VITOTRONIC 100, HC1 VITOCONTROL-S, WB2B Installation and ...

VITOTRONIC 100, HC1 VITOCONTROL-S, WB2B Installation and ...

VITOTRONIC 100, HC1 VITOCONTROL-S, WB2B Installation and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

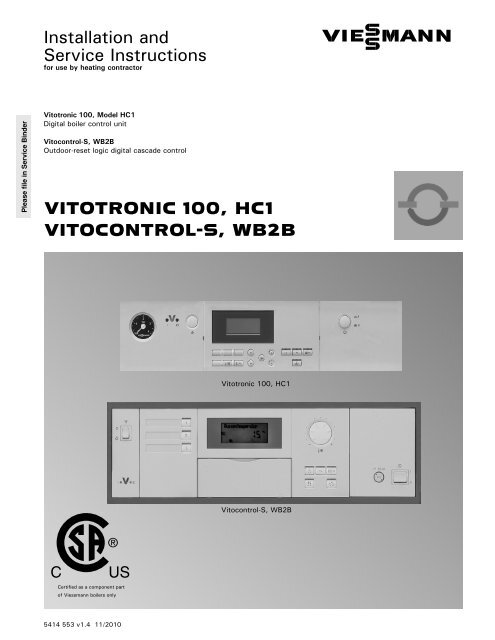

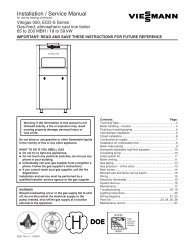

<strong>Installation</strong> <strong>and</strong>Service Instructionsfor use by heating contractorPlease file in Service BinderVitotronic <strong>100</strong>, Model <strong>HC1</strong>Digital boiler control unitVitocontrol-S, <strong>WB2B</strong>Outdoor-reset logic digital cascade control<strong>VITOTRONIC</strong> <strong>100</strong>, <strong>HC1</strong><strong>VITOCONTROL</strong>-S, <strong>WB2B</strong>Vitotronic <strong>100</strong>, <strong>HC1</strong>Vitocontrol-S, <strong>WB2B</strong>Certified as a component partof Viessmann boilers only5414 553 v1.4 11/2010

General informationSafety, <strong>Installation</strong> <strong>and</strong> Warranty RequirementsPlease ensure that this manual is read <strong>and</strong> understood before commencing installation. Failure to comply with theinstructions listed below <strong>and</strong> details printed in this manual can cause product/property damage, severe personal injury,<strong>and</strong>/or loss of life. Ensure all requirements below are understood <strong>and</strong> fulfilled (including detailed information found in manualsubsections).Licensed professional heatingcontractorThe installation, adjustment, service,<strong>and</strong> maintenance of this equipmentmust be performed by a licensedprofessional heating contractor.Please see sectionentitled “ImportantRegulatory <strong>and</strong><strong>Installation</strong>Requirements.”Advice to ownerOnce the installation work is complete,the heating contractor must familiarizethe system operator/ultimate ownerwith all equipment, as well as safetyprecautions/requirements, shut-downprocedure, <strong>and</strong> the need forprofessional service annually beforethe heating season begins.Product documentationRead all applicable documentation beforecommencing installation. Storedocumentation near boiler in a readilyaccessible location for reference in thefuture by service personnel.WarrantyInformation contained inthis <strong>and</strong> related productdocumentation must beread <strong>and</strong> followed. Failureto do so renders warrantynull <strong>and</strong> void.For a listing ofapplicable literature,please see sectionentitled “ImportantRegulatory <strong>and</strong><strong>Installation</strong> Requirements.”5414 553 v1.42

3Table of ContentsIndexPageGeneral InformationProduct information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heating System DesignsSystem design 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Installing the Cascade Communication Module 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Summary of electrical connections (Power Pump Module) 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Summary of electrical connections 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mounting the control unit 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Inserting cables <strong>and</strong> applying strain relief 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sensor connection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connection pumps 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connection to modulating valve actuators 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connection of external contacts 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connection to compiled failure alarm 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Making the LON connection 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power supply 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installing the control unit front 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Opening the control unit 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Initial Start-upSteps 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Further step-by-step instructions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Service Scanning – Vitotronic <strong>100</strong>, <strong>HC1</strong>Service level summary 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperatures, boiler coding card <strong>and</strong> quick scans 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Scanning operating conditions 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Scanning <strong>and</strong> resetting service displays 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Service Scanning – Vitocontrol-S, <strong>WB2B</strong>Service level summary 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperatures <strong>and</strong> quick scans 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Scanning operating conditions 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Troubleshooting – Vitotronic <strong>100</strong>, <strong>HC1</strong>Faults displayed at the programming unit 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retrieving fault codes from the fault memory (fault history) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Troubleshooting – Vitocontrol-S, <strong>WB2B</strong>Faults with fault display at the programming unit 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retrieving fault codes from the fault memory (fault history) 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5414 553 v1.4

4Table of ContentsIndex (continued)Function Description – Vitotronic <strong>100</strong>, <strong>HC1</strong>Boiler temperature control 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Function Description – Vitocontrol-S, <strong>WB2B</strong>Cascade control unit 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heating circuit control 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DHW tank temperature control 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Components – Vitocontrol-S, <strong>WB2B</strong>Components from the parts list 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .LON communication module 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DHW tank temperature sensor 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Flow temperature sensor (low-loss header) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Outdoor temperature sensor 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mixing valve motor 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<strong>Installation</strong> examples 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Remote control 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Vitotrol 200 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Vitotrol 300 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connecting several remote controls units 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Room temperature sensor 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Input Module 0 to 10 V 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding – Vitotronic <strong>100</strong>, <strong>HC1</strong>Resetting codes to the factory setting 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding Level 1 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Calling up coding level 1 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Summary 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding Level 2 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Calling up coding level 2 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Overall summary 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding – Vitocontrol-S, <strong>WB2B</strong>Resetting codings to the factory setting 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding Level 1 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Calling up coding level 1 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Summary 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Coding Level 2 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Calling up coding level 2 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Overall summary 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Slab curing function diagram 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5414 553 v1.4

Table of ContentsIndex (continued)Connection <strong>and</strong> Wiring Diagrams - Vitotronic <strong>100</strong>, <strong>HC1</strong>Boiler control, Power Pump Module (models 45, 60) wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Boiler control, Power Pump Module (models 80, 105) wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Connection <strong>and</strong> Wiring Diagrams – Vitocontrol-S, <strong>WB2B</strong>Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Low voltage motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109Line voltage motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110Mixing valve extension Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111AppendixSpecification – Vitocontrol-S, <strong>WB2B</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Product InformationVitotronic <strong>100</strong>, <strong>HC1</strong>, <strong>and</strong> Vitocontrol-S, <strong>WB2B</strong>Only for integration/installation on Viessmann boilers <strong>and</strong> for wall mounting.These application examples are only recommendations, <strong>and</strong> must therefore be checked on site for completeness <strong>and</strong>function.5414 553 v1.45

General InformationImportant Regulatory <strong>and</strong> Safety RequirementsApprovalsViessmann boilers, burners <strong>and</strong>controls are approved for sale in NorthAmerica by CSA International.CodesThe installation of this unit shall be inaccordance with local codes. In theabsence of local codes, use:CSA C22.1 Part 1 <strong>and</strong>/or local codesin CanadaNational Electrical Code ANSI/NFPA70 in the U.S.Always use latest editions of codes.Please carefully read this manual priorto attempting installation. Anywarranty is null <strong>and</strong> void if theseinstructions are not followed.For information regarding otherViessmann System Technologycomponentry, please referencedocumentation of the respectiveproduct.We offer frequent installation <strong>and</strong>service seminars to familiarize ourpartners with our products. Pleaseinquire.Working on the equipmentThe installation, adjustment, service,<strong>and</strong> maintenance of this product mustbe done by a licensed professionalheating contractor who is qualified <strong>and</strong>experienced in the installation, service,<strong>and</strong> maintenance of hot water boilers.There are no user serviceable parts onthe boiler, burner, or control.Ensure main power supply toequipment, the heating system, <strong>and</strong> allexternal controls has been deactivated.Close main oil or gas supply valve.Take precautions in both instances toavoid accidental activation of powerduring service work.The completeness <strong>and</strong> functionality offield supplied electrical controls <strong>and</strong>components must be verified by theheating contractor. These include lowwater cut-offs, flow switches (if used),staging controls, pumps, motorizedvalves, air vents, thermostats, etc.WARNINGTurn off electric powersupply before servicing.Contact with liveelectric componentscan cause shock orloss of life.Technical literatureLiterature applicable to all aspects ofthe Vitocontrol-S, <strong>WB2B</strong>:- <strong>Installation</strong> & Service Instructions- Operating & User Instructions- Instructions of other Viessmannproducts utilized <strong>and</strong> installed- <strong>Installation</strong> codes mentionedin this manualLeave all literature at the installationsite <strong>and</strong> advise the system operator/ultimate owner where the literaturecan be found. Contact Viessmann foradditional copies.5414 553 v1.46

General InformationImportant Regulatory <strong>and</strong> <strong>Installation</strong> RequirementsPower supplyInstall power supply in accordance withthe regulations of the authoritieshaving jurisdiction or, in the absence ofsuch requirements, in accordance withNational Codes. Viessmannrecommends the installation of adisconnect switch to the 120 VACpower supply outside of the boilerroom. The installer must providemaximum 15 A overcurrent protectionfor the 120 VAC power supply (fuse orcircuit breaker).Working with an open controlNo static discharge to the internalcomponentry must ever occur whenworking with opened controlequipment.About these <strong>Installation</strong> InstructionsTake note of all symbols <strong>and</strong> notations intended to draw attention to potential hazards or important product information.These include ”WARNING”, ”CAUTION”, <strong>and</strong> ”IMPORTANT”. See below.WARNINGIndicates an imminently hazardoussituation which, if not avoided, couldresult in death, serious injury orsubstantial product/property damage.CAUTIONIndicates an imminently hazardoussituation which, if not avoided, mayresult in minor injury orproduct/property damage.IMPORTANTWarnings draw your attention to thepresence of potential hazards orimportant product information.Cautions draw your attention to thepresence of potential hazards orimportant product information.Helpful hints for installation,operation or maintenance whichpertain to the product.This symbol indicates that additional,pertinent information is to be found incolumn three.This symbol indicates that otherinstructions must be referenced.5414 553 v1.47

Heating system designsSystem design2D20 M152LONLONFE22K20A Vitodens 200-W (models 45 to105) with the Vitotronic <strong>100</strong>, <strong>HC1</strong>,with KMK cascade communicationmodule as part of the st<strong>and</strong>arddeliveryB Vitocontrol-S, <strong>WB2B</strong> with LONcommunication module (accessory)C DHW cylinderD Vitotronic 200-H with LONcommunication module(accessories)E Mixing valve on Vitocontrol-S,<strong>WB2B</strong>F Mixing valve on Viotronic 200-HH Low loss header1431464040LONLON! Outdoor temperature sensor? Supply temperature sensorcommon heating flow(low loss header)?M1 Supply temperature sensormixing valve circuit 1 -extended circuit(Vitotronic 200-H)?M2/M3Supply temperature sensormixing valve circuit 2 or 3(Vitocontrol-S)% DHW temperature sensorsÖ Boiler pump (Vitotronic <strong>100</strong>,<strong>HC1</strong>)sÖM1 Mixing valve circuit 1(Vitotronic 200-H)sÖM2/M3Mixing valve circuit 2 or 3(Vitocontrol-S)sA DHW pumpsK DHW recirculation pumpfÖ Power supply, 120 V/60 HzgSM1 Motor mixing valve circuit 1(Vitotronic 200-H)gSM2/M3Motor mixing valve circuit 2or 3 (Vitocontrol-S)aVD/aVH External hook-up(Vitocontrol-S),see page 22.aVG/KMK Connection toVitotronic <strong>100</strong>, <strong>HC1</strong> toVitocontrol-SKMK Interconnection betweenboiler controls <strong>and</strong> Vitotronic<strong>100</strong>, <strong>HC1</strong>5414 553 v1.4M2 M32 20 52 2 20 522B128521145A AE205252KMK2PPMPPMKMK2020 2052HC8

Heating system designsSystem design (cont.)The codes must be set on every Vitotronic <strong>100</strong>.(see section on coding page 82)Vitotronic <strong>100</strong>, <strong>HC1</strong>Required coding01 : 2 Multi-boiler system with Vitocontrol-S, <strong>WB2B</strong>07 : 207 : 307 : 4Setting the boiler number at the Vitotronic <strong>100</strong> of thesecond boilerthird boilerfourth boilerVitocontrol-S, <strong>WB2B</strong>Required coding00 : 3,00 : 4,00 : 7,or00 : 835 : 135 : 235 : 335 : 4Heating circuit M2 without DHW heatingHeating circuit M2 with DHW heatingHeating circuit M2 <strong>and</strong> M3 without DHW heatingHeating circuit M2 <strong>and</strong> M3 with DHW heatingSetting up Vitocontrol-S withone Vitotronic <strong>100</strong>two Vitotronic <strong>100</strong>three Vitotronic <strong>100</strong>four Vitotronic <strong>100</strong>Vitotronic 200-H (if installed)Required coding97 : 1 The outdoor temperature is accepted by the LON BUS5414 553 v1.49

Heating system designsSystem design (cont.)Multiple (up to four) Vitodens 200-W, models <strong>WB2B</strong> 45, 60, 80 <strong>and</strong>d 105 with...– multiple heating circuits with mixing valves– low-loss headerVitocontrol-SPPM PPM PPM PPMBoiler 1 Boiler 2 Boiler 3 Boiler 4TPVPRV PRV PRV PRVCommonSupplyTemperatureSensor M MDHW TankLow-LossHeaderFig. 31When designing a multiple Vitodens system as shown above, please reference applicable multiple Vitodens technicaldocumentation, <strong>and</strong> contact your local Viessmann Sales Representative for further assistance.IMPORTANTThis installation example depicts apossible piping layout for multipleVitodens 200-W, <strong>WB2B</strong> boilersequipped with Viessmann systemTechnology. Please note that thisexample is based on a simplifiedconceptual drawing only! Piping <strong>and</strong>necessary componentry must be fieldverified.A low water cut-off (LWCO) must beinstalled where required by local codes.Proper installation <strong>and</strong> functionality inthe field is the responsibility of theheating contractor.WARNINGWhen extending wire, there is thepossibility of exposure toelectromagnetic interference.Avoid running wires beside or nearhigh voltage 120/240 VACconductors. If proximity to highvoltage conductors cannot beavoided, use str<strong>and</strong>ed, twisted pair orshield design wire. Ensure that onlyone end of the shielding is grounded.5414 553 v1.410

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Installing the Cascade Communication ModuleAThe cascade communication module2.<strong>Installation</strong> Instructions shippedwith boiler.A3.1.X7AB1453 2 1CCD5414 553 v1.4A Vitocontrol-S <strong>WB2B</strong>B KMK-BUSC Boiler control with Vitotronic <strong>100</strong><strong>and</strong> KMK Module (max 4 boilers)D 2-core Cable(cable cross-section 2 x 0.5 mm 2total length 164ft. / 50m)E Plug aVG into the Vitocontrol-S<strong>WB2B</strong>F Terminal strip ”KMK1/KMK2” atthe cascade communication moduleof the boiler control withVitotronic <strong>100</strong>1 2 3 4KMK1 KMK21 2 3 4KMK1 KMK2Note:The total length of BUS cables Bshould not exceed 164ft. / 50m.The wires from the BUS cables arecommutable.11

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Summary of electrical connections (Power Pump Module)MAIN POWER SUPPLY120V, 60HZ, 12AN G LPower/Pump module1 2 31431 2 31441 2 3145<strong>Installation</strong>Instructions,Power PumpModuleLOW WATER CUT-OFFSAFETY DEVICE-TYPICALL2L1P1P2AL2 L1 G NL N4040L N20A20AL N2121L N2020L N5050L28G N1431441451 2 3 1 2 3 1 2 3M120VACBOILERPUMP120VACFAULTALARMOUTPUT20 L N 40145X 7X47 6 5 4 3 2 1X3<strong>100</strong>35209640230 VACX 8X9Boiler Control BoardX11LONKMK5414 553 v1.4MAINDISCONNECTSWITCH120VACWALLRECEPTACLE120/230TransformerKMK1KMK2X11 2 3 4KMKModule12

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Summary of electrical connectionsLON5252202022M3M2M3M2M3M2 145145152/3143146282129205040156A15414 553 v1.4Mixing valve extension circuit board?M2/M3 Supply temperature sensorsÖM2/M3 Heating circuit pumpgSM2/M3 Mixing valve actuatorLow voltage motherboard! Outdoor temperature sensor? Common supply temperaturesensor% DHW tank temperature sensoraVD External connectionaVG Connection to Vitotronic <strong>100</strong>(KMK Module) <strong>and</strong> Vitotrolremote controlaVHLONConnection for external dem<strong>and</strong>LON BUS, interconnecting cablefor data transfer betweenVitocontrol-S <strong>and</strong>Vitotronic 200-H orVitocom 300Line voltage motherboardsÖ Heating circuit pump (hightemperature space heating)sA DHW pumpsK DHW re-circulation pumpfÖ Power supply connectiongÖ Compiled failure alarmaBH Internal power supply for mixingvalve extension circuit board <strong>and</strong>connections for accessoriessL Not used (no function)13

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Summary of electrical connections (continued)29Vitocontrol-S <strong>WB2B</strong>6295414 553 v1.414

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Mounting of the control unit1.1.Fasten metal backplate ontomounting surface with fourfasteners.2.3.2.Position midplate between backplate<strong>and</strong> connection enclosure.3.Install midplate <strong>and</strong> connectionenclosure onto backplate.4.Fasten connection enclosure <strong>and</strong>midplate onto backplate with twofasteners.5.Install control rear section ontoconnection enclosure housing. Hookcontrol onto backplate tabs <strong>and</strong>pivot downwards.4.6.Fasten control rear section ontoconnection enclosure with twofasteners.5.6.5414 553 v1.415

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Inserting cables <strong>and</strong> applying strain reliefRun the cables from the connection enclosure into the control unit.Apply strain relief to cables (see below).Cables with moulded strain reliefclampConnect cable <strong>and</strong> strain relief clamp.ORFasten cable to the cable lead withcable tie.5414 553 v1.416

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Sensor connection15 21 2 31 2 3 1 2 3A B CAOutdoor temperature sensor(not polarity sensitive)BDHW tank temperature sensorCSupply temperature sensor –common heating supply<strong>Installation</strong> location:North or north-western wall. Inmulti-storey buildings, in the upperhalf of the second floor.Not above windows, doors orventilation outlets.Not immediately below balcony orgutter.Do not paint over.Connection:Two-wire cable, max. 120ft. / 35mlength, AWG 16.5414 553 v1.417

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Sensor connection (continued)Outdoor temperature sensorThe outdoor temperature sensor should be mounted 6.5 to 8ft / 2 to 2.5m aboveground level on the north or north-west facing wall of the building. In the case ofmulti-storey buildings, it should be mounted in the upper half of the second storey.Make sure that the sensor is not located over windows, doors <strong>and</strong> air vents, norimmediately beneath a balcony or guttering.Do not paint over the outdoor temperature sensor housing.1. Remove the cap.2. Mount the bottom part of the sensorhousing.1.5.3.3. Pull the sensor wire through theopening in the terminal compartment<strong>and</strong> through the strain reliefprovided.4. Connect the wires to the terminals.5. Place the cap over the outdoortemperature sensor.4.6005802.560540WARNINGWhen extending wire, there is thepossibility of exposure toelectromagnetic interference.Avoid running wires beside or near highvoltage 120/240 VAC conductors. Ifproximity to high voltage conductorscannot be avoided, use str<strong>and</strong>ed,twisted pair or shield design wire.Ensure that only one end of theshielding is grounded.Resistance in520500480460440420400-40 -30 -20 -10 0 10 20 30-40 -22 -4 14 32 50 68 86Outdoor temperature in °C / °F5414 553 v1.418

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Sensor connection (continued)DHW tank temperature sensorThe sensor measures the domestic hotwater tank temperature.Heating systems with domestic hotwater heating (single-boiler systemsonly)1. Install the DHW tank temperaturesensor.Check the sensor1. Disconnect plug % in the terminalcompartment of the boiler control.2. Measure resistance of sensor atterminals ”1” <strong>and</strong> ”2” of the plug.5Resistance in720700680660640See installation instructionsfor domestic hot water tankNote:When installing the sensor in DHWtanks of other makes, make surethat the sensor is pressed againstthe sensor well of the DHW tank bymeans of a suitable device.2. Ensure that the maximumpermissible domestic hot watertemperature is not exceeded. Ifnecessary, install a suitable safetydevice for this purpose.DHW tanktemperaturein °F / °C /104 / 40122 / 50140 / 60Resistancein Ω5785976163. Compare the value measured withthe current temperature. If the valuediffers significantly, checkinstallation <strong>and</strong>, if necessary, replacesensor.Technical dataDegree of protection: IP 32Ambient temperatureDuring operation:32 to + 194°F0 to + 90°CDuring storage <strong>and</strong> transport:- 4 to + 158°F-20 to + 170°CElectrical connectionThe sensors are ready to plug in. Insertthe DHW temperature sensor in socket”5” of the boiler control.620600580Heating systems without domestic hotwater heatingDo not connect the DHW tanktemperature sensor.5605414 553 v1.45400 20 40 60 80 <strong>100</strong>32 68 104 140 176 212DHW tank temperature in °C / °F19

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Connection of the pumpsAvailable pump connectionssÖ Heating circuit high temperature(without mixing valve)sÖM2 Heating circuit M2 pumpTerminals 2 - L, - G , - NsÖM3 Heating circuit M3 pumpTerminals 1 - L, - G , - NTERMINAL4 or 3AsAsKDHW pump for heating up thedomestic hot water tank -Terminals 4 - L, - G , - NDHW recirulation pumpTerminals 3 - L, - G, - N.BInstall pumps: seemanufacturer’sinstructions.120 VAC pumpsNote:The maximum power consumption ofall pumps is 4A .Rated current: max. 2 FLARecommended connectioncable: AWG 14Connect the 3-wire cable from thepump to the corresponding terminals.240 VAC or 3 PH pumpsNote:Use contactor to switch pump.For activating the contactor:Rated current: max. 2 FLARecommended connectioncable: AWG 14Please ensure that all connections <strong>and</strong>cable gauge comply with local <strong>and</strong>national codes.1.Select the contactor <strong>and</strong> theconnecting cable in accordance withthe rating of the pump that is to beconnected.2.Connect the pump <strong>and</strong> power supplyto the contactor.3.Connect contactor coil to thecorresponding terminals.5414 553 v1.420

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Connection of modulating valve actuatorsControl unit1 120V or 24V valve adaptor2 DIN rail in connection enclosure3 aBH Terminals120V Valve AdaptorRated voltage: 120 VACRated current: max. 0.1 FLARecommended connectionwire size: AWG 1424V Valve AdaptorRated voltage: 24 VACRated current: max. 0.15 FLARecommended connectionwire size: AWG 14Operating time:5 to 199 sec. selected via codingaddress “40”.1 120V valve adaptor2 120V valve actuator1 24V valve adaptor2 24V valve actuator1. Disconnect power to control.2. Install 120V or 24V valve adaptoron DIN rail inside connectionenclosure.3. Insert the plug gS into socket gS onthe control.4. Fasten cable with tie.5. Connect black wire of the adaptor toconnection aBH on the DIN rail- Terminal 8,9 or 10.6. Connect valve actuator wires to theadaptor terminals as shown onfigures.5414 553 v1.421

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Connection of external contacts143 146ABCDry Contacts:A External heating programchangeover/external“Mix.valve open”B External blocking/external“Mix.valve closed”C External dem<strong>and</strong>A External heating programchangeover or ”Mix.valve open”Contact closed:The manually pre-selected heatingprogram can be modified via thiscontact, (see table below) enabling themixing valves to be opened.The “Mix.valve open” function can beallocated via coding address “9A”, <strong>and</strong>the heating program changeover can beallocated to the heating circuits viacoding address “91”.B External disable/external“Mix.valve close”Closing the zero volt contact causesthe burner to shut down or the mixerto be closed.Allocated boiler circuit pumps areswitched OFF <strong>and</strong> shut-off valves areclosed.WARNINGHeating circuits are no longer frostprotected during “Mix.valve close”. Alower boiler water temperature is notmaintained during external blocking.Via coding address “99”, you c<strong>and</strong>etermine what input aVD shouldaffect.C External dem<strong>and</strong>Closing the dry contact starts the boilerburners of the individual boilers subjectto load via a set supply temperature(coding address “9b”) on Vitocontrol-S,<strong>WB2B</strong>.The supply temperature is limited viathe set min. <strong>and</strong> max. supplytemperature.Manually pre-selectedheating program(with open contact)9orworRoom heating OFF/DHW OFFRoom heating OFF/DHW ONrw Room heating ON/DHW ONCoding 2d5: 0(factorydefault)Changed heating program(with closed contact) Continuous operation with reduced room temperature/DHW OFFd5: 1 Continuous operation with normal room temperature/DHW inaccordance with coding address “64”5414 553 v1.422

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Connection of the compiled failure alarmARated voltage: 120 VAC 60 HzRated current:max. 2 FLARecommended connectionwire size: AWG 141. Disconnect power to control <strong>and</strong>burner.2. Connect the compiled failure alarmas shown in the diagram.A Connect terminal strip inconnection enclosure of boilercontrolB Visual <strong>and</strong>/or audible alarm device(120 VAC)B5414 553 v1.423

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Making the LON connectionThe Viessmann LON system is designed for the Line BUS topology with end of line resistors on both ends.Connection with Viessmann LON cableA A AC23ft. / 7m23ft. / 7mCBBA Control unit or VitocomB LON cableC End of line resistorConnection with Viessmann LON cable <strong>and</strong> Viessmann LON couplingA A AC23ft. / 7m 23ft. / 7m 23ft. / 7m 23ft. / 7m 23ft. / 7m 23ft. / 7mCBDBDBB BBD DA Control unit or VitocomB LON cable (max. 3 cablesbetween two devices)C End of line resistorD LON extension jack,5414 553 v1.424

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Making the LON connection (continued)Connection withViessmann LON cable,On-site cable for extensions up to 900 m / 3000 ft.A A AC23ft. / 7mE E EE23ft. / 7m 23ft. / 7m 23ft. / 7mCB B B BFmax. 900 m / 3000 ft.DA Control unit or VitocomB LON cableC End of line resistor (st<strong>and</strong>arddelivery of Vitocontrol-S, <strong>WB2B</strong>)D Up to 99 participants <strong>and</strong> thecorresponding number of junctionboxes <strong>and</strong> cablesE Junction boxF Connecting cable (on site)Note:The Viessmann LON system alwaysrequires two conductors <strong>and</strong> shielding.Conductors are interchangeable.Observe the requirements for cabling<strong>and</strong> operation of the LON interfaceFTT-10A (see www.echelon.com).Power supply1. Ensure that the main power supplyto the control contains overcurrentprotection with a minimum rating of6A <strong>and</strong> 2-pole disconnect5414 553 v1.4LegendL: LineN: NeutralG: GroundA Power supply 120 VAC, 1PH,60Hz, provide disconnect means<strong>and</strong> overcurrent protection as perlocal codesB Terminal fÖ in connectionenclosureC Connection enclosureWARNINGThe control must be grounded.Ensure that “L”, “N” <strong>and</strong> “G” are notinterchanged.2. Connect power supply wire to theconnection fÖ terminals 11, N <strong>and</strong> Gon the DIN rail inside the connectionenclosure.25

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Installing the control unit front1.1. Position the front part of the housing<strong>and</strong> clip hinges to counter-parts onmain housing.8.7.2. Release the stay bar, open it up<strong>and</strong> lock in position.3. Insert the flat cable from theOptolink into plug ”X20”.4. Insert the plug of the programmingunit into plug ”X10”. Use cableguides in cover for routing.5. Engage the stay bar in the fronthousing.6.6. Close the front of the housing.7. Secure front housing with suppliedscrews.8. Install cover of the connectionenclosure <strong>and</strong> support with suppliedscrew.2.5.3.4.5414 553 v1.426

<strong>Installation</strong> – Vitocontrol-S, <strong>WB2B</strong>Opening the control unit1. Unscrew the screws from the fronthousing.2. Swing up the front part of thecontrol housing.3. Position the stay bar so that itsupports the front housing.2.1.3.5414 553 v1.427

Initial start-upSteps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1. Commissioning all Vitodens 200-W with Vitotronic <strong>100</strong>Vitodens 200-W Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.Page2. Controls <strong>and</strong> display elements Vitotronic <strong>100</strong>, <strong>HC1</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Vitocontrol-S, <strong>WB2B</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303. Checking the heating circuit allocation (Vitocontrol-S, <strong>WB2B</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304. Changing the display language (Vitocontrol-S, <strong>WB2B</strong> if required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305. Configuring a multi-boiler system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316. Connecting control units into the LON system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327. Carrying out a participant check (Vitocontrol-S, <strong>WB2B</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328. Reducing the maximum burner output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339. Matching the coding addresses to the system version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3310. Checking outputs (actuators) <strong>and</strong> sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3411. Selecting the boiler sequence (Vitocontrol-S, <strong>WB2B</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3512. Adjusting the heating curve (Vitocontrol-S, <strong>WB2B</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365414 553 v1.428

Initial start-upFurther step-by-step instructionsCommissioning of all Vitodens 200-W, <strong>WB2B</strong> with Vitotronic <strong>100</strong>, <strong>HC1</strong>Service Instructions Vitodens 200-W, <strong>WB2B</strong>AºC+OKiKHGFED CBA Heating programsB No functionC InformationD Fact0ory default settingE ConfirmationF Value settingG No functionH Emissions test functionK Boiler water temperature5414 553 v1.429

Initial start-upFurther step-by-step instructions (continued)Boiler sequenceA Heating circuit selectionB Reduced room temperatureC DHW temperatureD Normal room temperatureE St<strong>and</strong>by modeF DHW onlyG Heating <strong>and</strong> DHWH Economy modeK Party modeL InformationM St<strong>and</strong>ard settingsN ConfirmationO Adjusting valuesP Time programsR Holiday programS Time/dateT Heating curve level shiftU Heating curve slopeChecking the heating circuit allocation (Vitocontrol-S, <strong>WB2B</strong>) Check that the label for heatingcircuit allocation has been affixed tothe corresponding fields of theprogramming unit. Press the corresponding key beforecommencing all adjustments.Changing the display language (Vitocontrol-S, <strong>WB2B</strong>)1. Press i.3. Confirm with .2. Select the required languagewith .5414 553 v1.430

Initial start-upFurther step-by-step instructions (continued)The cascade communication module must be fitted into all Vitotronic <strong>100</strong> boiler control.Setting codes, see page 82 <strong>and</strong> 88.Example of a multi-boiler systemVitocontrol-S Vitotronic <strong>100</strong> Vitotronic <strong>100</strong>145KMK1KMK2KMK1Vitocontrol-S, <strong>WB2B</strong> Vitotronic <strong>100</strong>, <strong>HC1</strong> – – – – Vitocontrol-S, <strong>WB2B</strong>–– Multi-boiler systemSet code ”01:2”–– Boiler number 1Coding ”07:1”Number of connected boilers< 5 boilersSet code ”35:2”, ”35:3” or”35:4”Connecting control units into the LON systemThe LON communication module (accessories) must be fitted.Note:The data transfer via the LON system can take several minutes.Vitotronic 200-H– – – – Multi-boiler systemSet code ”01:2”Boiler number 4Set code ”07:4”–– ––Setting up LON participant numbersIn coding 1, set the LON participantnumber via coding address “77”.<strong>Installation</strong> <strong>and</strong> serviceinstructions, Vitotronic 200-H.Note:In one LON system, each numbermust only be allocated once.Vitocontrol-S, <strong>WB2B</strong>1. Set the number of boilersIn coding 1, set coding address “35”.Coding 1 see page 84.Note:In one LON system, each numbermust only be allocated once.Only one Vitotronic may beprogrammed as fault manager.5414 553 v1.431

Initial start-upFurther step-by-step instructions (continued)Update the LON particiapant list on Vitocontrol-S, <strong>WB2B</strong>Only possible if all users are connected <strong>and</strong> the control unit is encoded as fault manager (coding 79 : 1 factory defaultsetting)Note:In each heating system, only one Vitotronic may be encoded as fault manager.1. Press w <strong>and</strong> simultaneouslyfor approx. 2 s.The participant check is initiated.2. Press D.The participant list is updatedafter approx. 2 min.Participant check completed.Example of a LON systemVitocontrol-S Vitotronic 200-H Vitotronic 200-HVitocomLONLONLONParticipant no. 5Code ”77:5”Participant no. 10Set code ”77:10”Participant no. 11Set code ”77:11”Participant no. 99Send time via LONCode ”7b:1”Accept time via LONSet code ”81:3”Accept time via LONSet code ”81:3”Time received via LONTransmit outdoor temperaturevia LONSet code ”97:2”Receive outdoor temperaturevia LONSet code ”97:1”Device receives the timeCarrying out a participant checkThe communication with the system devices connected to the fault manager is tested by means of a participant check.Preconditions: The control unit must be programmed as fault manager (code 79:1). The LON participant number must be programmed in all control units(see page 31). The fault manager participant list must be up to date.Participant checkF01 : 011Consecutivenumber in theparticipant listParticipantnumber1. Press w <strong>and</strong> simultaneously forapprox. 2 seconds.2. Select the required participant with<strong>and</strong> .3. Activate check with .”Check” flashes until its completion.The display <strong>and</strong> all key illuminationsof the selected participant flash forapprox. 60 seconds. During communication betweenboth devices ”Check OK” isdisplayed. ”Check not OK” is displayed, if nocommunication is established.Check the LON connection <strong>and</strong>coding.4. To check further participantsproceed as described under points 2<strong>and</strong> 3.5. Press w <strong>and</strong> simultaneously forapprox. 1 second.5414 553 v1.432

Initial start-upFurther step-by-step instructions (continued)Reducing the maximum burner output (Vitotronic <strong>100</strong>)Vitodens 200 service instructionsMatching coding addresses to respective system versionVitotronic <strong>100</strong>In code 1, set the following codingaddresses:01 Multi-boiler system06 Maximum boiler07 Boiler number2F Air bleed functionIn code 2, set the following codingaddresses:76:2 With cascade communicationmodule KMKMatching coding addresses to respective system versionVitocontrol-S, <strong>WB2B</strong>In code 1, set the following codingaddresses:00 System design35 Number of boilers in cascade36 Minimum limit of the cascadesupply temperature37 Maximum limit of the cascadesupply temperature3b Control type3C Control strategy77 LON participant number *1A2 DHW priorityA5 Heating circuit pump logicfunction (economy control)C5 Minimum supply temperaturelimit, heating circuitsC6 Maximum supply temperaturelimit, heating circuitsIn code 2, set the following codingaddresses:38 Lead boiler rotation39 Permanent lead boiler3A Permanent last boiler55 Function DHW temperaturecontrol78 LON communication enabled7A Central control7F Detached house or apartmentbuilding98 Viessmann system number *1*1 Only in conjunction with LON system5414 553 v1.433

Initial start-upFurther step-by-step instructions (continued)Checking outputs (actuators) <strong>and</strong> sensorsVitotronic <strong>100</strong>Relay test1. Press 9 <strong>and</strong> simultaneously forapprox. two seconds.2. Select the relay outputswith or .3. Press .The following relay outputs may be selected:DisplayindicationRelay function11Burner modulation lower output12Burner modulation upper output13Internal pump/ output 20 ON (Power Pump module)14Output 50 ON/ fault indicator in Power Pump ModuleCheck sensors1. Press .Scanning operating conditions isactive, see page 41.2. Scan the actual temperature withor .3. Press .Scanning is completed.5414 553 v1.434

Initial start-upFurther step-by-step instructions (continued)Vitocontrol-S, <strong>WB2B</strong>Relay test1. Press 9 <strong>and</strong> simultaneously forapprox. two seconds.2. Select the relay outputswith or .3. Press .The following relay outputs may be selected:Output 20M1 ONOutput 52A1 openOutput 52A1 ntr.Output 52A1 closeDHW tank heating pump ONDHW recirculation pump ONHeating pump (M2) ONHeating pump (M3) ONMixing valve (M2) openMixing valve (M2) closeMixing valve (M3) openMixing valve (M3) closeCentral fault display ONNote:The illuminated heating circuit selectorbutton indicates the correspondingheating circuit.Check sensors1. Press .Scanning operating conditions isactive, see page 46.2. Scan the actual temperature withor .3. Press .Scanning is completed.Selecting the boiler sequence (Vitocontrol-S, <strong>WB2B</strong>)1. If required:In coding 2, set coding addresses 39(permanent lead boiler) <strong>and</strong> 3A(permanent last boiler).2. Press <strong>and</strong> simultaneously forapprox. two seconds.3. Select the required boiler sequencewith or .By pressing <strong>and</strong>simultaneously, you can exit theadjustment without saving anymodifications made.4. Press .The adjustment has beentransferred.5. In coding 2, set the codingaddresses 38, 41, 42, 43 <strong>and</strong> 44;see also the function descriptionfrom page 62.5414 553 v1.435

Initial start-upFurther step-by-step instructions (continued)Adjusting the heating curve (Vitocontrol-S, <strong>WB2B</strong>)The heating curves illustrate the relationship between the outdoor temperature <strong>and</strong> the boiler water or the supplytemperature. To put it simply: the lower the outdoor temperature, the higher the boiler water or supply temperature. Theroom temperature again depends on the boiler water or the supply temperature.Factory default settings:Slope: = 1.4Shift: = 0Generally, the heating curve is set:In range A for underfloor heating systems,In range B for low temperature heating systems (according to the Energy Savings Order),Slope3.43.23.02.8Supply tempertaure in ºC / ºF2.62.490/19480/17670/15860/14050/12240/1041.81.61.41.21.00.830/860.63595308625772068105015591050Set room temperature in ºC / ºF541541032-523-1014-155-20-4Outdoor temperature in ºC / ºF0.40.25414 553 v1.436

Initial start-upFurther step-by-step instructions (continued)Changing slope <strong>and</strong> shift(for every heating circuit separately)1. Call up slope with ,adjustable value 0.2 to 3.5;call up shift with ;adjustable value 8.6 to 104°F / –13to +40°C.2. Change the value with or .3. Confirm the set value with .1102303.5Supply temperature in °C / °FAB1.40.2+20 / 68 -20 / -4A Change slopeB Change shift5414 553 v1.4Outdoor temperature in °C / °F37

Initial start-upFurther step-by-step instructions (continued)Adjusting the normal room temperature(for every heating circuit separately)123St<strong>and</strong>ard room temp.20Normal room temperature:Select the normal day temperature withthe set value adjuster.The value will be automaticallytransferred after approx. 2 seconds.123Reduced room temp.14Reduced room temperature:1. Call up the reduced nighttemperature with tm.2. Change the value with or .3. Confirm the set value with .Temperature conversion:D E D E˚F˚C-4 -2041 557 1468 2079 26230 110Example 1:Adjustment of the normal roomtemperature from 68 to 79˚F / 20 to26˚C.Example 2:Adjustment of the reduced roomtemperature from 41 to 57˚F / 5 to14˚C.A Boiler water temperature or supplytemperature in ˚F / ˚CB Outdoor temperature in ˚F / ˚CC Set room temperature in ˚F / ˚CD Heating circuit pump OFFE Heating circuit pump ONAccordingly, the heating curve isadjusted along the set room temperatureaxis, resulting in modified start/shutdowncharacteristics for the heating circuitpumps, if the heating circuit pump logicis active.5414 553 v1.438

Service scanning – Vitotronic <strong>100</strong>, <strong>HC1</strong>Service level summaryFunction Entry Exit PageReducing the max.burner outputRelay testTemperatures,boiler coding card<strong>and</strong> brief scansPress 9 <strong>and</strong> twsimultaneously forapprox. 2 secondsPress 9 <strong>and</strong> “OK”simultaneously forapprox. 2 secondsPress 9 <strong>and</strong> rwsimultaneously forapprox. 2 secondsPress “OK” 32Press “OK” 35Press “OK” 35OperatingPress 8 Press 8 46conditionsTroubleshooting Press “OK” 47Fault historyResetting codesto the factorydefault settingCoding Level 1Coding Level 2Press rw <strong>and</strong> “OK”simultaneously forapprox. 2 secondsPress w <strong>and</strong> rwsimultaneously forapprox. 2 secondspress DPress 9 <strong>and</strong> wsimultaneously forapprox. 2 secondsPress w <strong>and</strong> rwsimultaneously for approx.2 secondsVitodens 200-W Service InstructionsPress “OK” 47–– 82Press 9 <strong>and</strong> wsimultaneously forapprox. 1 secondPress w <strong>and</strong> rwsimultaneously forapprox. 1 second81825414 553 v1.439

Service scanning – Vitotronic <strong>100</strong>, <strong>HC1</strong>Temperatures, boiler coding card <strong>and</strong> quick scans1. Press 9 <strong>and</strong> rw simultaneouslyfor approx. two seconds.2. Select the required scanwith or .Brief scans8 8 8 8 8 80 Systemdesign 1Control unit software versionProgrammingunit softwareversion1 Burner control unit softwareversionENo function3 Set boiler temperatureAHighest dem<strong>and</strong> temperature4 Burner control unit type Boiler type5 No functionb Maximum heating output in %CBoiler coding card (hexadecimal)Cascademodulesoftwareversionc Equipment version (EEPROM) Burner control unit version(EEPROM)dVariable speedpump0 without1 Wilo2 GrundfosVariable speedpump softwareversion5414 553 v1.440

Service scanning – Vitotronic <strong>100</strong>, <strong>HC1</strong>Scanning operating conditions1. Press 8. 2. Select the required operatingcondition scan with or .3. Press .ScansDisplayindicationExplanationNotes0 01Boiler number ––3__65263572030417°C Boiler temperature ––h Burner hours run The hours run can be reset to 0 with D.The hours run displayed are onlyapproximate values.h Burner starts The burner starts can be reset to 0 withD.5414 553 v1.441

Service scanning – Vitotronic <strong>100</strong>, <strong>HC1</strong>Scanning <strong>and</strong> resetting service displaysAfter the limits set up via coding addresses 21 <strong>and</strong> 23 (see page 82) have been reached, the programming unit displayflashes one of the following messages.Note:Set code 24:1 <strong>and</strong> then code 24:0, if maintenance is implemented before a maintenance message is displayed; the setmaintenance parameters for hours run <strong>and</strong> maintenance intervals are then reset to 0.Displayindication35510 h___12 uExplanationBurner run hours havebeen reachedTime interval(e.g. 12 months)has been reached1. Scan maintenance messages withor .2. Press .The maintenance indication in thedisplay is cleared.Note:An acknowledged maintenancemessage can be redisplayed bypressing (approx. three seconds).After maintenance has been carried out1. Reset coding 24: 1 (see page 82) to24: 0.Note:If coding address 24 is not reset, anew maintenance message will bedisplayed on Monday morning.2. If required:PressReset burner run hours <strong>and</strong> burnerstarts with D(see page 82)Press5414 553 v1.442

Service scans – Vitocontrol-S, <strong>WB2B</strong>Service level summaryFunction Entry Exit PageAdjusting displaycontrastParticipant checkRelay testBoiler sequenceTemperatures <strong>and</strong>quick scansPress the “OK” <strong>and</strong> “+”buttons simultaneously;the display will darkenPress the “OK” <strong>and</strong> “-” buttonssimultaneously;the display will get lighterPress the w <strong>and</strong> “OK” buttonssimultaneously for approx.2 secondsPress the 9 <strong>and</strong> “OK” buttonssimultaneously for approx. 2secondsPress the g <strong>and</strong> û buttonssimultaneously for approx. 2secondsPress 9 <strong>and</strong> rwsimultaneously for approx. 2seconds–– –––– ––Press the w <strong>and</strong> “OK” buttons simultaneously for approx. 1 sec 32Press the “OK” button 35Press the “OK” button 35Press the “OK” button 44Operating status Press the i button Press the i button 46Troubleshooting Press the i button Press the “OK” button 51Error historyResetting codingsto factory defaultsettingsCoding Level 1Coding Level 2Press the rw <strong>and</strong> “OK”buttons simultaneously forapprox. 2 secondsPress the w <strong>and</strong> rw buttonssimultaneously for approx.2 seconds; press the D button;confirm by pressing the “OK”buttonPress 9 <strong>and</strong> w simultaneouslyfor approx. 2 secondsPress the w <strong>and</strong> rw buttonssimultaneously for approx. 2seconds; confirm by pressing the“OK” buttonPress the “OK” button 51–– 81Press the 9 <strong>and</strong> w buttons simultaneously for approx. 1 sec 81Press the w <strong>and</strong> rw buttons simultaneously for approx. 1 sec 825414 553 v1.443

Service scans – Vitocontrol-S, <strong>WB2B</strong>Temperatures <strong>and</strong> quick scans1. Press 9 <strong>and</strong> rw simultaneouslyfor approx. 2 seconds.3. Press “OK”.2. Select the required scanwith or .The following values can be scanned subject to the actual equipment level:Outdoor temperature adjustedOutdoor temperature actualBoiler sequenceP-actual % boiler 1 to 4Output red. %IntegralBoiler temperature actual boiler . . . .1 to 4Sensor 17B actual (not used)Set DHW temperatureActual DHW temperatureSupply temperature setSupply temperature actualRoom temperature setRoomtemperature actualQuick scan 1 to quick scan 8The adjusted outdoor temperaturecan be reset to the current outdoortemperature with D.Boiler output - actual value.No function.at - 1 to - <strong>100</strong> start-up integral inpercent; at 1 to <strong>100</strong> shutdownintegral in percent ( - arrow aboveword, when integral grows).Display only if a sensor is connected.Display only if a system design witha DHW tankhas been encoded . . . . .(code 00).Display only if a remote control unitis installedQuick scans 1 to 7, see page 45.5414 553 v1.444

5414 553 v1.4Scan123Scan88Display acc. tosystem designs (see codingaddress 00)Software versioncontrol unitOperating modesys. circuit A10 w/o remotecontrol1 withVitotrol 2002 withVitotrol 300Software versionprogrammingunitSoftware versionremote controlsystem circuitA1N/A8Software versionmixing valveextension M2Printed CircuitBoardOperating modemixing valvecircuit M20 w/o remotecontrol1 withVitotrol 2002 withVitotrol 3008Number of KMBUSparticipantsN/ASoftware versionremote controlmixing valvecircuit M2N/A8Software versionmixing valveextension M3Printed CircuitBoardOperating modemixing valvecircuit M30 w/o remotecontrol1 withVitotrol 2002 withVitotrol 300N/A8Software versionremote controlmixing valvecircuit M3Temperatures <strong>and</strong> quick scans (continued)45678LON participant numberSNVTSoftware versionconfiguration communication0 = Auto co-processor1 = ToolDevice identificationhexa-decimal: b8 / decimal: 184N/AN/AN/ASubnet address/system numberSoftware versionneuron chipN/AN/AN/ANode addressNumber ofLON participantsN/AN/AMaximum system design temperatureService scans – Vitocontrol-S, <strong>WB2B</strong>45

Service scans – Vitocontrol-S, <strong>WB2B</strong>Scanning operating conditions1. Press .3. Press .2. Select the required scanwith or .The following values can be scanned subject to the actual equipment level:Participant numberHoliday program with departure <strong>and</strong>return dateHoliday program activeOutdoor temperatureBoiler sequenceCommon supply temperatureBoiler temp. 1 to 4Sensor 17B (not used)DHW temperatureSupply temperatureReturn temperatureRoom temperatureTimeDateOutput 20 ON/OFFOutput 29 ON/OFFOutput 52 open/closeDHW tank heating pump ON/OFFDHW recirculation pump ON/OFFHeating pump ON/OFFMixing valve open/closedLanguagesIf a holiday program has been enteredIf a central holiday program is activeActual value boilers 1 to 4Display only if a sensor is connectedDisplay only if a DHW tank sensor isconnectedDisplay only in conjunction withmixing valve circuitsDisplay only if a remote control unitis installedPosition detail in %Position detail in %.Each language can be selected aspermanent display languagewith5414 553 v1.446

Troubleshooting – Vitotronic <strong>100</strong>, <strong>HC1</strong>Faults displayed at the programming unitThe red faults indicator U flashes forevery fault.A fault code flashes in the display if afault message has been issued (seepage 47).i Consecutive fault number38 Fault codeU Fault symbolA fault can be acknowledged with“OK”. The fault message in the displaywill be hidden, but the red faultindicator U continues to flash.The fault message will be redisplayed,if an acknowledged fault message hasnot been removed by the followingmorning.Calling up acknowledged faultmessagesPress “OK” for approximately 2seconds.Select the acknowledged fault withor .Call up further fault codes with.orE in the display indicates that theburner control unit is locked out. Afterthe fault has been removed,acknowledge by pressing reset E.Note:After acknowledging the fault, E willbe displayed until the burner controlunit lockout has been lifted.Retrieving fault codes from the fault memory (fault history)The most recent 10 faults are saved <strong>and</strong> may be called up.Faults are sorted by date. The most recent fault is fault number 1.1. Press rw <strong>and</strong> simultaneouslyfor approx. 2 seconds.2. Press or for individual faultcodes.Note:All saved fault codes can be deletedwith D.3. Press to finish scan.5414 553 v1.447