Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

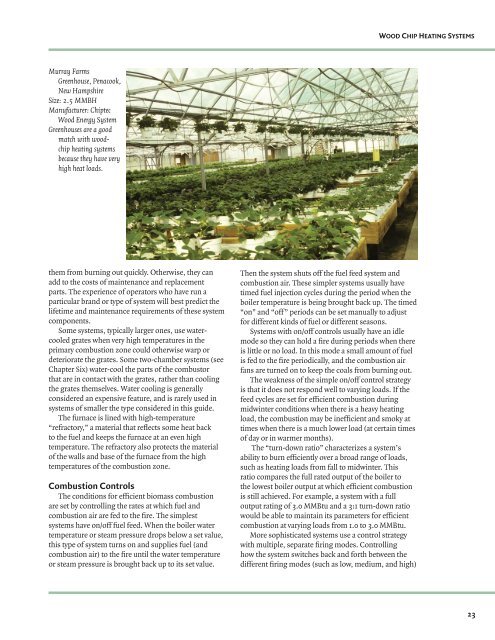

Murray Farms<br />

Greenhouse, Penacook,<br />

New Hampshire<br />

Size: 2.5 MMBH<br />

Manufacturer: <strong>Chip</strong>tec<br />

<strong>Wood</strong> <strong>Energy</strong> System<br />

Greenhouses are a good<br />

match with woodchip<br />

heating systems<br />

because they have very<br />

high heat loads.<br />

them from burning out quickly. Otherwise, they can<br />

add to the costs of maintenance and replacement<br />

parts. The experience of operators who have run a<br />

particular brand or type of system will best predict the<br />

lifetime and maintenance requirements of these system<br />

components.<br />

Some systems, typically larger ones, use watercooled<br />

grates when very high temperatures in the<br />

primary combustion zone could otherwise warp or<br />

deteriorate the grates. Some two-chamber systems (see<br />

Chapter Six) water-cool the parts of the combustor<br />

that are in contact with the grates, rather than cooling<br />

the grates themselves. Water cooling is generally<br />

considered an expensive feature, and is rarely used in<br />

systems of smaller the type considered in this guide.<br />

The furnace is lined with high-temperature<br />

“refractory,” a material that refl ects some heat back<br />

to the fuel and keeps the furnace at an even high<br />

temperature. The refractory also protects the material<br />

of the walls and base of the furnace from the high<br />

temperatures of the combustion zone.<br />

Combustion Controls<br />

The conditions for effi cient biomass combustion<br />

are set by controlling the rates at which fuel and<br />

combustion air are fed to the fi re. The simplest<br />

systems have on/off fuel feed. When the boiler water<br />

temperature or steam pressure drops below a set value,<br />

this type of system turns on and supplies fuel (and<br />

combustion air) to the fi re until the water temperature<br />

or steam pressure is brought back up to its set value.<br />

Then the system shuts off the fuel feed system and<br />

combustion air. These simpler systems usually have<br />

timed fuel injection cycles during the period when the<br />

boiler temperature is being brought back up. The timed<br />

“on” and “off ” periods can be set manually to adjust<br />

for different kinds of fuel or different seasons.<br />

<strong>Systems</strong> with on/off controls usually have an idle<br />

mode so they can hold a fi re during periods when there<br />

is little or no load. In this mode a small amount of fuel<br />

is fed to the fi re periodically, and the combustion air<br />

fans are turned on to keep the coals from burning out.<br />

The weakness of the simple on/off control strategy<br />

is that it does not respond well to varying loads. If the<br />

feed cycles are set for effi cient combustion during<br />

midwinter conditions when there is a heavy heating<br />

load, the combustion may be ineffi cient and smoky at<br />

times when there is a much lower load (at certain times<br />

of day or in warmer months).<br />

The “turn-down ratio” characterizes a system’s<br />

ability to burn effi ciently over a broad range of loads,<br />

such as heating loads from fall to midwinter. This<br />

ratio compares the full rated output of the boiler to<br />

the lowest boiler output at which effi cient combustion<br />

is still achieved. For example, a system with a full<br />

output rating of 3.0 MMBtu and a 3:1 turn-down ratio<br />

would be able to maintain its parameters for effi cient<br />

combustion at varying loads from 1.0 to 3.0 MMBtu.<br />

More sophisticated systems use a control strategy<br />

with multiple, separate fi ring modes. Controlling<br />

how the system switches back and forth between the<br />

different fi ring modes (such as low, medium, and high)<br />

WOOD CHIP HEATING SYSTEMS<br />

23