You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

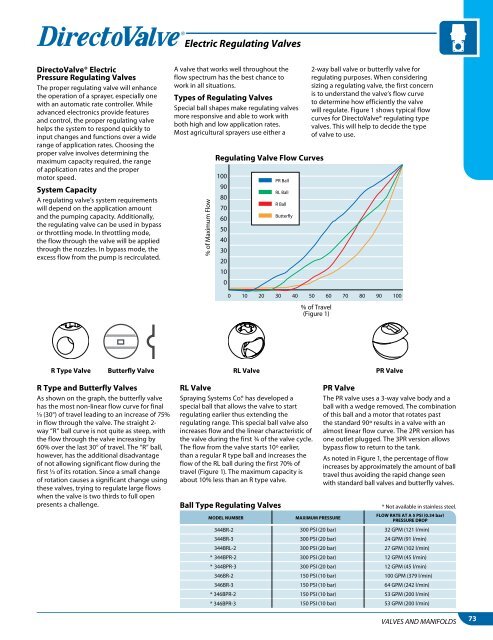

Electric Regulating ValvesDirectoValve® ElectricPressure Regulating ValvesThe proper regulating valve will enhancethe operation of a sprayer, especially onewith an automatic rate controller. Whileadvanced electronics provide featuresand control, the proper regulating valvehelps the system to respond quickly toinput changes and functions over a widerange of application rates. Choosing theproper valve involves determining themaximum capacity required, the rangeof application rates and the propermotor speed.System CapacityA regulating valve’s system requirementswill depend on the application amountand the pumping capacity. Additionally,the regulating valve can be used in bypassor throttling mode. In throttling mode,the flow through the valve will be appliedthrough the nozzles. In bypass mode, theexcess flow from the pump is recirculated.A valve that works well throughout theflow spectrum has the best chance towork in all situations.Types of Regulating ValvesSpecial ball shapes make regulating valvesmore responsive and able to work withboth high and low application rates.Most agricultural sprayers use either a% of Maximum FlowRegulating Valve Flow Curves1009080706050403020100PR BallRL BallR BallButterfly2-way ball valve or butterfly valve forregulating purposes. When consideringsizing a regulating valve, the first concernis to understand the valve’s flow curveto determine how efficiently the valvewill regulate. Figure 1 shows typical flowcurves for DirectoValve® regulating typevalves. This will help to decide the typeof valve to use.0 10 20 30 40 50 60 70 80 90 100% of Travel(Figure 1)R Type ValveButterfly ValveRL ValvePR ValveR Type and Butterfly ValvesAs shown on the graph, the butterfly valvehas the most non-linear flow curve for final1/3 (30°) of travel leading to an increase of 75%in flow through the valve. The straight 2-way “R” ball curve is not quite as steep, withthe flow through the valve increasing by60% over the last 30° of travel. The “R” ball,however, has the additional disadvantageof not allowing significant flow during thefirst 1/3 of its rotation. Since a small changeof rotation causes a significant change usingthese valves, trying to regulate large flowswhen the valve is two thirds to full openpresents a challenge.RL ValveSpraying Systems Co.® has developed aspecial ball that allows the valve to startregulating earlier thus extending theregulating range. This special ball valve alsoincreases flow and the linear characteristic ofthe valve during the first 3/4 of the valve cycle.The flow from the valve starts 10º earlier,than a regular R type ball and increases theflow of the RL ball during the first 70% oftravel (Figure 1). The maximum capacity isabout 10% less than an R type valve.Ball Type Regulating Valvesmodel number344BR-2344BR-3344BRL-2* 344BPR-2* 344BPR-3346BR-2346BR-3* 346BPR-2* 346BPR-3PR ValveThe PR valve uses a 3-way valve body and aball with a wedge removed. The combinationof this ball and a motor that rotates pastthe standard 90º results in a valve with analmost linear flow curve. The 2PR version hasone outlet plugged. The 3PR version allowsbypass flow to return to the tank.As noted in Figure 1, the percentage of flowincreases by approximately the amount of balltravel thus avoiding the rapid change seenwith standard ball valves and butterfly valves.* Not available in stainless steel.MAXIMUM PRESSUREFLOW RATE AT A 5 PSI (0.34 bar)PRESSURE DROP300 PSI (20 bar) 32 GPM (121 l/min)300 PSI (20 bar) 24 GPM (91 l/min)300 PSI (20 bar) 27 GPM (102 l/min)300 PSI (20 bar) 12 GPM (45 l/min)300 PSI (20 bar) 12 GPM (45 l/min)150 PSI (10 bar) 100 GPM (379 l/min)150 PSI (10 bar) 64 GPM (242 l/min)150 PSI (10 bar) 53 GPM (200 l/min)150 PSI (10 bar) 53 GPM (200 l/min)VALVES AND MANIFOLDS73