Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

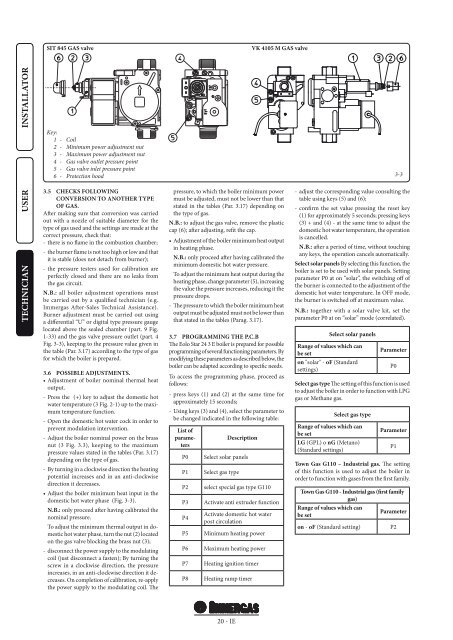

SIT 845 GAS valveVK 4105 M GAS valveINSTALLATORKey:1 - Coil2 - Minimum power adjustment nut3 - Maximum power adjustment nut4 - Gas valve outlet pressure point5 - Gas valve inlet pressure point6 - Protection hood3-3USERTECHNICIAN3.5 CHECKS FOLLOWINGCONVERSION TO ANOTHER TYPEOF GAS.After making sure that conversion was carriedout with a nozzle of suitable diameter for thetype of gas used and the settings are made at thecorrect pressure, check that:- there is no flame in the combustion chamber;- the burner flame is not too high or low and thatit is stable (does not detach from burner);- the pressure testers used for calibration areperfectly closed and there are no leaks fromthe gas circuit.N.B.: all boiler adjustment operations mustbe carried out by a qualified technician (e.g.Immergas After-Sales Technical Assistance).Burner adjustment must be carried out usinga differential “U” or digital type pressure gaugelocated above the sealed chamber (part. 9 Fig.1-33) and the gas valve pressure outlet (part. 4Fig. 3-3), keeping to the pressure value given inthe table (Par. 3.17) according to the type of gasfor which the boiler is prepared.3.6 POSSIBLE ADJUSTMENTS.• Adjustment of boiler nominal thermal heatoutput.- Press the (+) key to adjust the domestic hotwater temperature (3 Fig. 2-1) up to the maximumtemperature function.- Open the domestic hot water cock in order toprevent modulation intervention.- Adjust the boiler nominal power on the brassnut (3 Fig. 3.3), keeping to the maximumpressure values stated in the tables (Par. 3.17)depending on the type of gas.- By turning in a clockwise direction the heatingpotential increases and in an anti-clockwisedirection it decreases.• Adjust the boiler minimum heat input in thedomestic hot water phase (Fig. 3-3).N.B.: only proceed after having calibrated thenominal pressure.To adjust the minimum thermal output in domestichot water phase, turn the nut (2) locatedon the gas valve blocking the brass nut (3);- disconnect the power supply to the modulatingcoil (just disconnect a fasten); By turning thescrew in a clockwise direction, the pressureincreases, in an anti-clockwise direction it decreases.On completion of calibration, re-applythe power supply to the modulating coil. Thepressure, to which the boiler minimum powermust be adjusted, must not be lower than thatstated in the tables (Par. 3.17) depending onthe type of gas.N.B.: to adjust the gas valve, remove the plasticcap (6); after adjusting, refit the cap.• Adjustment of the boiler minimum heat outputin heating phase.N.B.: only proceed after having calibrated theminimum domestic hot water pressure.To adjust the minimum heat output during theheating phase, change parameter (5), increasingthe value the pressure increases, reducing it thepressure drops.- The pressure to which the boiler minimum heatoutput must be adjusted must not be lower thanthat stated in the tables (Parag. 3.17).3.7 PROGRAMMING THE P.C.BThe Eolo Star <strong>24</strong> 3 E boiler is prepared for possibleprogramming of several functioning parameters. Bymodifying these parameters as described below, theboiler can be adapted according to specific needs.To access the programming phase, proceed asfollows:- press keys (1) and (2) at the same time forapproximately 15 seconds;- Using keys (3) and (4), select the parameter tobe changed indicated in the following table:List ofparametersP0P1P2P3P4P5P6P7P8DescriptionSelect solar panelsSelect gas typeselect special gas type G110Activate anti extruder functionActivate domestic hot waterpost circulationMinimum heating powerMaximum heating powerHeating ignition timerHeating ramp timer- adjust the corresponding value consulting thetable using keys (5) and (6);- confirm the set value pressing the reset key(1) for approximately 5 seconds; pressing keys(3) + and (4) - at the same time to adjust thedomestic hot water temperature, the operationis cancelled.N.B.: after a period of time, without touchingany keys, the operation cancels automatically.Select solar panels By selecting this function, theboiler is set to be used with solar panels. Settingparameter P0 at on “solar”, the switching off ofthe burner is connected to the adjustment of thedomestic hot water temperature. In OFF mode,the burner is switched off at maximum value.N.B.: together with a solar valve kit, set theparameter P0 at on “solar” mode (correlated).Select solar panelsRange of values which canbe seton "solar" - oF (Standardsettings)ParameterP0Select gas type The setting of this function is usedto adjust the boiler in order to function with LPGgas or Methane gas.Select gas typeRange of values which canbe setLG (GPL) o nG (Metano)(Standard settings)ParameterP1Town Gas G110 – Industrial gas. The settingof this function is used to adjust the boiler inorder to function with gases from the first family.Town Gas G110 - Industrial gas (first familygas)Range of values which canParameterbe seton - oF (Standard setting)P220 - IE