Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

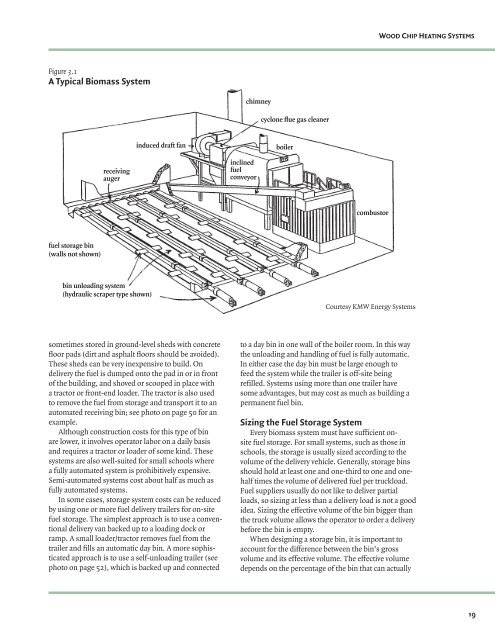

Figure 3.1<br />

A Typical <strong>Biomass</strong> System<br />

fuel storage bin<br />

(walls not shown)<br />

receiving<br />

auger<br />

bin unloading system<br />

(hydraulic scraper type shown)<br />

induced draft fan<br />

sometimes stored in ground-level sheds with concrete<br />

fl oor pads (dirt and asphalt fl oors should be avoided).<br />

These sheds can be very inexpensive to build. On<br />

delivery the fuel is dumped onto the pad in or in front<br />

of the building, and shoved or scooped in place with<br />

a tractor or front-end loader. The tractor is also used<br />

to remove the fuel from storage and transport it to an<br />

automated receiving bin; see photo on page 50 for an<br />

example.<br />

Although construction costs for this type of bin<br />

are lower, it involves operator labor on a daily basis<br />

and requires a tractor or loader of some kind. These<br />

systems are also well-suited for small schools where<br />

a fully automated system is prohibitively expensive.<br />

Semi-automated systems cost about half as much as<br />

fully automated systems.<br />

In some cases, storage system costs can be reduced<br />

by using one or more fuel delivery trailers for on-site<br />

fuel storage. The simplest approach is to use a conventional<br />

delivery van backed up to a loading dock or<br />

ramp. A small loader/tractor removes fuel from the<br />

trailer and fi lls an automatic day bin. A more sophisticated<br />

approach is to use a self-unloading trailer (see<br />

photo on page 52), which is backed up and connected<br />

inclined<br />

fuel<br />

conveyor<br />

chimney<br />

cyclone fl ue gas cleaner<br />

boiler<br />

combustor<br />

Courtesy KMW <strong>Energy</strong> <strong>Systems</strong><br />

to a day bin in one wall of the boiler room. In this way<br />

the unloading and handling of fuel is fully automatic.<br />

In either case the day bin must be large enough to<br />

feed the system while the trailer is off-site being<br />

refi lled. <strong>Systems</strong> using more than one trailer have<br />

some advantages, but may cost as much as building a<br />

permanent fuel bin.<br />

Sizing the Fuel Storage System<br />

Every biomass system must have suffi cient onsite<br />

fuel storage. For small systems, such as those in<br />

schools, the storage is usually sized according to the<br />

volume of the delivery vehicle. Generally, storage bins<br />

should hold at least one and one-third to one and onehalf<br />

times the volume of delivered fuel per truckload.<br />

Fuel suppliers usually do not like to deliver partial<br />

loads, so sizing at less than a delivery load is not a good<br />

idea. Sizing the effective volume of the bin bigger than<br />

the truck volume allows the operator to order a delivery<br />

before the bin is empty.<br />

When designing a storage bin, it is important to<br />

account for the difference between the bin’s gross<br />

volume and its effective volume. The effective volume<br />

depends on the percentage of the bin that can actually<br />

WOOD CHIP HEATING SYSTEMS<br />

19