Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

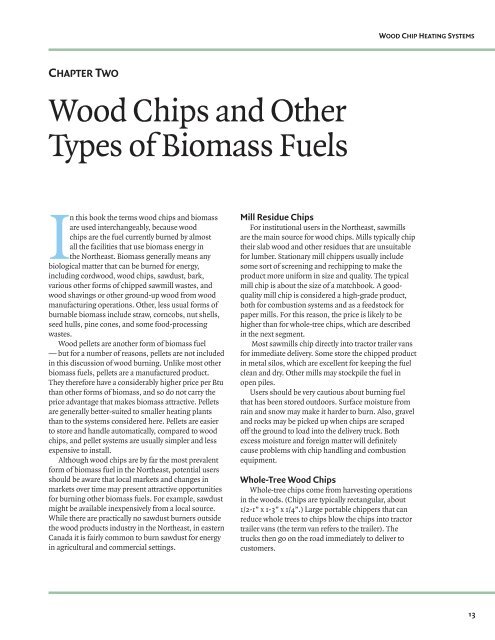

CHAPTER TWO<br />

<strong>Wood</strong> <strong>Chip</strong>s and Other<br />

Types of <strong>Biomass</strong> Fuels<br />

In this book the terms wood chips and biomass<br />

are used interchangeably, because wood<br />

chips are the fuel currently burned by almost<br />

all the facilities that use biomass energy in<br />

the Northeast. <strong>Biomass</strong> generally means any<br />

biological matter that can be burned for energy,<br />

including cordwood, wood chips, sawdust, bark,<br />

various other forms of chipped sawmill wastes, and<br />

wood shavings or other ground-up wood from wood<br />

manufacturing operations. Other, less usual forms of<br />

burnable biomass include straw, corncobs, nut shells,<br />

seed hulls, pine cones, and some food-processing<br />

wastes.<br />

<strong>Wood</strong> pellets are another form of biomass fuel<br />

— but for a number of reasons, pellets are not included<br />

in this discussion of wood burning. Unlike most other<br />

biomass fuels, pellets are a manufactured product.<br />

They therefore have a considerably higher price per Btu<br />

than other forms of biomass, and so do not carry the<br />

price advantage that makes biomass attractive. Pellets<br />

are generally better-suited to smaller heating plants<br />

than to the systems considered here. Pellets are easier<br />

to store and handle automatically, compared to wood<br />

chips, and pellet systems are usually simpler and less<br />

expensive to install.<br />

Although wood chips are by far the most prevalent<br />

form of biomass fuel in the Northeast, potential users<br />

should be aware that local markets and changes in<br />

markets over time may present attractive opportunities<br />

for burning other biomass fuels. For example, sawdust<br />

might be available inexpensively from a local source.<br />

While there are practically no sawdust burners outside<br />

the wood products industry in the Northeast, in eastern<br />

Canada it is fairly common to burn sawdust for energy<br />

in agricultural and commercial settings.<br />

Mill Residue <strong>Chip</strong>s<br />

For institutional users in the Northeast, sawmills<br />

are the main source for wood chips. Mills typically chip<br />

their slab wood and other residues that are unsuitable<br />

for lumber. Stationary mill chippers usually include<br />

some sort of screening and rechipping to make the<br />

product more uniform in size and quality. The typical<br />

mill chip is about the size of a matchbook. A goodquality<br />

mill chip is considered a high-grade product,<br />

both for combustion systems and as a feedstock for<br />

paper mills. For this reason, the price is likely to be<br />

higher than for whole-tree chips, which are described<br />

in the next segment.<br />

Most sawmills chip directly into tractor trailer vans<br />

for immediate delivery. Some store the chipped product<br />

in metal silos, which are excellent for keeping the fuel<br />

clean and dry. Other mills may stockpile the fuel in<br />

open piles.<br />

Users should be very cautious about burning fuel<br />

that has been stored outdoors. Surface moisture from<br />

rain and snow may make it harder to burn. Also, gravel<br />

and rocks may be picked up when chips are scraped<br />

off the ground to load into the delivery truck. Both<br />

excess moisture and foreign matter will defi nitely<br />

cause problems with chip handling and combustion<br />

equipment.<br />

Whole-Tree <strong>Wood</strong> <strong>Chip</strong>s<br />

Whole-tree chips come from harvesting operations<br />

in the woods. (<strong>Chip</strong>s are typically rectangular, about<br />

1/2-1” x 1-3” x 1/4”.) Large portable chippers that can<br />

reduce whole trees to chips blow the chips into tractor<br />

trailer vans (the term van refers to the trailer). The<br />

trucks then go on the road immediately to deliver to<br />

customers.<br />

WOOD CHIP HEATING SYSTEMS<br />

13