Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

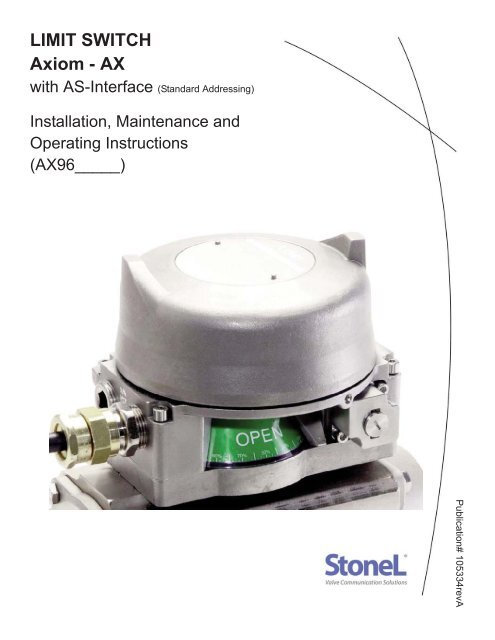

<strong>LIMIT</strong> <strong>SWITCH</strong><br />

<strong>Axiom</strong> - <strong>AX</strong><br />

with AS-Interface (Standard Addressing)<br />

Installation, Maintenance and<br />

Operating Instructions<br />

(<strong>AX</strong>96_____)<br />

Publication# 105334revA

2<br />

Table of Contents<br />

Publication# 105334revA<br />

Table Of Contents ............................................................................................................................................ Page 2<br />

<strong>Axiom</strong> Model Guide .......................................................................................................................................... Page 3<br />

Dimensions and General Specifications ...........................................................................................................Page 4<br />

Pneumatic Valve Specifications ....................................................................................................................... Page 5<br />

Assembly and Mounting Instructions ................................................................................................................Page 6<br />

<strong>Axiom</strong> Assembly Drawing .................................................................................................................................Page 7<br />

Communication Module Specifications .............................................................................................................Page 8<br />

Sensor Setting Instructions and Wiring Diagram ..............................................................................................Page 8<br />

Prefilter Removal Procedure ............................................................................................................................ Page 9<br />

READ THESE INSTRUCTIONS FIRST!<br />

These instructions provide information about safe handling and operation of the limit switch.<br />

If you require additional assistance, please contact the manufacturer or manufacturer’s representative.<br />

Address and phone numbers are printed on the back cover.<br />

SAVE THESE INSTRUCTIONS!<br />

Subject to change without notice.<br />

All trademarks are property of their respective owners.<br />

<strong>StoneL</strong><br />

Factory phone +1 (218) 739-5774

Publication# 105334revA<br />

Model Guide<br />

SERIES<br />

<strong>AX</strong> Explosionproof<br />

FUNCTION<br />

Sensor/switching modules<br />

33S SST N.O. sensor (2-wire AC/DC solid state sensor)<br />

35S SST N.O. sensor (2-wire AC/DC solid state sensor; 240VAC)<br />

44S Namur sensor (EN 60957-5-6; IS)<br />

80S Expeditor<br />

PNEUMATIC VALVE<br />

Single solenoid<br />

1H 0.6 Watt universal voltage input<br />

1J 4.5 W; 240 VAC coil<br />

1D 0.5 W; 24 VDC coil<br />

1B 1.8 W; 24 VDC coil<br />

1E 0.5 W; 12 VDC IS coil<br />

1A Piezo Electric<br />

PNEUMATIC OVERRIDE/Cv<br />

0.7Cv solenoid<br />

N<br />

M<br />

L<br />

Internal momentary override only<br />

External momentary and internal override<br />

External latching and internal override<br />

PNEUMATIC TEMPERATURE<br />

S<br />

T<br />

Standard<br />

Extended<br />

ENCLOSURE<br />

Epoxy-coated aluminum<br />

A<br />

V<br />

L<br />

North America<br />

International<br />

Brazilian<br />

Valve Communication Terminals (VCTs)<br />

71D 4-20mA with HART Diagnostics<br />

92S DeviceNet VCT<br />

93S FOUNDATION Fieldbus VCT (bus powered; IS)<br />

94S FOUNDATION Fieldbus VCT (externally powered)<br />

95S Modbus VCT<br />

96S AS-Interface with Standard Addressing VCT<br />

96D AS-Interface with Standard Addressing and Diagnostics VCT<br />

97S AS-Interface with Extended Addressing VCT<br />

Dual solenoid<br />

2H 0.6 Watt universal voltage input<br />

2J 4.5 W; 240 VAC coil<br />

2D 0.5 W; 24 VDC coil<br />

2B 1.8 W; 24 VDC coil<br />

2E 0.5 W; 12 VDC IS coil<br />

2A Piezo Electric<br />

1.2Cv solenoid<br />

E<br />

Y<br />

G<br />

CONDUIT ENTRY<br />

02 2 - 3/4” NPT<br />

05 2 - M25<br />

VISUAL INDICATOR<br />

R<br />

G<br />

1<br />

2<br />

X<br />

Internal momentary override only<br />

External momentary and internal override<br />

External latching and internal override<br />

Stainless steel<br />

S North America SS<br />

T International SS<br />

M Brazilian SS<br />

Red Closed/Green Open<br />

Green Closed/Red Open<br />

Three-way #1<br />

Three-way #2<br />

Special<br />

BRANDING<br />

A<br />

M<br />

<strong>StoneL</strong><br />

Metso<br />

3<br />

Model number example<br />

MODEL NUMBER<br />

Partnership ID*<br />

*Some models may include<br />

5-digit suffix for partnership<br />

identification<br />

<strong>AX</strong> 96S 1D L S A 02 R A - (optional)<br />

Technical hotline +1 (218) 737-0701<br />

www.<strong>StoneL</strong>.com

4<br />

Dimensions Inches [mm]<br />

Publication# 105334revA<br />

6.57”<br />

[167.0mm]<br />

** 5.17”<br />

[131.4mm]<br />

2 3<br />

1/4” NPT Air Ports (2)<br />

6.31”<br />

[160.2mm]<br />

**1.0” [25mm] vertical clearance<br />

required for cover removal<br />

E3<br />

E2<br />

S1<br />

3/4” NPT (2) or M25 (2)<br />

0.7Cv = 1/4” NPT Air Ports (3)<br />

1.2Cv = 3/8” NPT Air Ports (3)<br />

Materials of Construction<br />

Housing: Epoxy Coated Anodized Aluminum or 316<br />

stainless steel<br />

Valve Manifold: Epoxy Coated Anodized Aluminum or 316<br />

stainless steel<br />

Visual Indicator Drum: Polysolphone<br />

Visual Indicator Cover: Polycarbonate<br />

Fasteners<br />

Stainless Steel<br />

O-Rings:<br />

Nitrile compound<br />

Operating Life:<br />

1 million cycles (500,000 cycles for the<br />

Expeditor)<br />

Temperature Range: See Solenoid Specifications<br />

Enclosure Type 4, 4X & IP66/67<br />

Warranty<br />

Sensing & Communication Module: Five Years<br />

Mechanical Components:<br />

Five Years<br />

<strong>StoneL</strong><br />

General Specifications and Ratings<br />

Position Sensing<br />

Accuracy: Within 1°<br />

Repeatability: Within 1°<br />

Setting Buffer:<br />

4° from set point<br />

(Rotational distance from original set point<br />

where switch will energize on return stroke)<br />

Dead Band:<br />

6° from set point<br />

(Rotational distance from original set point<br />

where switch will de-energize)<br />

Max Rotational Range: 120°<br />

Enclosure Ratings<br />

Explosion Proof<br />

<strong>AX</strong> models*<br />

Ex d Zone 1; Class I&II, Div 1<br />

Nonincendive<br />

<strong>AX</strong> models*<br />

Ex n Zone 2; Class I&II, Div 2<br />

Intrinsically Safe<br />

Functions 44 and 93 only*<br />

Ex ia Zone 0; Class I&II, Div 1<br />

Approvals*<br />

Go to www.stonel.com/approvals for<br />

specific approvals information<br />

Factory phone +1 (218) 739-5774

Publication# 105334revA<br />

General Pneumatic Specifications<br />

Valve Design:<br />

Pilot operated spool valve<br />

Pilot Operator Options: Solenoid Coil or Piezo<br />

Configuration:<br />

Single Pilot:<br />

5-Way, 2-Position, Spring Return<br />

Dual Pilot:<br />

5-Way, 2-Position, Shuttle Piston<br />

Flow Rating:<br />

0.70Cv (Kv = 0.60 based on flow m3/h)<br />

1.20Cv (Kv = 1.04 based on flow m3/h)<br />

<strong>Axiom</strong> Porting:<br />

1/4” NPT (0.7Cv); 3/8” NPT (1.2Cv)<br />

Manifold Porting:<br />

1/4” NPT (0.7Cv and 1.2Cv)<br />

Operating Pressure: 40 psi to 120 psi (2.7 to 7.5 bar)<br />

Operating Temperature (0.7Cv)<br />

Standard Temp Coil: -18° C to 50° C (0° F to 120° F)<br />

Extended Temp Coil: -40° C to 80° C (-40° F to 176° F) (NEC)<br />

-40° C to 70° C (-40° F to 158° F) (IEC)<br />

Operating Temperature (1.2Cv)<br />

Standard Temp Coil: -10° C to 50° C (14° F to 120° F)<br />

Extended Temp Coil: -10° C to 80° C (14° F to 176° F) (NEC)<br />

-10° C to 70° C (14° F to 158° F) (IEC)<br />

Operating Life:<br />

1 million cycles<br />

(500,000 cycles for the Expeditor)<br />

Manual Override:<br />

Internal momentary<br />

Optional external momentary available<br />

Optional external latching available<br />

Material of Construction:<br />

Aluminum Enclosure<br />

Spool:<br />

Nickel plated aluminum<br />

Body:<br />

Epoxy coated anodized aluminum<br />

Seal Spacers:<br />

Polysulphone<br />

Spool Seals :<br />

Nitrile compound<br />

O-rings<br />

Buna-N compound<br />

End Caps & Fasteners: 316 stainless steel<br />

Stainless steel Enclosure<br />

Spool:<br />

Nickel plated, Teflon coated stainless steel<br />

Body:<br />

316L stainless steel<br />

Seal Spacers:<br />

Polysulphone<br />

Spool Seals :<br />

Nitrile compound<br />

O-rings<br />

Buna-N compound<br />

End Caps & Fasteners: 316 stainless steel<br />

Pneumatic Valve Specifications<br />

Solenoid Coil Specifications<br />

Universal (1H, 2H)<br />

For “33” Function<br />

Operating Voltage:<br />

22 VDC/130 VAC<br />

Power Consumption: 0.6 Watts<br />

Filtration Requirements: 40 Microns<br />

For “35” Function<br />

Operating Voltage:<br />

Power Consumption:<br />

Filtration Requirements:<br />

240 VAC (1J, 2J)<br />

Operating Voltage:<br />

Power Consumption:<br />

Filtration Requirements:<br />

24 VDC (1B, 2B)<br />

Operating Voltage:<br />

Power Consumption:<br />

Filtration Requirements:<br />

24 VDC (1D, 2D)<br />

Operating Voltage:<br />

Power Consumption:<br />

Filtration Requirements:<br />

20-60 VDC/20-250 VAC<br />

0.6 Watts<br />

40 Microns<br />

240 VAC<br />

4.5 Watts<br />

40 Microns<br />

24 VDC<br />

1.8 Watts<br />

40 Microns<br />

24 VDC<br />

0.5 Watts<br />

40 Microns<br />

12 VDC (1E, 2E) (Intrinsically Safe)<br />

Operating Voltage:<br />

12 VDC (output of barrier)<br />

Power Consumption: 0.5 Watts<br />

Filtration Requirements: 40 Microns<br />

Entity Parameters:<br />

Ui=28VDC; Ii=120mA; Ci=0; Li=0; Pi=1.0W<br />

Piezo (1A, 2A)<br />

Operating Voltage:<br />

5.5 VDC to 9.0 VDC<br />

Current Consumption: 2.0 mA @ 6.5 VDC<br />

Temperature Range: -10° C to 60° C (14° F to 140° F)<br />

Filtration Requirements: Dried/30 Microns<br />

5<br />

Spring Return Actuator with Rebreather Open<br />

Double Acting Actuator with Rebreather Closed<br />

Actuator<br />

Actuator<br />

3<br />

2<br />

3<br />

2<br />

SR<br />

DA<br />

<strong>Axiom</strong> Pneumatic Valve<br />

E3 S1 E2<br />

<strong>Axiom</strong> Pneumatic Valve<br />

E3 S1 E2<br />

Technical hotline +1 (218) 737-0701<br />

www.<strong>StoneL</strong>.com

6<br />

Publication# 105334revA<br />

Assembly and Mounting Instructions<br />

SPECIAL NOTES<br />

Note<br />

Mounting of the <strong>Axiom</strong> requires a <strong>StoneL</strong> mounting kit specific to the actuator the <strong>Axiom</strong> is to be mounted to.<br />

Note<br />

It is recommended that thread lubricant or anti-seize be used on the <strong>Axiom</strong> Body Screws (Item# 3) prior to assembly.<br />

Note<br />

Referring to Step 3 below. Depending on the version of <strong>Axiom</strong>, the DA/SR Plug (Item# 5) may be located in the <strong>Axiom</strong> Body<br />

(Item# 4) or the Air Manifold Plate of the mounting kit (Item# 14).<br />

Note<br />

In high cycle or high vibration applications, blue Loctite® may be used on the Air Manifold Mounting Screws (Item# 11) and<br />

the Visual Indicator Drum Retaining Screw (Item# 9).<br />

Note<br />

It is highly recommended that exhaust ports E2 and E3 be fitted with low restriction mufflers or breather vent caps to<br />

prevent ingestion of water and debris into the pneumatic valve.<br />

Note<br />

For epoxy coated aluminum models, conduit seal-offs are required with in 18” of the unit. Seal-offs are not required on<br />

models with a stainless steel housing.<br />

1. Refer to <strong>Axiom</strong> Assembly Drawing located on Page 7 when performing mounting and assembly procedures.<br />

2. Remove <strong>Axiom</strong> unit from shipping container. Ensure all listed items are present.<br />

3. Determine if the actuator the <strong>Axiom</strong> is to be mounted on is double acting (DA) or spring return (SR). Ensure the DA/SR Plug<br />

(Item# 5) is in the correct position. (See Detail - A on Page 7). If the DA/SR Plug is in the incorrect position, gently remove plug with<br />

a pair of pliers and insert into the proper orifice. (Note: For aluminum <strong>AX</strong> units, the DA/SR Plug is included in the manifold plate of<br />

the mounting kit. If there is a black DA/SR plug in the body of aluminum <strong>AX</strong> housing, this needs to be removed and discarded. For<br />

stainless steel <strong>AX</strong> units the DA/SR plug is located in the body of the stainless steel <strong>AX</strong> housing.)<br />

4. From the mounting kit package, locate the Air Manifold Plate (Item# 14). Place the Air Manifold Plate on the actuator. Using an M4<br />

allen wrench, fasten down with the four Air Manifold Mounting Screws (Item# 11). Torque screws to 25 - 30 in.lbs (2.8 - 3.4Nm).<br />

5. Place Visual Indicator Drive Block (Item# 10) into slot on the actuator shaft. Place Visual Indicator Drum Coupler (Item# 8) onto the<br />

Visual Indicator Drive Block. Next, place the Visual Indicator Drum (Item# 7) onto the Visual Indicator Drum Coupler. Align the<br />

holes in all three items with the the threaded hole in the actuator shaft and fasten down with the Visual Indicator Drum Retaining<br />

Screw (Item# 9). Leave screw loose in order to facilitate indexing of the visual indicator.<br />

6. With the actuator in the closed position, center the Visual Indicator Drum until the “OPEN” quadrant is centered between the “V.I<br />

INDEX” markings on the AIr Manifold Plate. (See Detail - B on Page 7). Tighten down with the Visual Indicator Drum Retaining<br />

Screw 15 - 20 in.lbs (1.7 - 2.3Nm).<br />

7. Verify Air Manifold Plate Orifice O-rings (Item# 12) and Visual Indicator Cover O-ring (Item# 13) are in place.<br />

8. Place the Visual Indicator Cover (Item# 6) over the Visual Indicator Drum assembly then set the <strong>Axiom</strong> Body (Item# 4) in place.<br />

With an M5 allen wrench, torque the <strong>Axiom</strong> Body Screws (Item# 3) to 8 - 10 ft. lbs (10.8 - 13.5Nm).<br />

9. After all wiring and sensor setting procedures have been completed, install <strong>Axiom</strong> Cover and tighten the <strong>Axiom</strong> Cover Lock set<br />

screw (Item# 2).<br />

<strong>StoneL</strong><br />

Factory phone +1 (218) 739-5774

Publication# 105334revA<br />

7<br />

<strong>Axiom</strong> Assembly Drawing<br />

ITEM# DESCRIPTION QTY<br />

1 <strong>Axiom</strong> Cover 1<br />

2 <strong>Axiom</strong> Cover Lock 1<br />

1<br />

3 <strong>Axiom</strong> Body Screws 4<br />

4 <strong>Axiom</strong> Body 1<br />

5 DA/SR Plug (may be located in mtg kit) 1<br />

6 Visual Indicator Cover 1<br />

7 Visual Indicator Drum 1<br />

8 Visual Indicator Drum Coupler 1<br />

2<br />

Item# 9 thru 14 are provided with the mounting kit.<br />

Mounting kits are sold separately<br />

9 Visual Indicator Drum Retaining Screw 1<br />

10 Visual Indicator Drive Block 1<br />

3<br />

11 Air Manifold Plate Mounting Screws 4<br />

12 Air Manifold Plate Orifice O-rings 3<br />

13 Visual Indicator Cover O-ring 1<br />

14 Air Manifold Plate 1<br />

4<br />

DA/SR Plug Placement<br />

PLUG FOR SR<br />

PLUG FOR DA<br />

8<br />

6<br />

7<br />

6<br />

8<br />

7<br />

5<br />

Bottom side of <strong>Axiom</strong> Body<br />

FOR DA<br />

PLUG FOR SR<br />

PLUG<br />

9<br />

V.I. INDEX<br />

7<br />

SR<br />

SED<br />

6<br />

6<br />

DA<br />

OPEN<br />

7<br />

8<br />

V.I. INDEX<br />

CLO<br />

8<br />

Air Manifold Plate<br />

10<br />

Detail - A<br />

Visual Indicator Indexing<br />

11<br />

12<br />

13<br />

V.I. INDEX<br />

6<br />

7<br />

OPEN<br />

SED<br />

14<br />

8<br />

V.I. INDEX<br />

CLO<br />

Detail - B<br />

Technical hotline +1 (218) 737-0701<br />

www.<strong>StoneL</strong>.com

8<br />

Publication# 105334revA<br />

AS-Interface Standard Addressing Sensing & Communications Module<br />

AS-Interface Module w/Standard Address Specifications Max. Output Current: 160mA (4 watts; both outputs combined<br />

Communication Protocol: AS-Interface v3.0<br />

ID/IO Codes:<br />

ID = F; IO = 4; ID1 = F; ID2 = E<br />

Configuration:<br />

(2) Discrete Inputs (Sensors)<br />

Default Address: 00<br />

(2) Auxiliary Discrete Inputs<br />

Bit Assignment: Inputs Outputs<br />

(2) Discrete Outputs (Solenoids)<br />

Bit 1 = Aux Input 1 Bit 1 = Not Used<br />

Voltage:<br />

26.5-30.6 VDC (AS-I Voltage)<br />

Bit 2 = Aux input 2 Bit 2 = Not Used<br />

Bit 3 = Green LED Bit 3 = OUT 1<br />

Output Voltage:<br />

24 VDC<br />

Bit 4 = Red LED Bit 4 = OUT 2<br />

Current Consumption: 42mA (1) 0.5w coil; 64mA (2) 0.5w coils<br />

96mA (1) 1.8w coil; 171mA (2) 1.8w coils<br />

To Bench Test an AS-Interface Sensing & Communications Module:<br />

To test sensors, use a 24 Vdc power supply. No series load resistor is required. Operate actuator to the closed position. Apply power<br />

across the “ASI+” and “ASI-” terminal points. Press and hold “Closed Set” button until “Closed LED is lit (two seconds). Release<br />

button. Operate actuator to the open position. Press and hold “Open Set” button until “Open LED is lit (two seconds). Release button.<br />

Set points are retained even after power is removed. A functioning AS-Interface network is required to test communications.<br />

WARNING:<br />

DO NOT APPLY EXTERNAL POWER TO THE OUTPUT TERMINALS. THIS WILL CAUSE PERMANENT DAMAGE TO THE UNIT<br />

Wiring Diagram<br />

SET<br />

OPEN<br />

SET<br />

CLOSED<br />

OPEN<br />

CLOSED<br />

Setup Instructions:<br />

Operate Actuator to Closed<br />

Position and Push SET CLOSED<br />

for 2 seconds.<br />

Operate Actuator to Open<br />

Position and Push SET OPEN<br />

for 2 seconds<br />

SOLENOID 1<br />

SOLENOID 2<br />

OUT 1 - (1)<br />

OUT 1 + (2)<br />

OUT 2 - (3)<br />

OUT 2 + (4)<br />

3 wire RTN (5)<br />

Aux IN 2 - (6)<br />

Aux IN 1 - (7)<br />

Aux IN + (8)<br />

ASI - (9)<br />

ASI + (10)<br />

Sensor Setting Instructions<br />

1. With the Sensor & Communication Module (CCM) wired to the control system and power applied, operate actuator to the closed<br />

position.<br />

2. Press and hold “Closed Set” button until “Closed LED is lit (two seconds). Release button.<br />

3. Operate actuator to the open position.<br />

4. Press and hold “Open Set” button until “Open LED is lit (two seconds). Release button.<br />

5. Set points are retained even after power is removed.<br />

<strong>StoneL</strong><br />

Factory phone +1 (218) 739-5774

Publication# 105334revA<br />

Prefilter Removal Procedure<br />

9<br />

WARNING<br />

Secure electrical power and supply air to <strong>Axiom</strong> unit prior to performing the Prefilter Removal Procedure.<br />

1. Secure electrical power and supply air to the <strong>Axiom</strong> unit.<br />

2. Loosen Cover Lock set screw and remove <strong>Axiom</strong> Cover.<br />

3. With an M3 allen wrench, loosen the two captive screws located next to the pilot valve/s. These hold the internal air interface plate<br />

in place. (See Fig. 1)<br />

4. Carefully lift the internal air interface plate to expose the prefilter (see Fig. 2).<br />

5. With an M8 allen wrench, remove the prefilter (See Fig. 3). Inspect and clean as necessary.<br />

6. Re-install prefilter and torque to 25 - 30 in.lbs (2.8 - 3.4Nm).<br />

7. Re-install the internal air interface plate and torque screws to 25 - 30 in.lbs (2.8 - 3.4Nm).<br />

8. Install unit cover and place unit back into service.<br />

Fig. 1 Fig. 2<br />

Fig. 3<br />

Technical hotline +1 (218) 737-0701<br />

www.<strong>StoneL</strong>.com