Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

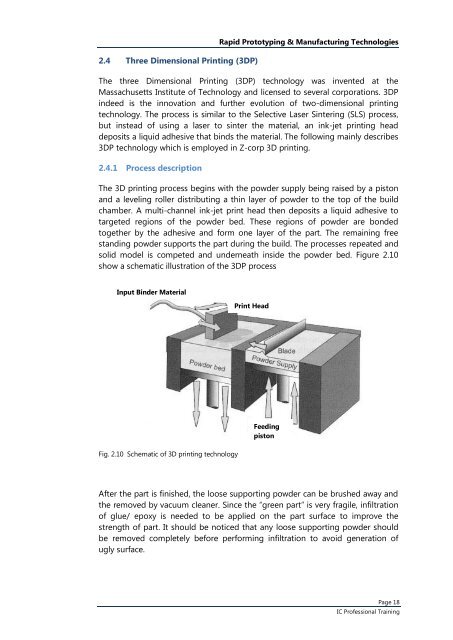

2.4 Three Dimensional Printing (3DP)<strong>Rapid</strong> <strong>Pro<strong>to</strong>typing</strong> & <strong>Manufacturing</strong> <strong>Technologies</strong>The three Dimensional Printing (3DP) technology was invented at theMassachusetts Institute of Technology and licensed <strong>to</strong> several corporations. 3DPindeed is the innovation and further evolution of two-dimensional printingtechnology. The process is similar <strong>to</strong> the Selective Laser Sintering (SLS) process,but instead of using a laser <strong>to</strong> sinter the material, an ink-jet printing headdeposits a liquid adhesive that binds the material. The following mainly describes3DP technology which is employed in Z-corp 3D printing.2.4.1 Process descriptionThe 3D printing process begins with the powder supply being raised by a pis<strong>to</strong>nand a leveling roller distributing a thin layer of powder <strong>to</strong> the <strong>to</strong>p of the buildchamber. A multi-channel ink-jet print head then deposits a liquid adhesive <strong>to</strong>targeted regions of the powder bed. These regions of powder are bonded<strong>to</strong>gether by the adhesive and form one layer of the part. The remaining freestanding powder supports the part during the build. The processes repeated andsolid model is competed and underneath inside the powder bed. Figure 2.10show a schematic illustration of the 3DP processInput Binder MaterialPrint HeadFig. 2.10 Schematic of 3D printing technologyFeedingpis<strong>to</strong>nAfter the part is finished, the loose supporting powder can be brushed away andthe removed by vacuum cleaner. Since the “green part” is very fragile, infiltrationof glue/ epoxy is needed <strong>to</strong> be applied on the part surface <strong>to</strong> improve thestrength of part. It should be noticed that any loose supporting powder shouldbe removed completely before performing infiltration <strong>to</strong> avoid generation ofugly surface.Page 18IC Professional Training