TECHNICAL & SERVICE MANUAL Ceiling Cassettes ... - Engvent.ru

TECHNICAL & SERVICE MANUAL Ceiling Cassettes ... - Engvent.ru

TECHNICAL & SERVICE MANUAL Ceiling Cassettes ... - Engvent.ru

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

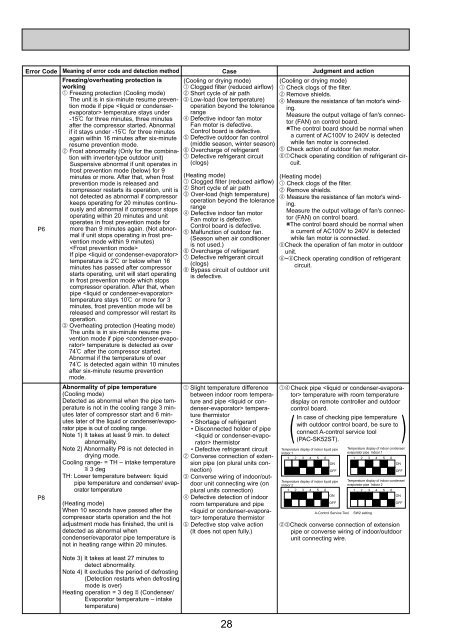

Error Code Meaning of error code and detection method Case Judgment and actionP6P8Freezing/overheating protection isworking1 Freezing protection (Cooling mode)The unit is in six-minute resume preventionmode if pipe temperature stays under-15: for three minutes, three minutesafter the compressor started. Abnormalif it stays under -15: for three minutesagain within 16 minutes after six-minuteresume prevention mode.2 Frost abnormality (Only for the combinationwith inverter-type outdoor unit)Suspensive abnormal if unit operates infrost prevention mode (below) for 9minutes or more. After that, when frostprevention mode is released andcompressor restarts its operation, unit isnot detected as abnormal if compressorkeeps operating for 20 minutes continuouslyand abnormal if compressor stopsoperating within 20 minutes and unitoperates in frost prevention mode formore than 9 minutes again. (Not abnormalif unit stops operating in frost preventionmode within 9 minutes)If pipe temperature is 2: or below when 16minutes has passed after compressorstarts operating, unit will start operatingin frost prevention mode which stopscompressor operation. After that, whenpipe temperature stays 10: or more for 3minutes, frost prevention mode will bereleased and compressor will restart itsoperation.3 Overheating protection (Heating mode)The units is in six-minute resume preventionmode if pipe temperature is detected as over74: after the compressor started.Abnormal if the temperature of over74: is detected again within 10 minutesafter six-minute resume preventionmode.Abnormality of pipe temperature(Cooling mode)Detected as abnormal when the pipe temperatureis not in the cooling range 3 minuteslater of compressor start and 6 minuteslater of the liquid or condenser/evaporatorpipe is out of cooling range.Note 1) It takes at least 9 min. to detectabnormality.Note 2) Abnormality P8 is not detected indrying mode.Cooling range- = TH – intake temperature[ 3 degTH: Lower temperature between: liquidpipe temperature and condenser/ evaporatortemperature(Heating mode)When 10 seconds have passed after thecompressor starts operation and the hotadjustment mode has finished, the unit isdetected as abnormal whencondenser/evaporator pipe temperature isnot in heating range within 20 minutes.Note 3) It takes at least 27 minutes todetect abnormality.Note 4) It excludes the period of defrosting(Detection restarts when defrostingmode is over)Heating operation = 3 deg [ (Condenser/Evaporator temperature – intaketemperature)(Cooling or drying mode)1 Clogged filter (reduced airflow)2 Short cycle of air path3 Low-load (low temperature)operation beyond the tolerancerange4 Defective indoor fan motorFan motor is defective.Control board is defective.5 Defective outdoor fan control(middle season, winter season)6 Overcharge of refrigerant7 Defective refrigerant circuit(clogs)(Heating mode)1 Clogged filter (reduced airflow)2 Short cycle of air path3 Over-load (high temperature)operation beyond the tolerancerange4 Defective indoor fan motorFan motor is defective.Control board is defective.5 Malfunction of outdoor fan.(Season when air conditioneris not used.)6 Overcharge of refrigerant7 Defective refrigerant circuit(clogs)8 Bypass circuit of outdoor unitis defective.1 Slight temperature differencebetween indoor room temperatureand pipe temperaturethermistor• Shortage of refrigerant• Disconnected holder of pipethermistor• Defective refrigerant circuit2 Converse connection of extensionpipe (on plural units connection)3 Converse wiring of indoor/outdoo<strong>ru</strong>nit connecting wire (onplural units connection)4 Defective detection of indoorroom temperature and pipetemperature thermistor5 Defective stop valve action(It does not open fully.)28(Cooling or drying mode)1 Check clogs of the filter.2 Remove shields.4 Measure the resistance of fan motor's winding.Measure the output voltage of fan's connector(FAN) on control board.WThe control board should be normal whena current of AC100V to 240V is detectedwhile fan motor is connected.5 Check action of outdoor fan motor.67Check operating condition of refrigerant circuit.(Heating mode)1 Check clogs of the filter.2 Remove shields.4 Measure the resistance of fan motor's winding.Measure the output voltage of fan's connector(FAN) on control board.WThe control board should be normal whena current of AC100V to 240V is detectedwhile fan motor is connected.5Check the operation of fan motor in outdoo<strong>ru</strong>nit.6~8Check operating condition of refrigerantcircuit.14Check pipe temperature with room temperaturedisplay on remote controller and outdoorcontrol board.In case of checking pipe temperaturewith outdoor control board, be sure toconnect A-control service tool(PAC-SK52ST).( )Temperature display of indoor liquid pipeIndoor 11 2 3 4 5 6ONOFFTemperature display of indoor liquid pipeIndoor 21 2 3 4 5 6ONOFFA-Control Service ToolTemperature display of indoor condenser/evaporator pipe Indoor 11 2 3 4 5 6ONOFFTemperature display of indoor condenser/evaporator pipe Indoor 21 2 3 4 5 6ONOFFSW2 setting23Check converse connection of extensionpipe or converse wiring of indoor/outdoo<strong>ru</strong>nit connecting wire.