Pad ROL⢠200 XT - Johnstech

Pad ROL⢠200 XT - Johnstech

Pad ROL⢠200 XT - Johnstech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

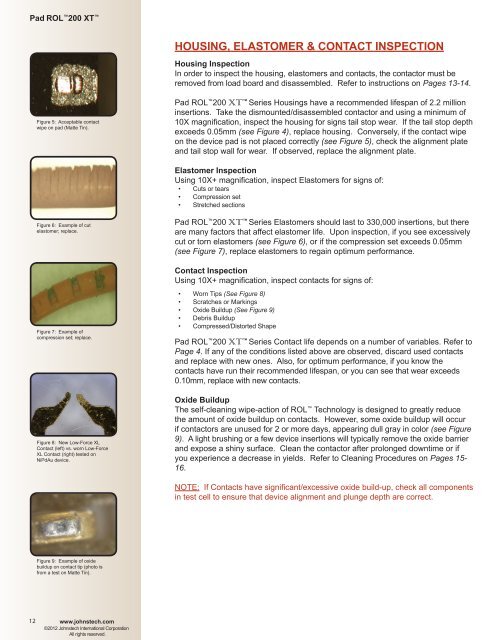

<strong>Pad</strong> ROL <strong>200</strong> <strong>XT</strong> HOUSING, ELASTOMER & CONTACT INSPECTIONHousing InspectionIn order to inspect the housing, elastomers and contacts, the contactor must beremoved from load board and disassembled. Refer to instructions on Pages 13-14.Figure 5: Acceptable contactwipe on pad (Matte Tin).<strong>Pad</strong> ROL <strong>200</strong> <strong>XT</strong> Series Housings have a recommended lifespan of 2.2 millioninsertions. Take the dismounted/disassembled contactor and using a minimum of10X magnification, inspect the housing for signs tail stop wear. If the tail stop depthexceeds 0.05mm (see Figure 4), replace housing. Conversely, if the contact wipeon the device pad is not placed correctly (see Figure 5), check the alignment plateand tail stop wall for wear. If observed, replace the alignment plate.Elastomer InspectionUsing 10X+ magnification, inspect Elastomers for signs of:• Cuts or tears• Compression set• Stretched sectionsFigure 6: Example of cutelastomer; replace.<strong>Pad</strong> ROL <strong>200</strong> <strong>XT</strong> Series Elastomers should last to 330,000 insertions, but thereare many factors that affect elastomer life. Upon inspection, if you see excessivelycut or torn elastomers (see Figure 6), or if the compression set exceeds 0.05mm(see Figure 7), replace elastomers to regain optimum performance.Contact InspectionUsing 10X+ magnification, inspect contacts for signs of:Figure 7: Example ofcompression set; replace.Figure 8: New Low-Force XLContact (left) vs. worn Low-ForceXL Contact (right) tested onNiPdAu device.• Worn Tips (See Figure 8)• Scratches or Markings• Oxide Buildup (See Figure 9)• Debris Buildup• Compressed/Distorted Shape<strong>Pad</strong> ROL <strong>200</strong> <strong>XT</strong> Series Contact life depends on a number of variables. Refer toPage 4. If any of the conditions listed above are observed, discard used contactsand replace with new ones. Also, for optimum performance, if you know thecontacts have run their recommended lifespan, or you can see that wear exceeds0.10mm, replace with new contacts.Oxide BuildupThe self-cleaning wipe-action of ROL Technology is designed to greatly reducethe amount of oxide buildup on contacts. However, some oxide buildup will occurif contactors are unused for 2 or more days, appearing dull gray in color (see Figure9). A light brushing or a few device insertions will typically remove the oxide barrierand expose a shiny surface. Clean the contactor after prolonged downtime or ifyou experience a decrease in yields. Refer to Cleaning Procedures on Pages 15-16.NOTE: If Contacts have significant/excessive oxide build-up, check all componentsin test cell to ensure that device alignment and plunge depth are correct.Figure 9: Example of oxidebuildup on contact tip (photo isfrom a test on Matte Tin).12www.johnstech.com©2012 <strong>Johnstech</strong> International CorporationAll rights reserved.