Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

Arctic technology: Winterisation of FPSO 38 Cruise ... - Ship & Offshore

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

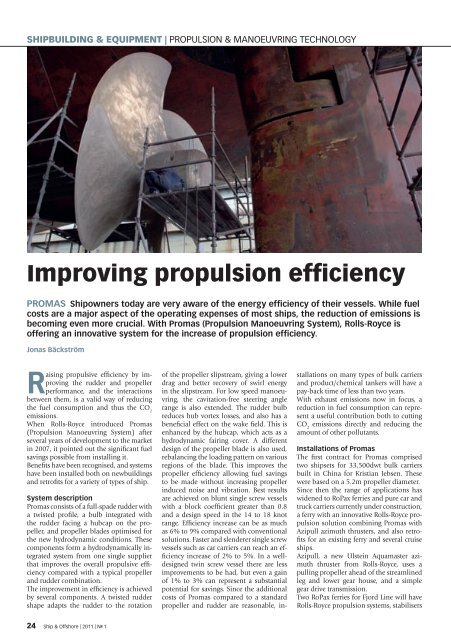

SHIPBUILDING & EQUIPMENT | PROPULSION & MANOEUVRING TECHNOLOGY<br />

Improving propulsion effi ciency<br />

PROMAS <strong>Ship</strong>owners today are very aware <strong>of</strong> the energy effi ciency <strong>of</strong> their vessels. While fuel<br />

costs are a major aspect <strong>of</strong> the operating expenses <strong>of</strong> most ships, the reduction <strong>of</strong> emissions is<br />

becoming even more crucial. With Promas (Propulsion Manoeuvring System), Rolls-Royce is<br />

<strong>of</strong>fering an innovative system for the increase <strong>of</strong> propulsion effi ciency.<br />

Jonas Bäckström<br />

Raising propulsive effi ciency by improving<br />

the rudder and propeller<br />

performance, and the interactions<br />

between them, is a valid way <strong>of</strong> reducing<br />

the fuel consumption and thus the CO 2<br />

emissions.<br />

When Rolls-Royce introduced Promas<br />

(Propulsion Manoeuvring System) after<br />

several years <strong>of</strong> development to the market<br />

in 2007, it pointed out the signifi cant fuel<br />

savings possible from installing it.<br />

Benefi ts have been recognised, and systems<br />

have been installed both on newbuildings<br />

and retr<strong>of</strong>i ts for a variety <strong>of</strong> types <strong>of</strong> ship.<br />

System description<br />

Promas consists <strong>of</strong> a full-spade rudder with<br />

a twisted pr<strong>of</strong>i le, a bulb integrated with<br />

the rudder facing a hubcap on the propeller,<br />

and propeller blades optimised for<br />

the new hydrodynamic conditions. These<br />

components form a hydrodynamically integrated<br />

system from one single supplier<br />

that improves the overall propulsive effi -<br />

ciency compared with a typical propeller<br />

and rudder combination.<br />

The improvement in effi ciency is achieved<br />

by several components. A twisted rudder<br />

shape adapts the rudder to the rotation<br />

24 <strong>Ship</strong> & <strong>Offshore</strong> | 2011 | N o 1<br />

<strong>of</strong> the propeller slipstream, giving a lower<br />

drag and better recovery <strong>of</strong> swirl energy<br />

in the slipstream. For low speed manoeuvring,<br />

the cavitation-free steering angle<br />

range is also extended. The rudder bulb<br />

reduces hub vortex losses, and also has a<br />

benefi cial effect on the wake fi eld. This is<br />

enhanced by the hubcap, which acts as a<br />

hydrodynamic fairing cover. A different<br />

design <strong>of</strong> the propeller blade is also used,<br />

rebalancing the loading pattern on various<br />

regions <strong>of</strong> the blade. This improves the<br />

propeller effi ciency allowing fuel savings<br />

to be made without increasing propeller<br />

induced noise and vibration. Best results<br />

are achieved on blunt single screw vessels<br />

with a block coeffi cient greater than 0.8<br />

and a design speed in the 14 to 18 knot<br />

range. Effi ciency increase can be as much<br />

as 6% to 9% compared with conventional<br />

solutions. Faster and slenderer single screw<br />

vessels such as car carriers can reach an effi<br />

ciency increase <strong>of</strong> 2% to 5%. In a welldesigned<br />

twin screw vessel there are less<br />

improvements to be had, but even a gain<br />

<strong>of</strong> 1% to 3% can represent a substantial<br />

potential for savings. Since the additional<br />

costs <strong>of</strong> Promas compared to a standard<br />

propeller and rudder are reasonable, in-<br />

stallations on many types <strong>of</strong> bulk carriers<br />

and product/chemical tankers will have a<br />

pay-back time <strong>of</strong> less than two years.<br />

With exhaust emissions now in focus, a<br />

reduction in fuel consumption can represent<br />

a useful contribution both to cutting<br />

CO 2 emissions directly and reducing the<br />

amount <strong>of</strong> other pollutants.<br />

Installations <strong>of</strong> Promas<br />

The fi rst contract for Promas comprised<br />

two shipsets for 33,500dwt bulk carriers<br />

built in China for Kristian Jebsen. These<br />

were based on a 5.2m propeller diameter.<br />

Since then the range <strong>of</strong> applications has<br />

widened to RoPax ferries and pure car and<br />

truck carriers currently under construction,<br />

a ferry with an innovative Rolls-Royce propulsion<br />

solution combining Promas with<br />

Azipull azimuth thrusters, and also retr<strong>of</strong>i<br />

ts for an existing ferry and several cruise<br />

ships.<br />

Azipull, a new Ulstein Aquamaster azimuth<br />

thruster from Rolls-Royce, uses a<br />

pulling propeller ahead <strong>of</strong> the streamlined<br />

leg and lower gear house, and a simple<br />

gear drive transmission.<br />

Two RoPax ferries for Fjord Line will have<br />

Rolls-Royce propulsion systems, stabilisers