Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

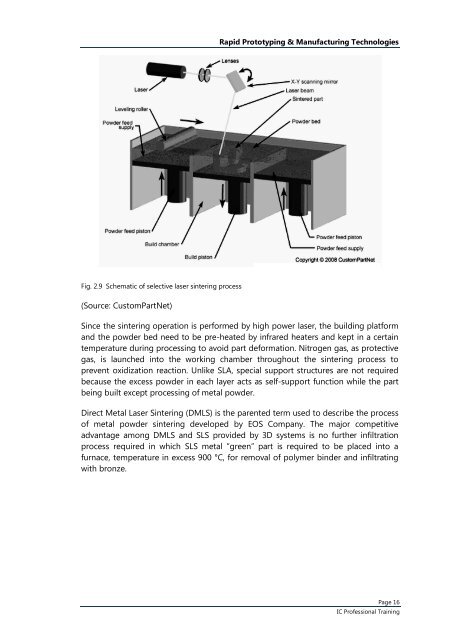

<strong>Rapid</strong> <strong>Pro<strong>to</strong>typing</strong> & <strong>Manufacturing</strong> <strong>Technologies</strong>Fig. 2.9 Schematic of selective laser sintering process(Source: Cus<strong>to</strong>mPartNet)Since the sintering operation is performed by high power laser, the building platformand the powder bed need <strong>to</strong> be pre-heated by infrared heaters and kept in a certaintemperature during processing <strong>to</strong> avoid part deformation. Nitrogen gas, as protectivegas, is launched in<strong>to</strong> the working chamber throughout the sintering process <strong>to</strong>prevent oxidization reaction. Unlike SLA, special support structures are not requiredbecause the excess powder in each layer acts as self-support function while the partbeing built except processing of metal powder.Direct Metal Laser Sintering (DMLS) is the parented term used <strong>to</strong> describe the processof metal powder sintering developed by EOS Company. The major competitiveadvantage among DMLS and SLS provided by 3D systems is no further infiltrationprocess required in which SLS metal “green” part is required <strong>to</strong> be placed in<strong>to</strong> afurnace, temperature in excess 900 °C, for removal of polymer binder and infiltratingwith bronze.Page 16IC Professional Training