium, 4% copper with manganese,<br />

silicon and iron and the resulting metal had nearly the strength <strong>of</strong> iron<br />

with the weight <strong>of</strong> aluminium. In practical terms, this meant that the<br />

strength <strong>of</strong> the ship wou ld be doubled wh ile saving a ton in weight. Tests<br />

proved the suitability <strong>of</strong> Duralumin and validated the <strong>Navy</strong>'s insistence<br />

on metal. The Admiralty gave its approval for the new alloy to be used<br />

early in 1910 and R1 was the first aircraft to be built using it. The first<br />

duralumin Zeppelin, LZ 56, did not fly until December 1914 nearly five<br />

years later. The only problem was that little was then known about<br />

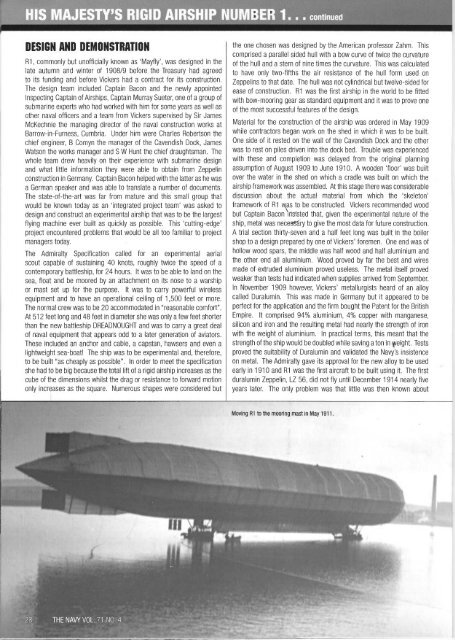

Moving R1 to the mooring mast in May 1911.