RP-01638

RP-01638

RP-01638

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

13<br />

8<br />

-6<br />

7<br />

9<br />

10<br />

A B C<br />

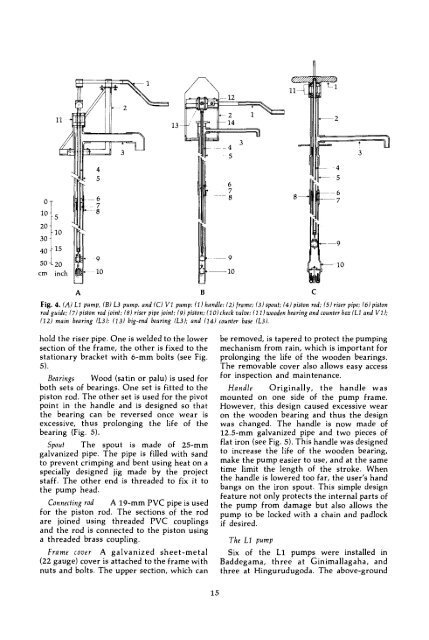

Fig. 4. (A) LI pump, (B) L3 pump, and (C) VI pump: (1) handle; (2) (rame; (3) spout; (4) piston rod; (5) riser pipe; (6) piston<br />

rod guide; (7) piston rod joint; (8) riser pipe joint; (9) piston; (10) check valve; (I I) wooden bearing and counter box (L7 and V I );<br />

(12) main bearing (L3); (13) big-end bearing (L3); and (14) counter base (L3).<br />

hold the riser pipe. One is welded to the lower<br />

section of the (rame, the other is fixed to the<br />

stationary bracket with 6-mm bolts (see Fig.<br />

5).<br />

Bearings Wood (satin or palu) is used for<br />

both sets of bearings. One set is fitted to the<br />

piston rod. The other set is used for the pivot<br />

point in the handle and is designed so that<br />

the bearing can be reversed once wear is<br />

excessive, thus prolonging the life of the<br />

bearing (Fig. 5).<br />

Spout The spout is made of 25-mm<br />

galvanized pipe. The pipe is filled with sand<br />

to prevent crimping and bent using heat on a<br />

specially designed jig made by the project<br />

staff. The other end is threaded to fix it to<br />

the pump head.<br />

Connecting rod A 19-mm PVC pipe is used<br />

for the piston rod. The sections of the rod<br />

are joined using threaded PVC couplings<br />

and the rod is connected to the piston using<br />

a threaded brass coupling.<br />

A galvanized sheet-metal<br />

Frame caver<br />

(22 gauge) cover is attached to the frame with<br />

nuts and bolts. The upper section, which can<br />

be removed, is tapered to protect the pumping<br />

mechanism from rain, which is important for<br />

prolonging the life of the wooden bearings.<br />

The removable cover also allows easy access<br />

for inspection and maintenance.<br />

Handle Originally, the handle was<br />

mounted on one side of the pump frame.<br />

However, this design caused excessive wear<br />

on the wooden bearing and thus the design<br />

was changed. The handle is now made of<br />

12.5-mm galvanized pipe and two pieces of<br />

flat iron (see Fig. 5). This handle was designed<br />

to increase the life of the wooden bearing,<br />

make the pump easier to use, and at the same<br />

time limit the length of the stroke. When<br />

the handle is lowered too far, the user's hand<br />

bangs on the iron spout. This simple design<br />

feature not only protects the internai parts of<br />

the pump from damage but also allows the<br />

pump to be locked with a chain and padlock<br />

if desired.<br />

The LI pump<br />

Six of the Li pumps were installed in<br />

Baddegama, three at Ginimallagaha, and<br />

three at Hingurudugoda. The above-ground<br />

15