About HYDAC - Intelligent Machine Dynamics Lab

About HYDAC - Intelligent Machine Dynamics Lab

About HYDAC - Intelligent Machine Dynamics Lab

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

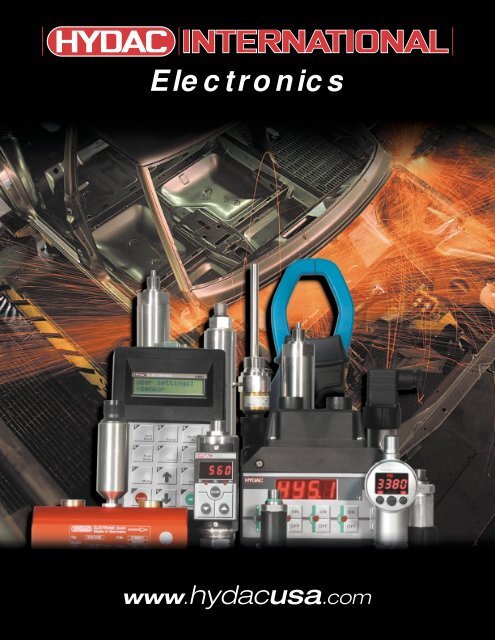

Electronics

<strong>About</strong> <strong>HYDAC</strong><strong>HYDAC</strong> stands for worldwide presence and accessibility to the customer. <strong>HYDAC</strong> has over 1000 distributorsworldwide and more than 30 wholly owned branches. <strong>HYDAC</strong> has been active in the field of pressure monitoringfor more than 20 years and has become one of the leaders in innovative pressure monitoring in hydraulics andpneumatics. Our know-how has evolved primarily from solving customers’ problems, combined with the extensiveexperience of the whole <strong>HYDAC</strong> group.<strong>HYDAC</strong> ProductsOur product range extends from simple pressure transmitters to theintelligent multiple pressure switches with customized software. Inthe field of sensors, we employ different techniques, enabling us tooffer the most appropriate solution to a customer’s specific application.<strong>HYDAC</strong> Quality<strong>HYDAC</strong> stands for quality and customer satisfaction. We are certifiedto ISO 9001 and can supply our products with certification ifrequired. To ensure that our products are as innovative as possible,they are developed, manufactured, and tested by qualified personnelusing advanced technology.<strong>HYDAC</strong> Customer ServiceOur internal staff and worldwide distribution network take care ofthe important matter of customer service. <strong>HYDAC</strong> values highstandards, professional ethics, and mutual respect in all transactionswith customers, vendors, and employees. We invest in our relationshipsby providing expertise, quality, dependability, and accessibility tofoster growth and a sense of partnership. Our customer servicerepresentatives are committed to serving the customers’ needs.Energy and Environmental Technology<strong>HYDAC</strong> Electronics have played a key role inproviding innovative developments in hydroelectric,heating, wind, and waste power plants. <strong>HYDAC</strong>has vast expertise in solvent and waste waterprocessing technologies.Offshore Shipbuilding andMarine TechnologyMaritime technology places special demands onmaterial functionality and reliability. <strong>HYDAC</strong>products meet these demands due to our highquality and test standards. <strong>HYDAC</strong> products havebeen applied under the toughest conditions fromdrilling rigs to deep sea applications.Mobile MarketThe aim of our engineers has always been to reducevolume and weight, resulting in increased productperformance. <strong>HYDAC</strong> provides compact highperformance components for the Mobile Market,which can be found in construction, forestry, andagricultural equipment.Process TechnologyThe core products of <strong>HYDAC</strong> process technologyare electronics, filters, and filtration systems for theindustrial and environmental processing industries.<strong>HYDAC</strong> products are found in chemical, petrochemical,and plastics industries. Also, paper anddye production, foundries, steel manufacturing, andpower plants.Industrial EngineeringSince we began, <strong>HYDAC</strong> has been involved inmany industrial engineering applications. Ourknowledge and expertise of many industriesprovides a comprehensive range of versatilehydraulic components. <strong>HYDAC</strong> offers customsolutions for machine tools, plastic injectionmolding machines, test equipment, presses, andwelding robots. Other industrial applicationsinclude: steel and heavy industry, powertransmissions, and paper mills.

Table of ContentsIntroductionISO Certified / Common Terms.............1Symbols / Approvals.............................2Temperature TransducersETS 4000 Series..................................39ETS 7000 Series .................................41Pressure TransducersHDA 3700/3800 Series..........................3HDA 4400/4700 Series .........................5HDA 4100/4300 Series .........................7HDA 7000 Series...................................9Temperature SwitchesETS 300 Series....................................43ETS 1700 Series..................................45Special Environment TransducersHDA 3000 Series - CAN Bus ..............11HDA 3400/3700 SeriesShipbuilding and Offshore..........13HDA 3700 SeriesHazardous Locations..................15HDA 3700 SeriesIntrinsically Safe..........................17HDA 3800 SeriesSteel Works.................................19Display UnitsHDA 6000 Series.................................21Flow SensorsEVS 3100/3110 Series ........................47DiagnosticsHMG 2020 Series................................49SMZ 1000 Series ................................53HMG Deluxe Diagnostic Kit ................60Pressure SwitchesEDS 300 Series ...................................23EDS 300 SeriesShipbuilding and Offshore ..........25EDS 410 Series ...................................27EDS 505 Series ...................................29EDS 601 Series ...................................31EDS 710 Series ...................................33EDS 1700 Series .................................35EDS 3000 Series .................................37AccessoriesTFP 100 & Safety Sleeve ....................55TestPoints............................................55Connectors..........................................56Adapters..............................................57Mounting Kits......................................58Demonstration Kits .............................59

ISO Certified:ISO Certified / Common Terms<strong>HYDAC</strong> has become a leader in hydraulicsand pneumatics. We have earned that roleby emphasizing quality, innovation, andexcellence in everything we manufacture.<strong>HYDAC</strong> is committed to maintaining thosehigh standards of quality and service inaccordance with the ISO 9001International Standard.Common Terms:Accuracy - the error ratio of the full scale output or the error ratio of the output expressed in %Ambient Conditions - conditions of the medium surrounding the transducer (pressure, temperature, etc...)Best Fit Straight Line (BFSL) - an average of the deviation of all calibration pointsExcitation - the external power supply applied to a device for its proper operationEMI Susceptibility - the level or degree to which a device is vulnerable to electromagnetic interferenceFull Scale (FS) - relative to the full measuring rangeHysteresis - the maximum difference in electrical output at any pressure value within the specified range betweenan increasing and decreasing cycleLinearity - the closeness of a calibration curve to a specified straight linePressure - force per unit of area exerted by a fluid at some point in the systemRepeatability - the ability of a transducer to reproduce outputTemperature Range (Operating) - the interval of temperatures in which the transducer is intended to be usedPLEASE NOTE:Certain combinations are subject to availability and/or approval. There may be a minimum quantity required for certain combinations.Requirements will be determined at time of inquiry or purchase order. Alternatives may be suggested by product management.Specifications and dimensions given in this catalog represent engineering configurations at the time of printing.Modifications may take place and product materials are subject to change without prior notice.1Electronics Catalog

Symbols / ApprovalsSymbols:GearboxesRailwaysAgriculturalConstructionPulp & PaperPower GenerationSteel / Heavy IndustrialShipbuildingIndustrialOffshoreApprovals:1-877-GO <strong>HYDAC</strong>Electronics Catalog 2

Pressure TransducersHDA 3700 & 3800<strong>About</strong> HDA 3700 & 3800 Pressure Transducers:The HDA 3000 family of transducers is designed to provide exceptional durabilityand accuracy in demanding industrial and mobile applications. They are used toconvert hydraulic or pneumatic pressure into an electrical output signal linearlyproportional to the input pressure. The signals can be sent to most commonlyused processors and controllers, including PLC's, computers, recorders, anddigital displays. Frequently, HDA 3000's are packaged with <strong>HYDAC</strong> digital displays,such as the HDA 5000 or HDA 6000, to monitor, regulate, or control processesin hydraulic or pneumatic systems.Technical Details:Input Data HDA 3700 HDA 3800Measuring ranges6, 16, 60, 100,250, 400, 600 bar6, 16, 60, 100,250, 400, 600 barOverload pressure 200% FS, maximum 900 bar 200% FS, maximum 900 barBurst pressure 300% FS 300% FSMechanical ConnectionG 1/4 A DIN 3852SAE 6 9/16-18 UNF2A maleG 1/4 A DIN 3852SAE 6 9/16-18 UNF2A male(with adapter)(with adapter)Tightening torque 15 lb-ft (20 Nm) 15 lb-ft (20 Nm)Parts in contact with media Stainless steel, FPM seal Stainless steel, FPM sealOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability≤ ±0.25 %FS max≤ ±0.15 %FS maxTemperature compensation ≤ ±0.0045%FS/°F typ. ≤ ±0.003%FS/°F typ.zero point ≤ ±0.0085%FS/°F max. ≤ ±0.006%FS/°F max.Temperature compensation ≤ ±0.0045%FS/°F typ. ≤ ±0.003%FS/°F typ.over range ≤ ±0.0085%FS/°F max. ≤ ±0.006%FS/°F max.Rise time approx. 0.5 ms approx. 0.5 msLong-term drift ≤ ±0.1%FS typ. / year ≤ ±0.1%FS typ. / yearAmbient ConditionsNominal temperature range -13 to +185°F (-25° to +85 °C) -13 to +185°F (-25° to +85 °C)Operating temperature range -40 to +185°F (-40° to +85 °C) -40 to +185°F (-40° to +85 °C)Storage temperature range -40 to +212°F (-40° to +100 °C) -40 to +212°F (-40° to +100 °C)Fluid temperature range -40 to +212°F (-40° to +100 °C) -40 to +212°F (-40° to +100 °C)markEN 50081-1, EN 50081-2EN 50082-1, EN 50082-2EN 50081-1, EN 50081-2EN 50082-1, EN 50082-2Vibration resistance toIEC 68-2-6 at 10 to 500Hz≤ 20g (196.2 m/s 2 ) ≤ 20g (196.2 m/s 2 )Safety type to DIN 40050 IP 65 IP 65Other dataSupply voltage 2-conductor 10 to 30 VDC 10 to 30 VDCSupply voltage 3-conductor 12 to 30 VDC 12 to 30 VDCResidual ripple supply voltage ≤ 5% ≤ 5%Current consumption 3-conductor approx. 15 mA approx. 15 mAReverse polarity protection of thesupply voltage, excess voltage, standard standardoverride and short circuit protectionLife expectancy 10 million load cycles, 10 million load cycles,0 to 100%FS 0 to 100%FSWeight approx. 180 g approx. 180 gSpecial models on request.Applications:Approvals:3Electronics Catalog

Model Code:HDA 3 X X X - X - XXX - 000.SeriesHDA 3 = 3000 series Pressure TransducerAccuracy7 = 0.25% B.F.S.L.8 = 0.15% B.F.S.L.Mechanical Connection4 = G 1/4 A DIN 38527 = SAE 6 9/16-18 UNF2A male supplied with adapter*Electrical Connection4 = 4 pole Binder plug 714 Mx18 (connector not included)5 = DIN43650/ISO4400 plug, 3 pole + ground (connector ZBE 01 included)Output SignalA = 2 conductor, 4-20 mAB = 3 conductor, 0-10 VDCE = 3 conductor, 0-20 mA, sourcingPressure Range006 = 87 psi (6 bar)* 250 = 3625 psi (250 bar)*016 = 232 psi (16 bar)* 400 = 5800 psi (400 bar)*060 = 870 psi (60 bar)* 600 = 8700 psi (600 bar)*100 = 1450 psi (100 bar)*Modification Number000 = Standard* Adapter is included to convert G1/4 Male to SAE-6 Male connection on some modelsCircuit Connection:Two Conductor Output: Max. Load = Supply - 10V (Ω)0.02 Amp2HDA-3XX4-A31Free+ SupplyRL 10 to 30VHDA-3XX5-A0VRLFreeThree Conductor Output: Min. Load = 2k (Ω)123RLRLFree+ Supply0VPlug Connection:HDA 3XX5 use with ZBE 01 (see page 56)1 23HDA 3XX4 use with ZBE 02 or ZBE 03(see page 56)HDA-3XX4-B123V+ Supply12 to 30VSignal0 to 10V0VHDA-3XX5-B123V+ Supply0VSignal0 to 10V2 31 4FreeFreeThree Conductor Output: Max. Load = Supply - 7V (Ω)0.02 Amp12+ Supply12 to 30V12+ Supply0VHDA-3XX4-E3RLSignal0 to 20mA0VHDA-3XX5-E3RLSignal0 to 20mAFreeFreeDimensions:ø 1.06"(27 mm)1.34"(34 mm)1.06" Hexbetween flatsG 1/41.10"(28 mm)0.47"(12 mm)0.31"(8 mm)3.33"(84.5 mm)1.61"(41 mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 4

Model Code:SeriesHDA 4 = 4000 series Pressure TransducerAccuracy4 = 0.5% BFSL7 = 0.25% BFSLMechanical Connection7 = SAE 6 9/16-18 UNF2A maleElectrical Connection4 = 4 pole Binder plug 714 Mx18 (connector not included)5 = DIN 43650/ISO 4400 plug, 3 pole + ground (connector ZBE 01 included)Output SignalA = 2 conductor, 4-20 mAB = 3 conductor, 0-10 VDCPressure Range0150 = 150 psi (10 bar) 3000 = 3000 psi (207 bar)0750 = 750 psi (52 bar) 5000 = 5000 psi (345 bar)1000 = 1000 psi (69 bar) 6000 = 6000 psi (413 bar)1500 = 1500 psi (103 bar) 9000 = 9000 psi (620 bar)Modification Number000 = StandardHDA 4 X 7 X - X - XXXX - 000Circuit Connection:Plug Connection:HDA4X74 use with ZBE 01 (see page 56)HDA 4X74-B1234freeRLRLfree+supply0VHDA4X75-A1234freeRLRL+supply0V1 23HDA4X75 use with ZBE 02 or ZBE 03(see page 56)Three-Conductor 0 to 10 VDCRLmin = 2k12+supplysignalThree-Conductor 0 to 10 VDCRLmin = 2k12free+supply0V2 31 4HDA 4X74-B34freeV0VHDA4X75-B34VsignalDimensions:HDA 4474/4774, illustrated with ZBE 03Xø 1.26"(32 mm)HDA 4475/4775, illustrated with ZBE 013.642"(92.5 mm)ø 1.378"(35 mm)SAE 6Hex SW(27mm)1.063"2.244"(57mm)Dimension X: with right angled plug ZB 03 ≈ 4.252" (108mm)Dimension X: with straight plug ZB 02 ≈ 5.0" (127mm)≈1.181"(30 mm)SSAE 6Hex SW 1.063"(27mm)2.244"(57mm)≈1.378"(35 mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 6

Pressure TransducersHDA 4100 & 4300<strong>About</strong> HDA 4100 & 4300 Pressure Transducers:The HDA 4100 & 4300 is similar in design to our HDA 4400 series. This transducerutilizes a ceramic sensor element to provide our customers a low cost, lowpressure sensor while maintaining accuracy, repeatability, and stability. Thebody is a brass/steel combination but is available in an all steel version. Pressureranges from 0 to 15 psi up to 1500 psi are available. A number of port sizes andelectrical connection combinations make this an attractive and affordable solutionto your low pressure needs.Technical Details:Input DataMeasurement range0 to 15, 50 psi (A)0 to 15, 30, 50, 100, 150, 250, 500 psi (G)Overload pressure200%FSBurst pressure300%FSMechanical connection1/4”-18 NPT maleParts in contact with mediaBrass, FPM seal, ceramicOutput dataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability≤ ±0.5 %FS max.Temperature compensation≤ ±0.012%/°F typ.Zero point≤ ±0.017%/°F max.Temperature compensation≤ ±0.012%/°F typ.over range≤ ±0.017%/°F max.Rise time approx.2 msLong-term drift≤ ±0.3%FStyp. / yearAmbient ConditionsNominal temperature range32° to 176°F (0° to 80˚C)Operating temperature range-13° to 185°F (-25° to 85˚C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)markEN 50081-1, EN 50081-2EN 50082-1, EN 50082-2Vibration resistance to IEC 68-2-6 at 10 to 500Hz ≤ 20 g (196,2 m/s 2 )Safety type to DIN 40050IP 65 (DIN 43650 connector)IP 67 (ZBE 06 molded cable)Other DataSupply voltage 2-conductor10 to 30 V DCSupply voltage 3-conductor12 to 30 V DCResidual ripple supply voltage ≤ 5 %Current consumption 3-conductorapprox. 25 mAReverse polarity protection of the supplyvoltage, excess voltage, override andstandardshort circuit protectionLife expectancy>10 million load cycles (0 to 100%FS)Weightapprox. 145 gApplications:Approvals:7Electronics Catalog

Model Code:SeriesHDA 4 = 4000 series Pressure TransducerAccuracy1 = Absolute (ceramic) 0.5% BFSL3 = Gauge (ceramic) 0.5% BFSLMechanical Connection8 = 1/4” - 18 NPT male threadElectrical Connection5 = DIN 43650/ISO 4400 plug, 3 pole + ground (connector ZBE 01 included)6 = M12x1 plug, 4-pole (connector not included)Output SignalA = 2 conductor, 4-20 mAB = 3 conductor, 0-10 VDCPressure RangeAbsoluteGauge0015 = 0 to 15 psi 0015 = 0 to 15 psi0050 = 0 to 50 psi 0030 = 0 to 30 psi0050 = 0 to 50 psi0100 = 0 to 100 psi0150 = 0 to 150 psi0250 = 0 to 250 psi0500 = 0 to 500 psiModification Number000 = StandardHDA 4 X X X - X - XXXX - 000Circuit Connection:Plug Connection:HDA 4X65 use with ZBE 01(see page 56)HDA 4X85-A1234freeRLRL+supply0VHDA 4X86-A1234RLfreeRLfree+supply0V1 23HDA 4X66 use with ZBE 06(see page 56)Three-Conductor 0 to 10 VDCRLmin = 2kHDA 4X85-B1234freeV+supplysignal0VThree-Conductor 0 to 10 VDCRLmin = 2kHDA 4X86-BDimensions:The body is brass (stainless steel available on request)3.71"(94 mm)1234freeVø 1.26"(32 mm)+supply0Vsignal431 21/4 NPTHex SW 1.06"(27mm)2.37"(60mm)1.378"(35 mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 8

Pressure TransducersHDA 7000<strong>About</strong> HDA 7000 Pressure Transducers:The pressure transducer series HDA 7000 combines excellent technical specificationswith a very compact design.The HDA 7000 was specifically developed for severe applications e.g. mobile applications.A thin film sensor cell is the basis for a robust, long-life pressure transmitter.Various pressure ranges between 0 to 150 psi and 0 to 9000 psi facilitate adaptationto the particular application.For integration into modern controls (e.g. with PLC) different analog output signals,including 4 to 20 mA or 0 to 5 V, are available on the standard version. Ratio-metricoutput signals are also available on request.Technical Details:Input DataMeasuring rangesOverload pressureBurst pressureMechanical ConnectionTightening torque G 1/4, SAE 6SAE 4Parts in contact with mediaOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatabilityTemperature compensationzero pointTemperature compensationover rangeRise timeLong-term driftAmbient ConditionsNominal temperature rangeOperating temperature rangeStorage temperature rangeFluid temperature rangemarkVibration resistance toIEC 68-2-6 at 10 to 500HzSafety type to DIN 40050Other dataReverse polarity protection of thesupply voltage, excess voltage,override and short circuit protectionLife expectancyWeight (with M12 connector)0 to 150, 750, 1000, 1500,3000, 5000, 6000, 9000 psi150% FS, maximal 13000 psi300% FSSAE 6 9/16-18 UNF2A male,G 1/4 A DIN 3852, SAE 4, 1/4” NPTapprox. 15 lb-ft (20 Nm)approx. 11 lb-ft (15 Nm)Stainless steel, FPM seal≤ ±0.5 %FS≤ ±0.0085%FS/°F≤ ±0.017%FS/°F≤ ±0.0085%FS/°F≤ ±0.017%FS/°Fapprox. 1 ms≤ ±0.3%FS typ. / year-13° to 185°F (-25° to 85°C)-40° to 185°F (-40° to 85°C)-40° to 212°F (-40° to 100°C)-40° to 212°F (-40° to 100°C)EN 50081-1, EN 50081-2EN 50082-1, EN 50082-2≤ 20g (196.2 m/s 2 )IP 67 (w/ ZBE 06 molded cableor flying lead)standard≥ 10 million load cycles 0 to 100%FSapprox. 48 gApplications:Approvals:9Electronics Catalog

This is an OEM Product:Part number and Model Code are created with an order. A minimum order of 250 pieces will be expected from all OEMs. Thecustomer is to provide electrical connection, mechanical connection, and electrical output requirement. Choices to include butare not limited to:Electrical Mechanical OutputM12x1 G 1/4 A DIN 3852 0 - 5 VDCFlying lead SAE 4 - 7/16 4 to 20 mASAE 6 9/16-18 UNF2A maleRatio - metric1/4” NPT 1 - 6 VDC0.5 - 4.5 VDCCircuit Connection:Flying Leads:Plug Connection:HDA 7000 use with ZBE 06 (see page 56)4 to 20 mAbrownblackRLRL+supply0V431 20 to 5 V1 to 6 V0.5 to 4.5 VredbrownblackV+supplysignal0VM12x1:12RLfree+supply4 to 20 mA34RLfree0V0 to 5V1 to 6 V0.5 to 4.5 V1234freeV+supply0VsignalDimensions:1.398"ø 0.728" (18.5mm)(35.5mm)0.078"(2mm)SAE-69/16-18 UNF0.744"(18.9mm)ø 0.728"(18.5mm)M12x12.047"(52mm)Pressure connectionDIN3852G 1/4Aø 0.8.27"(21mm)hex-SW07480.394"(10.0mm)hex-SW07486kt-SW191-877-GO <strong>HYDAC</strong>Electronics Catalog 10

Specialty Pressure TransducersHDA 3000 - CAN Bus<strong>About</strong> HDA 3000 - CAN Bus Pressure Transducers:<strong>HYDAC</strong> has developed the HDA 3000 CAN-bus sensor to meet the needs ofthe marketplace for a field-bus sensor. There are several field-bus systems onthe market designed for specific industries. One of the most known in thehydraulic industry is the CAN-bus. The purpose of CAN-bus is to eliminate theneed for heavy cabling trees, particularly in the automotive and process industries.The HDA 3000 CAN-Bus sensors are interfaced by a pair of twisted wires whichenables a CAN system to receive, dispatch and monitor information fromhydraulic systems. CAN-bus is a relatively simple and uncomplicated system. Inthe hydraulic field there are applications for many mobile machine manufacturerssuch as excavators and tractors. Each CAN-bus sensor is custom designed forevery OEM to meet their individual system needs.Technical Details:Input DataMeasuring rangesOverload pressureBurst pressureMechanical ConnectionTightening torqueParts in contact with mediaOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatabilityTemperature compensationzero pointTemperature compensationover rangeRise timeLong-term driftAmbient ConditionsNominal temperature rangeOperating temperature rangeStorage temperature rangeFluid temperature rangemarkVibration resistance toIEC 68-2-6 at 10 to 500HzSafety type to DIN 40050Other dataSupply voltageLife expectancyWeight0 to 150, 750, 1000, 1500,3000, 5000, 6000, 9000 psi150% FS, maximal 13000 psi300% FSSAE 6 9/16-18 UNF2A maleapprox. 15 ft-lb (20 Nm)Stainless steel, FPM seal≤ ±0.5 %FS≤ ±0.0085%FS/°F max.≤ ±0.0085%FS/°F max.approx. 1 ms≤ ±0.3%FS typ. / year32° to 158°F (0° to 70°C)-13° to 185°F (-25° to 85°C)-40° to 212°F (-40° to 100°C)-40° to 212°F (-40° to 100°C)EN 50081-1, EN 50081-2EN 50082-1, EN 50082-2≤ 20g (196.2 m/s 2 )IP 67 (M12x1 molded connector is used)18 to 32 V DC10 million load cycles 0 to 100%FSapprox. 200 gApplications:Approvals:11Electronics Catalog

What Are Field-Bus Systems?A field-bus system is a data network with the objective to receive data from a production process, exchange data betweendevices or machines, control steps or processes in production. Data transmission happens serially with digital signals(equivalent to Internet data transmission.)The most basic design of such a data network is a 2-wire cable with various individual sensors (e.g. Pressure transmitters),actors (e.g. solenoid valves), controllers, periphery units, and control units (e.g. PLC, industrial PCs) connected at any point.BUS participants need a suitable interface, which transfers flow of data. Each individual component gets its own address.Structure of a Bus System:Bus mastere.g. PLCNode 1Node 2 Node 3 Node 30 Node 31e.g. pressuretransmittere.g. valvee.g. temperaturesensorRemarks: Communication of process data is performed by means of every individual sensor, component, and so on,being connected via it’s own wiring to high layer control.Advantages:• Easy wiring with clear reduction of cabling (best case: only two cables)• Clear structure• Diagnostic functions, connected units may be checked on functionality• All system functions are available in high layer control at any time• High level of transmission safety, information may be checked on validity through multiple transmissions• Easy to be enlarged, since at any place of network a unit may be added• Easy implementation into higher leveled systems:- connection to other bus system- distance diagnostic systems- service units1-877-GO <strong>HYDAC</strong>Electronics Catalog 12

Specialty Pressure TransducersHDA 3400 & 3700 - Shipbuilding and Offshore<strong>About</strong> HDA 3400 Pressure Transducers:This pressure transmitter, which has been specially developed for shipbuilding andoffshore applications, is based on a very robust and accurate sensor cell with a thinfilm strain gauge on a stainless steel membrane.All parts in contact with the fluid are in stainless steel and are welded together.Since no seals are required in the sensor chamber, leakage is eliminated.The 4 to 20 mA output signal in two conductor technic enables connection to therelevant evaluation electronics. Since accuracy varies markedly with the temperatureof the fluid being measured, this instrument offers outstanding characteristicsin this respect.Areas of application are pressure monitoring on marine transmissions, dieselengines, pumps and general hydraulic and pneumatic systems.Technical Details:Input Data HDA 3400 HDA 3700Measuring ranges 16, 60, 100, 6, 16, 60, 100,250, 400, 600 bar 250, 400, 600 barOverload pressure200% FS, maximal 900 barBurst pressure400% FSMechanical Connection G 1/4 A DIN 3852Tightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediaStainless steel, FPM sealOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability≤ ±0.5%FS≤ ±0.25%FSTemperature compensation ≤ ±0.0085%FS/°F typ. ≤ ±0.0045%FS/°F typ.zero point ≤ ±0.014%FS/°F max. ≤ ±0.0085%FS/°F max.Temperature compensation ≤ ±0.0085%FS/°F typ. ≤ ±0.0045%FS/°F typ.over range ≤ ±0.014%FS/°F max. ≤ ±0.0085%FS/°F max.Rise timeapprox. 1 msLong-term drift≤ ±0.3%FS typ. / yearAmbient ConditionsNominal temperature range 32° to 158°F (0° to 70°C) -13° to 185°F (-25° to 85°C)Operating temperature range -13° to 185°F (-25° to 85°C) -40° to 185°F (-40° to 85°C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)markEN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-2Vibration resistance to5 to 25 Hz: 3.2 mmIEC 68-2-6 at 10 to 500Hz25 to 100 Hz: 4 gSafety type to DIN 40050 IP 65Other DataSupply voltage10 to 30 VResidual ripple supply voltage ≤ 5%Current consumption 3-conductorapprox. 25 mAReverse polarity protection of thesupply voltage, excess voltage,availableoverride and short circuit protectionLife expectancy> 10 million load cycles 0 to 100%FSWeightapprox. 145 gApplications:Approvals:American Bureau of ShippingNo.: 00-ES 19976-XLloyds Register of ShippingNo.: 00/20049Det Norske VeritasNo.: A-7711 (892.10)Germanischer LloydNo.: 15520-00HHBureau VeritasNo.: 10342 /A0 BV13Electronics Catalog

Model Code:HDA 3 X 4 5 - A - XXX - S00SeriesHDA3 = 3000 series Pressure Transducer for Shipbuilding & OffshoreAccuracy4 = 0.5% B.F.S.L.7 = 0.25% B.F.S.L.Mechanical Connection4 = G 1/4 A DIN 3852Electrical Connection5 = DIN 43650/ISO 4400 plug, 3 pole + ground (connector ZBE 01 included)Signal TechnologyA = 2-conductor, 4 to 20 mAMeasuring Ranges006 = 6 bar (HDA 3700 only)016 = 16 bar060 = 60 bar100 = 100 bar250 = 250 bar400 = 400 bar600 = 600 barModification NumberS00 = standardNote: On units with a different modification number, please read the label or the technical amendment details supplied with the unit.All details are subject to technical modifications.Circuit Connection:2-conductor 4 to 20 mAPlug Connection:HDA 3X45 use with ZBE 01 (see page 56)12RLRL1 23HDA3X45-A3FreeRL max. = UB - 10 V [Ω]0.02 ANote: The load resistance RL is producedby the measuring resistanceinside the evaluation unit and the lineresistance of the connection line.Dimensions:0.08"(2mm)ø 1.06"(27mm)ø 1.38"(35mm) 1.34"(34mm)HexSW27ø 0.74" G 1/4 A(18.9mm)1.97"(50mm)0.47"(12mm)3.23"(82mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 14

Specialty Pressure TransducersHDA 3700 - Hazardous Locations<strong>About</strong> HDA 3700 Pressure Transducers:The pressure transducer series HDA 3700 is available in a version for measuringpressure in hazardous locations. This model is certified for use in Class I, Division 2,groups A, B, C, and D, along with Class II, Division 2, groups F and G hazardouslocations.The HDA 3700 family of transducers is designed to provide exceptional durability andaccuracy in demanding industrial and process applications. They are used to converthydraulic or pneumatic pressure into an electrical output signal linearly proportionalto the input pressure. The signals can be sent to most commonly used processorsand controllers, including PLC’s, computers, recorders, and digital displays.The pressure measured by the sensor is converted to a proportional, analog 4 to 20mA output signal. The signals can be sent to most commonly used processorsand controllers, including PLC's, computers, recorders, and digital displays.Technical Details:Input DataMeasuring rangeson requestOverload pressureon requestBurst pressureon requestMechanical ConnectionSAE 6 9/16-18 UNF2A male1/4”-18 NPT male thread1/4”-18 NPT female threadTightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediaStainless steel, FPM sealOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability±0.25 %FS maxTemperature compensation≤ ±0.0045%FS/°F typ.zero point≤ ±0.0085%FS/°F max.Temperature compensation≤ ±0.0045%FS/°F typ.over range≤ ±0.0085%FS/°F max.Rise timeapprox. 0.5 msLong-term drift≤ ±0.1%FS typ. / yearAmbient ConditionsNominal temperature range-13° to 185°F (-25° to 85˚C)Ambient temperature range-40° to 185°F (-40° to 85°C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)markEN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-2Vibration resistance toIEC 68-2-6 at 10 to 500Hz196.2 m/s 2 (≤ 20g)Safety type to DIN 40050 IP 65Other DataApproval CL. I, Div. 2, GRPS. A,B,C, & D,CL. II, Div. 2, GRPS. F & G,CSA Certification, FM approvalSupply voltage 12 to 28 V (max 1 W)Residual ripple supply voltage ≤ 5%Reverse polarity protection ofthe supply voltage, and shortstandardcircuit protectionLife expectancy> 10 million load cycles 0 to 100%FSWeight180 gApplications:Approvals:15Electronics Catalog

Model Code:SeriesHDA3 = 3000 series Pressure Transducer for Hazardous LocationsAccuracy7 = 0.25% BFSLMechanical Connection7 = SAE-6 9/16-18 UNF2A male8 = 1/4”-18 NPT male threadF = 1/4”-18 NPT female threadElectrical Connection8 = 1/2” NPT male conduit (wire leads)HDA 3 7 X 8 - A - XXXX - C 00 (48 inch)SignalA = 4 to 20mAPressure Rangeson requestApprovalC = CL. I, Div. 2, GRPS. A,B,C, & D, CL. II, Div. 2, GRPS. F & G, CSA Certification, FM approvalModification Numberused for pin connection, special calibration in pressure rangeWire Length48 inchlonger wires on requestModel Codes Containing RED are non-standard items - Minimum quantities may applyContact <strong>HYDAC</strong> for information and availabilityCircuit Connection:greenRL+ SupplyHDA37X8-AwhiteRL0VDimensions:green/yellow0.75"ø (19mm)0.39"(10mm)Hex SW1.063Hex SW0.7481/2 - 14 NPT9/16-18UNF2A0.09"ø1.16"(2mm)(29mm)O-ring 0.468 x 0.078FPM (Viton) - 90 shore4.41"(112mm)1.08"(27mm) 48"(1219mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 16

Specialty Pressure TransducersHDA 3700 - Intrinsically Safe<strong>About</strong> HDA 3700 Pressure Transducers:The pressure transducer series HDA 3700 is available in a version for intrinsicallysafe circuits for measuring pressure in hazardous applications. The safety classEEx ia IIC T6 covers nearly all requirements with regard to ignition group, error classand temperature class.Like the industrial version of the HDA 3700, the EX-version also has a very accurate,robust pressure sensor. With a basic accuracy of ≤ 0.25% BFSL and outstandingspecifications regarding the temperature effect, this series is suitable for use in awide range of applications. The pressure measured by the sensor is converted to aproportional, analog 4 to 20 mA signal. The signals can be sent to most commonlyused processors and controllers, including PLC's, computers, recorders, anddigital displays.Technical Details:Input DataMeasuring ranges6, 16, 60, 100,250, 400, 600 barOverload pressure200% FS, maximal 900 barBurst pressure300% FSMechanical Connection G 1/4 A DIN 3852Tightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediaStainless steel, FPM sealOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability≤±0.25% FS maxTemperature compensation≤ ±0.0045%FS/°Fzero point≤ ±0.0085%FS/°FTemperature compensation≤ ±0.0045%FS/°Fover range≤ ±0.0085%FS/°FRise timeapprox. 0.5 msLong-term drift≤ ±0.1%FS typ. / yearAmbient ConditionsNominal temperature range-13° to 140°F (-25° to 60°C)Operating temperature range-40° to 140°F (-40° to 60°C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)Approval no. BVS 95.0.2030 EN 50014 and EN 50020Vibration resistance toIEC 68-2-6 at 10 to 500Hz196.2 m/s 2 (≤ 20g)Safety type to DIN 40050 IP 65Other DataSupply voltage12 to 28 V (max 1W up to 26 V,max 0.8W for 26 - 28 VConnection capacity≤ 7 nFInductance0HResidual ripple supply voltage ≤ 5%Reverse polarity protection of thestandardsupply voltage, short circuit protectionLife expectancy> 10 million load cycles 0 to 100%FSWeight180 gSafety Rating:EEx Component identification for use onapplications with an explosion hazard,according to safety class definition.i Intrinsic safety: the circuits are designedso that no spark or thermal effect which canoccur under the test conditions stipulated inthe standard, can cause an ignition of a certainenvironment with an explosion hazard.a Error class“a” signifies that up to two independent errorscan occur on the component without thiscausing any danger. “a” is the highest possibleerror class. ‘b” is the lower level which allowsno more than 1 error on the component(i.e. if two errors occur) the safety is at risk.“a” specified components can be used inapplications which only have “b” requirements.IIC “IIC” is the highest possible flash pointrange in the standard. “II” specifies the areaof application for all environments with anexplosion hazard, except for flame-proofprotection. (Flame-proof protection is designatedby 1”)“C” designates the actual flash point range(i.e. the ignitability of the environment.) Class C isthe highest requirement, i.e. the environmentaccepted to be the most critical. The subordinateclasses A and B can be equipped with a “C”registered unit. “C” means, for example, thatgas mixtures with up to 23% of hydrogen willnot ignite.T6 Temperature class“T6” is the highest temperature class specifiedin the standard which ensures that, at amaximum ambient temperature, the surfacetemperature never exceeds 85°C.Components of temperature class T6 can ofcourse also be used for lower classes T1 - T5.Applications:Approvals:17Electronics Catalog

Model Code:SeriesHDA 3 = 3000 series Intrinsically Safe Pressure TransducerAccuracy7 = 0.25% BFSLMechanical Connection4 = G 1/4 A DIN 38525 = SAE-4 female thread (7/16”-20)7 = SAE-6 9/16-18 UNF2A male (with adapter)C = Autoclave female port (7/16”-20, for pressure ≥ 10k psi)F = 1/4”-18 NPT female threadElectrical Connection4 = 4 pole Binder plug 714 M18x1 plug (connector not included)5 = DIN48650/ISO4400 plug, 3 pole + ground (connector ZBE 01 included)8 = 1/2” NPT male conduitOutput SignalA = 2-conductor / 4 to 20mAPressure Ranges006, 016, 060, 100, 250, 400, 600 bar (available in psi)Modification NumberE00 = Safety Class EEx ia IIC T6HDA 3 7 X X - A - 006 - E00Circuit Connection:HDA3744-AModel Codes Containing RED are non-standard items - Minimum quantities may applyContact <strong>HYDAC</strong> for information and availability1234FreeFreeRLRL+ Supply0VPlug Connection:HDA 37X5 use with ZBE 01 (see page 56)1 23HDA 37X4 use with ZBE 02 or ZBE 03(see page 56)2 314HDA3745-A123FreeRLRL+ Supply0V1/2” NPT male conduit:consult factory for availabilityDimensions:ø 1.06"(27 mm)1.34"(34 mm)1.06" Hexbetween flatsG 1/41.10"(28 mm)0.47"(12 mm)0.31"(8 mm)3.33"(84.5 mm)1.61"(41 mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 18

Specialty Pressure TransducersHDA 3800 - Steel Works<strong>About</strong> HDA 3800 Pressure Transducers:This high-precision pressure transducer has been specially developed and adaptedfor the sophisticated measurement demands of steelworks technology. The unit hasa very robust sensor cell with a thin-film DMS which is applied to a stainless steelmembrane. It’s outstanding specifications with reference to temperature effect(temperature drift for zero point and range are at maximum ≤ ± 0.01 FS/°C each) and accuracy(≤ ± 0.15% FS typ.) makes it ideally suited for use in the harsh ambient conditionsfound in steelworks. The excellent EMC characteristics guarantee signal stabilityduring the harshest high-frequency, electro-magnetic interference.Technical Details:Input DataMeasuring rangesOverload pressureBurst pressureMechanical ConnectionTightening torqueParts in contact with mediaOutput DataAccuracy (B.F.S.L) including linearity,hysteresis, and repeatabilityTemperature compensationzero pointTemperature compensationover rangeRise timeLong-term driftAmbient ConditionsNominal temperature rangeOperating temperature rangeStorage temperature rangeFluid temperature range350 bar900 bar2000 barG1/4 A DIN 3852, G1/2 A maleSAE 6 9/16-18 UNF2A maleapprox. 15 lb-ft (20 Nm) for G1/4 Aapprox. 33 lb-ft (45 Nm) for G1/2 AStainless steel,FPM seal (G1/4 A) NBR O-ring (G 1/2 A)≤ ±0.15 %FS max.≤ ±0.0028%FS/°F typ.≤ ±0.056%FS/°F max.≤ ±0.0028%FS/°F typ.≤ ±0.056%FS/°F max.≤ 1.5 ms≤ ±0.1%FS typ. / year-13° to 185°F (-25° to 85˚C)-40° to 185°F (-40° to 85°C)-40° to 212°F (-40° to 100°C)-40° to 212°F (-40° to 100°C)EN 50081-1 and EN 50081-2markEN 50082-1 and EN 50082-2Vibration resistance to≤ 25 gIEC 68-2-6 at 10 to 500HzSafety type to DIN 40050 IP 68Other DataSupply voltage2 conductor - 10 to 30 V3 conductor - 12 to 30 VResidual ripple supply voltage ≤ 5%Current consumption 3-conductorapprox. 25 mAReverse polarity protection of thesupply voltage, excess voltage,standardoverride and short circuit protectionLife expectancy≥ 10 million load cycles, 0 to 100%FSWeight210 gApplications:Approvals:Note: F.S. (Full Scale) = Relative to the full measuring range* = Other measuring ranges on request19Electronics Catalog

Model Code:SeriesHDA 38 = Pressure Transducer for Steel WorksMechanical Connection0 = G 1/2 A male thread4 = G 1/4 A DIN 38527 = SAE 6 9/16-18 UNF2A maleElectrical Connection0 = flying lead 6m (Teflon cable, silicon-free)Signal TechnologyA = 2 conductor, 4-20 mAE = 3 conductor, 0-20 mAPressure Range350 = 350 bar (5075 psi)Modification Number124 (determined by manufacturer)HDA 38 X 0 - X - 350 - 124Note: PSI pressures on request— Contact <strong>HYDAC</strong> for availabilityCircuit Connection:2 conductor 4 to 20 mAHDA38xx-AbrownblueRLRL0VUB3 conductor 0 to 20 mAblackHDA38xx-EbrownblueRLUBSignal0VPlug Connection:A-SignalBrown:Blue:E-SignalBlack:Brown:Blue:+ Supply0V+ SupplySignal0VRLmax. = UB - 10 V [Ω]0.02 ARLmax. = UB - 7 V [Ω]0.02 ANote: The load resistance RL is produced by the measuring resistance inside the evaluation unitand the line resistance of the connection line.UB = + supply voltageDimensions:cable glandpg 7ø1.18"(30mm)ø1.06"(27mm)0.31"(8mm)ø0.74"Hex1.17"(18.9mm) G1/4 A(29.6mm)cable glandpg 7ø1.18"(30mm)ø1.06"(27mm)0.31"(8mm)ø1.06"HexG1/2 A 1.17"(26.9mm) (29.6mm6 m(fully extendedcord length)3.23"(82mm)4.13"(105mm)0.08"(2mm)6 m(fully extendedcord length)3.23"(82mm)4.13"(105mm)0.12"(3mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 20

Display UnitsHDA 6000<strong>About</strong> HDA 6000 <strong>Intelligent</strong> Display Unit:The HDA 6000 is a microprocessor controlled display and control unit in standardcontrol panel module housing. A single-chip microprocessor controls all functions.A maximum of 3 analog inputs and 1 analog output is possible. The analog inputsignals are converted by a 10 bit A/D converter and displayed according to themeasuring scale selected by the user. Each of the 4 maximum possible relayscan be allocated to each of the 3 analog sensor inputs or the differentialbetween sensor signals 1 and 2. All operating parameters such as switchingpoints and switch-back (i.e. hysteresis) points can be programmed by means ofthe MODE and SET keys. The relays switch as soon as a pre-set switching pointis reached, or after a programmed delay. This function suppresses the reactionof the relays to short-term and irrelevant variations such as pressure spikes.Technical Details:HousingSupply voltagePower consumptionSupply sensor 1 and 2Input sensor 1 and 2Input sensor 3Interrogation rate of sensorError recognitionReset peak valueOutput sensor 1RS 232 C interfaceRelay outputConnectionsTemperature effectsmarkWeightControl panel module housing 48 x 96 mmControl panel cut out 45 x91Max. front panel thickness 23 mmDepth max. 200 mm115/230 V AC ±10%50 - 60 Hz24 V DC option (20.4 to 31.4)Residual ripple max. 2 V pp15 VA at 115/230 VFuse rating 0.32 AM at 115 VFuse rating 0.16 AM at 230 VFuse rating 0.8 AT 24 V DC± 12 V max. ±20 mA per sensor4 to 20 mA input resistance approx. 160 ΩOverload protection via PTC(positive temperature coefficient) connected in series0 to 10 V input resistance approx. 30 kΩ0 to 10 V input resistance approx. 45 kΩ16 ms, 4 ms for peak valuesError report if sensor current < 3.5 mAError output against 0 V(during standard operation 2 Hz pulse, 12 V pp)Level for “Reset” = 7.5 to 15 V, 12 V nominal0 to 10 V load resistance ≥ 2 kΩSignal according to RS 232 Cadjustable Baud rate 300 - 96001 start bit, 1 stop bit, no parity8 data bitsMechanical service life of contact 10 7 cyclesSwitching capacity: 30 W / 50 VASwitching voltage: 24 V DC / 50 V ACSwitching current: 0.01 mA to 3 APower supply via cable (length 1.5 meters)at the back, with main plug to Euro standardSignals via double pin terminal plug at the back,max. cable diameter 1.5mmPermissible ambient temperature 273 K to 323 K(0 to 50°)Temp. variation of zero point 0.12% / 10 K typ.Temp. variation of sensitivity 0.2% / 10 K typ.800 gApplications:Approvals:Note: During switching of inductive loads, a protection diode (DC voltage) ora varistor (AC voltage) must be connected parallel to the load.21Electronics Catalog

Model Code:SeriesSeries = HDA 6000Sensor inputs0 = 1 sensor (4 to 20 mA), 2 relay outputs1 = 3 sensors (2 x 4 to 20 mA, 1 x 0 to 10 V), 4 relay outputs2 = 3 sensors (3 x 0 to 10 V), 4 relay outputsSupply voltage115 = 115 V / 50 - 60 Hz230 = 230 V / 50 - 60 Hz024 = 24 V DCModification number000 = standardCircuit Connection:HDA 6000 - X - XXX - 000Plug Connection:sensor 1+HDA 3000-DApressure sensorthree-conductorsensor 2+HDA 3000-DApressure sensorthree-conductorsensor 3+with built-in0 Vpower supplyI = 4 to 20 mAI = 4 to 20 mA0 to 10 Vremote displayof sensor 10 to 10 V1231141256+12 Vsensor 1 signal 4 to 20 mA–12 Vsensor 2 signal 4 to 20 mAsensor 1 analogue output0 to 10 Vsensor 30 V analogueHDA 6000sensor 1 +with built-inpower supplysensor 1HDA 3000-B +Asensor 24 to 20 mA 12312+12 Vsensor 1 signal 4 to 20 mA–12 VHDA 6000+12 Vsensor 1 signal 4 to 20 mAHDA 60001111020 110/220 V AC ±10%24 V DCload 1varistor U7relay K 1HDA 3000-B +A11sensor 2 signal 0 to 10 Vauxillary voltagefor load 1 -4load 2varistor Uload 3varistor U891718relay K 2relay K 3sensor 3HDA 3000-B +A125sensor 3 0 to 10 V0 V analogue19depending on auxillary voltageand load: add external varistorload 4varistor U20relay K 4S1*16programming enable15digital 0V* S1 closed or bridge connected = programming enableS1 open = programming disableprinterRXD313TXDcomputerTXD214RXDHDA 6000terminalGND115digital 0 Vsensor 1HDA 3000-A +I = 4 to 20 mA12+12 Vsensor 1 signal 4 to 20 mApressure sensortwo-conductor3–12 Vsensor 2HDA 3000-A +pressure sensortwo-conductorI = 4 to 20 mA11HDA 6000sensor 2 signal 4 to 20 mAS211015+ 12 Vpulse output*reset inputdigital 0 VDimensions:max. front panel thickness 0.91" (23 mm)mounting frameHDA 6000ELECTRONIC0.55"(14mm)MODE1 2 3 4SET1.89"(48mm)1.67"(42.5mm)3.78"(96mm)4.41"(112mm)0.20"(5mm)5.75"(146mm)min.7.09"(180mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 22

Pressure SwitchesEDS 300<strong>About</strong> EDS Pressure Switches:The EDS 300 is a compact unit which combines a pressure transducer, digitaldisplay, 2 switches, and analog output for controlling pressure in hydraulic andpneumatic systems. The transducer converts system pressure into an electricalsignal for the display and analog output. External adjustments allow the user toset the pressure switch points and switchback points. The 3 way functionality ofthis device offers a large cost savings to purchasing a gauge, transducer, andswitch individually.Technical Details:Input DataMeasuring RangesOverload PressuresBurst PressureOutput DataAccuracy (display, analog output)RepeatabilityTemperature DriftAnalog OutputSwitching OutputsTypeSwitching CurrentSwitching CyclesReaction TimeAmbient ConditionsTemperature Range of MediumAmbient Temperature RangeStorage Temperature RangeNominal Temperature Range-14 to 75 psi;0 to 150, 1000, 3000, 6000, 9000 psi150% FS300% FS≤ ±1.0% FS max.≤ ±0.5% FS max.zero point max:≤ ±0.016% / ˚F (≤ ±0.03% / ˚C)range max: ≤ ±0.016% / ˚F (≤ ±0.03% / ˚C)4 to 20 mA, ohmic resistance ≤ 400 ΩPNP transistor outputmax. 1.2 A≥ 100 millionapprox. 10 ms-13 to 176 ˚F (-25 to 80 ˚C)-13 to 176 ˚F (-25 to 80 ˚C)-40 to 176 ˚F (-40 to 80 ˚C)14 to 158 ˚F (-10 to 70 ˚C)mark EN 50081-1 and -2, EN 50082-1 and -2Vibration Resistanceapprox. 10 g / 0 to 500 HzShock Resistanceapprox. 50 g / 1msOther DataSupply Voltage: EDS 356-112 to 32 VDCEDS 356-2, EDS 356-320 to 32 VDCElectrical Connection4 pole plug M12x1Current Consumptionapprox. 100 mA (without switching output)Safety TypeIP65Hydraulic ConnectionSAE 4 femaleParts in Contact with MediumStainless SteelMaterial of HousingTube: Stainless SteelGf30Keypad Housing PA6.6Display4-digit, 7-segment LED, redWeightapprox. 300 gApplications:Approvals:23Electronics Catalog

Model Code:SeriesEDS 3 = 300 Series Electronic Pressure SwitchMechanical Connection5 = SAE-4 female thread (7/16-20 UNF2B)Electrical Connection6 = M12x1 plug, 4 pole (connector not included)Output1 = 1 Switching output2 = 2 Switching outputs3 = 1 Switching output and 1 analog outputPressure Ranges0089 = -14 to 75 psi (-1 to 5 bar) (vacuum version see also modification number)0150 = 0 to 150 psi (10.3 bar)1000 = 0 to 1000 psi (69 bar)3000 = 0 to 3000 psi (207 bar)6000 = 0 to 6000 psi (414 bar)9000 = 0 to 9000 psi (620 bar)Modification Number400 = standard401 = vacuum versionNote: Refer to Standard Stock list for popular model code combinations.Circuit Connection:Model EDS 356-11 switching outputPlug Connection:EDS 3 5 6 - X - XXXX - XXX.EDS 300 use with ZBE 06 (see page 56)+ 112 to 32 VDC- 3lmax. 1.2 AEDS 356-1 4SP 1431 2Model EDS 356-22 switching outputsDimensions:ConnectorM12x1 4 pole male1.16"(29.5mm)lmax. 1.2 A+ 1 4SP 120 to 32 VDC EDS 356-2lmax. 1.2 A- 3 2SP 21.4"ø (35mm)EDSModel EDS 356-31 switching output 1 analogue outputSP1PSISP2lmax. 1.2 A+ 1 4SP 120 to 32 VDC EDS 356-3l = 4 to 20 mA- 3 2analogueRLmode3.54"(90mm)ø 0.787"(20mm)HexSW 1.053"(27mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 24

Pressure SwitchesEDS 300 - Shipbuilding<strong>About</strong> EDS 300 Pressure Switches:The EDS 300 is a compact, electronic pressure switch with digital display. The pressuremeasurement is based on a thin film strain gauge sensor cell in stainless steel. All partsin contact with the fluid are in stainless steel, and are welded together. Since no sealsare required in the sensor chamber, leakage is eliminated.Two relay switching outputs with N/O function and an additional analog output signal (4to 20 mA) enable the pressure switch to be incorporated into the most modern controlconcepts. The switching points and the corresponding hysteresis can easily be adjustedvia the keypad.For optimum adaptation to a particular application, the unit has many additionaladjustment parameters, e.g. switching direction of the relays, switching delay times.Areas of application are pressure or maximum value monitoring on marine transmissions,diesel engines, pumps and general hydraulic and pneumatic systems.Technical Details:Input DataMeasuring ranges-14 to 75, 150, 1000, 3000, 6000, 9000 psi-1 to 5, 006, 016, 040, 100, 250, 400, 600 barOverload pressure200, 300, 3000, 7000, 11000, 13000 psi15, 15, 32, 80, 200, 500, 800, 900 barBurst pressure400% FSOutput DataAccuracy (display, analog output)≤ ±1% FS max.Repeatability≤ ±0.5% FS max.Temperature drift≤ ±0.3% / 10 K zero point max.≤ ±0.3% / 10 K range max.Analog output4 to 20 mA, ohmic resistance ≤ 400 ΩSwitching OutputsType2 relay contacts (N/O)Switching voltage10 mV to 60 V (AC or DC)Switching current0.01 mA to 1AMaximum switching output30 W / 30 VA(for inductive load, use varistors)Life expectancy20 million (min. load)0.5 million (max. load)Reaction timeapprox. 10 msAmbient ConditionsTemperature range of medium-13° to 176°F (-25° to 80°C)Ambient temperature range-13° to 176°F (-25° to 80°C)Storage temperature range-40° to 176°F (-40° to 80°C)Nominal temperature range-14° to 158°F (-10° to 70°C)markEN 50081-1, EN 50081-2EN 50082-1, EN 50082-2Vibration resistance5 to 25 Hz: 3.2 mm25 to 500 Hz: 4 gOther DataSupply voltage20 to 32 VDCElectrical connectionplug to DIN 43651 (6 pole + earth)Current consumptionapprox. 100 mASafety type IP 65Hydraulic connectionG 1/4 A male, (torque rating approx. 15 lb-ft)SAE 4 female thread (torque rating approx. 6 lb-ft)Parts in contact with fluidstainless steel, FPM sealMaterial of housingtube: stainless steelkeypad housing: PA6.6 Gf30Display4-digit, 7 segment LED, redWeightapprox. 300 gApplications:Approvals:American Bureau of ShippingNo.: 00-ES 19976-XLloyds Register of ShippingNo.: 00/20048Det Norske VeritasNo.: A-7710 (895.10)Germanischer LloydNo.: 15519-00HHBureau VeritasNo.: 10343 /A0 BV25Electronics Catalog

Model Code:EDS 3 X 7 - 4 - XXX - S00 (PSI)SeriesEDS 3 = 300 Series Electronic Pressure Switch for ShipbuildingMechanical Connection4 = G 1/4 A DIN 38525 = SAE-4 7/16-20 UNF2B female7 = SAE-6 9/16-18 UNF2A maleElectrical Connection7 = DIN43651 plug, 6 pole + ground (connector ZBE 10 not included)Output4 = 2 switching outputs and 1 analog outputMeasuring Rangesbar version: only in conjunction with connection thread G 1/4 A:XXX = 006, 016, 040, 100, 250, 400, 600 with modification no. S00for -1 to 5 bar use “006” and modification no. S13psi version: only in conjunction with connection thread SAE 4:XXXX = 0150, 1000, 3000, 6000 with modification no. S40for -14 to 75 psi use “0089” and modification no. S41Modification NumbersS00 = bar version (except for -1 to 5 bar)S13 = vacuum version -1 to 5 barS40 = psi version (except for -14 to 75 psi)S41 = vacuum version -14 to 75 psiPSI = Additional code for psi version (not required for bar versions)Circuit Connection: Plug Connection: Plug Connection:PE1+20 .. 32 V4-SP 1SP 23265RLAnaloguel = 4 .. 20 mAPin 1:Pin 2:Pin 3:Pin 4:Pin 5:Pin 6:+ SupplySP Common PoleSP1 Contact0V4 to 20 mA SignalSP2 ContactZBE 10 (see page 56)Dimensions:ø1.4"(35mm)M25PlugDIN 436516 pole + earth1.16"(29.5mm)0.08"2mm0.47"(12mm)Adapter Available:Adapter SAE-4 (m) to 1/4 NPT (m) StainlessPart Number - 02701426SP1EDSPSI SP2mode3.54"(90mm)2.15"(54.5mm)G 1/4 Aø 0.74"(18.9mm)0.27"(7mm)0.56"(14mm)0.59"(15mm)SAE 4hex. -SW27ø 0.79"(20mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 26

Pressure SwitchesEDS 410<strong>About</strong> EDS 410 Pressure Switches:The electronic pressure switch EDS 410 was specially developed for use inindustrial, mobile, and transit applications.The small, compact unit has a very robust pressure sensor with thin film on astainless steel membrane. The transistor switching output (PNP) is designed sothat switching valves can be controlled directly, up to a current consumption of1.2 Amps. The switching point and switch-back point of the EDS 410 is set bythe manufacturer according to customer specification.Various pressure ranges are available between 0 to 10 bar and 0 to 600 bar.The EDS 410 offers great flexibility with various options for electrical connections.Standard connections such as the DIN 43650 are available, as well as flyingleads if necessary.A minimum order of 50 pieces is needed.Technical Details:Input DataMeasuring ranges232 to 8700 PSI (16 to 600 bar)Overload pressure150% FSBurst pressure300% FSMechanical ConnectionSAE 6 9/16-18 UNF2A maleTightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediastainless steel, FPM sealOutput DataType1 PNP transistor outputMaximum output load1.2 ASwitch pointto defineSwitch-back pointto defineAccuracy (B.F.S.L) including linearity,hysteresis, and repeatability±0.5 %FSTemperature compensation≤ ±0.03%FS/°Czero point≤ ±0.017%FS/°FTemperature compensation≤ ±0.03%FS/°Cover range≤ ±0.017%FS/°FLong-term drift≤ ±0.3%FS typ. / yearAmbient ConditionsNominal temperature range-13° to 185°F (-25° to 85°C)Operating temperature range-13° to 185°F (-25° to 85°C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)mark, EMCEN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-2Vibration resistance toIEC 68-2-6 at 10 to 500Hz< 20g (196.2m/s 2 )Safety type to DIN 40050 IP 65Other DataSupply voltage:12 to 32 VDCfuse: 5 A normal blow or5 A slow blowResidual ripple supply voltage ≤ 5%Electrical connection Connector DIN 43650Reverse polarity protection of thesupply voltage, excess voltage,standardoverride and short circuit protectionLife expectancy>10 mil load cycles 0 to 100% FSWeight145 gApplications:Approvals:27Electronics Catalog

Model Code:SeriesEDS 410 = 410 Series Electronic Pressure SwitchPressure RangeXXX = 232, 580, 1450, 3625, 5800, 8700 psi= 016, 040, 100, 250, 400, 600 barSwitch Function0 = normally open1 = normally closedModification NumbersXXX = defined by manufacturerSwitch PointXXX = XXXSwitchback PointXXX = XXXEDS 410 - XXX - X - XXX -(XXX/XXX bar or psi)Circuit Connection:Fuse 5A 1+12 to 32 VDC_2EDS 410-X3SP1 Imax. 1.2 APlug Connection:EDS 410 use with ZBE 01 (see page 56)1 23Dimensions:SAE 63.642"(92.5 mm)ø 1.378"(35 mm)ø 0.748"(18.9mm)0.091"(2.3mm)Hex SW(27mm)1.063"2.244"(57mm)1.378"(35 mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 28

Pressure SwitchesEDS 505 Adjustable Pressure Switch<strong>About</strong> EDS 505 Adjustable Pressure Switches:Technical Details:Input DataMeasuring ranges16, 40, 100, 250, 400, 600 barOverload pressure32, 80, 200, 500, 800, 900 barBurst pressure200, 200, 500, 1000, 2000, 2000 barMechanical ConnectionG 1/4 A maleTightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediastainless steel, FPM sealOutput DataAccuracy including linearity, hysteresis≤ ±0.5%FS BFSLTemp. comp. zero point≤ ±0.017%FS/°FTemp. comp. over range≤ ±0.017%FS/°FRise timeapprox. 1 msLong-term drift≤ ±0.3%FS typ. / yearSwitching OutputType1 PNP transistor outputMaximum output load1.2 ARepeatability≤ ±0.5%FS max.Switching cycles> 100 millionReaction time20 ms16 bar: 1 to 16 bar40 bar: 3 to 40 barField adjustable setting100 bar: 8 to 100 barranges of the switch point250 bar: 15 to 250 bar400 bar: 30 to 400 bar600 bar: 40 to 600 barSetting range of the hysteresis1.5 to 20% FSAmbient ConditionsNominal temperature range14° to 158°F (-10° to 70°C)Operating temperature range-13° to 185°F (-25° to 85°C)Storage temperature range-40° to 212°F (-40° to 100°C)Fluid temperature range-40° to 212°F (-40° to 100°C)markEN 50081-1 and EN 50081-2EN 50082-1 and EN 61000-6-2Vibration resistance toIEC 68-2-6 at 10 to 500Hz20 gShock resistance50 g/msSafety type to DIN 40050 IP 65Other DataSupply voltage:12 to 32 VDCCurrent consumptionapprox. 50 mAElectrical connectionDIN 43650 (3 pole + ground)Reverse polarity protection of thesupply voltage, excess voltage,standardoverride and short circuit protectionWeight260 gThe EDS 505 is robust and simple to operate. Essentially, it consists of a pressuremeasuring cell and evaluation electronics which convert the measuring cell signalinto a switching signal.Long life and vibration resistance are guaranteed because the unit is constructedwithout moving parts. The EDS 505 is used in hydraulic systems, process engineeringand mobile applications as a pressure monitor and two-position controller.Accumulator charging, pressure control in chucks and compressor controls are afew examples where the mechanical pressure switch has a limited use and canbe replaced by the EDS 505. An LED light on the end of the switch gives animmediate visual indication when the switches been activated.Applications:Approvals:29Electronics Catalog

Model Code:SeriesPressure Range016 = 16 bar (232 psi)040 = 40 bar (580 psi)100 = 100 bar (1450 psi)250 = 250 bar (3625 psi)400 = 400 bar (5800 psi)600 = 600 bar (8700 psi)Mechanical Connection4 = G 1/4 A maleSwitch Function0 = normally open1 = normally closedModification Numbers000 = standardEDS 505 - XXX - 4 X - 000Circuit Connection:Plug Connection:+12-32 V–1 32EDS 505I max1.2 APE 2131 = 12V - 32 V DC2 = 0V3 = output (PNP)I max = 1.2 APE = groundDimensions:~1.38"(35mm)0.74"(18.9mm)SW 27~2.38"Sleeve (60.5mm)withLED Lighttransparent lidG 1/4ø 1.38"(35mm)1.02"(26mm)2.36"(60mm)3.34"(84.9mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 30

Pressure SwitchesEDS 601<strong>About</strong> EDS 601 Pressure Switches:The EDS 601 is an electronic two-channel pressure switch with display and analogoutput. Its digitally adjustable switching points and switching hysteresis make itparticularly suitable for applications requiring frequent change-overs or accurateswitching point settings.The variety of setting parameters ensures versatility for use in all control andmonitoring tasks in hydraulics, pneumatics, process controls and in general testand control engineering applications.Technical Details:Input DataMeasuring ranges16, 40, 100, 250, 400, 600 barOverload pressure24, 60, 150, 375, 600, 900 barBurst pressure300% FSMechanical ConnectionG 1/4 B femaleTightening torqueapprox. 15 lb-ft (20 Nm)Parts in contact with mediastainless steelOutput DataAccuracy including linearity, hysteresis≤ 0.5% FS B.F.S.LTemp. comp. zero point≤ ±0.014%FS/°F max.Temp. comp. over range≤ ±0.014%FS/°F max.Long-term drift≤ ±0.3%FS typ. / yearSignal signal0 to 10 V ohmic resistance: min 2 kΩ4 to 20 mA ohmic resistance: max. 400ΩMax. frequency signal output20 HzRelay OutputsNumber / function2 relays with change-over contactsRepeatability≤ 0.5% FS max.Switching voltage0.1 to 250 VSwitching current0.025 to 2 ASwitching capacity50 W / 400 VALife expectancy10 million without load / 1 million at nominal loadReaction timeapprox. 10 ms incl. electronicsAmbient ConditionsNominal temperature range-13° to 158°F (-25° to 70°C)Operating temperature range-13° to 158°F (-25° to 70°C)Storage temperature range-40° to 185°F (-40° to 85°C)Fluid temperature range-40° to 185°F (-40° to 85°C)mark EN 50081-1 and -2, EN 50082-1 -2Vibration resistance25 g / 0 to 500 HzShock resistance50 g/msSafety type to DIN 40050 IP 65Other DataDisplay7 segment LED display, 4 digits, 13 mm highHousing materialaluminum, anodizedDimensionsapprox. 72 x 72 x 110 mm (WxHxD)Connection supply voltageplug to DIN 43650 / ISO 4400 (3 pole + ground)Connection relayplug to DIN 43651 (6 pole + ground)Supply voltage18 to 32 VDCCurrent consumptionapprox. 120 mASwitch on Currentapprox. 1.5 A (0.1 sec)Reverse polarity protection of thesupply voltage, excess voltage,standardoverride and short circuit protectionWeight200 gApplications:Approvals:31Electronics Catalog

Model Code:SeriesPressure Range016 = 16 bar (232 psi)040 = 40 bar (580 psi)100 = 100 bar (1450 psi)250 = 250 bar (3625 psi)400 = 400 bar (5800 psi)600 = 600 bar (8700 psi)Modification Numbers000 = standardAccessories Included:Mating plug to DIN 43650 (supply voltage)Mating plug to DIN 43651 (relay contacts)Other Accessories:Assembly set for front panel mountingEDS 601 - XXX - 000Circuit Connection:Plug Connection:PE2 13 64 51 = relay 1 N/C contact2 = relay 1 N/O contact3 = relay 1 common supply4 = relay 2 N/C contact5 = relay 2 N/O contact6 = relay common supplyPE1 231 = supply2 = 0V3 = analog outputPE = groundDimensions:3.68"2.83"(93.5mm)(72mm) 0.35"(9mm)6.44"(163.5mm)Without cable plug 7 poleELECTRONICEDS 601PROGSP 1 SP 2bar2.83"(72mm)2.64"(67mm)3.19"(81mm)G 1/4 (DIN3852)4.13"(105mm)4.13"(105mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 32

Pressure SwitchesEDS 710<strong>About</strong> EDS 710 Pressure Switches:Specifically for OEM applications in mobile industry, the EDS 710 was developedas one of the smallest electronic pressure switches in the world. Switch andswitch-back points are factory set as NO or NC according to customerrequirements. Output load capacity of 400 mA enables connection to controlunits (e.g. PLC) as well as small electronic devices (e.g. relays). Featuring anM12x1 connector or flying leads alternatively as electric connection, enablesflexibility regarding various wiring systems. Class of protection is IP 67 standard.In order to protect in more harsh applications, a special protective rubber coverwas invented. When used, the protection class is extended to IP 69K.A minimum order of 250 pieces per model is usually required.Technical Details:Input DataMeasuring rangesOverload pressureBurst pressureMechanical ConnectionTightening torqueParts in contact with mediaOutput DataTypeMaximum output loadSwitch pointSwitch-back pointAccuracy (B.F.S.L) including linearity,hysteresis, and repeatabilityTemp. comp. zero pointTemp. comp. over rangeLong-term driftAmbient ConditionsNominal temperature rangeOperating temperature rangeStorage temperature rangeFluid temperature rangemark, EMCVibration resistance toIEC 68-2-6 at 10 to 500HzSafety type to DIN 40050232 to 8700 PSI (16 to 600 bar)150% FS300% FSSAE 6 9/16-18 UNF2A maleapprox. 15 lb-ft (20 Nm)stainless steel, FPM seal1 PNP transistor output400 mAto defineto define±0.5 %FS≤ ±0.017%FS/°F≤ ±0.017%FS/°F≤ ±0.3%FS typ. / year-13° to 185°F (-25° to 85°C)-13° to 185°F (-25° to 85°C)-40° to 212°F (-40° to 100°C)-40° to 212°F (-40° to 100°C)EN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-210 mil. load cycles, 0 to 100%FSWeight145 gApplications:Approvals:33Electronics Catalog

Model Code:SeriesEDS 710 = 710 Series Electronic Pressure SwitchPressure RangeXXX = 232, 580, 1450, 3625, 5800, 8700 psi= 016, 040, 100, 250, 400, 600 barSwitch Function0 = normally open1 = normally closedModification NumbersXXX = defined by manufacturerSwitch PointXXX = XXXSwitchback PointXXX = XXXEDS 710 - XXX - X - XXX -(XXX/XXX bar or psi)Circuit Connection:Plug Connection:EDS 710 use with ZBE 06 (see page 56)+–EDS 710-XSP1 Imax. 400 mA431 2Dimensions:1.40"(35.5mm)0.08"(2mm)SAE-69/16-18 UNFø0.73"(18.5mm)0.74"(18.9mm)hex-SW0748 0.39"(10.0mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 34

Pressure SwitchesEDS 1700<strong>About</strong> EDS 1700 Pressure Switches :The EDS 1700, with its built-in pressure measuring cell, a 4-digit display andthe 4 switching outputs, offers the user all the advantages of a modern electronicpressure switch.4 switching points and switch-back points can be adjusted very simply andindependently of each other via a membrane keypad. For optimum incorporationinto monitoring systems (eg with PLC) an analog output is also available(4 to 20 mA or 0 to10 V.)The main applications of the EDS 1700 are in hydraulics and pneumatics. Theinstrument is ideal for use where frequent switching cycles (several million)require permanent switching point accuracy or simple and precise adjustment.Technical Details:Input DataMeasuring Ranges232, 580, 1450, 3625, 5800, 8700 psiOverload Pressures200%, max. 1300 psiBurst Pressure300% FSHydraulic ConnectionG 1/4 B femaleTorque rating15 lb-ft (20 Nm)Parts in contact with mediaStainless SteelOutput DataAccuracyP = 0.5% / N = 1.0% or(display, analog output) max. P = 0.25%FS / N = 0.5%FS both as B.F.S.L.Temperature Drift EDS 1700...P zero point max. ≤ ±0.2% / 10 Krange max.≤ ±0.2% / 10 KEDS 1700...N zero point max. ≤ ±0.3% / 10 Krange max.≤ ±0.3% / 10 KAnalog Output4 to 20 mA, ohmic resistance ≤ 400 Ω0 to 10 V ohmic resistance ≥ 2 kΩSwitching OutputsType4 relays with change-over contacts in 2 groups(common supply of each group connected)RepeatabilityEDS 1700...P ≤ ±0.25% FS max.EDS 1700...N ≤ ±0.5% FS max.Switching Voltage0.1 to 250 VAC / VDCSwitching Current0.009 to 2 ASwitching Capacity400 VA, 50 W (for inductive load use varistors)Life Expectancy of Contacts≥ 20 million (minimum load)≥ 1 million (maximum load)Reaction Timeapprox. 20 msSwitching Point Setting Range1.5 to 100% FSSetting Range of Switch-backHysteresis / Switch-back Points1 to 99% FSAmbient ConditionsTemperature Range of Medium -13 to 176 ˚F (-25 to 80˚C)Ambient Temperature Range-13 to 140 ˚F (-25 to 60˚C)Storage Temperature Range-40 to 176 ˚F (-40 to 80˚C)Nominal Temperature Range50 to 158 ˚F (10 to 70˚C)mark EN 50081-1 and -2, EN 50082-1 and -2Vibration Resistanceapprox. 5 gShock Resistanceapprox. 10 gSafety TypeIP65Other DataSupply Voltage 22 to 32 VDC (residual ripple ≤ 10%)Electrical Connection14 pole terminal block(cross-section of connection max. 1.5 mm 2 )Current Consumptionapprox. 200 mADisplay4-digit, 7-segment LED, red (digits 13mm high)Weightapprox. 800 gApplications:Approvals:35Electronics Catalog

Model Code:SeriesEDS 17 = 1700 Series Electronic Pressure SwitchMechanical Connection9 = G 1/4 B femaleEDS 17 9 X - X - XXX - 000Display (units of pressure)1 = 4 digit bar2 = 4 digit psiAccuracyP = 0.25% BFSLN = 0.50% BFSLPressure Ranges016 = 16 bar (232 psi)040 = 40 bar (580 psi)100 = 100 bar (1450 psi)250 = 250 bar (3625 psi)400 = 400 bar (5800 psi)600 = 600 bar (8700 psi)note: vacuum version on requestModification Number000 = standardCircuit Connection:Relay 4= Switching Point 41413Mechanical Connection:For other mechanical connections, refer to our 1620 seriestestpoint and hose accessories.Relay 3= Switching Point 31211109TestPoint with Hose Connection:Relay 2= Switching Point 2Relay 1= Switching Point 18765Analogue Output (0 V)Analogue Output (signal +)43GroundSupply (0 V)2Supply (+ input voltage)1Dimensions:PG 11 Cable gland(2 places)countersunkto DIN 74-Km5(4 places)5.9"(150mm)EDS17003.76"(95.5mm)3.3"(84mm)modeONOFFONOFFresetmaxONOFFmaxbarONOFF+-SP1SP2SP3SP4portcenterline4.49"(114mm)4.96"(126mm)portcenterline3.15"(80mm)1.5"(38.5mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 36

Pressure SwitchesEDS 3000270˚350˚<strong>About</strong> EDS 3000 Pressure Switches:The EDS 3000 electronic pressure switch is the result of joint development andinnovation in the field of adjustable pressure switches with display. It is a compactunit which combines a pressure switch, digital display, and transducer for controllingpressure in hydraulic and pneumatic applications. The most noticeable innovationis the alignment of the serial four-digit display. After mounting, the switch may beturned as a whole. Additionally, the front panel with push buttons may be turned.This eliminates the need for mechanical adapters. Display units can be shown inbar, psi, or mpa. Pressure ranges from vacuum to 9000 psi are available.Switching outputs in one or two switch versions with or without analog outputare available when choosing model code.Technical Details:Input DataMeasuring ranges (type 1)(type 3)(type 4)Overload pressureBurst pressureMechanical ConnectionTightening torqueParts in contact with mediaOutput DataAccuracy (B.F.S.L)including linearity & hysteresisTemp. comp. zero pointTemp. comp. over rangeAnalog output signal, adjustableSwitching OutputsTypeRepeatabilitySwitching currentSwitching cyclesReaction timeAmbient ConditionsNominal temperature rangeAmbient Temperature rangeStorage temperature rangeFluid temperature rangemarkVibration resistance toIEC 68-2-6 at 10 to 500HzShock resistanceSafety type to DIN 40050Other dataSupply voltageElectrical connectionCurrent consumptionReverse polarity protection of thesupply voltage, excess voltage,override and short circuit protectionDisplayWeight0 to 15, 50 psi0 to 15, 30, 50, 150, 250, 500 psi-14 to 75 psi0 to 1000, 3000, 6000, 9000 psi200%FS max. 900 bar (13000 psi)300%FS max. 2000 bar (29000 psi)G 1/4 A male, 1/4”-18 NPT maleSAE 6 9/16-18 UNF2A maleapprox. 15 lb-ft (20 Nm)Stainless steel, FPM seal (type 4)brass, ceramic, FPM seal (types 2 & 3)≤ ±0.5 %FS≤ ±0.017%FS/°F max.≤ ±0.017%FS/°F max.4 to 20 mA, ohmic resistance ≤ 500Ω0 to 10 V, ohmic resistance ≥ 1k ΩPNP transistor output≤ ±0.5%FS max.max. 1.2 A≥ 100 million< 10 ms-13° to 185°F (-25° to 85°C)-13° to 176°F (-25° to 80°C)-40° to 176°F (-40° to 80°C)-13° to 176°F (-25° to 80°C)EN 50081-1, EN 50081-2EN 50082-1, EN 61000-6-2ca. 10 g50 g/msIP 67 (molded M12x1 connector is used)18 to 32 VDCM12x1 (4 pin or 5 pin)approx. 100 mA (without switching output)standard4 digit, 7 segment LED redapprox. 300 gApplications:Approvals:37Electronics Catalog

Model Code:SeriesEDS 3 = 3000 Series Electronic SensorSensor Type1 = Ceramic absolute3 = Ceramic relative4 = Thin-film relativeMechanical Connection6 = 1/4” - 18 NPT male thread (brass types 1 and 3)7 = SAE-6 male thread (9/16-18 UNF2A stainless steel type 4)Electrical Connection6 = M12x1 plug, 4 pole for output codes 1, 2, and 3 (connector not included)8 = M12x1 plug, 5 pole for output code 5 (connector not included)Output1 = 1 Switch output (only with electrical connection 6)2 = 2 Switch outputs (only with electrical connection 6)3 = 1 Switch with analog output (only with electrical connection 6)5 = 2 Switch with analog output (only with electrical connection 8)Pressure RangesType 1 (ceramic - absolute) Type 3 (ceramic - relative) Type 4 (thin-film, relative)0015 = 0 to 15 psi 0015 = 0 to 15 psi 1000 = 0 to 1000 psi0050 = 0 to 50 psi 0030 = 0 to 30 psi 3000 = 0 to 3000 psi0050 = 0 to 50 psi 6000 = 0 to 6000 psi0150 = 0 to 150 psi 9000 = 0 to 9000 psi0250 = 0 to 250 psi0500 = 0 to 500 psi0089 = -14 to 75 psiModification Number400 = standard in psiNote: G 1/4 port sizes are available upon requestCircuit Connection:Model with 1 switch outputPlug 4-pol. M12x1+18 to 32 V–EDS 3X46-11Imax 1.2 A4SP 13Plug Connection:EDS 3 X X X - X - XXXX - 400EDS 3XX6 EDS 3XX8 use with ZBE 06 (4-pole) & ZBE 08 (5-pole)(4-pole) (5-pole) (see page 56)431 24 31 5 2Model with 1 switch output and signal outputPlug 4-pol. M12x1+18 to 32 V–EDS 3X46-3Imax 1.2 A1 4SP 13I = 4 to 20 mA2AnalogDimensions:ø 2.15" (54.5mm)ø 1.65"(42mm)M12x1RLModel with 2 switch outputsPlug 4-pol. M12x1EDS 3X46-2Imax 1.2 A+ 1 4SP 118 to 32 VImax 1.2 A– 3 2SP 2mode2.95"(75mm)3.68"(93.5mm)Model with 2 switch outputs and signal outputPlug 5-pol. M12x1+18 to 32 V–EDS 3X48-5Imax 1.2 A1 4SP 1Imax 1.2 A5SP 23I = 4 to 20 mA2AnalogRLSAE 6ø 0.74"(18.9mm)6kt-SW270.08"(2mm)0.47"(12mm)ø 1.16"(29.5mm)0.63"(16mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 38

Temperature TransducersETS 4000<strong>About</strong> ETS 4000 Temperature Transducers:The temperature transducer series ETS 4000 was designed to be fitted directly tothe hydraulic system to ensure direct contact with the media for the most accurateand up to date temperature reading. This unit converts the fluid temperaturemeasurement into a usable, 4 to 20mA output signal.The ETS 4000 has solid construction with all stainless steel wetted parts and tubehousing. The transducer hydraulic connection is rated to 8700 psi.All units are individually calibrated on a computer-controlled test rig and subjectedto a final test. The quality system is ISO 9001 certified.Technical Details:Input DataMeasuring range-25° to 100°C (-13° to 212°F)Pressure resistance600 bar (8700 psi)Pressure overload900 bar (13050 psi)Mechanical connectionG 1/4 A maleTorque ratingapprox. 15 lb-ft (20 Nm)Parts in contact with mediaStainless steel, FPM sealOutput DataOutput signal2-conductor, 4 to 20 mAAccuracy≤ ±1°C (1.8°F) max.Temperature drift 0.006%FS / °FAmbient ConditionsAmbient temperature-30°C to 80°C (-22°F to 176°F)Media temperature -25° to 100°C (-13° to 212°F )markEN50081-1, EN50081-2,EN50082-1, EN50082-2Vibration resistance toIEC 68-2-6 at 10 to 500 Hz≤ 20 g (196.2m/s 2 )Safety type IP 65Other DataSupply voltage10 to 30 V DCElectrical connection4 pole Binder plug 714 M18x1Residual ripple max. 5%Maximum load resistanceRL max. = (UB-10V) / 0.02 A [Ω]Safety measuresReverse polarity and excess voltageprotection, electronic current limitApplications:Approvals:39Electronics Catalog

Model Code:SeriesETS 4 = 4000 series temperature transducerAccuracy1 = 1°C (1.8°F)Mechanical Connection4 = G1/4 A maleElectrical Connection4 = 4 pole Binder plug 714 M18x1 (connector not included)Output SignalA = 2 conductor, 4 to 20mAModification Number000 = standardETS 4 1 4 4 - A - 000Circuit Connection:Plug Connection:ETS 4144 use with ZBE 02 or ZBE 03(see page 56)ETS 4144-A1234FreeRLRLFree+ Supply0V2 31 4Dimensions:0.69"(17.5mm)3.23"(82mm)Hex 6kt-SW270.08"(2mm)0.47"0.18"(12mm) (4.5mm)G 1/4 Aø1.18"ø1.06"(30mm) (27mm)0.31"(8mm)0.24"(6mm)(Stem)0.74"(18.9mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 40

Temperature TransducersETS 7000<strong>About</strong> ETS 7000 Temperature Transducers:The ETS 7000 joins the lineup of of our smallest series of transmitters. Due toit’s pressure resistance the small partner of ETS 4000 also is applicable tohydraulic systems up to 600 bar. Temperatures in the range of -25° to 100°Care transformed into output signal of 4 to 20 mA. As with the complete 7000series electric connection, M12x1, or flying leads are available alternatively.Type of protection is IP 67. While using a special protective rubber cover, thetype of protection is extended to IP 69K.Technical Details:Input dataMeasuring principleMeasuring rangePressure resistancePressure overloadMechanical connectionTorque ratingParts in contact with mediaOutput dataOutput signalAccuracyRise timeAmbient conditionsFluid temperature rangeOperating temperature rangeStorage temperature rangemarkVibration resistance toSafety type to DIN 40050Other dataSupply voltageElectrical connectionHousing materialWeightSilicon semiconductor element-13° to 212°F (-25° to 100°C)8700 psi (600 bar)13000 psi (900 bar)G 1/4 A maleapprox. 15 lb-ft (20 Nm)Stainless steel, Seal: FPM4 to 20 mA≤ ±1.5%FS typ.≤ 15 s-13° to 212°F (-25° to 100°C)-13° to 176°F (-25° to 80°C)-40° to 212°F (-40° to 100°C)EN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-2≤ 196.2m/s 2 (20g)IP 67 (w/ ZBE 06 molded cableor flying lead)8 to 32 V DCM12x1Stainless steelapprox. 145 gApplications:Approvals:41Electronics Catalog

Model Code:SeriesETS 7 = 7000 series temperature transducerAccuracy2 = 1.5%FSMechanical Connection4 = G1/4 A maleElectrical Connection6 = M12x1 plug, 4 pole (connector not included)0 = flying leadOutput SignalA = 2 conductor, 4 to 20mAModification Number000 = standardETS 7 2 4 X - A - 000Model Codes Containing RED are non-standard items - Minimum quantities may applyContact <strong>HYDAC</strong> for information and availabilityCircuit Connection:12RLFree+ SupplyPlug Connection:ETS 7246 use with ZBE 06 (see page 56)4 31 2ETS 7246-A34RLFree0VDimensions:1.48"(37.53mm)G 1/40.47"(9.53mm)ø0.73"(18.65mm)M12x10.27"(6.87mm)0.38"(11.86mm)1-877-GO <strong>HYDAC</strong>Electronics Catalog 42

Temperature SwitchesETS 300<strong>About</strong> ETS 300 Temperature Switches:The ETS 300 is a compact, electronic temperature switch with digital display. Itis used with the TFP 100 temperature sensor, which was especially developedfor tank mounting, or with its own integral sensor.The ETS 300 has a 2 temperature ranges allowing for use in a wide range ofindustrial applications: -13° to 212°F (-25° to 100° C) and -22° to 302°F(-30° to 150°C).The ETS 300 is offered with one or two switching outputs with an optional 4 to20 mA analog output signal for remote temperature monitoring.The switching points and hysteresis are easily adjustable via the membranekeypad. Other parameters are accessible and displayed on the digital readout,then adjustable via the keypad.Technical Details:Input data for integral sensorMeasuring range-13° to 212°F (-25° to 100°C)Pressure resistance13000 psi (600 bar)Hydraulic connectionG 1/2 A maleTorque ratingapprox. 33 lb-ft (45 Nm)Parts in contact with mediaStainless steel, Seal: FPMInput data for separate sensorDisplay range-22 to 302°F (-30° to 150°C)Sensor connectionM 12x1, 4 poleOutput dataAccuracy (display, analog output)≤ ± 2.0°F (≤ ± 1.0°C)Temperature drift (zero point and range) ≤ ± 0.0085% / °FReaction time (T09)approx. 20 sAnalog output4 to 20 mA, ohmic resistance ≤ 400 ΩSwitching outputsTypePNP transistor outputSwitching currentmax. 1.2 AAmbient conditionsTemperature range of medium-13° to 212°F (integral sensor)Ambient temperature range -13° to 176°FStorage temperature range -40° to 176°FNominal temperature range -14° to 158°FmarkEN 50081-1 and EN 50081-2EN 50082-1 and EN 50082-2Vibration resistanceapprox. 10 g / 0 to 500 HzShock resistanceapprox. 50 g / 1msOther dataSupply voltage20 to 32 VDCCurrent consumptionapprox. 100 mA (without switching output)Safety type IP 65Material of housingtube: stainless steelkeypad housing: PA6.6 Gf30Display3 digit, 7 segment LED, red,height of digits 9.2 mmWeightapprox. 300 gTemperature Sensor TFP 100Temperature range of medium-40° to 257°F (-40° to 125°C)Electrical connection4 pole Binder plug 714 M18x1Safety Sleeve for Tank-Mounting the TFP 100Parts in contact with mediumAll materials compatible with nickelNote: Depending on the temperature range of the temperature sensor fitted, this canreduce the display range of the ETS 300 with separate sensor input.Applications:Approvals:43Electronics Catalog

SP1SP2SP1SP2Model Code:EDS 3 X X - X - XXX - XXX.SeriesETS 3 = 300 series electronic temperature SwitchMechanical Connection2 = G 1/2 A male thread with integral sensor8 = electrical connection for separate sensor (TFP 100)Electrical Connection6 = M12x1 plug, 4 pole for output codes 2 & 3 (connector not included)8 = M12x1 plug, 5 pole for output codes 5 (connector not included)Output2 = 2 switching outputs (only in conjunction with electrical connection type “6”)3 = 1 switching output and 1 analog output (only in conjunction with electrical connection type “6”)5 = 2 switching output and 1 analog output (only in conjunction with electrical connection type “8”)Measuring Ranges100 = -25° to 100°C (-13° to 212°F) only for version with integral sensor150 = -30° to 150°C (-22° to 302°F) only for version with separate sensorModification Number000 = display in °C400 = display in °FCircuit Connection:Model ETS 3X6-22 switching outputslmax. 1.2 A+ 1 4SP 120 to 32 VDC ETS 3X6-2lmax. 1.2 A- 3 2SP 2Model ETS 3X8-52 switching outputs 1 analogue ouputlmax. 1.2 A+ 1 4 SP 1lmax. 1.2 A20 to 32 VDC ETS 3X8-5 SP 1l = 4 to 20 mA- 3 2analogueRLPlug Connection:ETS 3X6 ETS 3X8 ZBE 06 (4-pole) & ZBE 08 (5-pole)(4-pole) (5-pole) (see page 56)431 24 31 5 2Model ETS 3X6-31 switching output 1 analogue outputlmax. 1.2 A+ 1 4SP 120 to 32 VDC ETS 3X6-3l = 4 to 20 mA- 3 2analogueRLDimensions:ConnectorM12x14 pole male3.44"(87.5mm)PSImodeETSø 1.4"(35mmConnectorM12x14 pole male2.97"(75.5mm)PSImodeETSø 1.4"(35mm)0.65"(16.5mm)ZBE 03 plugø 1.06"(27mm)ø 0.76"(9.3mm)0.73"(18.5mm)0.55"(14mm)26mmG 1/2hex SW270.12"(3mm)0.55"(14mm)0.67"(17mm)4.96"(126mm)0.55"(14mm)3.94"(100mm)0.12"(3mm)ø 0.24"(6mm)G 1/2AHexSW270.71"(18mm)1.16"(29.5mm)~2.05"(52mm)ø 0.87"(22mm)M 12x1connectorconnection cable LIYCY(3m length)1.16"(29.5mm)ø 0.24"(6mm)TFP 100 (temp. sensor)ø 0.31"(8mm)Safety Sleeve1-877-GO <strong>HYDAC</strong>Electronics Catalog 44