Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

Wood-Chip Heating Systems - Biomass Energy Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

fully trained in operating, maintaining, and troubleshooting<br />

the system. The required time allocated<br />

for operator training should be specifi ed in the bid<br />

documents, and the training must be done before<br />

the contractor leaves the site after initial startup. The<br />

contractor must also provide maintenance schedules,<br />

manuals, product literature, and wiring diagrams to<br />

cover all the components of the system.<br />

System Adjustments During the Warranty<br />

Period<br />

The new owners of a biomass system should expect<br />

some things to go wrong in the fi rst year. This is<br />

generally true for any large mechanical system during<br />

its initial year of full operation. It is important to use<br />

this warranty year to get all the bugs out of the system<br />

while it is still the contractor’s and the manufacturer’s<br />

responsibility. If the owner has been careful about<br />

specifying the system and if the contractor has done a<br />

good job, these adjustments will be minor.<br />

At the end of the warranty period, the system<br />

should be operating smoothly with no outstanding<br />

areas of concern. If major areas needing improvement<br />

are identifi ed that are not the responsibility of the<br />

manufacturer or contractor, then it is best to deal with<br />

these problem areas immediately. It is to the owner’s<br />

advantage to have the system running smoothly as<br />

soon as possible, rather than putting off the necessary<br />

improvements and keeping the system in a poor<br />

operating condition.<br />

Ongoing Maintenance<br />

The manufacturer should provide a list of the<br />

required maintenance procedures and recommended<br />

frequency of each one. Some of the most important<br />

maintenance tasks for most systems are:<br />

• ash removal — grates (may be automatic);<br />

• ash removal — under grates;<br />

• boiler tube cleaning (see photo on this page);<br />

• fl y ash removal;<br />

• cleaning of fi re box and other heat exchange<br />

surfaces;<br />

• lubrication;<br />

• inspection of drive chains, belts and gearboxes;<br />

• inspection of refractory;<br />

• checking of safety devices; and<br />

• checking and adjustment of fuel feed rates and<br />

combustion air.<br />

The system operator will learn how fast ash builds<br />

up in key places, and may need to adjust the frequency<br />

of cleaning accordingly. Ash buildup in the heat<br />

exchanger, particularly the boiler tubes, can reduce<br />

effi ciency dramatically. It should be carefully controlled<br />

by cleaning.<br />

The system manufacturer’s service representative<br />

should be hired to come back and tune the system, on<br />

all fi ring levels, once a year.<br />

Maintenance Contracts<br />

The system manufacturer, the installer, or<br />

an experienced contractor may be interested in<br />

providing ongoing maintenance on a contract basis.<br />

A maintenance contract may work well for facilities<br />

where the in-house staff does not have the time or<br />

the capability to handle the wood-chip system’s<br />

maintenance. Maintenance contracts also have the<br />

advantage of building in regular oversight by someone<br />

WOOD CHIP HEATING SYSTEMS<br />

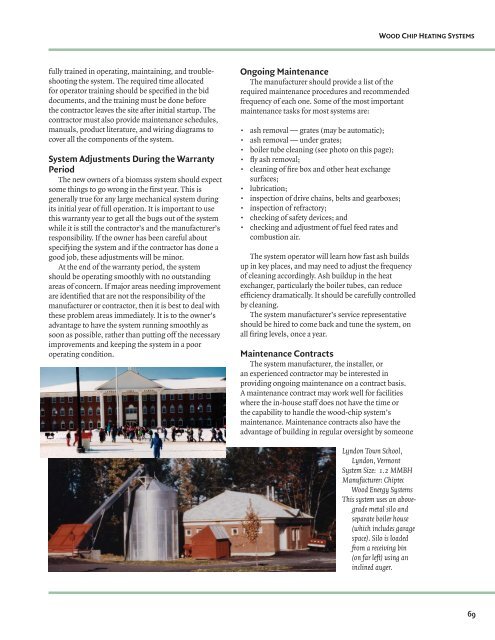

Lyndon Town School,<br />

Lyndon, Vermont<br />

System Size: 1.2 MMBH<br />

Manufacturer: <strong>Chip</strong>tec<br />

<strong>Wood</strong> <strong>Energy</strong> <strong>Systems</strong><br />

This system uses an abovegrade<br />

metal silo and<br />

separate boiler house<br />

(which includes garage<br />

space). Silo is loaded<br />

from a receiving bin<br />

(on far left) using an<br />

inclined auger.<br />

69