Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

Rapid Prototyping & Manufacturing Technologies - to submit your ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

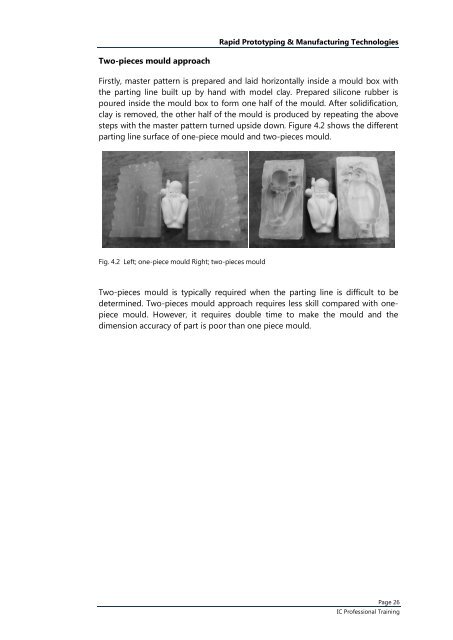

<strong>Rapid</strong> <strong>Pro<strong>to</strong>typing</strong> & <strong>Manufacturing</strong> <strong>Technologies</strong>Two-pieces mould approachFirstly, master pattern is prepared and laid horizontally inside a mould box withthe parting line built up by hand with model clay. Prepared silicone rubber ispoured inside the mould box <strong>to</strong> form one half of the mould. After solidification,clay is removed, the other half of the mould is produced by repeating the abovesteps with the master pattern turned upside down. Figure 4.2 shows the differentparting line surface of one-piece mould and two-pieces mould.Fig. 4.2 Left; one-piece mould Right; two-pieces mouldTwo-pieces mould is typically required when the parting line is difficult <strong>to</strong> bedetermined. Two-pieces mould approach requires less skill compared with onepiecemould. However, it requires double time <strong>to</strong> make the mould and thedimension accuracy of part is poor than one piece mould.Page 26IC Professional Training