How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tor’s experience.<br />

<strong>Concrete</strong> Strengths<br />

Normally shotcrete is much<br />

stronger than conventional concrete<br />

because of several factors. First more<br />

cement is used in the mix. Also the<br />

impaction created by the air tends to<br />

drive out the larger air spaces thus<br />

providing a somewhat denser product.<br />

Usually shotcrete will have a compressive<br />

strength of more than 4,000 psi.<br />

The concrete strength depends<br />

greatly on the aggregate, the amount<br />

of cement and the amount of water.<br />

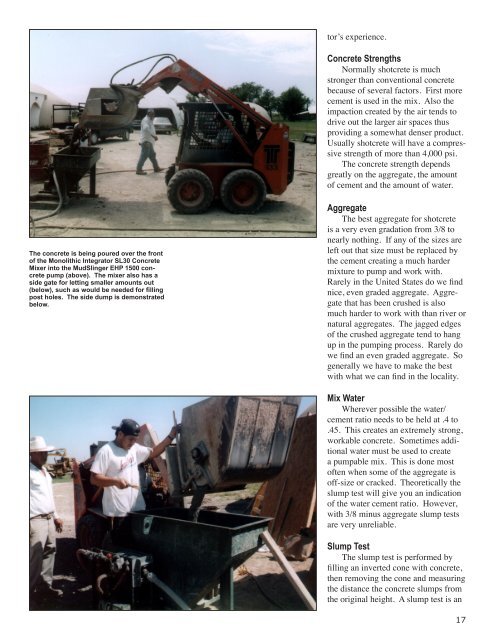

The concrete is being poured over the front<br />

of the <strong>Monolithic</strong> <strong>In</strong>tegrator SL30 <strong>Concrete</strong><br />

Mixer into the MudSlinger EHP 1500 concrete<br />

pump (above). The mixer also has a<br />

side gate for letting smaller amounts out<br />

(below), such as would be needed for filling<br />

post holes. The side dump is demonstrated<br />

below.<br />

Aggregate<br />

The best aggregate for shotcrete<br />

is a very even gradation from 3/8 to<br />

nearly nothing. If any of the sizes are<br />

left out that size must be replaced by<br />

the cement creating a much harder<br />

mixture to pump and work with.<br />

Rarely in the United States do we find<br />

nice, even graded aggregate. Aggregate<br />

that has been crushed is also<br />

much harder to work with than river or<br />

natural aggregates. The jagged edges<br />

of the crushed aggregate tend to hang<br />

up in the pumping process. Rarely do<br />

we find an even graded aggregate. So<br />

generally we have to make the best<br />

with what we can find in the locality.<br />

Mix Water<br />

Wherever possible the water/<br />

cement ratio needs to be held at .4 to<br />

.45. This creates an extremely strong,<br />

workable concrete. Sometimes additional<br />

water must be used to create<br />

a pumpable mix. This is done most<br />

often when some of the aggregate is<br />

off-size or cracked. Theoretically the<br />

slump test will give you an indication<br />

of the water cement ratio. <strong>How</strong>ever,<br />

with 3/8 minus aggregate slump tests<br />

are very unreliable.<br />

Slump Test<br />

The slump test is performed by<br />

filling an inverted cone with concrete,<br />

then removing the cone and measuring<br />

the distance the concrete slumps from<br />

the original height. A slump test is an<br />

17