RP-01638

RP-01638

RP-01638

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

inch<br />

0t-r1<br />

10<br />

10<br />

30<br />

cm<br />

20<br />

50<br />

B<br />

CD<br />

1<br />

C (top)<br />

A<br />

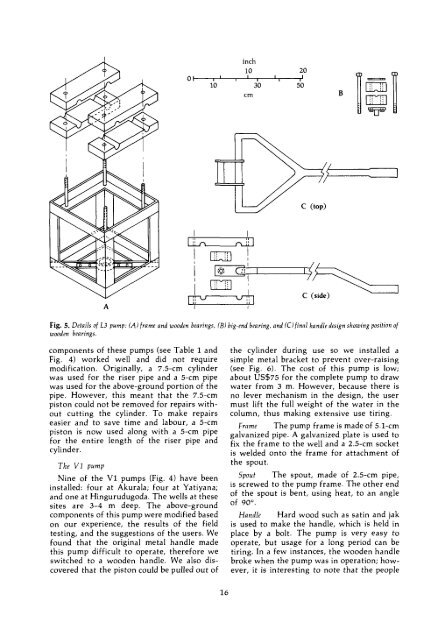

Fig. 5. Details of L3 pump: (A) (rame and wooden bearings, (B) big-end bearing, and (C) final handle design showing position of<br />

wooden bearings.<br />

components of these pumps (see Table 1 and<br />

Fig. 4) worked well and did not require<br />

modification. Originally, a 7.5-cm cylinder<br />

was used for the riser pipe and a 5-cm pipe<br />

was used for the above-ground portion of the<br />

pipe. However, this meant that the 7.5-cm<br />

piston could not be removed for repairs without<br />

cutting the cylinder. To make repairs<br />

easier and to save time and labour, a 5-cm<br />

piston is now used along with a 5-cm pipe<br />

for the entire length of the riser pipe and<br />

cylinder.<br />

The V i pump<br />

Nine of the Vl pumps (Fig. 4) have been<br />

installed: four at Akurala; four at Yatiyana;<br />

and one at Hingurudugoda. The wells at these<br />

sites are 3-4 m deep. The above-ground<br />

components of this pump were modified based<br />

on our experience, the results of the field<br />

testing, and the suggestions of the users. We<br />

found that the original metal handle made<br />

this pump difficult to operate, therefore we<br />

switched to a wooden handle. We also discovered<br />

that the piston could be pulled out of<br />

the cylinder during use so we installed a<br />

simple metal bracket to prevent over-raising<br />

(see Fig. 6). The cost of this pump is low;<br />

about US$75 for the complete pump to draw<br />

water from 3 m. However, because there is<br />

no lever mechanism in the design, the user<br />

must lift the full weight of the water in the<br />

column, thus making extensive use tiring.<br />

Frame The pump frame is made of 5.1-cm<br />

galvanized pipe. A galvanized plate is used to<br />

fix the frame to the well and a 2.5-cm socket<br />

is welded onto the frame for attachment of<br />

the spout.<br />

Spout The spout, made of 2.5-cm pipe,<br />

is screwed to the pump frame. The other end<br />

of the spout is bent, using heat, to an angle<br />

of 90°.<br />

Handle Hard wood such as satin and jak<br />

is used to make the handle, which is held in<br />

place by a bolt. The pump is very easy to<br />

operate, but usage for a long period can be<br />

tiring. In a few instances, the wooden handle<br />

broke when the pump was in operation; however,<br />

it is interesting to note that the people<br />

16