How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>To</strong> Mix or Not to Mix<br />

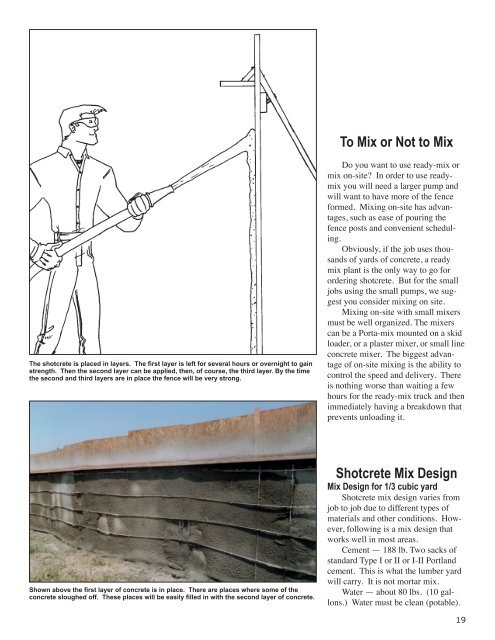

The shotcrete is placed in layers. The first layer is left for several hours or overnight to gain<br />

strength. Then the second layer can be applied, then, of course, the third layer. By the time<br />

the second and third layers are in place the fence will be very strong.<br />

Do you want to use ready-mix or<br />

mix on-site? <strong>In</strong> order to use readymix<br />

you will need a larger pump and<br />

will want to have more of the fence<br />

formed. Mixing on-site has advantages,<br />

such as ease of pouring the<br />

fence posts and convenient scheduling.<br />

Obviously, if the job uses thousands<br />

of yards of concrete, a ready<br />

mix plant is the only way to go for<br />

ordering shotcrete. But for the small<br />

jobs using the small pumps, we suggest<br />

you consider mixing on site.<br />

Mixing on-site with small mixers<br />

must be well organized. The mixers<br />

can be a Porta-mix mounted on a skid<br />

loader, or a plaster mixer, or small line<br />

concrete mixer. The biggest advantage<br />

of on-site mixing is the ability to<br />

control the speed and delivery. There<br />

is nothing worse than waiting a few<br />

hours for the ready-mix truck and then<br />

immediately having a breakdown that<br />

prevents unloading it.<br />

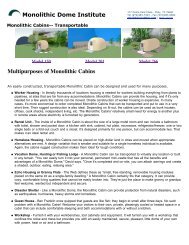

Shown above the first layer of concrete is in place. There are places where some of the<br />

concrete sloughed off. These places will be easily filled in with the second layer of concrete.<br />

Shotcrete Mix Design<br />

Mix Design for 1/3 cubic yard<br />

Shotcrete mix design varies from<br />

job to job due to different types of<br />

materials and other conditions. <strong>How</strong>ever,<br />

following is a mix design that<br />

works well in most areas.<br />

Cement — 188 lb. Two sacks of<br />

standard Type I or II or I-II Portland<br />

cement. This is what the lumber yard<br />

will carry. It is not mortar mix.<br />

Water — about 80 lbs. (10 gallons.)<br />

Water must be clean (potable).<br />

19