RP-01638

RP-01638

RP-01638

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

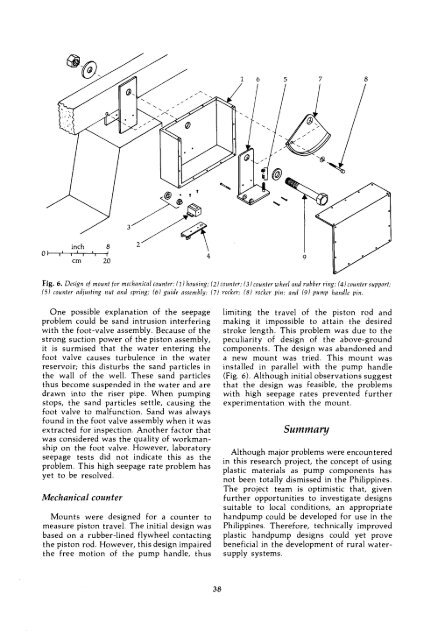

Fig. 6. Design of mount for mechanical counter: (1) housing; (2) counter; (3) counter wheel and rubber ring; (4) cou nter support;<br />

(5) counter adjusting nul and spring; (6) guide assembly; (7) rocker; (8) rocker pin; and (9) pump handle pin.<br />

One possible explanation of the seepage<br />

problem could be sand intrusion interfering<br />

with the foot-valve assembly. Because of the<br />

strong suction power of the piston assembly,<br />

it is surmised that the water entering the<br />

foot valve causes turbulence in the water<br />

reservoir; this disturbs the sand particles in<br />

the wall of the well. These sand particles<br />

thus become suspended in the water and are<br />

drawn into the riser pipe. When pumping<br />

stops, the sand particles settle, causing the<br />

foot valve to malfunction. Sand was always<br />

found in the foot valve assembly when it was<br />

extracted for inspection. Another factor that<br />

was considered was the quality of workmanship<br />

on the foot valve. However, laboratory<br />

seepage tests did not indicate this as the<br />

problem. This high seepage rate problem has<br />

yet to be resolved.<br />

Mechanical counter<br />

Mounts were designed for a counter to<br />

measure piston travel. The initial design was<br />

based on a rubber-lined flywheel contacting<br />

the piston rod. However, this design impaired<br />

the free motion of the pump handle, thus<br />

limiting the travel of the piston rod and<br />

making it impossible to attain the desired<br />

stroke length. This problem was due to the<br />

peculiarity of design of the above-ground<br />

components. The design was abandoned and<br />

a new mount was tried. This mount was<br />

installed in parallel with the pump handle<br />

(Fig. 6). Although initial observations suggest<br />

that the design was feasible, the problems<br />

with high seepage rates prevented further<br />

experimentation with the mount.<br />

Summary<br />

Although major problems were encountered<br />

in this research project, the concept of using<br />

plastic materials as pump components has<br />

not been totally dismissed in the Philippines.<br />

The project team is optimistic that, given<br />

further opportunities to investigate designs<br />

suitable to local conditions, an appropriate<br />

handpump could be developed for use in the<br />

Philippines. Therefore, technically improved<br />

plastic handpump designs could yet proue<br />

beneficial in the development of rural watersupply<br />

systems.<br />

38