Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SHIPBUILDING & EQUIPMENT | GREEN SHIP TECHNOLOGY<br />

Developments for a<br />

sustainable shipping industry<br />

INITIATIVE “Green <strong>Ship</strong> <strong>of</strong> the Future” is a Danish untraditional joint-cooperative forum with a<br />

vision <strong>of</strong> demonstrating and developing environmentally friendly and energy effi cient<br />

technologies for reduction <strong>of</strong> emissions and air pollution arising from the activities <strong>of</strong> the<br />

shipping industry<br />

Magnus Gary, Christian Schack<br />

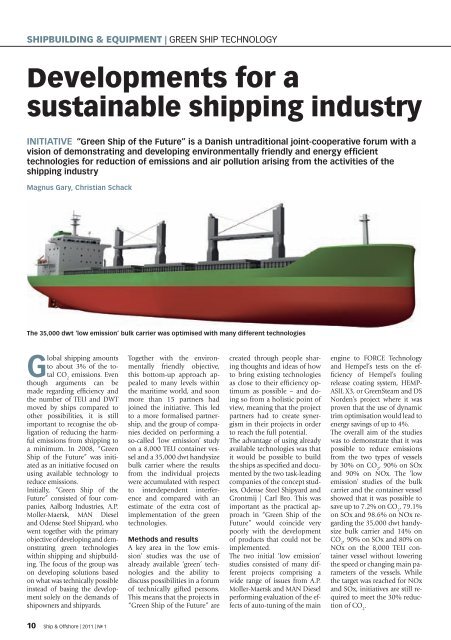

The 35,000 dwt ‘low emission’ bulk carrier was optimised with many different technologies<br />

Global shipping amounts<br />

to about 3% <strong>of</strong> the total<br />

CO 2 emissions. Even<br />

though arguments can be<br />

made regarding effi ciency and<br />

the number <strong>of</strong> TEU and DWT<br />

moved by ships compared to<br />

other possibilities, it is still<br />

important to recognise the obligation<br />

<strong>of</strong> reducing the harmful<br />

emissions from shipping to<br />

a minimum. In 2008, “Green<br />

<strong>Ship</strong> <strong>of</strong> the Future” was initiated<br />

as an initiative focused on<br />

using available <strong>technology</strong> to<br />

reduce emissions.<br />

Initially, “Green <strong>Ship</strong> <strong>of</strong> the<br />

Future” consisted <strong>of</strong> four companies,<br />

Aalborg Industries, A.P.<br />

Moller-Maersk, MAN Diesel<br />

and Odense Steel <strong>Ship</strong>yard, who<br />

went together with the primary<br />

objective <strong>of</strong> developing and demonstrating<br />

green technologies<br />

within shipping and shipbuilding.<br />

The focus <strong>of</strong> the group was<br />

on developing solutions based<br />

on what was technically possible<br />

instead <strong>of</strong> basing the development<br />

solely on the demands <strong>of</strong><br />

shipowners and shipyards.<br />

10 <strong>Ship</strong> & <strong>Offshore</strong> | 2011 | N o 1<br />

Together with the environmentally<br />

friendly objective,<br />

this bottom-up approach appealed<br />

to many levels within<br />

the maritime world, and soon<br />

more than 15 partners had<br />

joined the initiative. This led<br />

to a more formalised partnership,<br />

and the group <strong>of</strong> companies<br />

decided on performing a<br />

so-called ‘low emission’ study<br />

on a 8,000 TEU container vessel<br />

and a 35,000 dwt handysize<br />

bulk carrier where the results<br />

from the individual projects<br />

were accumulated with respect<br />

to interdependent interference<br />

and compared with an<br />

estimate <strong>of</strong> the extra cost <strong>of</strong><br />

implementation <strong>of</strong> the green<br />

technologies.<br />

Methods and results<br />

A key area in the ‘low emission’<br />

studies was the use <strong>of</strong><br />

already available ‘green’ technologies<br />

and the ability to<br />

discuss possibilities in a forum<br />

<strong>of</strong> technically gifted persons.<br />

This means that the projects in<br />

“Green <strong>Ship</strong> <strong>of</strong> the Future” are<br />

created through people sharing<br />

thoughts and ideas <strong>of</strong> how<br />

to bring existing technologies<br />

as close to their effi ciency optimum<br />

as possible – and doing<br />

so from a holistic point <strong>of</strong><br />

view, meaning that the project<br />

partners had to create synergism<br />

in their projects in order<br />

to reach the full potential.<br />

The advantage <strong>of</strong> using already<br />

available technologies was that<br />

it would be possible to build<br />

the ships as specifi ed and documented<br />

by the two task-leading<br />

companies <strong>of</strong> the concept studies,<br />

Odense Steel <strong>Ship</strong>yard and<br />

Grontmij | Carl Bro. This was<br />

important as the practical approach<br />

in “Green <strong>Ship</strong> <strong>of</strong> the<br />

Future” would coincide very<br />

poorly with the development<br />

<strong>of</strong> products that could not be<br />

implemented.<br />

The two initial ‘low emission’<br />

studies consisted <strong>of</strong> many different<br />

projects comprising a<br />

wide range <strong>of</strong> issues from A.P.<br />

Moller-Maersk and MAN Diesel<br />

performing evaluation <strong>of</strong> the effects<br />

<strong>of</strong> auto-tuning <strong>of</strong> the main<br />

engine to FORCE Technology<br />

and Hempel’s tests on the effi<br />

ciency <strong>of</strong> Hempel’s fouling<br />

release coating system, HEMP-<br />

ASIL X3, or GreenSteam and DS<br />

Norden’s project where it was<br />

proven that the use <strong>of</strong> dynamic<br />

trim optimisation would lead to<br />

energy savings <strong>of</strong> up to 4%.<br />

The overall aim <strong>of</strong> the studies<br />

was to demonstrate that it was<br />

possible to reduce emissions<br />

from the two types <strong>of</strong> vessels<br />

by 30% on CO 2 , 90% on SOx<br />

and 90% on NOx. The ‘low<br />

emission’ studies <strong>of</strong> the bulk<br />

carrier and the container vessel<br />

showed that it was possible to<br />

save up to 7.2% on CO 2 , 79.1%<br />

on SOx and 98.6% on NOx regarding<br />

the 35,000 dwt handysize<br />

bulk carrier and 14% on<br />

CO 2 , 90% on SOx and 80% on<br />

NOx on the 8,000 TEU container<br />

vessel without lowering<br />

the speed or changing main parameters<br />

<strong>of</strong> the vessels. While<br />

the target was reached for NOx<br />

and SOx, initiatives are still required<br />

to meet the 30% reduction<br />

<strong>of</strong> CO 2 .