Hydrotech Brochure - Barbour Product Search

Hydrotech Brochure - Barbour Product Search

Hydrotech Brochure - Barbour Product Search

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Maintaining a Flow of Informationwww.alumascwaterproofing.co.ukThe Alumasc waterproofing website provides a wealth ofinformation on all aspects of Flat Roofing, Waterproofing andGreen Roof systems and compatible products. Also included areFAQs, file downloads for NBS specification clauses, COSHHinformation, a CAD library, and much more.Technical SupportAlumasc Waterproofing Systems arebacked up by comprehensive technical literature and byhands-on project support starting with technical and design advice,and extending through site installation to recommendation of appropriate maintenance regimes.Implementation is led by the Alumasc Waterproofing Manager appointed to the project.2www.alumascwaterproofing.co.uk

ContentsIntroduction■ Alumasc 4■■■■■■Quality and Sustainability 5<strong>Hydrotech</strong> Structural Waterproofing Systems 6Key Benefits 8Typical Areas of Application 10<strong>Hydrotech</strong> Project Gallery 12<strong>Hydrotech</strong> Track Record 14Installation■Installation Procedure 15Specification■Protected Roofs 20■■■■■Plaza Decks or Podiums 21Green Roofs 22Substructures 24Water Features 25Access Roadways 26Components and Accessories■<strong>Hydrotech</strong> System Components and Accessories 28Complementary <strong>Product</strong>s and Systems■Thermal Insulation Systems for InvertedRoof Construction 29■■■■■ZinCo Green Roof Systems 30Harmer Flat Roof Outlets 32Harmer Raised Paving Support Systems 33Skyline Coping 34ROOF-PRO Roofing <strong>Product</strong>s 35Application Details■Scope of the Details 36■■Index of Application Details 37Application Details 38<strong>Product</strong> Data 52Alumasc Project Support 54Approved Contractors and Warranties 55Alumasc Technical Helpline +44 (0) 1744 6484003

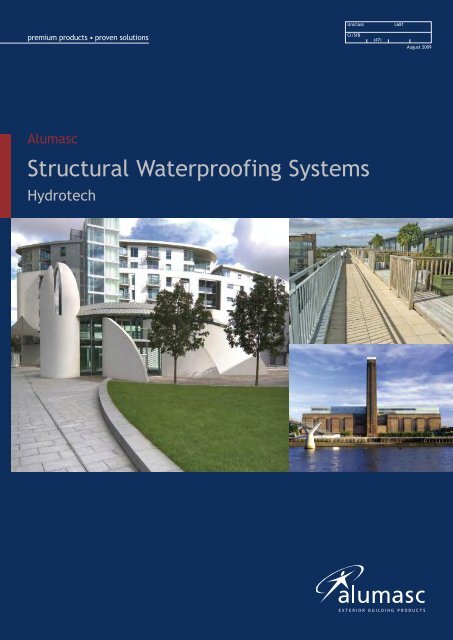

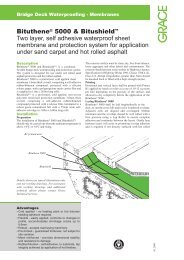

<strong>Hydrotech</strong> Structural Waterproofing Systems<strong>Hydrotech</strong> is the leading structural waterproofing system, successfully used for over 45 yearsby architects and specifiers on some of the world’s most prestigious buildings and structures.A unique formulation of modified bitumens, synthetic rubbers and antioxidants, combinedwith reinforcement ensures <strong>Hydrotech</strong> is a tough yet flexible, self-healing monolithicmembrane with guaranteed 100% bond to a properly prepared concrete substrate.<strong>Hydrotech</strong> System Summary<strong>Hydrotech</strong> is a 6mm thick, hot meltliquid applied solution with integralreinforcement and a fully bondedprotection sheet.The system consists of two coatsof <strong>Hydrotech</strong> Monolithic Membrane6125 (hot melt rubberised bitumen)incorporating Flex Flash F polyesterreinforcement fabric between bothlayers, and Hydrogard protectionsheet.Flex Flash UN, an uncured neoprenerubber sheet, is used to provide addedreinforcement and movement capabilityat cracks, construction joints, controljoints at changes of plane, expansionjoints, drains, and in exposed conditionssuch as flashing parapets, walls andcurbs.Application<strong>Hydrotech</strong>’s high performance bituminous rubberblend allows fast and simple installation overcomplex roof details and around penetrations.Specifications for a wide range of project typesare available, for use in the following typical areasof application:■ Protected roofs■ Plaza decks or podiums■ Substructures■ Green roofs■ Water features■ Access Roadways<strong>Hydrotech</strong> is the first choice for zero fallswaterproofing on inverted green roofs and hardlandscaped podium structures in new buildapplications.Approvals<strong>Hydrotech</strong>’s durability and performance is fullywarranted and is approved as follows:■ BBA Certificate 90/2431■ BBA Certificate 90/2432■ European Technical Approval 05/0152Tate Modern6www.alumascwaterproofing.co.uk

<strong>Hydrotech</strong> Structural Waterproofing Systems1Alumasc Bitumen Primer2A specially formulated, spray applied, bituminousprimer that increases the adhesion of <strong>Hydrotech</strong>Monolithic Membrane 6125 to concrete surfaces.<strong>Hydrotech</strong> Monolithic Membrane 61256A nominal 3mm thick first coat.53Flex Flash FA spun-bond polyester fabric, used asa reinforcement embedded into the<strong>Hydrotech</strong> membrane, for laying overgeneral areas and normal conditions.43245Flex Flash UNAn uncured neoprene rubber sheet, isused to provide added reinforcementand movement capability at cracks,construction joints, control joints atchanges of plane, expansion joints, drains,and in exposed conditions such as flashingparapets, walls and curbs as directed byAlumasc.<strong>Hydrotech</strong> Monolithic Membrane 6125A nominal 3mm thick second coat, fully encapsulating theFlex Flash reinforcement.16HydrogardA range of protection layers in different grades for use in protecting the <strong>Hydrotech</strong>membrane following installation.Hydrogard 40-AR Root Barrier is available to protect <strong>Hydrotech</strong> in green roofingapplications.135Spraying Alumasc Bitumen PrimerLaying Flex Flash FSpreading <strong>Hydrotech</strong> MonolithicMembrane 6125 (Second coat)2Spreading <strong>Hydrotech</strong> MonolithicMembrane 6125 (First coat)4Flex Flash UN6Laying Hydrogard Protection SheetAlumasc Technical Helpline +44 (0) 1744 6484007

Key Benefits<strong>Hydrotech</strong> is BBA accredited, fully warranted and is designed to last for the life of thebuilding. The system fully bonds to the structure avoiding any chance of water tracking,with no possibility of lap failure.Lifetime Performance<strong>Hydrotech</strong>, the original hot-melt, rubberised bitumen membrane, isdesigned to last for the lifetime of the building or structure to which itis applied, which means long-term waterproofing integrity and no futurereplacement costs.Low Lifecycle CostThe <strong>Hydrotech</strong> System’s proven longevity, durability, unique formulationand method of application make it the most cost effective, long-termwaterproofing solution.British Board of Agrément Approved<strong>Hydrotech</strong> is approved by the British Board of Agrément, who state“...when fully protected and subjected to normal service conditions,<strong>Hydrotech</strong> will provide an effective barrier to the transmission of liquidwater and water vapour for the design life of the structure/roof in whichit is incorporated”.European Technical Approval<strong>Hydrotech</strong> is the only 6mm hot melt rubberised bitumen waterproofingsystem to hold European Technical Approval, which confirms compliancewith the EC Construction <strong>Product</strong>s Directive.Fully Bonded Monolithic ApplicationApplied in a liquid state to the deck (with a polyester reinforcement),the bond of <strong>Hydrotech</strong> Monolithic Membrane 6125 is 100% absolute.There is no risk whatsoever of water tracking below the membraneand, because it is monolithic, no possibility of lap failure.No Fall RequiredCost savings will be made by the omission of screeds to falls and on thereduction of weight and curing time involved. The <strong>Hydrotech</strong> systemis unaffected by standing water, dilute acids and fertilizers, and doesnot leach.Recycled Content<strong>Hydrotech</strong> is a hot applied, rubberised bitumen. Specially formulatedfrom refined bitumen, synthetic rubber and inert clay filler, <strong>Hydrotech</strong>contains up to 25% post-consumer recycled content.Acid/Alkali Resistance<strong>Hydrotech</strong> is highly resistant to fertilisers, building washes and acid raindue to its inert clay content, unlike most other rubberised bitumenproducts which use various forms of inferior calcium carbonate filler.8www.alumascwaterproofing.co.uk

Key Benefits<strong>Hydrotech</strong>'s unique formulation of modified bitumen, synthetic rubbers and antioxidants,combined with reinforcement, guarantees lifetime performance whether it is used forprotected roofs, plaza decks, green roofs, water features or access roadways.100% Solids<strong>Hydrotech</strong> Monolithic Membrane 6125 contains no solvents. There is notwo part system to mix and therefore no on-site curing requirements andassociated limitations of use.Self Healing<strong>Hydrotech</strong> Monolithic Membrane 6125 will self heal minor damage whilstclean, dry and warm with limited pressure.Waterproofing Details Can Be Completed FirstBecause <strong>Hydrotech</strong> is a monolithic liquid applied system, plinths andupstands can be completed first so that other specialist subcontractorscan proceed quickly, shortening construction times. With the main deckarea remaining free of waterproofing, there is no need to provideexpensive protection. Once clear of site traffic, the deck areas arewaterproofed and the <strong>Hydrotech</strong> Monolithic Membrane 6125 is blendedinto the plinth and upstand details, forming a monolithic layer.The use of Flex Flash UN sheet reinforcement encapsulated between twocoats of <strong>Hydrotech</strong> Monolithic Membrane 6125 provides triple protectionfor flashings at upstands, plinths and minor movement joints.Low Temperature Flexibility<strong>Hydrotech</strong> Monolithic Membrane 6125 exhibits excellent low-temperatureflexibility and adhesion characteristics. It can be readily applied intemperatures down to -18ºC on a clean, dry, frost-free surface, andenables work to proceed during winter months, minimising lostconstruction time.It is not affected by rain, snow or frost immediately after its application.SubstratesA good bond will be obtained between <strong>Hydrotech</strong> Monolithic Membrane6125 and a range of substrates including precast concrete, concrete blockunits, WBP plywood, and detail work consisting of metal, plywood ortimber boarding.Note that <strong>Hydrotech</strong> Monolithic Membrane 6125 is not suitable for use overlightweight structural concrete without prior written approval from Alumasc.In addition, lightweight, insulating concrete is not a suitable substrate.Phased ConstructionPreviously applied material softens when reheated to form a completelymonolithic bond when lapped with new material, making the <strong>Hydrotech</strong>System perfect for phased construction.Alumasc Technical Helpline +44 (0) 1744 6484009

Typical Areas of Application1Protected Roofs (inverted - ballast/paving shown)(Inverted roofs, plant rooms, cradle runways, helipads, high impact areas)Ballast or paving slabs 1Harmer Modulock paving supports232MK separator sheetAlumasc Roofmate TF extruded polystyrene insulation346745Hydrogard 10<strong>Hydrotech</strong> Monolithic Membrane 612556Flex Flash F78<strong>Hydrotech</strong> Monolithic Membrane 612589Concrete deck, surface conditioned9Plaza Decks or Podiums(Pedestrian areas, balconies, walkways, entrance halls, stairways)211234Paving slabsSand/cement beddingHydrodrain 300Hydrogard 204536785<strong>Hydrotech</strong> Monolithic Membrane 61256Flex Flash F7<strong>Hydrotech</strong> Monolithic Membrane 61258Concrete deck, surface conditionedSubstructures (tanking shown)(Tanking, dpms, bund walls, drainage pits, pile caps)Concrete wall, surface conditioned1123465<strong>Hydrotech</strong> Monolithic Membrane 6125Flex Flash F<strong>Hydrotech</strong> Monolithic Membrane 6125Hydrogard 40-AR Root Barrier2345Hydrodrain 300 incorporating filter layer6Earth/backfill7710www.alumascwaterproofing.co.uk

Typical Areas of ApplicationGreen Roofs (inverted, intensive shown)(Lawns, recreation areas, planters, roof gardens, internal garden areas)2112TurfZincolit Intensive Soil3453Filter sheet SF4ZinCo Floradrain ®656MK separator sheetAlumasc Roofmate TF extruded polystyrene insulation109877Hydrogard 40-AR Root Barrier891011<strong>Hydrotech</strong> Monolithic Membrane 6125Flex Flash F<strong>Hydrotech</strong> Monolithic Membrane 6125Concrete deck, surface conditioned11Please refer to Alumasc ZinCo Green Roofing Systemsliterature for more comprehensive informationWater Features(Reflecting pools, cascades, swimming pools, cooling towers, fountains)1WaterTiles in waterproof screed122Hydrogard 2033<strong>Hydrotech</strong> Monolithic Membrane 61254456Flex Flash F<strong>Hydrotech</strong> Monolithic Membrane 612556Concrete deck, surface conditioned77Access Roadways(Access ramps, car parks, loading bays, vehicular access, bridges)2112MacadamSub-base34563Hydrogard 304<strong>Hydrotech</strong> Monolithic Membrane 61255Flex Flash F76<strong>Hydrotech</strong> Monolithic Membrane 61257Concrete deck, surface conditionedAlumasc Technical Helpline +44 (0) 1744 64840011

<strong>Hydrotech</strong> Project GalleryAlumasc’s fully warranted <strong>Hydrotech</strong> system offers fullybonded, seamless structural waterproofing solutions.Glaxo SmithKline HQ<strong>Hydrotech</strong> has a proven 45 year track record of meetingrequirements for waterproofing performance, lifeexpectancy and budget.RBS HQThe MailboxTate Modern201 Bishopsgate & The Broadgate TowerProject Listing ■ Glaxo SmithKline HQ, London ■ RBS HQ, Edinburgh ■ The Mailbox, Birmingham ■ Tate Modern, London ■ 201 Bishopsgate & The Broadgate Tower, London12www.alumascwaterproofing.co.uk

<strong>Hydrotech</strong> Project GalleryMBNA EuropeTabard SquareMuseum of ScotlandThe Petchey AcademyThe HeartProject Listing ■ MBNA Europe, Chester ■ Tabard Square, London ■ Museum of Scotland, Edinburgh ■ The Heart, Walton-on-Thames ■ The Petchey Academy, LondonAlumasc Technical Helpline +44 (0) 1744 64840013

<strong>Hydrotech</strong> Track RecordProject Date Size (m 2 ) Architect Main Contractor201 Bishopsgate & Broadgate Tower, London 2008 8,000 Skidmore Owings & Merrill Bovis Lend LeaseManchester Hospitals Pfi 2008 25,000 Dyer Associates Bovis Lend LeaseDowne Hospital, Downpatrick 2008 13,000 Scott Wilson McLaughlin & HarveyThe Petchey Academy, East London 2008 4,000 Aedas Norwest HolstOntario Tower, New Providence Wharf, London 2007 3,000 Skidmore Owings & Merrill BallymoreVictoria Square, Belfast 2007 25,000 BDP Belfast Farrans & Gilbert AshThe Heart, Walton-on-Thames 2006 14,000 E P R Architects Ltd O & H PropertiesFreeman Hospital, Newcastle 2006 7,500 Anshen Dyer Laing O'RourkeUrban Village Phase 4, London 2005 15,000 RMA Architects Miller HomesWoolwich Arsenal - Building 22 2005 5,000 Broadway Malyan Berkeley Homes Limited199 Knightsbridge, London 2004 4,500 Squire & Partners MultiplexMBNA Building, Phase 7, Chester 2004 5,000 Dyer Associates MACEPfizer Building 530, Kent 2003 3,000 HDR CUH2A Fluor DanielRoyal Artillery Quays & Gunnery Fields, London 2003 10,000 RMA Architects Barratt HomesJubilee Gardens/RT3, Canary Wharf, London 2002 22,000 BDP Canary Wharf ContractsHQ5 Canary Wharf, London 2002 10,000 Adamsons Canary Wharf ContractsNortel Networks, Harlow 2001 3,500 HOK International Wilmott DixonHSBC HQ, Canary Wharf, London 2000 4,000 Foster & Partners Canary Wharf ContractsMailbox, Birmingham 2000 14,000 Weedon Partnership CarillionPrince Regent Gate, London 2000 15,000 CHBC Architects Barratt HomesGlaxoSmithKline HQ, London 2000 10,000 RHWL, London MACETate Modern, London 1999 9,000 Herzog de Meuron Schal InternationalC A Computers HQ, Slough 1998 9,000 Blair Eastwick John Mowlem ConstructionBritish Airways Combined Operations Centre 1996 35,000 RHWL, London MACEDTI, London 1995 3,500 GEGW, London MACETerminal 1, Heathrow Airport 1994 20,000 Richard Rogers Partnership Bovis Construction ManagementBarclays Bank HQ, London 1993 3,500 G M W Partnership CostainIntegra Hotel Arts, Barcelona 1992 30,000 Skidmore, Owings & Merrill Bovis Construction ManagementLombard Street, London 1991 2,500 G M W Partnership CostainCentre West, London 1990 3,250 E P R Architects Ltd WimpeyCanary Wharf, London 1989 24,000 Adamson Associates Bovis Construction ManagementBroadgate Development, London 1988 30,000 Skidmore, Owings & Merrill Bovis SchalBarbican Fitness Centre, London 1987 1,200 Whinney Mackay-Lewis Wates14www.alumascwaterproofing.co.uk

Installation ProcedureSubstrate RequirementsLightweight Structural ConcreteWhen installing a lightweight structuralconcrete slab, upon which it is intendedto install <strong>Hydrotech</strong>, it is most importantto ensure that the contractor provides asuitable, wood float finish free of laitanceand free of all but minor surface defects.ScreedsWhen installing a screed system toprovide falls to a flat structural slab,upon which it is intended to install<strong>Hydrotech</strong>, it is critical for the contractorto ensure that the screed mix is of thecorrect density and not overly wettedduring the course of installation.When preparing a layout for a screedscheme it is imperative that the falls arefully mitred to all outlets and that thereare no steps in the screed surface. Alloutlets must be set flush with the topsurface of the screed.<strong>Hydrotech</strong> waterproofing must not bedressed down a vertical screed surfaceand onto the horizontal concrete slab.General PreparationSubstrate SurfacesTo ensure the successful performanceof the <strong>Hydrotech</strong> system, it is veryimportant to prepare the substratecorrectly.1. Surfaces are cleaned of allcontaminants such as un-approvedcuring compounds, form releaseagents, oils, dirt, etc.2. Alumasc Bitumen Primer is sprayapplied to the cleaned surface andleft to thoroughly dry.<strong>Hydrotech</strong> MembraneBefore <strong>Hydrotech</strong> Monolithic Membrane6125 can be applied, whether for formingdetailed work or applying to the mainhorizontal roof areas, the material mustfirst be melted. It is then further heatedto the required temperature and mixedto develop its full physical properties.The rubber content of the membranemakes it necessary to use indirect heat asobtained with an oil or air type doublejacketedmelter.The Correct Sequence ofWork StagesOf equal importance are the correctsequence of work stages during theinstallation of <strong>Hydrotech</strong> MonolithicMembrane 6125 and other componentsof the <strong>Hydrotech</strong> system to ensure awatertight finish.■ Detail Work (Stage 1)Upstand details are completed first,before the waterproof membrane isapplied to the main horizontal roofarea. The steps taken to formupstands are shown on page 17 and18.Flex Flash UN is used as reinforcementwhere minor movement in detailedwork is anticipated.■ Main Horizontal Areas (Stage 2)The waterproof membrane completewith integral reinforcement, is thenapplied to horizontal main roof areas,merging with the previouslycompleted detailed work to form amonolithic watertight barrier. Thesteps to be taken are shown on page19 and 20.Alumasc Technical Helpline +44 (0) 1744 64840015

Installation ProcedureFlex Flash F DetailReinforcementDetailed reinforcement work consists of asandwich of:■ <strong>Hydrotech</strong> 6125■ Flex Flash F reinforcement■ <strong>Hydrotech</strong> 6125■ Hydrogard protection sheetThe steps taken to form reinforcedexternal and internal corners forupstands in Flex Flash F, are illustratedon this page.Reinforcement at External Corner of UpstandStep AFlex Flash FreinforcementStep BFlex Flash Freinforcement<strong>Hydrotech</strong>Monolithic Membrane 6125<strong>Hydrotech</strong>Monolithic Membrane 6125Step CCompletely encapsulate exposed reinforcement by applying a top coat of <strong>Hydrotech</strong> Monolithic Membrane6125, and finally cover with Hydrogard protection sheet.Reinforcement at Internal Corner of UpstandStep AFlex Flash F reinforcement(cut and folded to formdouble layer at stop end)Step BOverlapping Flex Flash F reinforcement(cut and folded to form double layer at stop end)<strong>Hydrotech</strong> MonolithicMembrane 6125Step C<strong>Hydrotech</strong> MonolithicMembrane 6125Completely encapsulate exposed reinforcement by applying a top coat of <strong>Hydrotech</strong> Monolithic Membrane6125, and finally cover with Hydrogard protection sheet.16www.alumascwaterproofing.co.uk

Installation ProcedureFlex Flash UN DetailReinforcementWhere minor movement is anticipated,Flex Flash UN, an uncured neoprenewith a peel-off protective outer film,must be employed.Detailed reinforcement work consists ofa sandwich of:Reinforcement at External Corner of UpstandStep ARemove outer film at end only. Whilst the membrane isstill warm the Flex Flash UN is stretched around thecorner and moulded tightly into the angles, leaving noairspaces. The Flex Flash UN will permanently cure intothis shape upon cooling.50mmminStep BRemove outer film from preceding piece and fromend of new piece. The overlapping Flex Flash UN isapplied as per step A, with a minimum overlap of50mm. Remove outer film when cool.50mmmin■ <strong>Hydrotech</strong> 6125■ Flex Flash UN reinforcement■ <strong>Hydrotech</strong> 6125■ Hydrogard protection sheet.The steps taken to form reinforcedexternal and internal corners forupstands in Flex Flash UN, areillustrated on this page.Outer film<strong>Hydrotech</strong>Monolithic Membrane 6125Flex Flash UNreinforcement<strong>Hydrotech</strong>Monolithic Membrane 6125Flex Flash UNreinforcementReinforcement at Internal Corner of UpstandStep AWhilst the membrane is still warm, the Flex FlashUN is manoeuvred into the corner with the excessmaterial pinched into the vertical corner.Outer filmpeeled backFlex Flash UNreinforcementStep BA small amount of membrane is applied inside theexcess loop, the sides of which will then sticktogether when pressure is applied.Flex Flash UNreinforcementStep CWait for membrane to cool and remove outer film.Flex Flash UNreinforcement<strong>Hydrotech</strong>Monolithic Membrane 6125Step DThe excess material flap is then adhered to oneside with a small amount of membrane.<strong>Hydrotech</strong>Monolithic Membrane 6125Step EThe next piece of membrane is dressed into thecorner, but not around it. Wait for membrane tocool and remove outer film.Outer filmNotes■ Always pull back 25mm or so from a cornerof the peel off separator film prior toinstallation, for ease of removal after cooling.Flex Flash UNreinforcementFlex Flash UNreinforcementFlex Flash UNreinforcement■ As the final step in the formation of theexternal and internal upstands, completelyencapsulate exposed reinforcement byapplying a top coat of <strong>Hydrotech</strong> MonolithicMembrane 6125, and finally cover withHydrogard protection sheet.<strong>Hydrotech</strong>Monolithic Membrane 6125Alumasc Technical Helpline +44 (0) 1744 64840017

Installation Procedure<strong>Hydrotech</strong> MonolithicMembrane 6125 to MainHorizontal AreasAfter the details have been completed,<strong>Hydrotech</strong> Monolithic Membrane 6125 isthen applied to the main roof areas usinga squeegee.1. The first coat of <strong>Hydrotech</strong> MonolithicMembrane 6125 is applied to a nominalthickness of 3mm.2. Flex Flash F fabric reinforcement isembedded while the <strong>Hydrotech</strong> isstill warm and tacky.3. A second coat of <strong>Hydrotech</strong> MonolithicMembrane 6125 is applied also to anominal thickness of 3mm, fullyencapsulating the fabric reinforcementwithin the membrane.4. A protecting sheet of Hydrogard islaid over the completed <strong>Hydrotech</strong>membrane. The grade of Hydrogardis chosen to match the anticipatedintensity of subsequent operations.Refer also to <strong>Hydrotech</strong> SystemComponents and Accessories,page 28.5. Install the chosen roof finish.In the diagram on page 19, an invertedroof construction is shown completewith insulation, filter sheet, andpaving slabs using Harmer Modulockraised paving supports.1. Applying the first coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 with asqueegee2. Laying Flex Flash F reinforcement3. Applying the second coat of <strong>Hydrotech</strong>Monolithic Membrane 61254. Laying the Hydrogard protection layerover second coat of <strong>Hydrotech</strong>Monolithic Membrane 612518www.alumascwaterproofing.co.uk

Installation Procedure<strong>Hydrotech</strong> MonolithicMembrane 6125 to MainHorizontal AreasMain Roof Areas1 Substrate23456789Alumasc Bitumen PrimerFirst coat of <strong>Hydrotech</strong> Monolithic Membrane 6125Flex Flash F reinforcementSecond coat of <strong>Hydrotech</strong> Monolithic Membrane 6125Hydrogard protection sheetExtruded polystyrene insulationMK separator sheetPaving slabs on supports (Harmer Modulock shown)987652431Alumasc Technical Helpline +44 (0) 1744 64840019

Specification - Protected Roofs (inverted - ballast or paving)Inverted Roofs, Plant Rooms, Cradle Runways, Helipads,and High Impact Areas on a Concrete DeckPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.Install a layer of Hydrogard 10 brushrolled into the final coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 with 75mmlaps.DetailingWhere minor movement or change in leveldirection or dissimilar materials occur, thereinforcement is to be Flex Flash UN,overlap to Flex Flash F, 75mm.All detail work to be a minimum of150mm from finished roof, includingsurfacing.Please note that entry of water over anydetail work of less than 150mm in height,(above the finished roof surface, includingpaving/ballast etc.) would not be coveredunder the terms and conditions of thewarranty.Thermal InsulationSupply and lay on to the completed roofwaterproofing, Alumasc Roofmate TFextruded polystyrene insulation ofsufficient thickness to meet the “U” valuerequirement for the structure. InstallMK separator sheet and either ballast,comprising 20-40mm river washed ballast,or paving slabs on Harmer Deck Modulockadjustable paving supports, the loading tobe sufficient to prevent wind uplift andflotation.General NotesThe contractor is to install all details tocomply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.On completion the integrity of thewaterproofing must be tested by meansof an electronic detector system to provethat the waterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.It is assumed that the building owner orhis advisors have satisfied themselvesthat the roof structure and deck aresuitable to receive the dead load bothduring construction and on completion ofthe works.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.20www.alumascwaterproofing.co.uk

Specification - Plaza Decks or PodiumsPedestrian Areas, Balconies, Walkways, Entrance Halls,and StairwaysPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.Install a layer of Hydrogard 10 brushrolled into the final coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 with 75mmlaps.DetailingWhere minor movement or change in leveldirection or dissimilar materials occur, thereinforcement is to be Flex Flash UN,overlap to Flex Flash F, 75mm.All detail work to be a minimum of150mm from finished roof, includingsurfacing.Please note that entry of water over anydetail work of less than 150mm in height,(above the finished roof surface, includingpaving/ballast etc.) would not be coveredunder the terms and conditions of thewarranty.Thermal InsulationSupply and lay on to the completed roofwaterproofing, Alumasc Roofmate TFextruded polystyrene insulation ofsufficient thickness to meet the “U” valuerequirement for the structure. InstallMK separator sheet and either ballast,comprising 20-40mm river washed ballast,or paving slabs on Harmer Deck Modulockadjustable paving supports, the loading tobe sufficient to prevent wind uplift andflotation.General NotesThe contractor is to install all details tocomply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.On completion the integrity of thewaterproofing must be tested by meansof an electronic detector system to provethat the waterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.It is assumed that the building owner orhis advisors have satisfied themselvesthat the roof structure and deck aresuitable to receive the dead load bothduring construction and on completion ofthe works.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.Alumasc Technical Helpline +44 (0) 1744 64840021

Specification - Green RoofsLawns, Recreation Areas, Planters, Roof Gardens andInternal Garden AreasPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Note:The structural deck is to be designed to aminimum 1:60 falls to ensure an actualminimum 1:80 is achieved after allowingfor building tolerances, deflection andsettlement on site.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.Install a layer of Hydrogard 40-AR RootBarrier brush rolled into the final coat of<strong>Hydrotech</strong> Monolithic Membrane 6125with torch welded laps.Detailing of ReinforcementWhere minor movement or change in leveldirection or dissimilar materials occur, thereinforcement is to be Flex Flash UN,lapped 75mm over Flex Flash F.All detail work to be a minimum of150mm from finished roof, includingsurfacing.Please note that entry of water over anydetail work of less than 150mm in height,(above the finished roof surface, includingpaving/ballast etc.) would not be coveredunder the terms and conditions of thewarranty.Thermal InsulationSupply and lay on to the completed roofwaterproofing Alumasc Roofmate TFextruded polystyrene insulation ofsufficient thickness to meet the U valuerequirement for the structure, plus MKseparator sheet. The loading to beimposed by the green roof system to beengineered to be sufficient to ballastagainst flotation and wind uplift.Drainage LayerSupply and lay appropriate Alumasc/ZinCo drainage layer over the insulation.The drainage sheets are to be overlappedand fixed in accordance with Alumasc’sinstructions. The drainage units can becut to fit around roof protrusions with aheavy duty knifeor small toothed saw.Filter SheetSupply and lay Filter Sheet SF overthe drainage layer. Laps to be 150mm.The Filter Sheet must be taken up allprotrusions and upstands to at leastsoil level.22www.alumascwaterproofing.co.uk

Specification - Green RoofsSubstrate LayerSupply and lay ZinCo Roof GardenSubstrate to a minimum depth of150mm, over the filter sheet.PlantingSupply and lay turf as selected by theclient or their advisors, loose laid ontothe Roof Garden Substrate, close buttedand staggered. The turf to have aminimum thickness of 20mm.An approved organic slow releasefertiliser must be sprinkled over the turfat the rate specified by the manufacturers.The Roof Garden Substrate and turf mustbe thoroughly watered to encourageimmediate growth. The system must notbe allowed to dry out within the first 4weeks of installation of the turf. Furtherirrigation after this period will be aprerequisite to maintaining a healthyand vigorous grassed surface.AccessoriesSupply and install an outlet inspectionchamber over each outlet within the softlandscape area. The drainage layershould be close butted to the base of theinspection chamber. The filter sheetshould be dressed up all sides of theinspection chamber to substrate level.Detailing of Vegetation BarriersProvision should be made to install andform a barrier between the vegetationand all vulnerable roof details, i.e. atupstands, outlets, rooflights, vent pipesetc. The barrier must be a minimum of300mm wide, and can take the form oflarge rounded pebbles 16mm to 32mmgrade, paving slabs, decorative bricksetc.The waterproofing should be taken up allupstands, protrusions etc., a minimum of150mm above substrate level.General NotesThe following are vital to the accuratepricing, correct installation, andultimately the long-term life of a greenroof, and must therefore be includedwithin the specification and tenderdocuments.The installation of an Alumasc ZinCoGreen Roof will only be carried out by acontractor approved by Alumasc. Theworkmanship of the contractor is to beregularly checked during the contracteither by Alumasc personnel or personsapproved by Alumasc.On completion of the membrane andbefore the landscape is installed, theintegrity of the waterproofing must betested by means of an electronicdetector system to prove that thewaterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.It is assumed that the building owner orhis advisors have satisfied themselvesthat the roof structure and deck aresuitable to receive the dead load of theproposed green roof system andlandscape both during construction andon completion of the works.Provision should be made to estimate thenumber of site visits required of thegreen roof contractor to enable them tocomplete the contract. The number ofvisits estimated should be entered intothe tender documents in order tofacilitate accurate pricing.A planned or contractual delay betweenthe installation of the waterproofingand landscape will almost certainlynecessitate additional/increasedprotection to the waterproofing.This protection may be temporary orpermanent. The responsibility for the costof this possible extra protection should beclearly included within the tenderdocuments.It is essential to the long-term life ofintensive landscapes that some form ofirrigation system is provided, preferablyon an automatic basis.Although extensive landscapes aredesigned to withstand droughtconditions, it is advisable to allow for awater point to be installed in case ofextreme conditions.Correct detailing and their constructionare essential to the long-term life of thegreen roof. Therefore, detail drawingsillustrating their construction must beincluded in the tender documents inorder to enable the contractor to tenderaccurately.The waterproofing and protection layersmust always be mechanically fixed with atermination bar, placed at the top of theflashing detail. The termination bar mustbe fixed with the appropriate fixings at300mm centres, bedded in non-settingmastic.The contractor is to install all details tocomply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.Alumasc Technical Helpline +44 (0) 1744 64840023

Specification - SubstructuresTanking, Damp Proof Membranes, Bund Walls,Drainage Pits and Pile CapsPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.Install a layer of Hydrogard 40-AR RootBarrier, brush rolled into the final coatof <strong>Hydrotech</strong> Monolithic Membrane 6125with torch welded laps. Prior tobackfilling, install Hydrodrain 300drainage layer, looselaid over theprotection layer with 100mm overlappingfabric selvedge. All to be overlapped ontothe horizontal waterproofing by aminimum of 150mm.DetailingWhere minor movement or change inlevel direction or dissimilar materialsoccur, the reinforcement is to beFlex Flash UN, lapped 75mm overFlex Flash F.General NotesThe contractor is to install all details tocomply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.On completion the integrity of thewaterproofing must be tested by meansof an electronic detector system to provethat the waterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.Where the height of the vertical workexceeds 1000mm, mechanical retentionwith continuous termination bar fixed at150mm centres is required.24www.alumascwaterproofing.co.uk

Specification - Water FeaturesReflecting Pools, Cascades, Swimming Pools,Cooling Towers and FountainsPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.General NotesThe contractor is to install all details tocomply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.On completion the integrity of thewaterproofing must be tested by meansof an electronic detector system to provethat the waterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.Install a layer of Hydrogard 20 brushrolled into the final coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 with 75mmlaps.SurfacingSupply and install onto the Hydrogardprotection layer a waterproofscreed/adhesive and decorative tilesurface as specified elsewhere by theclient’s representative.DetailingWhere minor movement or change in leveldirection or dissimilar materials occur, thereinforcement is to be Flex Flash UN,lapped 75mm over Flex Flash F.Alumasc Technical Helpline +44 (0) 1744 64840025

Specification - Access RoadwaysAccess Ramps, Car Parks, Loading Bays andVehicular Access AreasPreparationIn situ structural concrete surface to befinished with wood float (not steel trowelor power floated). Concrete density 2160kg/m 3 to 2563 kg/m 3 cured for 28 days.Surface must be dry and clean of allcontaminants. All loose dirt or debris tobe brushed and blown clear using dry airor industrial vacuum machine.Prime concrete with Alumasc BitumenPrimer using hand held air sprayer at arate of 8-16m 2 per litre and allow to drycompletely. Do not prime metal or timbersurfaces.WaterproofingHeat blocks of <strong>Hydrotech</strong> MonolithicMembrane 6125 in an oil or air jacketedmelter to 205ºC and apply to substrate ata rate of circa 3mm thick spreading witha squeegee.Apply reinforcement of Flexflash Fpolyester in roll form and brush into<strong>Hydrotech</strong> Monolithic Membrane 6125ensuring no air pockets.Apply a second coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 at a rate of3mm thick spreading with a squeegeewhile hot, ensuring no air pockets.Install a layer of Hydrogard 30 brushrolled into the final coat of <strong>Hydrotech</strong>Monolithic Membrane 6125 with 75mmlaps.Notes:Care is to be taken to ensure that thereis no Hydrogard 6125 membrane adheringto the top surface of the Hydrogard 30protection layer, either in the field area,at the laps or at detail items. Any traceof <strong>Hydrotech</strong> 6125 membrane found is tobe carefully removed or covered overwith a fresh piece of Hydrogard 30protection layer prior to the installationof the wearing course, sub-base andfinish.PavingSupply and install an asphalt/macadamsub-base and wearing course as specifiedelsewhere by the client’s representative.DetailingWhere minor movement or change in leveldirection or dissimilar materials occur, thereinforcement is to be Flex Flash UN,lapped 75mm over Flex Flash F.All detail work to be a minimum of150mm from finished surface, includingsurfacing.Please note that entry of water overany detail work of less than 150mm inheight, (above the finished roof surface,including paving/ballast etc.) would notbe covered under the terms andconditions of the warranty.General NotesThe contractor is to install all detailsto comply with the <strong>Hydrotech</strong> QualityAssurance Manual for <strong>Hydrotech</strong> hot-meltmembrane systems. Should any detailarise where it is not clear that this canbe achieved, the contractor is to seekadvice and approval for all fabricationproposals from Alumasc beforecompleting the works.On completion the integrity of thewaterproofing must be tested by meansof an electronic detector system to provethat the waterproofing is 100% free frompunctures and defects. The issue of the<strong>Hydrotech</strong> warranty is conditional uponthe provision of a leak test certificate.The waterproofing contractor shouldinclude a sum for such a test within hisquotation.The above specification shall be installedin accordance with the manufacturers’installation instructions. Alumasc fixinginstructions shall be followed for productsupplied by the company. The works shallbe installed by an Alumasc <strong>Hydrotech</strong>Approved Contractor, and the <strong>Hydrotech</strong>Warranty shall be issued uponcompletion.26www.alumascwaterproofing.co.uk

Components, Accessories and Complementary <strong>Product</strong>sAlumasc Technical Helpline +44 (0) 1744 64840027

<strong>Hydrotech</strong> System Components and AccessoriesAlumasc Bitumen PrimerA specially formulated spray appliedbituminous primer that enhances theadhesion of <strong>Hydrotech</strong> MonolithicMembrane 6125 to concrete surfaces.<strong>Hydrotech</strong> MonolithicMembrane 6125A hot rubberised bitumen, modifiedwith styrene resins, natural rubbers,oils, fillers and antioxidants. Used forthe main areas to be waterproofed,including upstands.Flex Flash FAlumasc Bitumen PrimerA spun-bonded polyester fabric,designed as reinforcement to the<strong>Hydrotech</strong> Monolithic Membrane 6125.For use over general areas and innormal conditions. Can accommodatestructural and shrinkage cracks up to6mm wide.Hydrogard ProtectionSheetsA range of protection sheets used toprotect <strong>Hydrotech</strong> Monolithic Membrane6125 and <strong>Hydrotech</strong> Liquid Membrane6090 following installation. There arefour standard grades:Hydrogard 10Lightweight oxidised bitumen glass fibrereinforced sheet for use where thesubsequent build up is being installedimmediately.Hydrogard 20Polyester reinforced modified bitumensheet suitable for use where normal siteconditions apply (i.e. some followingtrades but no abnormally heavy trafficanticipated).Hydrogard 30Heavy duty dual reinforced modifiedbitumen sheet suitable for use whereabnormally heavy traffic is expectedprior to application of topping.Hydrogard 40-ARA root resistant dual reinforced modifiedbitumen sheet incorporating rootrepellent, suitable for use under greenroof applications.HydrodrainA range of drainage layers each comprisinga HDPE drainage core and a filter fabricthat prevents clogging of the core. Usedwherever subsurface drainage is required,and ideal below planters, plaza decks, andagainst exterior vertical foundations.There are two standard grades:Hydrodrain 200Filter fabric bonded to one side of HDPEcore, and suitable for areas subject tonormal loading and traffic.Hydrodrain 300As Hydrodrain 200, but for areas subjectto heavy loading and traffic.Other grade specifications are availableto order.Flex Flash FFlex Flash UNA flashing reinforcement of uncuredneoprene rubber, used at expansionjoints and as a transition across thejunction of dissimilar materials.<strong>Hydrotech</strong> LiquidMembrane 6090A cold-applied alternative for <strong>Hydrotech</strong>Monolithic Membrane 6125, used mainlyfor localised repair work and pitch pockets.A two-part system comprising a basecomponent and an activator component,mixed together prior to application. Availablein horizontal and vertical grades.Flex Flash UN<strong>Hydrotech</strong> Liquid Membrane 609028www.alumascwaterproofing.co.uk

Complementary <strong>Product</strong>s and SystemsThermal Insulation Systems forInverted Roof ConstructionThere are various options for inverted roof construction.Alumasc Roofmate TF-XAn HFC blown CFC/HCFC-free extrudedpolystyrene board with shiplap edgeprofiles and a thermal conductivity of0.029 - 0.031 W/mºC.The calculated thickness of insulation toachieve any specific insulation value isincreased proportionally to take accountof the rainwater cooling effect.Sufficient ballast must be employed(eg, paviours on paving supports, roundwashed stone, green roof build-up) tocounteract the forces of wind uplift andflotation.An MK separator sheet should alwaysbe installed over the insulation prior toinstallation of the paviours or ballast,with 300mm laps.Alumasc Roofmate MKA water vapour permeable, spun bondedpolyethylene separator sheet based uponTyvek ® , loose laid over the insulationat right angles to the roof slope with300mm laps, reduces the cooling effecton the insulation to a minimal 2% bypreventing the rainwater from reachingthe waterproof layer. Its use minimisesthe thickness of insulation required ineach case, and is designed for use withAlumasc Roofmate TF-A and TF-X .The Roofmate MK should be extended tofinish at least flush with the surface ofthe ballast.Alumasc Roofmate TF-AA completely environmentally friendlyoption, Alumasc Roofmate TF-A is aCO 2 blown CFC/HCFC-free extrudedpolystyrene board, with shiplap edgeprofiles and a thermal conductivity of0.036 W/mºC (up to and including130mm) and 0.038 W/mºC (greaterthan 120mm).The calculated thickness of insulation toachieve any specific insulation value isincreased proportionally to take accountof the rainwater cooling effect.Sufficient ballast must be employed(eg, paviours on paving supports, roundwashed stone, green roof build-up) tocounteract the forces of wind uplift andflotation.An MK separator sheet should alwaysbe installed over the insulation prior toinstallation of the paviours or ballastwith 300mm laps.BREEAM RatingsAlumasc Roofmate TF-A and TF-LG-Aare CO 2 blown products with a GWPof 1, which qualify for additionalcredits under the BREEAM ratingsystem, which rewards productswith a GWP of less than 5.Alumasc Roofmate TF-LG-XAn HFC blown CFC/ HCFC-freecementitious topped extrudedpolystyrene board with shiplap endsand tongued and grooved sides, and athermal conductivity of 0.029 - 0.031W/mºC.Alumasc Roofmate TF-LG-AA CO 2 blown alternativecementitious topped board forminimal environmental impact.The calculated thickness of insulation toachieve any specific insulation value isincreased proportionally to take accountof the rainwater cooling effect.This product provides a lightweightsolution to inverted roofing systems inlow wind uplift locations, and can also beemployed in exposed situations such asupstands as a self protected insulationboard, in conjunction with AlumascRoofmate TF-X or TF-A on the horizontalareas.Alumasc Technical Services must becontacted in every instance in order toascertain the suitability of the proposedspecification.Alumasc Technical Helpline +44 (0) 1744 64840029

Complementary <strong>Product</strong>s and SystemsZinCo Green Roof SystemsA range of products and systems forlandscaped roofs that use <strong>Hydrotech</strong>structural waterproofing.ZinCo Green Roofs offer three alternativeplanting regimes :1. Extensive green roof:Using hardy plants for lowmaintenance and where general roofaccess is not required.2. Semi-intensive green roof:Provides all year round colour withminimal maintenance.3. Intensive green roof:Using vegetation ranging from grass tosemi-mature trees, and mainly forrecreational activities, and requiringnormal garden maintenance.The products and systems include:Lightweight SubstratesPlant growing mediums, available inseveral varieties, including:ZinCo ‘Sedum Carpet’ SubstrateRecycled crushed brick with fines, for‘extensive planting’ZinCo ‘Heather with Lavender’ SubstrateA mixture of crushed brick and compostfor ‘semi-intensive’ planting.ZinCo ‘Roof Garden’ SubstrateA mixture of crushed brick, compost andsandy loam, suitable for use on intensiveroofs.Filter SheetsFor preventing particles of substrateand other matter from entering thedrainage layer. Available in rolls astwo product variants:Filter Sheet TGA loose laid filter sheet specifically foruse over Elastodrain EL 200 and EL 202.Filter Sheet SFA loose laid filter sheet for generalpurpose use with Floradrain ® ,Floratherm ® and Floraset, whererequired.Drainage LayersThese continuous layers allow waterto drain unimpeded from any type oflandscape, with some systems retainingwater for plant use. There are fivesystems:1. Floradrain ®Used for unimpeded drainage and alsowater retention for plants. Available asthree product variants:Floradrain ® FD 25 E25mm deep polyethylene sheet or rollfor shallow 80-100mm soil depths onextensive roofs to falls of at least 1:60.Floradrain ® FD 40 E40mm deep polyethylene sheet or rollfor roofs with or without falls, forcomplex extensive or semi-intensivelandscaping.Floradrain ® FD 6060mm high profiled polythene board forintensive green roofs with or withoutfalls, which may incorporate high loadsand dwarf walls. Can be used aspermanent shuttering for furtherconstructions or vehicle surfaces.2. Stabilodrain SD 30A heavy duty extremely stable andtraffickable drainage and water storageelement made of thermoformedpolystyrene for use over underground carpark decks under vegetation, walkwaysand driveways.3. FlorasetAn expanded polystyrene board, looselaid, for draining landscaped pitchedroofs. Available in three grades: FS 50,FS 75, and ultra lightweight FS 100 forup to 25º.4. Elastodrain/ProtectodrainA rubber mat with large studs on one side,loose laid over a slip sheet, for use undervehicular and pedestrian paving, and largeirrigated intensive roofs. Available inthree grades: EL 200, EL 202 andProtectodrain PD 250.5. DBV12 Drainage MatA 12mm polyethylene/polypropylene roll,loose laid, and used for protection againstfoundation walls or as a protection matwith additional drainage.Root BarriersUsed for preventing root damage tothe waterproof membrane. Available astwo product variants:WSF 40Polyethylene sheet, loose laid.Hydrogard 40-ARPolyester reinforced modified bitumenincorporating root repellent, rolled into<strong>Hydrotech</strong>, or torch applied to suitableunderlayer.Anti-Erosion NetFor binding new soil surfaces on slopingareas greater than 15º. Available as:JEG Anti-Erosion NetHeavy, wide mesh jute fibre sheet, 100%bio-degradable, and secured with woodenpegs.Moisture Retention andProtection Mats (uninsulatedareas only)For protecting the waterproof membranewhilst retaining moisture and nutrients.Available as three product variants:BSM 64A loose laid polypropylene fibre mat witha needlepunched carrier, in rolls.SSM 45A loose laid fibre mat with apolypropylene carrier, in rolls.Iso-mat ISM 50A loose laid fibre mat combined withpolypropylene and rubber, in rolls,reinforced for spade resistance.30www.alumascwaterproofing.co.uk

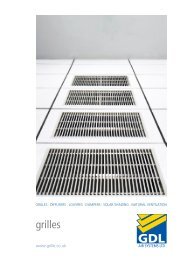

Complementary <strong>Product</strong>s and SystemsTerrace GrillsFor use over outlets in paved areas.Placed over Floradrain ® layer andadjusted to level of paving. Availablein three sizes, in steel or aluminium.Terrace Linear GratingsA range of adjustable gratings for lineardrainage channels. Contact Alumasc forfull details.Roof Edge ProfileA range of edge profiles to retainsubstrate or paving, in either aluminium(80 or 120mm deep profile) or stainlesssteel (80, 120 or 140mm). Jointing insertsalso available to maintain alignment.Roof DamFor fixing over roof outlets to retainwater on roof. Available in copper.Outlet Inspection ChambersProvide access to outlets in plantedareas. Chambers have variable heightsto suit substrate depths from 50mm to500mm. There are seven types ofinspection chamber:KS 5Plastic coated steel(for 50mm substrate).KS 8Plastic coated steel(for 80mm substrate).KS 12Plastic coated steel(for 120mm substrate).KS 15Polystyrene (for 150mm substrate).KS 25Polystyrene (for 250mm substrate).KS 30Polyethylene (for 300mm substrate).Also available in stainless steel.KS 52Polyethylene (for 500mm substrate).Note: Extension pieces are available forall inspection chambers.Terrace GrillRoof DamOutlet Inspection ChamberChannel DrainChannel DrainsFor collecting water from downpipesand at abutments with falls and otherfeatures. Channel Drains comprise aremovable grill set in a U-frame casingperforated along its base length. Madefrom stainless steel or galvanised steel,the latter available in variable lengths.KerbsConcrete L-shaped kerbs for retainingsubstrate at junctions with paved areasand changes in level or materials.Complete with internal and externalcorners.Automatic Irrigation UnitsAutomated water top up mechanisms formaintaining predetermined water levelson roofs without falls, and available astwo product variants:Type B 32Can be situated in any roof position,except directly over outlets.Type B 52Can be situated in any roof position,primarily directly over outlets.KerbPlease refer to Alumasc ZinCo Green Roofing Systemsliterature for more comprehensive informationAlumasc Technical Helpline +44 (0) 1744 64840031

Complementary <strong>Product</strong>s and SystemsHarmer Flat Roof Rainwater OutletsHarmer Roof metal and insulated rainwater outlets, offer comprehensive and innovativedrainage solutions for all types of flat roof, including those carrying vehicular traffic. AllHarmer Roof metal and insulated rainwater outlets are designed and manufactured toensure trouble free performance over a long period, in whatever type of roofconstruction they are incorporated.For detailed information on these systems, please contact Alumasc Technical Services.AV Vertical Spigot or Screw Outlets■ Harmer Roof AV Vertical Spigot andScrew outlets provide anti-vortexperformance within an economicrange of general purpose outlets■ Diecast in LM6 aluminium silicon alloyto BS 1490: 1988■ AV outlets are designed for connectionto individual downpipes and must notbe used in siphonic rainwater systemsAV Retro-Gulley Outlets■ Harmer Roof AV Retro-Gulley outletsincorporate anti-vortex performanceand are designed for flat roofupgrading without necessitatingremoval of the old rainwater outlet■ The body is diecast in LM6 aluminiumsilicon alloy to BS 1490: 1988■ The Retro-Gulley aluminium tail pipeconnects directly into the existingpipework via the old outletAV Multi-Gulley Outlets■ Harmer Roof AV Multi-Gulley outletsincorporate an adjustable spigot thatcan be rotated to suit any angle ofoutflow from horizontal to vertical■ Interchangeable spigots provide for75mm or 100mm pipe connections■ Bodies and spigots are diecast in LM6aluminium silicon alloy to BS 1490:1988Detail Outlets■ Harmer Roof Detail outletscomprise a range designed to solveproblematic detailing requirements■ The range includes two way, balcony,car park and gulley outlets■ Detail outlets are diecast in LM6aluminium silicon alloy to BS 1490: 1988Accessories■ There is also a comprehensive rangeof accessories available to ensure thesuccessful installation of Harmer Roofrainwater outlets in most types ofroof construction32www.alumascwaterproofing.co.uk

Complementary <strong>Product</strong>s and SystemsHarmer Raised Paving Support SystemsThese systems are designed to meet a wide range of paving support requirementsapplicable to terraces, walkways, balconies and ballasted roof constructions.There are two systems:1. Harmer ModulockA raised, adjustable pedestal system,based on four basic modules, whichcan support paving slabs or timberdecking at varying heights from thesub-structure.2. Harmer Uni-RingA shallow injection mouldedpolyethylene ring, that is stackable,and designed to allow concealeddrainage beneath paving slabs.Harmer ModulockHarmer ModulockHarmer Uni-RingHarmer ModulockHarmer Uni-RingAlumasc Technical Helpline +44 (0) 1744 64840033

Complementary <strong>Product</strong>s and SystemsSkyline CopingThe Skyline Coping system provides an economical and easily installed capping toupstand parapets, in conjunction with flat or pitched roofs. The strap fixing methodavoids penetration of the capping, whilst allowing ventilation over the top of the wall.Skyline Coping is maintenance free, available in a wide range of colours and is equallysuited to retrofit and new build.For detailed information, please contact Alumasc Technical Services.Skyline Copings have the following keyfeatures:■ Attractive, clean lines are maintained as fixings are not visibleon the surface of the coping■ Totally weatherproof covering achieved as the fixingmechanism involves no penetration of the coping■ The fixing strap profile allows ventilation over the top of thewall whilst remaining weatherproof■ Simple and quick to install and in most cases fixing can becarried out from the roof so no external access is requiredmaking it particularly suitable for renovation work■ Lightweight, durable and corrosion resistant■ Virtually maintenance free, with a lifespan well in excess of25 years■ Material thickness and fixing mechanism gives excellent rigidity■ Aluminium is 100% recyclable■ Choice of standard, BBA approved polyester powder coatingcolours with others available to special orderSkyline Coping Components■ Copings are fabricated from 2mm or 3mm thick aluminiumalloy sheet, depending on width■ Fixing straps are pressed 3mm aluminium with extruded EPDMseals bonded to the top surface■ All fabricated fittings (90º corners, irregular corners, stop ends,closed ends, upstands, 90º tee junctions) are mitred, weldedand have a smooth finish on the front face■ Waterproof membrane will be required beneath coping toprovide an effective sealSkyline CopingEPDM sealFixing strapWaterproofmembrane byothersPerformance■ Coefficient of linear thermal expansion is 23 x 10 -6 mm/m/ºC■ A gap of 3–4mm should be left between coping sections toaccommodate thermal expansion■ Aluminium is a suitable material for use as a lightning conductor■ Alumasc Lightning Link can be supplied for fitting to adjacentsections to provide good electrical conductivity in accordancewith BS 6651■ Alumasc hold British Board of Agrément Certificate No.86/1671 for a range of polyester colours34www.alumascwaterproofing.co.uk

Complementary <strong>Product</strong>s and SystemsROOF-PRO Roofing <strong>Product</strong>sROOF-PRO systems are designed to provide future-proof solutions for the support ofroof-mounted building services and engineered expansion joint solutions.For detailed information on these systems, please contact Alumasc Technical Services.ROOF-PRO Support SystemsThe ROOF-PRO solution is flexible and efficient, supporting servicesfrom 50mm pipes to 10,000 kg Air Handling Units independently ona range of flat roof designs.ROOF-PRO supports are quickly and simply positioned on theroof finish without penetrating or damaging the waterproofing.The systems range includes:■ Supports for ladder and cable trays■ Small to large pipe supports■ Support systems for AHUs, heat pumps and chillers■ Duct, attenuator and extract fan supports■ Condenser supports, small splits, VRV and VRF■ Access, step-overs, and maintenance platformsROOF-PRO support systems are designed to each individualroof structure utilising standard and bespoke designs to providestability, weight distribution and building clearance, ensuring yourservices are fully supported without the need for penetrativedesign details to the waterproofing.RedLINE and FlamLINE Expansion JointsRedLINE and FlamLINE sealed, flat expansion joints arecompatible with the <strong>Hydrotech</strong> system and are designed forcontinuous waterproofing integrity at simple or complex movementjoint details.RedLINEThe ideal joint tape for bituminous seals. RedLINE consists of ahighly elastic movement section made of EPDM and two laterallyflexible adhesive flanges.The flanges are reinforced by a polyester fleece that stabilises theEPDM, forcing movement to occur only in the movement sectionand provides a surface that gives high bonding strength.FlamLINECompatible with torch-on roofing membranes. FlamLINE ismanufactured from a single flexible sheet of high gradeButyl-Elastomer.The flanges contain a mesh that, like RedLINE, stabilises theadhesive flanges for sealing the waterproofing membrane to it.Movement is again forced to occur in the movement section that ispositioned over the expansion joint.Alumasc Technical Helpline +44 (0) 1744 64840035

Scope of the DetailsThe structural waterproofing applicationdetails illustrated on these pages showthe scope and versatility of the<strong>Hydrotech</strong> system, and are grouped intothe categories listed below:■ Main roof areas■ Rainwater outlets■ UpstandsMain roof areasp 40■ Abutments■ Penetrations■ Joints■ Green roofsThese typical waterproofing detailapplications are illustrative only.Application details are periodicallyupdated in accordance with updatedBuilding Regulations and Codes ofPractice. It is therefore advised to seekconfirmation that the current version isbeing used.Rainwater outletspp 41-43Upstandspp 43-45Abutmentspp 46-47Penetrationspp 48-49Jointspp 50-53Green roofsp 5436www.alumascwaterproofing.co.uk

Index of Application DetailsMain Roof Areas1. (a) Inverted roof and (b) Un-insulated plaza roof 38Rainwater Outlets1. Outlet with clamping ring (outlet exposed) 392. Outlet with clamping ring (outlet hidden) 393. Two-way outlet with clamping grate 404. Rainwater chute 405. Rainwater overflow 41Upstands1. Upstand with stone coping/aluminium coping 412. Un-insulated upstand with termination bar 423. Insulated upstand with termination bar 424. Insulated upstand to cladding cill 43Abutments1. Plinth (cleaning track rail) 442. Window cill (EPDM to <strong>Hydrotech</strong>) 443. Balustrade post 454. Steel base plate 45Penetrations1. Pitch pocket 462. Metal pipe/vent (cold) — built in 463. Metal pipe/vent (hot) 474. Metal pipe/vent (cold) — retro fitted 47Joints1. Precast panel side joint 482. General cracks 483. Expansion joint — (a) up to 12mm width and (b) 12-50mm width 494. Proprietary expansion joint 505. <strong>Hydrotech</strong> junction to Voltex 50Green Roofs1. Inverted/extensive build-up 512. Intensive un-insulated irrigated build-up 51Alumasc Technical Helpline +44 (0) 1744 64840037

Application DetailsMain Roof Area — 1a<strong>Hydrotech</strong> waterproofing to inverted roofStandard pressed concrete paving slabs,by others, seated on flat roof pavingsupports (Harmer Uni-Ring shown)MK Separator SheetExtruded polystyrene insulation, thickness determined tomeet the required U valueConcrete surface to be finished with a wood float, then primedwith Alumasc Bitumen Primer<strong>Hydrotech</strong> Monolithic Membrane 6125structural waterproofing systemincorporating Flex Flash F polyesterreinforcementHydrogard protection sheet, brush rolledinto the final coatMain Roof Area — 1b<strong>Hydrotech</strong> waterproofing to un-insulated plaza roofStandard pressed concrete pavingslabs or sets, by others25mm mortar bedCementitious sub-baseConcrete surface to be finished with a wood float,then primed with Alumasc Bitumen Primer<strong>Hydrotech</strong> Monolithic Membrane 6125structural waterproofing systemincorporating Flex Flash F polyesterreinforcementHydrodrain drainage layer, looselaidwith 100mm overlapping fabric selvedgeHydrogard protection sheet, brush rolledinto the final coat38www.alumascwaterproofing.co.uk

Application DetailsRainwater Outlet — 1<strong>Hydrotech</strong> waterproofing to rainwater outlet with clamping ring (outlet exposed)Harmer AV outlet incorporatingclamping ring, extension piece,domical grateLarge rounded pebbles 16-32mm grade, by othersStandard pressed concrete paving slabs, byothers, seated on flat roof paving supports(Harmer Modulock shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thicknessdetermined to meet the required U valueHydrogard protection sheet, brush rolled into the final coatFlex Flash UN uncured neoprenerubber reinforcement fullyencapsulated in <strong>Hydrotech</strong>Monolithic Membrane 6125(Refer to enlarged detail)<strong>Hydrotech</strong> structural waterproofing system consistingof two coats of <strong>Hydrotech</strong> Monolithic Membrane 6125incorporating Flex Flash F polyester reinforcementfabric between both layersConcrete surface to be finished with a wood float,then primed with Alumasc Bitumen PrimerNotes1. Concrete around gulley should be dressed to promote positive water drainage.2. Flex Flash UN should be one sheet extending a minimum of 75mm beyond thegulley flange on all sides, and secured by clamping ring.3. Gulley must be maintained free to weep at membrane level.12-20mm75mmmin75mmminRainwater Outlet — 2<strong>Hydrotech</strong> waterproofing to rainwater outlet with clamping ring (outlet hidden)Enlarged detail of dressing into AV outlet(Read with rainwater outlet details 1 and 2)Harmer AV outlet incorporatingdomical grateStandard pressed concrete paving slabs, by others, seatedon flat roof paving supports (Harmer Modulock shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thickness determined tomeet the required U valueHydrogard protection sheet, brush rolled into the final coatFlex Flash UN uncured neoprenerubber reinforcement fullyencapsulated in <strong>Hydrotech</strong>Monolithic Membrane 6125(Refer to enlarged detail)<strong>Hydrotech</strong> structural waterproofing system consisting of two coatsof <strong>Hydrotech</strong> Monolithic Membrane 6125 incorporating Flex Flash Fpolyester reinforcement fabric between both layersConcrete surface to be finished with a wood float, then primedwith Alumasc Bitumen PrimerNotes as aboveAlumasc Technical Helpline +44 (0) 1744 64840039

Application DetailsRainwater Outlet — 3<strong>Hydrotech</strong> waterproofing to two-way outlet with clamping grateAlumasc Roofmate TF-LG in accordance with BuildingRegulations requirements (Opening cut locally around outlet)Large rounded pebbles 16-32mm grade, by othersStandard pressed concrete paving slabs, byothers, seated on flat roof paving supports(Harmer Uni-Ring shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thicknessdetermined to meet the required U valueHydrogard protection sheet, brush rolledinto the final coatHarmer AV Two-Way outlet incorporating clamping grateFlex Flash UN uncured neoprene rubberreinforcement fully encapsulated in <strong>Hydrotech</strong>Monolithic Membrane 6125 (Refer to enlarged detail)<strong>Hydrotech</strong> structural waterproofing systemconsisting of two coats of <strong>Hydrotech</strong>Monolithic Membrane 6125 incorporatingFlex Flash F polyester reinforcement fabricbetween both layers12-20mmNotes1. Concrete around gulley should be dressed to promote positive water drainage.2. Flex Flash UN should be one sheet extending a minimum of 75mm beyond thegulley flange on all sides, and secured by clamping grate.3. Gulley must be maintained free to weep at membrane level.Concrete surface to be finished with a wood float,then primed with Alumasc Bitumen Primer75mmmin75mmminEnlarged detail of dressing into two-way outletRainwater Outlet — 4<strong>Hydrotech</strong> waterproofing to rainwater chuteAlumasc Roofmate TF-LG in accordancewith Building Regulations requirements(Opening cut locally around chute)75mmmin75mmminEnlarged detail of dressing at metal sleeveMetal sleeve,by othersLarge rounded pebbles 16-32mm grade, by othersStandard pressed concrete paving slabs, byothers, seated on flat roof paving supports(Harmer Uni-Ring shown)Extruded polystyrene insulation, thicknessdetermined to meet the required U valueHydrogard protection sheet, brush rolledinto the final coatMesh, by others<strong>Hydrotech</strong> structural waterproofing systemconsisting of two coats of <strong>Hydrotech</strong>Monolithic Membrane 6125 incorporatingFlex Flash F polyester reinforcement fabricbetween both layersFlex Flash UN uncured neoprene rubber reinforcement fullyencapsulated in <strong>Hydrotech</strong> Monolithic Membrane 6125(Refer to enlarged detail)MK Separator Sheet, loose laidConcrete surface to be finished with a wood float, thenprimed with Alumasc Bitumen Primer40www.alumascwaterproofing.co.uk

Application DetailsRainwater Outlet — 5<strong>Hydrotech</strong> waterproofing to rainwater overflow<strong>Hydrotech</strong> structural waterproofing system consisting of two coats of<strong>Hydrotech</strong> Monolithic Membrane 6125 incorporating Flex Flash Fpolyester reinforcement fabric between both layersFlex Flash UN uncured neoprene rubber reinforcement fullyencapsulated in <strong>Hydrotech</strong> Monolithic Membrane 6125 and dressedaround metal sleeve perimeter (Refer to enlarged detail)Metal sleeve,by othersAlumasc Roofmate TF-LG inaccordance with BuildingRegulations requirements(Opening cut locally aroundoverflow)Large rounded pebbles 16-32mm grade, by othersStandard pressed concrete paving slabs, byothers, seated on flat roof paving supports(Harmer Uni-Ring shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thicknessdetermined to meet the required U valueHydrogard protection sheet, brush rolledinto the final coat with 75mm lapsSee alternative junctiondetail above rightConcrete surface to be finished with a wood float,then primed with Alumasc Bitumen Primer<strong>Hydrotech</strong> structural waterproofing systemconsisting of two coats of <strong>Hydrotech</strong>Monolithic Membrane 6125 incorporatingFlex Flash F polyester reinforcement fabricbetween both layersUpstand — 1<strong>Hydrotech</strong> waterproofing to upstand with stone or aluminium copingStone coping, by othersFlex Flash F within<strong>Hydrotech</strong> MonolithicMembrane 6125Flex Flash UN75mm min150mm min upstandProprietary metal flashingLarge rounded pebbles 16-32mm grade, by othersAlternative junction detail75mm minWhere minor movement or change in level or dissimilarmaterials occur, the reinforcement is to be Flex FlashUN, overlapped with Flex Flash F by 75mmAlumasc Roofmate TF-LGin accordance withBuilding RegulationsrequirementsStandard pressed concrete paving slabs, byothers, seated on flat roof paving supports(Harmer Uni-Ring shown)Extruded polystyrene insulation, thicknessdetermined to meet the required U valueSee alternative junctiondetail aboveMK Separator Sheet, loose laidSkyline polyester powdercoated aluminium copingsystem, fixed tomanufacturer’s instructionsHydrogard protection sheet, brush rolledinto the final coat<strong>Hydrotech</strong> structural waterproofing system consistingof two coats of <strong>Hydrotech</strong> Monolithic Membrane 6125incorporating Flex Flash F polyester reinforcementfabric between both layersConcrete surface to be finished with a wood float,then primed with Alumasc Bitumen PrimerAlumasc Technical Helpline +44 (0) 1744 64840041

Application DetailsUpstand — 2<strong>Hydrotech</strong> waterproofing to un-insulated upstand with termination barLow modulus siliconesealant/bitumen compatible masticLow modulus silicone sealant/bitumen compatible masticAngled termination bar, mechanicallyfixed at 300mm centresSurface mounted termination bar, mechanicallyfixed at 300mm centresEnlarged detail of termination bar — option 1 Enlarged detail of termination bar — option 2Termination bar detail (see above)150mm minupstandLarge rounded pebbles 16-32mm grade, by othersStandard pressed concrete paving slabs, by others, seatedon flat roof paving supports (Harmer Uni-Ring shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thickness determined tomeet the required U valueHydrogard protection sheet, brush rolled into the final coat<strong>Hydrotech</strong> structural waterproofing system consisting of twocoats of <strong>Hydrotech</strong> Monolithic Membrane 6125 incorporating FlexFlash F polyester reinforcement fabric between both layersNoteFor alternative junction detail see Upstand — 1, page 43Concrete surface to be finished with a wood float, then primedwith Alumasc Bitumen PrimerUpstand — 3<strong>Hydrotech</strong> waterproofing to insulated upstand with termination barLow modulus silicone sealant/bitumen compatible masticProprietary metal flashingAlumasc Roofmate TF-LG in accordancewith Building Regulations requirements150mm minupstandLarge rounded pebbles 16-32mm grade,by othersStandard pressed concrete paving slabs, by others, seated onflat roof paving supports (Harmer Uni-Ring shown)MK Separator Sheet, loose laidExtruded polystyrene insulation, thickness determinedto meet the required U valueHydrogard protection sheet, brush rolled into the final coat42NoteFor alternative junction detail see Upstand — 1, page 43www.alumascwaterproofing.co.uk<strong>Hydrotech</strong> structural waterproofing system consisting of twocoats of <strong>Hydrotech</strong> Monolithic Membrane 6125 incorporating FlexFlash F polyester reinforcement fabric between both layersConcrete surface to be finished with a wood float, then primedwith Alumasc Bitumen Primer