Cut Costs and Optimize Performance with: - StoneL

Cut Costs and Optimize Performance with: - StoneL

Cut Costs and Optimize Performance with: - StoneL

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cut</strong> <strong>Costs</strong> <strong>and</strong> <strong>Optimize</strong><strong>Performance</strong> <strong>with</strong>:•Process Networking Solutions•Valve Communication & Control

Our Focus is to enable you to cut installation costs <strong>and</strong> improve process operatingperformance by utilizing field-based communication technologies.FieldLink enables you to link your automatedvalves <strong>and</strong> plant instruments into your processcontrol architecture using st<strong>and</strong>ardized, proven,field-based communication technologies.FieldLink supports proven contemporarycommunication protocols <strong>with</strong> a full array ofproducts <strong>and</strong> services designed to make yourentire network operate reliably in the rigorousprocess environments.process networking solutionsValvePoint offers a broad array of valvecommunication <strong>and</strong> monitoring products that enablediscrete automated valves to think <strong>and</strong> communicate.Whether using point-to-point wiring <strong>with</strong> conventional monitorsor communication networking in hazardous or general purposeenvironments, <strong>StoneL</strong> offers an optimal solution for your application.Direct your browser to www.stonel.com for a complete viewof <strong>StoneL</strong> capabilities, products <strong>and</strong> services.

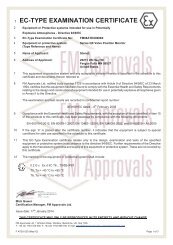

Delivering Field-Based Communication TechnologySince our founding in 1989 <strong>StoneL</strong> hasField-based Communication Network by <strong>StoneL</strong>become a leading supplier of valvemonitoring systems because of ourreputation for reliability, overallquality <strong>and</strong> technological leadership.With the evolution of field-basedcommunication technologies, <strong>StoneL</strong>has become the leading supplier ofboth valve communication <strong>and</strong> processnetworking systems. As a result <strong>StoneL</strong>has developed the products <strong>and</strong> services to not only enable your valves to think <strong>and</strong> communicate but also tointerconnect them, as well as your other instruments, into your plant’s control architecture.Demonstrated <strong>Performance</strong><strong>StoneL</strong> is committed to delighting our customers <strong>with</strong>exceptional product quality, value <strong>and</strong> technological leadership.In order to support our promise <strong>with</strong> consistent ongoingperformance <strong>and</strong> continued improvement we have implementedthe ISO international quality st<strong>and</strong>ards.Hazardous Area ComplianceThe ability to operate reliably in corrosive, hazardous processenvironments is a cornerstone of our product <strong>and</strong> service programs.Whether your applications utilize explosion proofing, intrinsic safetyor nonincendive protection concepts, <strong>StoneL</strong> is able to offer theinstallation support <strong>and</strong> component certifications to satisfy yourrequirements. The results are lower costs, improved safety <strong>and</strong>increased maintenance flexibility.Worldwide Support<strong>StoneL</strong>’s global network of distribution partners* offersyou competent local support for your applications.Direct your browser to www.stonel.com for <strong>StoneL</strong> factory <strong>and</strong>distributor/integrator contacts.• ValvePoint Distributors - Valve automation centersdelivering sales, application <strong>and</strong> service support for valvecommunication <strong>and</strong> control products.• FieldLink Integrators <strong>and</strong> Distributors - Instrumentsupply centers <strong>and</strong> control systems experts providingnetwork system integration services as well as salesapplication <strong>and</strong> service support for process communicationnetworks.*Most <strong>StoneL</strong> distribution partners offer both ValvePoint <strong>and</strong> FieldLink sales,application <strong>and</strong> service support capabilities.

ValvePoint offers a full range of monitoring, communication<strong>and</strong> control systems ideally suited for quarter-turn <strong>and</strong> lineardiscrete automated valve systems. Products featurestate-of-the-art electronic systems integrating positionsensing, switching, diagnostics, <strong>and</strong>/or communication <strong>and</strong>control capabilities in rugged industrial enclosures. As aresult you can expect exceptional performance in extremeprocess environments. You may select from traditionalswitching systems or valve communication terminals(VCTs) <strong>with</strong> on-board valve diagnostics depending on yourspecific requirements.Quarter-Turn Valve/Actuator ApplicationsAxiomAdvancedElectronics <strong>with</strong>Integral PneumaticControlQuartzExplosion Proof/Flame ProofAluminumEnclosureEclipseCompact <strong>and</strong>ModularFeaturing solid state position sensing, push buttonsettings, integral pneumatic control <strong>and</strong> valve diagnostics,the Axiom offers the ultimate in reliability <strong>and</strong> convenience.This platform is suitable for use in most corrosive <strong>and</strong>hazardous process environments <strong>and</strong> offers a broad arrayof communication <strong>and</strong> electronic switching outputs.This rugged epoxy coated anodized aluminum platformis ideally suited for explosion proof areas. It is corrosionproof, water tight <strong>and</strong> approved for use in mosthazardous applications. You may select from awide variety of switching, position transmitter <strong>and</strong>communication options.The Eclipse features two integral solid state positionsensors <strong>and</strong> directly attaches to VDI/VDE 3845 (Namur)actuator mounting pads. This compact modular unit isconstructed of durable Lexan suitable for corrosive,heavy wash down environments <strong>and</strong> is rated for use innonincendive <strong>and</strong> intrinsically safe applications. Select fromNamur sensors, switching <strong>and</strong> communication options.Proven Reliabilityin the ProcessIndustries:• Chemical• Oil & Gas• Pharmaceutical• Food & Beverage• Pulp & Paper• Biotech• Shipping• Biofuels• And More...Linear Valve/Actuator ApplicationsHawkeyeLinear PointSensorsThese solid state point sensors are made of corrosion proof316 stainless steel <strong>and</strong> Lexan. They may be convenientlyinstalled on knife gates <strong>and</strong> globe valves or be attachedto sense rotary valve/actuator coupling motion. Sensorsfeature two wire switching or Namur outputs <strong>and</strong> are ratedfor nonincendive <strong>and</strong> intrinsically safe applications.PrismDiaphragm <strong>and</strong>Angle ValveApplicationsThe Prism offers self adjusting switching <strong>and</strong> optionallyintegrates pneumatic control. Made of durable Lexan itis suitable for heavy wash down, corrosive environments<strong>and</strong> is rated for use in nonincendive <strong>and</strong> intrinsically safeapplications. Electronic options include solid state Namur,switching <strong>and</strong> communication.www.stonel.com

process networking solutions<strong>StoneL</strong>’s FieldLink program enables you to takeadvantage of field-based communication technologiesto cut installation <strong>and</strong> maintenance costs <strong>and</strong> improveoperating performance. In thous<strong>and</strong>s of applications<strong>StoneL</strong> has demonstrated installation savings up to40%, improved flexibility <strong>and</strong> reduced infrastructurerequirements. With communication networks, vitalpredictive maintenance <strong>and</strong> performance measuresmay also be transmitted from field instruments to theasset management or operation control centersfurther reducing maintenance costs.A broad range of networking protocols is supported.They include AS-Interface, DeviceNet, Modbus,Profibus, HART, Foundation Fieldbus <strong>and</strong> more. TheFieldLink program continues to be dynamic asit encompasses proven communication basedtechnologies that enable improved asset utilization.Complete Array of Networking ProductsMasters/Gateways:Devices control communicationnetworks <strong>and</strong> offer manyoptions for interfacing <strong>with</strong> yourcontrol architecture.Drop Connectors:Modules offer a variety ofswitching <strong>and</strong> protectionoptions providing improvedreliability, enhanced safety<strong>and</strong> increased networkmaintainability.Power Supplies:General purpose ornonincendive rated forhazardous areas, they offersignal conditioning circuits<strong>and</strong> short circuit protection forpowering up networks.I/O Modules: Interface discrete<strong>and</strong> analog conventional devicesinto communication networksin the field. Select from severalconfigurations developed forfield-based interfaces.Networking Accessories:Bus cabling, terminators,repeaters, h<strong>and</strong> helds, tuners,trouble shooting/training tools<strong>and</strong> more are available.Field Enclosures:Durable <strong>and</strong> corrosion proofenclosures specifically designedfor containing networkingcomponents in processenvironments are available forexplosion proof, nonincendive <strong>and</strong>general purpose applications.FieldLink Support ServicesNetwork Training: <strong>StoneL</strong> offers comprehensive training programs to facilitate your networkdesign, installation <strong>and</strong> operation. Courses provide an academic underst<strong>and</strong>ing of networkingconcepts <strong>and</strong> protocols as well as h<strong>and</strong>s on application. Training sessions are held at the factoryor at selected FieldLink integrator locations throughout the world. Hazardous area compliance isalso included.On-Site Installation <strong>and</strong> Service Support: <strong>StoneL</strong> service staff may provide I/O mapping,commissioning assistance, trouble shooting <strong>and</strong> personnel training on-site.<strong>StoneL</strong> Certified Integrators <strong>and</strong> Service Providers make it all work for You!Each of <strong>StoneL</strong>’s integration partners has the capabilities to interface field networks <strong>with</strong>your process control architecture. They offer:• Network design, commissioning <strong>and</strong> service support• Local back-up 24/7• Communication networking <strong>and</strong> hazard protection expertise

<strong>StoneL</strong>’s Technology Development1990 Quartz explosion proof valve monitor1992 Onyx Lexan enclosure <strong>with</strong> integral pneumatic valve1995 Solid state AC/DC proximity sensors1996 Hawkeye hazardous area solid state point sensors1997 Eclipse modular solid state monitoring system1998 AS-I valve communication terminal (VCT) <strong>and</strong> I/O modules1998 FieldLink process networking solutions1999 DeviceNet & Modbus VCT <strong>and</strong> I/O modules2000 JM hazardous area protected drop connectors2001 Hazardous rated communication power supplies2002 Foundation Fieldbus VCT <strong>and</strong> I/O modules2002 FieldBlock General Purpose multi-drop connectors2003 Prism valve communication & control for diaphragm valves2006 Axiom advanced valve communication & control system2007 Axiom VCT diagnostic systems2008 FieldBlock Nonincendive switched multi-drop connectors2009 Axiom HART diagnostic system2009 Axiom Expeditor <strong>with</strong> intermediate control<strong>StoneL</strong> CorporationOne <strong>StoneL</strong> Drive26271 US Highway 59Fergus Falls, Minnesota56537 USATelephone: 1 (218) 739-5774Tech Hotline: 1 (218) 737-0701Fax: 1 (218) 739-5776E-mail: sales@stonel.comWebsite: www.stonel.comPublication NumberS-913-06/09