Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

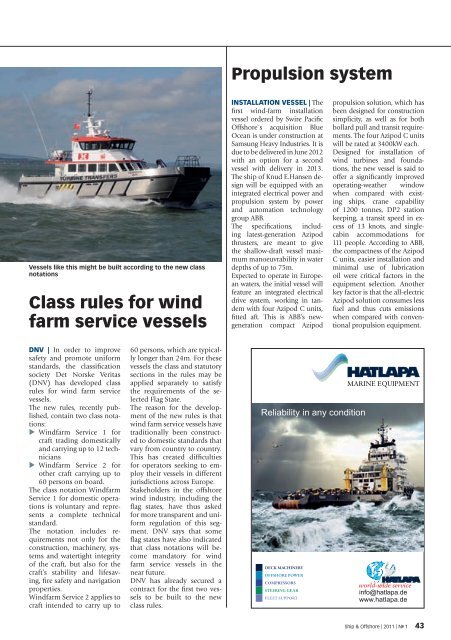

Vessels like this might be built according to the new class<br />

notations<br />

Class rules for wind<br />

farm service vessels<br />

DNV | In order to improve<br />

safety and promote uniform<br />

standards, the classifi cation<br />

society Det Norske Veritas<br />

(DNV) has developed class<br />

rules for wind farm service<br />

vessels.<br />

The new rules, recently published,<br />

contain two class notations:<br />

�<br />

�<br />

Windfarm Service 1 for<br />

craft trading domestically<br />

and carrying up to 12 technicians<br />

Windfarm Service 2 for<br />

other craft carrying up to<br />

60 persons on board.<br />

The class notation Windfarm<br />

Service 1 for domestic operations<br />

is voluntary and represents<br />

a complete technical<br />

standard.<br />

The notation includes requirements<br />

not only for the<br />

construction, machinery, systems<br />

and watertight integrity<br />

<strong>of</strong> the craft, but also for the<br />

craft’s stability and lifesaving,<br />

fi re safety and navigation<br />

properties.<br />

Windfarm Service 2 applies to<br />

craft intended to carry up to<br />

60 persons, which are typically<br />

longer than 24m. For these<br />

vessels the class and statutory<br />

sections in the rules may be<br />

applied separately to satisfy<br />

the requirements <strong>of</strong> the selected<br />

Flag State.<br />

The reason for the development<br />

<strong>of</strong> the new rules is that<br />

wind farm service vessels have<br />

traditionally been constructed<br />

to domestic standards that<br />

vary from country to country.<br />

This has created diffi culties<br />

for operators seeking to employ<br />

their vessels in different<br />

jurisdictions across Europe.<br />

Stakeholders in the <strong>of</strong>fshore<br />

wind industry, including the<br />

fl ag states, have thus asked<br />

for more transparent and uniform<br />

regulation <strong>of</strong> this segment.<br />

DNV says that some<br />

fl ag states have also indicated<br />

that class notations will become<br />

mandatory for wind<br />

farm service vessels in the<br />

near future.<br />

DNV has already secured a<br />

contract for the fi rst two vessels<br />

to be built to the new<br />

class rules.<br />

Propulsion system<br />

INSTALLATION VESSEL | The<br />

fi rst wind-farm installation<br />

vessel ordered by Swire Pacifi c<br />

<strong>Offshore</strong>`s acquisition Blue<br />

Ocean is under construction at<br />

Samsung Heavy Industries. It is<br />

due to be delivered in June 2012<br />

with an option for a second<br />

vessel with delivery in 2013.<br />

The ship <strong>of</strong> Knud E.Hansen design<br />

will be equipped with an<br />

integrated electrical power and<br />

propulsion system by power<br />

and automation <strong>technology</strong><br />

group ABB.<br />

The specifi cations, including<br />

latest-generation Azipod<br />

thrusters, are meant to give<br />

the shallow-draft vessel maximum<br />

manoeuvrability in water<br />

depths <strong>of</strong> up to 75m.<br />

Expected to operate in European<br />

waters, the initial vessel will<br />

feature an integrated electrical<br />

drive system, working in tandem<br />

with four Azipod C units,<br />

fi tted aft. This is ABB’s newgeneration<br />

compact Azipod<br />

����������������������������<br />

propulsion solution, which has<br />

been designed for construction<br />

simplicity, as well as for both<br />

bollard pull and transit requirements.<br />

The four Azipod C units<br />

will be rated at 3400kW each.<br />

Designed for installation <strong>of</strong><br />

wind turbines and foundations,<br />

the new vessel is said to<br />

<strong>of</strong>fer a signifi cantly improved<br />

operating-weather window<br />

when compared with existing<br />

ships, crane capability<br />

<strong>of</strong> 1200 tonnes, DP2 station<br />

keeping, a transit speed in excess<br />

<strong>of</strong> 13 knots, and singlecabin<br />

accommodations for<br />

111 people. According to ABB,<br />

the compactness <strong>of</strong> the Azipod<br />

C units, easier installation and<br />

minimal use <strong>of</strong> lubrication<br />

oil were critical factors in the<br />

equipment selection. Another<br />

key factor is that the all-electric<br />

Azipod solution consumes less<br />

fuel and thus cuts emissions<br />

when compared with conventional<br />

propulsion equipment.<br />

���������������<br />

��������������<br />

<strong>Ship</strong> & <strong>Offshore</strong> | 2011 | N o 1 43