TORQUE LIMITERS

TORQUE LIMITERS

TORQUE LIMITERS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

single-position<br />

multi-position<br />

load holding<br />

full disengagement<br />

GENERAL FUNCTION<br />

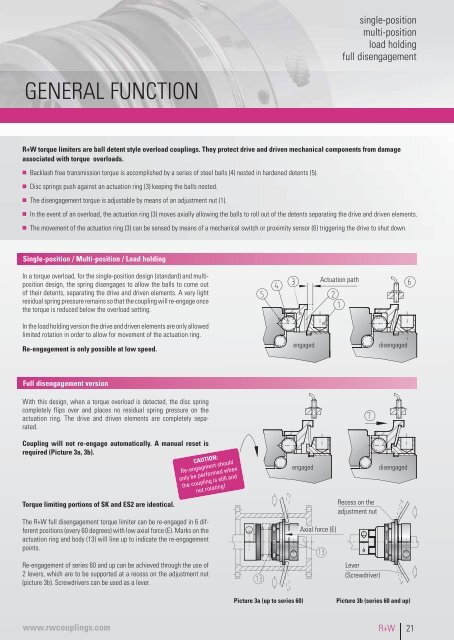

R+W torque limiters are ball detent style overload couplings. They protect drive and driven mechanical components from damage<br />

associated with torque overloads.<br />

■ Backlash free transmission torque is accomplished by a series of steel balls (4) nested in hardened detents (5).<br />

■ Disc springs push against an actuation ring (3) keeping the balls nested.<br />

■ The disengagement torque is adjustable by means of an adjustment nut (1).<br />

■ In the event of an overload, the actuation ring (3) moves axially allowing the balls to roll out of the detents separating the drive and driven elements.<br />

■ The movement of the actuation ring (3) can be sensed by means of a mechanical switch or proximity sensor (6) triggering the drive to shut down.<br />

Single-position / Multi-position / Load holding<br />

In a torque overload, for the single-position design (standard) and multiposition<br />

design, the spring disengages to allow the balls to come out<br />

of their detents, separating the drive and driven elements. A very light<br />

residual spring pressure remains so that the coupling will re-engage once<br />

the torque is reduced below the overload setting.<br />

Actuation path<br />

In the load holding version the drive and driven elements are only allowed<br />

limited rotation in order to allow for movement of the actuation ring.<br />

Re-engagement is only possible at low speed.<br />

engaged<br />

disengaged<br />

Full disengagement version<br />

With this design, when a torque overload is detected, the disc spring<br />

completely flips over and places no residual spring pressure on the<br />

actuation ring. The drive and driven elements are completely separated.<br />

Coupling will not re-engage automatically. A manual reset is<br />

required (Picture 3a, 3b).<br />

Torque limiting portions of SK and ES2 are identical.<br />

The R+W full disengagement torque limiter can be re-engaged in 6 different<br />

positions (every 60 degrees) with low axial force (E). Marks on the<br />

actuation ring and body (13) will line up to indicate the re-engagement<br />

points.<br />

Re-engagement of series 60 and up can be achieved through the use of<br />

2 levers, which are to be supported at a recess on the adjustment nut<br />

(picture 3b). Screwdrivers can be used as a lever.<br />

CAUTION:<br />

Re-engagment should<br />

only be performed when<br />

the coupling is still and<br />

not rotating!<br />

engaged<br />

Axial force (E)<br />

Recess on the<br />

adjustment nut<br />

Lever<br />

(Screwdriver)<br />

disengaged<br />

Picture 3a (up to series 60)<br />

Picture 3b (series 60 and up)<br />

www.rwcouplings.com<br />

R+W<br />

21