FEM 9.832

FEM 9.832

FEM 9.832

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

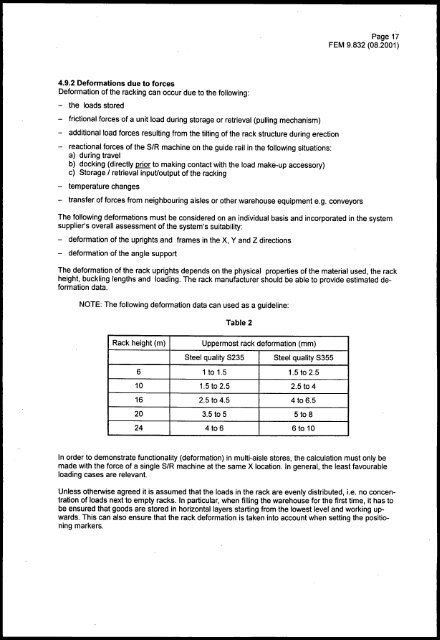

Page 17<strong>FEM</strong> <strong>9.832</strong> (08.2001)4.9.2 Deformations due to forcesDeformation of the racking can occur due to the following:- the loads stored- frictional forces of a unit load during storage or retrieval (pulling mechanism)- additional load forces resulting from the tilting of the rack structure during erection·- reactional forces of the SIR machine on the guide rail in the following situations:a) during travelb) docking (directly prior to making contact with the load make-up accessory)c) Storage I retrieval input/output of the racking- temperature changes- transfer of forces from neighbouring aisles or other warehouse equipment e.g. conveyorsThe following deformations must be considered on an individual basis and incorporated in the systemsupplier's overall assessment of the system's suitability:- deformation of the uprights and frames in the X, Y and Z directions- deformation of the angle supportThe deformation of the rack uprights depends on the physical properties of the material used, the rackheight, buckling lengths and loading. The rack manufacturer should be able to provide estimated deformationdata.NOTE: The following deformation data can used as a guideline:Table 2Rack height (m)Uppermost rack deformation (mm)Steel quality S235Steel quality S3556 1 to 1.5 1.5 to 2.510 1.5 to 2.5 2.5 to 416 2.5 to 4.5 4 to 6.520 3.5 to 5 5 to 824 4 to 6 6.to 10In order to demonstrate functionality (deformation) in multi-aisle stores, the calculation must only bemade with the force of a single SIR machine at the same X location. In general, the least favourableloading cases are relevant.Unless otherwise agreed it is assumed that the loads in the rack are evenly distributed, Le. no concentrationof loads next to empty racks. In particular, when filling the warehouse for the first time, it has tobe ensured that goods are stored in horizontal layers starting from the lowest level and working upwards.This can also ensure that the rack deformation is taken into account when setting the positioningmarkers.