MODEL V1433XL, V1433 MODEL V1833XL, V1833 - MinnPar

MODEL V1433XL, V1433 MODEL V1833XL, V1833 - MinnPar

MODEL V1433XL, V1433 MODEL V1833XL, V1833 - MinnPar

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

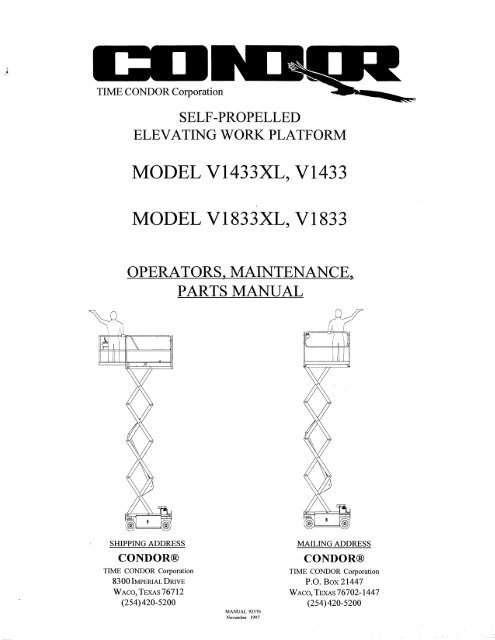

TIME CONDOR CorporationSELF-PROPELLEDELEVATING WORK PLATFORM<strong>MODEL</strong> <strong><strong>V1433</strong>XL</strong>, <strong>V1433</strong><strong>MODEL</strong> <strong><strong>V1833</strong>XL</strong>, <strong>V1833</strong>OPERATORS, MAINTENANCE,PARTS MANUALSHIPPING ADDRESSCONDOR®TIME CONDOR Corporation8300 IMPERIAL DRIVEVVAco,TEXAs76712(254)420-5200MANUAL 92370November 1997MAILING ADDRESSCONDOR®TIME CONDOR CorporationP.O. Box 21447VVACO, TEXAS 76702-1447(254)420-5200

TIME CONDOR CorporationSELF-PROPELLEDELEVATING WORK PLATFORM<strong>MODEL</strong> <strong><strong>V1433</strong>XL</strong>, <strong>V1433</strong><strong>MODEL</strong> <strong><strong>V1833</strong>XL</strong>, <strong>V1833</strong>OPERATOR SECTIONSHIPPING ADDRESSCONDOR®TIME CONDOR Corporation8300 IMPERIAL DRIVEVVAco,TEXAS76712(254)420-5200MAILING ADDRESSCONDOR®TIME CONDOR CorporationP.O. Box 21447VVAco,TEXAS76702-1447(254)420-5200MANUAL 92370-001November 1997

F. DECK EXTENSIONB. RAMP MEmOD•Lift lockpin, at right side of deck, and pushextension deck forward (or out). When fullyextended, lockpin will automatically lock. Toretract, lift lockpin and pull extension deck all theway back untillockpin automatically locksextension deck in place.CAUTIONDo not lower extension deck ontopeople or any objects!G. 'REMOVABLE' UPPER CONTROLBOXUnsnap overcenter latch at bottom of uppercontrol box and pull plug out of receptacle. Bendcable so that plug faces down. Snap cover ontoreceptacle at bottom of box. Lift box and store itin a secure place to prevent unauthorized use ofthe CONDOR®.III. MOVING FROM JOB-SITE TOJOB-SITEA. LOADING AND UNLOADINGAlthough this CONDOR® is somewhat smallcompared with larger construction equipment, itrequires the same care and attention in loading,transporting, and unloading. At no time should itssize,or weight be under estimated. Beforeloading or unloading, inspect the CONDOR® forany physical damage or defects.The means by which you load or unload theCONDOR® should be of sufficient strength towithstand its weight.<strong>MODEL</strong> WEIGHT(#) WEIGHT(KG)<strong>V1433</strong>1XL 2,200Ibs. 998 kg<strong>V1833</strong>1XL 2,400Ibs. 1089 kgEnsure that the ramp is sufficiently strong tosupport the weight ofthe CONDOR®.The ramp should be set, not steeper than thisCONDOR®'s rated gradeability, which for Model<strong>V1433</strong>1XL, <strong>V1833</strong>1XL is 14° or 25%, or a rise of30 inches in a run of 10 feet.Before driving the CONDOR® on a ramp, lowerthe platform completely, test the drive/steercontrols and the brake system.CAUTIONSelect "low" drive speed,not "high" and not "creep".The front of the CONDOR® should be uphill,meaning: Drive forward uphill and reversedown.Keep CONDOR® in alignment with the rampduring loading and unloading procedures.C. FORKLIFT LOADING ANDUNLOADING METHODEnsure that the forklift has sufficient capacity tohandle the weight of this CONDOR®.This CONDOR® can be lifted from the rear,using the forklift pockets provided.NOTE THAT THE CENTER OF GRA VlTYIS 50 INCHES FROM THE END OF THECONDOR®.The CONDOR® should only be raised to a heightsufficient to clear any obstructions.Keep forklift travel to a minimum, carryCONDOR® as close as possible to the ground,and set it down gently.MANUAL 92370-001November 1997

• D.TRANSPORTINGThis CONDOR® can be easily transportedbetween job-sites ifthe following rules andprocedures are followed:Block all wheels to prevent forward and reversemotion.Tie down the CONDOR® with chains or cables,running them through the tie-down holes only. Donot tie down over the guardrails or entry steps.Always tum the power 'off at the lower controlstation.E. FREEWHEEL OPERATIONCAUTIONThis CONDOR® must be on firm, levelground when releasing the parking brakes.To put the CONDOR® into freewheel mode,use the brake release handles on the rear axle.One handle is on the front side of the axle andthe other is on the rear side ofthe axle. Tumeach release handle 90 0 and at the same time,slightly rotate it. The brakes are now released.(Released brakes will automatically reset thenext time forward or reverse drive is used,then will engage when drive is stopped.)Never exceed 5 mph when moving theCONDOR® in the freewheel mode.IV. STORAGEWhen you get out of the platform, leave it all theway down.CAUTIONNever park the CONDOR®with platform raised.MANUAL 92370-001November 1997

NOTES•MANUAL 92370-001November 1997

•APPENDIX: DECALS ILLUSTRATION18000000o 0 000000000000000000000000000000°0°0°0°0°0°0°0°0o 0 000 0 0 0o 0 000 0 000a a 0 0 0 000o 0 000 0 00020PARTIAL SECTION AAPPLIES TO ALL <strong>MODEL</strong>SNOTES:<strong>MODEL</strong> <strong><strong>V1833</strong>XL</strong> IS ILLUSTRATED, OTHER <strong>MODEL</strong>S ARE SIMILAR.MANUAL 92370-001November 1997

APPENDIX: DECALS ILLUSTRA nON•ITEM PART NUMBER DESCRIPTION QTYRef *55892-104 ................... Decal Kit, <strong><strong>V1833</strong>XL</strong> Essential ....................................................... Ref.*55892-103 ................... Decal Kit, <strong>V1833</strong> Essential ............................................................ Ref.*55892-102 ................... Decal Kit, <strong><strong>V1433</strong>XL</strong> ...................................................................... Ref.*55892-101 ................... Decal Kit, <strong>V1433</strong> ........................................................................... Ref.* 1 55890 ............................ Decal, V Upper Operator Instructions ............................................... 155889 ............................ Decal, V XL Upper Operator Instructions ......................................... 1*2 55894 ............................ Decal, V General Caution .................................................................. 1*3 54652-003 ..................... Decal, Guardrail/Chain Caution ......................................................... 1*4 55944-600 ..................... Decal, 250/600 Rated Load VI433/XL ............................................. 255944-500 ..................... Decal, 250/500 Rated Load <strong>V1833</strong>/XL ............................................. 2*5 55877-003 ..................... Decal, V14/18 Lower Operating Instructions .................................... 1*6 55877-001 ..................... Decal, V14/18 Lower Controls .......................................................... 1*7 55877-002 ..................... Decal, V14/18 StoplFuse ................................................................... 1*8 54652-002 ..................... Decal, Ann Strand Caution ................................................................ 1*9 54984-005 ..................... Decal, Rear Bumper ........................................................................... 1*10 55882 ............................ Decal, Electrocution Hazard .............................................................. 2*11 55871-001 ..................... Decal, V14/18 Upper Electrical Box Top .......................................... 155856-001 ..................... Decal, V XL Upper Control Box Top ................................................ 1*12 55871-002 ..................... Decal, V14118 Upper Electrical Box Front ........................................ 155856-002 ..................... Decal, V XL Upper Control Box ....................................................... 113 54984-007 ..................... Decal, Hydraulic Fluid ....................................................................... 114 55940-023 ..................... Decal, CONDOR 3.45 x 23 ............................................................... 215 55935 ............................ Decal, <strong><strong>V1433</strong>XL</strong> ................................................................................ 255936 ............................ Decal, <strong><strong>V1833</strong>XL</strong> ................................................................................ 216 55941-017 ..................... Decal, Condor Bird ............................................................................ 217 53259 ............................ Tape, Non-Skid Jet Black ......................................................... 1.50LF18 66921 ............................ Coating, Non-Skid Jet Black ...................................................... .25GL19 55892-DWG ................. Dwg. V1418 Decal Installation ......................................................... 120 54984-006 ..................... Decal, 110 Volt Extention To Platform V14/18XL .......................... 131 51340 ............................ Namplate Scissors Indentification ................................................. Ref.- Indicates Items Not Shown*Indicates Included In Essential Decals2 1/4 MARGINNO NON-SLIPCOATINGPLANVIEW OF<strong>MODEL</strong>S <strong>V1433</strong> & <strong>V1833</strong>MANUAL 92370-001November 1997PARTIAL REAR VIEW OF<strong>MODEL</strong>S <strong>V1433</strong> & <strong>V1833</strong>

APPENDIX: DECALS ILLUSTRA nON1OPERAT~G INSTRUCTIONSo TURN SWITCH, ON LOWER CONTROL BOX, TO "UPPER" POSITION, TO OPERATE FROM PLATFORM .• IN AN EMERGENCY, PUSH RED BUTTON. TO OPERATE 'FROM PLATFORM,BOTH RED BUTTONS, ON LOWER AND ON UPPER CONTROLS, MUST BE PULLED OUT.o TO RAISE AND LOWER PLATFORM, PUSH AND HOLD THE GREEN "ENABLE" BUTTON, ANDPUSH THE "up" OR "DOWN" BUTTON.RELEASE BUTTONS TO STOP MOVEMENT.• SELECT DRIVE SPEED WITH "FAST/SLOW/CREEP" SWITCH.A LIMIT SVHCH AUTOMATICALLY REDUCES DRIVE SPEED AS THE PLATFORM IS RAISED.o TO DRIVE FORWARD OR REVERSE, SQUEEZE GRIP SWITCH ON HANDLE, ANDPUSH OR PULL HANDLE IN IN TENDED DIRECTION OF TRAVEl.RELEASE LEVER SWITCH OR LET GO OF HANDLE TO STOP MOVEMENT.o BRAKES ARE AUTOMATICALLY RELEASED WHENEVER DRIVE MOVES,RELEASE GRIP SWITCH OR LET GO OF HANDLE TO AUTOMATICALLY SET BRAKES.• TO STEER LEFT OR RIGHT, SQUEEZE GRIP SWITCH ON HANDLE, ANDDEPRESS ROCKER SWITCHES ON TOP OF HANDLE IN INTENDED DIRECTION OF TRAVEL.STEERING IS NOT AUTOMA TICALL Y SELF -CENTERING. BE SURE STEERING WHEELS POINTIN DIRECTION YOU WANT BEFORE LETTING GO OF SWITCHES.OPERA TING INSTRUCTIONSo TURN SWITCH, ON LOWER CONTROL BOX, TO "UPPER" POSITION, TO OPERATE FROM PLATFORM.olN AN EMERGENCY, PUSH RED BUTTON. TO OPERATE FROM PLATFORM, BOTH RED BUTTONS,ON LOWER AND ON UPPER CONTROLS, MUST BE PULLED OUT.• TO RAISE AND LOWER PLATFORM, PUT AND KEEP FOOT ON SWITCH, ANDPUSH TOGGLE SWITCH IN "UP" OR "DOWN" DIRECTION,RELEASE SWITCH OR TAKE FOOT OFF SWITCH TO STOP MOVEMENT.o SELECT DRIVE SPEED WITH "FAST/SLOW/CREEP" SWITCH.A LIMIT SWITCH AUTOMATICALLY REDUCES DRIVE SPEED AS THE PLATFORM IS RAISED.o TO DRIVE FORWARD OR REVERSE, PUT AND KEEP FOOT ON SWITCH, ANDPUSH OR PULL TOGGLE SWITCH IN INTENDED DIRECTION OF TRAVEL.RELEASE SWITCH, OR TAKE FOOT OFF SWITCH TO STOP MOVEMENT.o BRAKES ARE AUTOMATICALLY RELEASED WHENEVER DRIVE MOVES.RELEASE SWITCH OR TAKE FOOT OFF SWITCH TO AUTOMATICALLY SET BRAKES.o TO STEER LEFT OR RIGHT, PUT AND KEEP FOOT ON SWITCH, ANDMOVE "STEERING" SWITCH IN INTENDED DIRECTION OF TRAVEL.STEERING IS NOT AUTOMATICALLY SELF -CENTERING, BE SURE STEERING WHEELS POINTIN DIRECTION YOU WANT BEFORE LETTING GO OF SWITCH.5551102lib. CAUr~ON I• DO NOT OPERATE THIS CONDoR"UNTIL YOU HAVE BEEN PROPERLY TRAINED AND HAVECOMPLETELY REAO AND UNDERSTOOD THE OPERA TOR'S MANUAL LOCATED ON THIS CONDOR"• THIS CONDOR'" IS NOT ELECTRICALLY INSULATED.SEE OPER A TOR'S MANUAL FOR SAFE APPROACH DISTANCES TO ENERGIZEO POWER LINES.• PRIOR TO EACH DAY'S USE, CHECK TO MAKE SURE ALL FUNCTIONS ARE OPERATING PROPERLY.PERFORM ALL INSPECTIONS REQUIRED BY SEC1l0N 6 OF THE ANSI 92.6 STANDARD.• DO NOT USE THE CONDORS. IF IT IS MALFUNCTIONING OR DAMAGED IN ANY WAY,OR IF THE WIND BLOWS OVER 15 MPH.• RAISE PLATFORM ONLY WHEN CONDORslS ON FIRM, LEVEL GROUND.• DO NOT DRIVE ON A SLOPE UNLESS THE PLATFORM IS FULLY LOWERED.• ALWAYS LOOK IN THE OIRECTION IN WHICH THE PLATFORM IS MOVING.VIA TCH FOR, AND AVOID. OVERHEAD OBSTRUCTIONS AND ANYTHING ELSE THAT MAY STRIKEPLATFORM, PERSONNEL, CONTROLS, OR CONDORs.• FOLLOW INSTRUCTIONS IN OPERATOR'S MANUAL WHEN SERVICING BATTERIES.EACH REPLACEMENT BATTERY MUST WEIGH AT LEAST AS MUCH AS ORIGINAL EQUIPMENT.• REPL,o,CEMENT TIRES MUST BE SAME AS ORIGINAL EQUIPMENT.• IN CASE OF EMERGENCY, PUSH RED "EMERGENCY STOP" BUTTON.MANUAL 92370-001November 1997

APPENDIX: DECALS ILLUSTRATION•3I it Cfo\UlnO~ IGUARDRAILS AND SAFETYCHAINS MUST BE SECUREDAND USED AT ALL TIMES54652-0034RA TED WORK LOADON EXTENSION DECK ONLY,IS 250LBS OR ONE OCCUPANT.TOTAL RATED WORK LOAD ISXXXLBS OR TWO OCCUPANTS.5594~-X)()(5OPERA TING INSTRUCTIONSo TO OPERATE FROM GROUND,TURN SWITCH TO "LOWER" POSITION.olN AN EMERGENCY, PUSH RED BUTTON.TO OPERATE, BUTTON MUST BE PULLED OUT.o PUSH TOGGLE SWITCH TO MOVE PLATFORM .• TURN SWITCH TO "UPPER" POSITION,TO OPERATE FROM PLATFORM.55877-00.36PLATFORMRAISEoDOWN,1\ UPPER( \ OFF7EMERGENCYSTOPoFUSE55877-002VLOWER55877-001MANUAL 92370-001November 1997

•APPENDIX: DECALS ILLUSTRA nON8I Lt CAU1~ON ISTAND CLEARUNLESS ARM STANDIS IN PLACE54652-0029lFORKLIFT JPOCKETEMERGENCY LOWERINGPULL T -HANDLE, TO LOWER PLATFORM.RELEASE HANDLE TO STOP MOVEMENT.BRAKE RELEASEONL Y ON FIRM, LEVEL GROUND,ROTATE BOTH LEVERS TO RELEASE BRAKES.I [FORKLIFT JPOCKET~10ELECTROCUTION HAZARDDEATH OR SERIOUS INJURY WILL RESULTFROM CONTACT WITH THIS MACHINE IF ITSHOULD BECOME ELECTRICALLY CHARGED.KEEP CLEARxxxxx13HYDRAULICFLUID54984-00MANUAL 92370-001November 1997

APPENDIX: DECALS ILLUSTRA nON2011 0 VOLTEXTENSION TOPLATFORM54984-006318300 IMPERIAL DRIVEWACO, TEXAS 76712oI MANUFACTURED IN U.S.A.~IC==O=N==D=O=R===M=O==D=E=L================~II I SERIAL NO.I RATED WORK LOAD750#I~P==L=A=T=F=O=R=M===H=E=I (:;:=::-"H=T===2:::0='=-=0=="===:::;1 I H YD. PRE S SU R E 2,700 PSIILS~Y~S~T~E~M~V~0~L~T~A~G~E~~2~4 ___ V_.~D~C ____ ~1 LI ______________________________ ~oTHIS UNIT IS NOT ELECTRICALLY INSULATED.THIS SELF-PROPELLED ELEVATING WORK PLATFORM CONFORMSTO ALL APPLICABLE REQUIREMENTS OF ANSI A92.6-199051340oMANUAL 92370-001November 1997

TIME CONDOR CorporationSELF -PROPELLEDELEVATING WORK PLATFORM<strong>MODEL</strong> <strong><strong>V1433</strong>XL</strong>, <strong>V1433</strong><strong>MODEL</strong> <strong><strong>V1833</strong>XL</strong>, <strong>V1833</strong>MAINTENANCE SECTIONSHIPPING ADDRESSCONDOR®TIME CONDOR Corporation8300 IMPERIAL DRIVEVVAco,TEXAs76712(254)420-5200MAILING ADDRESSCONDOR®TIME CONDOR CorporationP.O. Box 21447VVACO, TEXAS 76702-1447(254)420-5200MANUAL 92370-002November 1997

INTRODUCTIONiThe primary purpose of this manual is to provide the user with a thorough understanding of the properoperating procedures necessary to comply with the intended use of the CONDOR®, and to provide theinformation necessary to maintain and service the CONDOR®.THE OPERATOR'S MANUAL MUST BE RETAINED ON THE CONDOR®AT ALL TIMES.Do not attempt to operate or service the CONDOR® until you have read andunderstood all information provided in this manual. Familiarizeyourselfwith thefunctions and operations ofthe upper and lower controls. A good understandingofthe controls, their limitations, and their capabilities will maximize operatingefficiency. The various decals attached to this CONDOR® also contain vitaloperational instructions. Read the decals before operating this CONDOR®.It is YOURRESPONSIBILITYto follow procedures while operating the CON DOR®.The manufacturer of this CONDOR® cannot control the wide range of applications that may be used incarrying out a variety of jobs. Therefore, it is THE USER'S RESPONSIBILITY to consider all personnelwhen making decisions regarding the CONDOR®'s intended use.It is also YOUR RESPONSIBILITY to understand and obey all federal, state, and local regulations regardingthe operation and use of aerial work platforms. A copy of the ANSI!SIA Manual ofResponsibilities is attachedfor your use: ANSI!SIAA92.5-1992 is provided for Boom-Supported Elevating Work Platforms, and ANSI!SIAA92.6-1990 is provided for Self-Propelled Elevating Work Platforms.TIME CONDOR Corporation reserves the right to modify, improve, add, andlordelete certain design featuresofits products without any obligation to incorporate new features into products previously sold. Our manualsare continually updated to reflect these changes.DO NOT ALTER OR MODIFY THIS CONDOR® WITHOUT PRIOR WRITTEN APPROVALFROM THE MANA GEMENT OF TIME CONDOR CORPORATIONSERVICE & MAINTENANCEMany of the parts used in the manufacture of the CONDOR® have specific properties, and the manufacturerrecommends that replacement parts be purchased through TIME CONDOR Corporation in order to ensurethe original integrity of the product. Repairs and adjustments should only be made by trained and qualifiedpersonnel. Please refer to the maintenance and parts sections of the TIME CONDOR Operation,Maintenance, & Parts Manual forinformation on service and maintenance of the CONDOR®.NOTE:Please refer to the TIME CONDOR section of the Operation, Maintenance, & Parts Manual forinformation pertaining to your CONDOR®.

iiTIME CONDOR CorporationCONDOR® SERVICE INFORMATION1. If you need assistance or have any service or maintenance questions, TIME CONDORCorporation service and parts personnel are always available by phone or fax. The telephonenumbers are:(254) 420-5200 Telephone(254)420-5298 Voice Mail(800) 443-5803 FAX2. There are numerous written Maintenance Procedures available forthis CONDOR®.These procedures are available through the TIME CONDOR Service Departmentto anyonewho requests them.3. Service and maintenance are nota substitute for trained, qualified service technicians.TIME CONDOR conducts service schools on a continuing basis. Call any of our serviceor sales persons for a schedule. Remember, training of mechanics is the responsibility oftheiremployer, but TIME CONDOR Service Schools help you provide this training.4. TIME CONDOR Service School Training Manuals are available for purchase through theparts department. The part numbers for these manuals are: #92333 for self-propelled models;and #92334 for truck-mounted models.TIME CONDOR Corporation8300 IMPERIAL DRIVE, P.o. Box 21447, WACO, TEXAS 76702-1447- 254-420-5200, 254-666-4544 FAX

iiiCondor® Self-Propelled Booms and ScissorsWARRANTYTIME CONDOR Corporation warrants to the purchaser that each new aerial work platform made by TIMECONDOR is free from defects in material and workmanship arising under normal use and service-in thecase ofmajor weldments, (chassis, turret, and booms), for a period offive (5) years after the original shipmentof the aerial work platform from TIME CONDOR's plant; and in the case of all other parts, for a period ofone (I) year after the aerial work platform is placed in service or two (2) years after the original shipmentof the aerial work platform from TIME CONDOR's plant, whichever comes first.The obligation and liability under this Warranty is expressly limited to repairing or, at TIME CONDOR'soption, replacing free of charge at its factory in Waco, Texas or at an authorized repair facility designated byTIME CONDOR, the defective part. In no event shall TIME CONDOR or its suppliers be liable to thepurchaser or any other person for transportation charges or for any incidental, collateral, special, orconsequential damages, including without limitation damages for loss of profits, loss of customers, loss ofgoodwill or work stoppage, claims by any party other than the purchaser, or any other similar damage or losseven if TIME CONDOR, its suppliers, or its representatives have been advised of the possibility of suchdamages.Parts claimed to be defective and for which repair or replacement is desired shall be returned transportationprepaid to TIME CONDOR factory for inspection. This Warranty applies to replacement parts providedunder the terms ofthis Warranty only for the remainder ofthe Warranty period applicable to the originalpurchase.Any operation of the equipment beyond rated capacity, improper use or application of the equipment,substitution upon it of parts not approved by TIME CONDOR or alteration or repair of the equipment byany person not authorized by TIME CONDOR shall, at TIME CONDOR's option, void this Warranty.TIME CONDOR shall have no liability or responsibility for damages resulting from accident or themalfunction of equipment and components not supplied by TIME CONDOR.No agent, employee, distributor, dealer, or other representative of TIME CONDOR is authorized to modifythis Warranty in any way. Accordingly, additional statements or presentations by any such representative,whether oral or written, do not constitute warranties by TIME CONDOR and should not be relied upon aslimited warranties of TIME CONDOR, and no attempt, effort, or promise to repair equipment by TIMECONDOR or any such representative at any time shall modify or extend this Warranty in any way. If thepurchaser has used its own order form, no additional or different warranty terms contained in the purchaser'sform will be honored by TIME CONDOR. This Warranty covers only new and unused aerial work platformsmanufactured by TIME CONDOR. Products or parts manufactured by others are covered only by suchwarranties as are extended to the purchaser by TIME CONDOR's suppliers.This Warranty is in lieu of all other warranties, expressed or implied, including but not limited to warrantiesof merchantibility and fitness for a particular purpose. Any applicable implied warranty shall be limited induration to the warranty period.8300 Imperial Drive, P.O. Box 21447, Waco, Texas 76702-1447

Effective January 1, 1993WARRANTY PROGRAMWarranty is a function of a manufacturing company to back up the product it manufactures. It is aguarantee against defects in design and workmanship of components utilized in the product, and is offeredfor a fixed period of time following the purchase of the product by a customer.TIME CONDOR Corporation Warranty states, in general, that TIME CONDOR Corporation will replacefree of charge any components found to be defective within the time frame of the warranty period. Thereare exceptions to some components which are not the responsibility of TIME CONDOR Corporation.These will be outlined in subsequent paragraphs.A. WARRANTY PERIOD1. The Self-Propelled Boom and Scissor Warranty is one (1) year from placing theCONDOR® in service or two (2) years following shipment from TIME CONDORCorporation, whichever comes first. In the case of majorweldments (chassis, turret, andbooms), the Warranty Period is five (5) years following shipment from TIME CONDORCorporation.2. The Truck-Mounted CONDOR® Warranty Period is one (1) year from shipment of theCONDOR® from TIME CONDOR Corporation's plant.3. For parts sold through the Parts Department, the Warranty Period is six (6) months fromutilizing the component or placing it in service, or twelve (12) months following shipmentfrom TIME CONDOR Corporation, whichever comes first, unless the part is furnishedto correct a defective part on the original shipment still under Warranty.4. Replacement parts provided under the terms of the Warranty are for the Warranty Periodapplicable to the unit in which they were installed as if such parts were originalcomponents of the aerial work platform.5. During the Warranty Period, in addition to covering the parts replaced under Warranty,Condor Division will pay a Dealer Warranty Labor Rate which is based on a percentageof your standard shop labor rate.NOTE:The term "IN SERVICE" means that the Warranty starts at the time the CONDOR®is first used for any purpose. An example: The dealer may have purchased aCONDOR® to have in stock, but may not use it. After three months, the CONDOR®is sold or the dealer decides to put the CONDOR® into its rental fleet. In this situation,the Warranty Period begins the day the dealer puts the CONDOR® into the fleet orwhen the CONDOR® is delivered to the end user.The submittal of a warranty claim against a stock machine constitutes it as being "inservice," initiating the warranty period.

D. PROCESSING OF WARRANTY CLAIMDuring the Warranty Period, should a component failure be encountered within the guidelines ofthe TIME CONDOR Corporation Warranty Policy, the following procedure is to be followed:1. Upon identifying the defective component, the replacement can be obtained by:a. Issuing an order to our Parts Department through normal channels, whichentails your being invoiced.b. Y oumay have previously purchased the part from TIME CONDOR Corporationfor your stock and will utilize it for this replacement.The above two methods will enable you to indicate on the claim the TIME CONDORCorporation invoice number to substantiate the parts purchase and the amount to becredited.c. Although not recommended, you may purchase the part locally. When this isdone, a copy ofthe purchase order or receipt MUST accompany the claim. TIMECONDOR Corporation has the option to ship a replacement part at no charge ifthe local cost would be greater, in lieu of issuing credit for locally purchased parts.d. When parts are puchased from TIME CONDOR Corporation, part numbers withinvoice numbers MUST be referenced in the appropriate section of the claimform.2. Complete the Warranty Claim as noted in the "Warranty Claim Procedure" section.Provide as much information as possible to enable TIME CONDOR Corporation tothoroughly evaluate the claim and process it in the shortest amount of time possible.NOTE:WARRANTY CLAIMS WILL NOT BE ACCEPTED BY TIME CONDORCorporation AFTER 45 DAYS AFTER FAILURE3. Provided no return parts are required and all the information has been verified, the claimwill be processed and credit will be issued against your account.E. RETURN AUTHORIZATION1. If a component is found to be defective within the normal guidelines ofthe Warranty, aWarranty Claim Form must be completed.t2. It will be necessary for you to call the TIME CONDOR Corporation Service Departmentand ask to be issued a Return Authorization (R/ A) number. You will be asked for a DealerClaim Number. As noted in Section 2, Item A, of the Warranty Claim Procedure, this isa number assigned by the dealer for the purpose of tracking the claim, as there may bemore than one claim for the same CONDOR®. The R/ A number issued must be loggedin the appropriate section of the claim form, and the gold copy (R/ A) ofthe form must bereturned with the parts being returned.

NOTE:DO NOT SHIP ANY RETURN PARTS WITHOUTA RETURN AUTHORIZATION (RIA) NUMBERDoing so may result in parts getting lost in the system and may delay processing the claim,or may cause denial due to the time element ofthe claim.3. All RIA parts must be received at TIME CONDOR Corporation within 45 days from thedate the RIA number was issued. Failure to do so will cause the claim to be denied.4. All parts claimed under W arrrantywill be required to be shipped back to TIME CONDORCorporation FREIGHT PREPAID. No freight collect shipments will be accepted.

• NOTESMANUAL 92370-002November 1997

SPECIFICATIONS•SPECIFICATIONS <strong>V1433</strong>1XL <strong>V1833</strong>1XLMaximum Working Height 19'10" 24 ft.Platform Height 13'10" 17'10"Stowed Platform Height 35.25" 39.25"Overall Length 63" 63"Overall Width 33" 33"Overall Height 74.25" 78.25"Overall Height With Rails Removed 46.25" 49.75"Platform Size 63" x 30" 92.5" x 30"Platform Capacity 600lbs 5001bs.Gross Weight 2,1001bs 2,400Ibs.2,200Ibs-XL 2,500Ibs-XLPower System 24 volt DC 24 volt DCBattery Capacity 235 amp hour 235 amp hourNumber of Batteries 4 4Battery Voltage 6 volt 6 voltBattery Charger 25 amp 25 ampWheelBase 48.5" 48.5"Tires 14 x 4.5 14 x 4.5(Solid Rib) (Solid Rib)Inside Turning Radius 17" 17"Drive Speed 75/1.5/3 mph .75/1.5/3 mphGradeability 29%/16° 290/0/16°LiftlLower Time 15/19 sec. 22/28 secOPTIONS* Battery Condition Indicator * MotionIMovement Alarm* Strobe Light * Descend Alarm* 250 Amp Hour Deep Cycle Batteries * 5° Slope Alarm* Hour Meter * Low Volt Warning/lnterrupt Battery* Travel Alarm Protection System* Larger BatteriesThe CONDOR® Model <strong>V1433</strong>1XL, <strong>V1833</strong>IXL is designed and built to conform to Condor Div.understanding and interpretation of all applicable OSHA rules and regulations as well as ANSIstandards:ANSI Standard A92.6 - 1990 ................... Self Propelled Elevating Work PlatformCAUTION(It is imperative that all owners and operators of the CONDOR® read, understand and conform tothese regulations. Ultimate compliance to prevailing OSHA regulations is the RESPONSIBILITYof the employer utilizing the equipment.MANUAL 92370-002November 1997

• RECOMMENDEDTOOL LISTThe following is a list of tools that you will find helpful when performing service, maintenanceor troubleshooting the CONDOR®equipment.1 each Volt/Ohm Test Meter1 each Hydraulic Flow Meter, 0-10 GPM1 each Hydraulic Flow Meter, 0-50 GPM1 each Hydraulic Quad Meter Pressure Gauge1 each Battery Hydrometer1 each Battery Load Tester1 each 112" Drive Torque Wrench, 0-250 ft/lbs1 each Pry Bar1 each Strap Type Filter Wrench1 each Grease Gun1 each Hammer, 24 oz.1 each Vice Grip Pliers1 each Combination Wrench Set, 114" to 1-112"1 each 3/8" Drive Socket Set, 114" to 3/4"1 each 112" Drive Socket Set, 3/8" to 1-112"1 each Hex Key (allen wrench) Set, up to 112"1 each Screwdriver Set, Phillips Tip & Slot Tip1 each Punch Set; Drift, Lineup and Straight1 pair Wire Stripping Pliers1 pair Wire Crimping Pliers1 pair Wire Cutting Pliers1 pair Needle Nose Pliers2 pair Jumper Wires with Alligator ClipsNOTE: This list is not intended to be all inclusive of the tools required to perform every maintenancefunction that may be required on this specific CONDOR® model. However, these tools will greatlyassist in troubleshooting problems and conducting routine maintenance on the equipment.MANUAL 92370-002November 1997

Serial Number Location.21The CONDOR® Model <strong>V1433</strong>1XL, VI 8331XL Serial Number is stamped in two locations onthe machine.I. The first place to find the serial number is on the data plate affixed to thechassis, at the rear between fork lift pockets.2. The second place to fmd the serial number is at the front steering knucklekingpin.MANUAL 92370-002November 1997

•This Page Intentionally Left BlankMANUAL 92370-002November 1997

HYDRAULIC SYSTEM DESCRIPTION•The following is a detailed description ofthe hydraulic system used on the CONDOR® model<strong>V1433</strong>1XL, VI 833IXL scissor, and how it designed to operate. To assist in understanding the system,this description should be used in conjunction with the hydraulic schematics found at the end of thissection.GENERALThe hydraulic system on the CONDOR® model VI 4331XL, <strong>V1833</strong>IXL consists primarily of asingle manifold assembly, used to control all the hydraulic functions through the use of hydrauliccylinders and motors. The system is electric over hydraulic, meaning that the hydraulic valve assemblyis activated by electrical signals from the function controls. The system is also of the open-center valvetype, meaning that the hydraulic fluid circulates back to the tank when the pump is running and nofunctions are being operated. All lift and drive functions can be performed from the platform console,while ONL Y lift functions are available from the lower control console.HYDRAULIC TANKThe hydraulic tank is an ItL It shapedweldment having a fluid capacity of 7 US gallons.The main portion of the tank is locatedbetween the batteries in the belly pan, with thesmaller portion extending outward to the rightside ofthe unit (See FIG. 1) next to the hydraulicpump. A filler neck and cap, and a sight glass areprovided at the extended section of the tank forchecking and maintaining the fluid level. Filtrationof the hydraulic oil is provided through a 10micron spin-on return filter, and a 100 mesh, 10GPM, tank-mounted strainer. The filter, andstrainer are located at the end of the tank, justbehind the pump.BallValveFiller CapFIG. 1NOTE: Only check the tank fluid level when the unit is in its stowed position to ensure the level willbe at its highest. The hydraulic fluid used is Shell Tellus T -32 and only this fluid, or its equivalent shouldbe used.DO NOT MIX HYDRAULIC FLUIDS.MANUAL 92370-002November 1997

• PUMPIMOTORThe pump wall motor assembly is locatedin the right side of the belly pan, (See FIG.2). A 24 volt DC motor drives a tandem pump,which consists of two separate pumps drivenfrom the same shaft. Both sections have a size of.161 cubic inch per revolution, which equals to2.25 GPM of hydraulic flow at 3600 rpm. Onesection of the pump is only used for drive, whilethe other pump section supplies fluid for steering,lift, or to increase the drive speed whendirected to the drive circuit.FIG. 2MAIN VALVE ASSEMBLYLocated in the left side wall of the bellypan is the main valve assembly which performsall of the hydraulic functions of the machine(See FIG. 3). This assembly includes threedirectional control valves and a variety of cartridgevalves to achieve the operation of thecylinders and motors for the machine functions.These individual functions are described in detailbelow.FIG. 3Battery ChargerMACHINE FUNCTIONSThe hydraulic functions of the CONDOR® model <strong>V1433</strong>1XL, <strong><strong>V1833</strong>XL</strong> includes: forward andreverse drive with three selectable speeds at limited height, spring applied/hydraulically released brakecylinders, left and right steering, and platform raising or lowering. Each ofthese functions are performedby the main valve assembly via electrical control signals. A detailed description of the electrical controlsand their circuits can be found in the Electrical System Description of this maintenance section.DRIVE FUNCTIONThe drive function is only available at the platform controls. Movement of the drive controlhandle 13 0 from its center position in either direction will tum the pump motor on and energize therespective forward/reverse electrical circuit. The forward/reverse electrical circuits consist solely ofthe drive controller and the drive directional control valve located on top ofthe main valve assembly (seeFIG. 4).MANUAL 92370-002November 1997

-----------------------------------------~Drive DirectionalControl ValveCreep SpeedSolenoid ValveUr---,/Flow Divider/CombinerFIG. 4Creep SpeedNeedle ValveDRIVE FUNCTION (cont'd)Pump flow circulates through the main valve assembly and back to tank if no functions areactivated when the pump is running. Once the directional control valve shifts, fluid is directed to oneof the load control valves in its free-flow direction, and then to the normally open positraction valve.Fluid flows through the positraction valve cartridge, then to both drive motors which each have an 8.0cubic inch per revolution displacement and are located on the steer axle.The deceleration valve is utilized to cushion the braking action of the drive circuit. This isaccomplished by letting fluid by-pass between the two drive motors. Since the deceleration valve is a2-way normally open spool valve, it allows fluid to flow through it at all times. When the drive controlhandle is actuated, energizing the drive circuit, the deceleration valve becomes energized and closes,blocking the flow of fluid through it. When the drive handle is released (circuit de-energized), thedeceleration valve opens, and lets the drive pressure by-pass to the opposite drive motor, allowing thetwo drive motors to continue to roll momentarily without creating a hydrostatic lock in the circuit. A0.040 dia. orifice, located under the deceleration valve, is used to control the amount of by-pass thatoccurs which affects the deceleration of the machine.The 2633 has a creep speed which is either automatically activated at platform heights aboveseven feet by a limit switch, or is operator selectable at heights below seven feet. Creep speed is a situationin the drive circuit whereas when the creep speed solenoid valve is energized, some of the drive flow isdiverted back to the tank. The speed at which the machine travels when in creep, is controlled by the creepspeed needle valve (See FIG. 4). The creep speed is factory set to obtain a travel speed of 80-1 00 sec/88 feet, on firm, level ground; (Ref.. 75/.6 mph), (see note #2 on schematic at end of hydraulic section).MANUAL 92370-002November 1997

•DRIVEFUNCTION (cont'd)When the speed selector switch is in thehigh position, the drive speed increases by theaddition of the P2 pump's fluid displacement(steer/lift pump) being diverted to the drivecircuit. This is accomplished by activation ofthe select directional control valve. The hydraulicpump contains two individual pump sections,one of which is used solely for the drive circuit.The other pump section supplies fluid for theoperation oflift and steer, and will supply fluidto the drive circuit when the machine is in highspeed. A check valve cartridge is used to isolatethe drive-only pump flow for use in the drivecircuit (See FIG. 5).Select DirectionalControl Valve(between drive and steer)Creep ValveFIG. 5Steer DirectionalControl ValveCheck ValveCartridgeSTEERING FUNCTIONSteering is accomplished with a cylinder,knuckle, and connecting arm arrangement,which in its configuration provides a tight turningradius. The drive motors are mounted to thesteering knuckles, thus enhancing driveability.The steering cylinder, located just behind thefront bumper plate of the chassis, is controlledby the steer directional control valve on top ofthe manifold assembly (See FIG. 5&6).Steer CylinderLIFT FUNCTIONFIG. 6Lifting of the platform is accomplishedby energizing the select directional control valve.This will direct fluid from the P2 pump to theCylinderbase end of the lift cylinder, with the rod end ofManifoldthe lift cylinder being vented back to the tank.CoilLocated on the cylinder body (See FI G. 7), is theholding valve, which consists of a manifoldCablebody, a 2-way normally closed cartridge with amanual override, and an electric coil. Attachedto the cartridge is a cable assembly used forFIG. 7manually lowering the platform via aT-handlelocated at the rear of the machine, under the rearbumper plate. Descent speed is controlled by a flow control valve (See FIG. 3), in which clockwiserotation decreases descent speed, while counterclockwise rotation increases the descent speed.MANUAL 92370-002November 1997

PRESSURE ADJUSTMENT PROCEDURES•NOTES: All pressure adjustments are to be made with the pump motor running, and with the hydraulicfluid at operating temperature. Ensure that the tank is filled to its recommended level, and that thebatteries are fully charged. To simplify the adjustment procedure, install a pressure gauge at the "G 1 "port, and install another pressure gauge at the "G2" port, which are both located at the creep valve endof the main valve assembly. All relief valves adjust in the same manner: clockwise increases pressuresetting, and counterclockwise decreases pressure setting. All flow control cartridges adjust in the samemanner: clockwise decreases flow, and counterclockwise increases flow. Refer to FIG. 8 foradjustments.Drive Pressure Adjustment1. Chock both drive wheels to prevent them from spinning in the forward drive direction.2. With the drive speed selector in the low position, activate forward drive with the drive controller.3. While drive is activated, adjust "RVI" to 2700 psi while observing the gauge reading from the"GI" port.4. After setting, lock the adjustment screw with the jam nut.High Drive Pressure Adjustment1. Select high speed at upper control box.2. Observe the pressure reading at the "G 1 " port while climbing a grade, and note pressure readingat which the high drive shifts to low.3. Adjust the "SEQ" valve until the pressure reading is 1100 psi when high drive shifts to low.4. After setting, lock the adjustment screw with the jam nut.NOTE: The load control valves, "CB 1 " and "CB2", are factory set. Ifthey are not functioning properly,they must be replaced; DO NOT ATTEMPT ADJUSTMENT.Lift PressurelDescent Speed Adjustment1. With pump running, and platform raised completely (cylinder bottomed out), observe thepressure reading on the gauge connected to the "G2" port. Adjust "RV2" to 2700 psi.2. Adjust "FCI" to obtain a 25-35 second descent from a fully raised position.MANUAL 92370-002November 1997

• Toaid troubleshooting, some ofthe valves and cartridges are identical to others and can be swapped tohelp determine faulty components:1. "RV3" and "RV 4" steer reliefs are identical with same pressure settings.2. "FCl" and "FC2" brake and descend flow control valves are identical while settings may differ.3. "CBl" and "CB2" are identical-- DO NOT ADJUST!4. "RVI" and "RV2" are identical with the same pressure settings.5. "CREEP" and "DECEL" solenoid cartridge valves are identical."G2" Gauge Port-+t--+----- (Reads Steer/Lift!High Drive Pressure)"G1" Gauge Port(Reads Drive OnlyPressure)"FC1" - Controls PlatformDescent Speed"RV2" Relief For Steer/Lift("G2" Gauge Port)"RV5" Secondarylift ReliefCreep SpeedAdjustment"SEQ" (Sequence) ValveControls High Drive Shifting"RV1" Relief For Drive Only("G1" Gauge Port)"CB1" and "CB2" loadControl Valves(DO NOT ADJUST)FIG. 8MANUAL 92370-002November 1997

Hydraulic Schematic..DRIVEMOTORS54644-00354596-001 eODY54635-001 VALVElin CVl..INDERSV14JJ<strong>V1833</strong>55538 55540<strong>V1433</strong>lCLVlBJJXl55539 555362.501A.J.C OIA1.75 ROO 2.0 ROOSOlIOl Y WELDEDSTEEL TUB£S 2 ON ~l(l ~~PLAIN~1 TUBE ONLY,",cons HAVEONLYu ,«::::;~::;)«Ct:VJ«0X >-IWI-IX)~0u '- (0i« '

This Page Intentionally Left BlankMANUAL 92370-002November 1997

ELECTRICAL SYSTEM DESCRIPTIONThe following is a detailed description of the electrical system used on the CONDOR® model<strong>V1433</strong>1XL, <strong>V1833</strong>IXL scissor, and how it designed to operate. To assist in understanding the system,this description should be used in conjunction with the electrical schematics found at the end of thissection.GENERALThe CONDOR® model <strong>V1433</strong>1XL, <strong>V1833</strong>IXL uses a 24 volt direct current (DC) electricalsystem consisting offour, 6 volt DC batteries, an electric motor to drive the hydraulic pump, and variouselectrical controls to operate the system. Included in this system description is a Machine Optionssection, describing options which are available on the model <strong>V1433</strong>1XL, <strong>V1833</strong>1XL. All of the optionscontained in this description are electrical only, and do not affect the hydraulic performance of themachine.BATTERIESThe model <strong>V1433</strong>1XL, <strong>V1833</strong>IXL scissor uses four, 6 volt DC batteries, each having a 235 amphour capacity. There are two batteries on each side of the belly pan nearest the steer axle. The fourbatteries are connected in series, combining their voltage, to make up the 24 volt DC system. The batteriesare of the wet-cell type, and when filled with electrolyte, each battery weighs 661bs. More informationon batteries in general can be found in the Battery Service Section beginning on page 23.BATTERY CHARGERThe battery charger has a 25 amp @ 24volt DC nominal rating, and operates off of a 115volt alternating current (AC), 160 Hz, 8 ampinput. The charger features contains an ammeterfor reading the DC amp output, and two LEDstatus indicator lights; a red LED indicates thecharger is on, charging, while a green LED indicatesthe charging is complete. The charger islocated on the right side of the belly pan, betweenthe pump/motor assembly and batteries (See FIG.9). More detailed information of the charger canbe found in the Battery Charger TroubleshootingGuide beginning on page 43.Main ManifoldAssemblyGround ControlsFIG. 9CIRCUIT BREAKERIFUSELocated below the control selector switch on the lower control box (see FIG. 11), is a 15 ampfuse. This circuit fuse protects all the machine control circuits.MANUAL 92370-002November 1997

• PUMPMOTORThe CONDOR® model <strong>V1433</strong>/XL,<strong>V1833</strong>IXL utilizes a pump motor which is a 24volt DC unit, rated 6 hp @ 3600 rpm. Since themodel VI4331XL, VI8331XL utilizes a gravitylowering system, the motor does not run while thelowering function is activated.FIG. 10LOWER CONTROL FUNCTIONSLocated above the left rear wheel is thelower control box, which provides a junctionconnection through the use of two terminal strips,for the limit switch cable, the hydraulic valvecable, the pump motor contactor cable, and thecable to the upper controls. At the lower controlsare switches (see FIG. II), to provide operationof the lift function only; drive is not availablefrom this control box. The lower control boxcontains an emergency stop button which must bepulled out to supply power to both control boxes.The control selector switch is a 3-position maintainedrotary switch that directs power to eithercontrol box for operation of the machine,Emergency Stop ButtonPlatform Lift ControlControl Selector Switch ----ti!--!-I-~"'J15 Amp Circuit Breaker/Fuse _-I!I-r---@FIG. 11IIIII___________ -.lwhile the box not selected, will not have power. The platform lift control consists of two pushbuttons,which, through the use of contact blocks, energize the pump motor and selector valve for raising, or theholding valve for lowering. The pump motor does not run during lowering.UPPER CONTROL FUNCTIONS (XL Models)The upper control box, located at the right hand forward comer ofthe platform, is a fiberglassenclosure which contains two slip-fit inserts on its underside that allow the box to press onto two pinswhich are part of the platform weldment. The control box is removeable by disconnecting the cableharness plug underneath, and lifting upward on the box assembly. The feature allows for disabling themachine, storage of the box, or ease of repair to the controls. Some of the controls used are identical tothe those found at the lower control box (See FIG. 12), primarily the emergency stop button and the liftcontrols. The platform lift control buttons operate similar to the lower control pushbuttons. However,at this control box, the green "POWER" pushbutton must be depressed to supply power to either the raiseor lower lift button. To provide electrical power to the upper control box, both emergency stop buttonsmust be in the "out" position, the control selector switch must be in the "UPPER" position.MANUAL 92370-002November 1997

UPPER CONTROL FUNCTIONS (XL Models cont'd)•Cut-Away Viewof Slip-Fit InsertLift Controlsr --------- ----- -1fl \\Drive Controllerw/Steer RockerSwitchPower Button(green)DriveSpeedSelectorCable Harness ./PlugHidden View ofSlip-FitlnsertFIG. 15Integrated in the forward edge ofthe drive handle is a grip lever which is a substitute for the footswitch commonly used on other machines. The grip levermust be squeezed to perform drive (movementof the handle), or steer (activation ofthe rocker switch) functions. This lever, however, does not affectthe lift controls. Movement of the drive handle 13 0 in either direction will tum the pump motor on, andenergize the drive directional control valve, thus initiating drive motion. Drive speeds are selectablefrom the drive speed selector switch. Selecting "fast" will energize the select directional control valve. and increase drive speed by adding the second pump's flow to the drive hydraulic circuit. Selecting "low"will de-energize the select valve, and drive speed will then rely on the single pump output. Pressing theblack positraction button energizes the positraction valve in the main manifold assembly, thus forcinghydraulic flow through the flow divider/combiner. When in "fast" or "low", the creep valve is alwaysenergized because it is a normally open valve. When "creep" speed is selected, or when the platform isabove six. to seven feet, it is de-energized, thereby letting fluid by-pass to tank through an adjustableneedle valve.MANUAL 92370-002November 1997

NOTESMANUAL 92370-002November 1997

MACHINE OPTIONS DESCRIPTION•The following descriptions are intended to be used with wiring diagrams at the end of thiselectrical section.STROBE LIGHT (OPTION)This option is to indicate that the machine is on or ready to operate. The strobe has: a plug-inflash tube for easy replacement, an energy output of2 joules, a power output of3 watts, and a flash rateof 60 + 10 flashes per minute. The strobe is energized whenever the control selector switch is in the"UPPER" or "LOWER" position and the lower control emergency stop button is pulled out.5°SLOPE ALARM (OPTION)This option sounds an alarm when the V141l833 is 5° or more out oflevel. A 5° omni-directionalsensor is mounted in the belly pan to sense a 5° out-of-Ievel condition. In this situation, a fast pulse/loudtone alarm at the upper control box (See FIG. 13), is activated until the machine is returned to a less than5° condition. This serves as a warning, and does not inhibit any functions. The sensor is mounted on aspring loaded base which is adjustable to allow leveling. Testing of the system is accomplished bymanually tilting the sensor against its spring tension mount, to physically put the sensor in a 5° out-oflevelcondition, causing the alarm to sound. Power is supplied to the sensor, and the alarm, only whenthe machine is in the "UPPER" control position. When the sensor is activated (5° or greater), the sensor'swhite wire (connected to the alarm), becomes grounded after a few second delay, through circuits insidethe sensor.BATTERY CONDITION INDICATOR (OPTION)This option is to monitor the batteries'state-of-charge, (See FIG. 13). The indicator iswired directly to the batteries with the 15 ampcircuit breaker, or fuse, included in the circuit.Consisting of an analog 10-LED bar display, theindicator provides a visual reference for readingproperly charged batteries (top LED lit), batteriesat 70% depth-of-discharge (second from bottomLED flashes), and when the batteries have reachedan 80% depth-of-discharge (bottom two LED'sflash alternately).BatteI)'ConditionIndicator08Slope AlarmFIG. 13SIGNAL HORN (OPTION)This option consists of a 133 db automotive type horn mounted in the chassis, and a whitepushbutton on the side of the upper control box (See FIG. 14). The hom is only operable when the controlselector switch is in the "UPPER" position.MANUAL 92370-002November 1997

EDLOW VOLTAGE BATTERYPROTECTION SYSTEM (OPTION)This option prevents operation when thebatteries are in a low voltage condition. It becomesenergized whenever the control selectorswitch is in either "UPPER" or "LOWER" position(lower emergency stop button must be pulledout). While energized, the module monitors thebatteries' voltage level, and will prevent the pumpmotor contactor from being activated once thebattery voltage reaches 12.5% undervoltage, orapproximately 21 volts. This condition must bepresent for 21 seconds to activate the interruptsystem. Terminals 3 & 4 of the module arenormally closed contacts which complete theLow Volt Override Pushbutton(w/Amber Indicator Lamp)SlopeAlarmSignal HornPushbutton(white)~~3"- Cable Harness PlugFIG. 14pump motor contactor circuit, and it is these contacts which are opened during a low voltage condition.Terminal 7 ofthe module is the battery input voltage, while terminal 6 is machine ground. Terminals 1& 2 are normally open contacts which close during a low voltage condition and turns on an amberindicator light (pushbutton) at the upper control box. The system can be overridden by pressing thepushbutton on the side ofthe upper control box (See FIG. 14), which energizes terminal 5 of the module.However, the override will only allow three repeated by-pass cycles of2 minutes 30 seconds each. TheLVI module will reset when the battery voltage reaches approximately 25.5 volts during re-charging.Once the batteries have been properly charged and the L VI module has automatically reset, theCONDOR® can be operated once again.TRAVEL ALARM (OPTION)This option indicates forward or reverse drive (travel) of the machine. The alarm signal isactivated by the deceleration valve circuit since the deceleration valve is always energized during bothforward and reverse drive.DESCEND ALARM (OPTION)This option indicates descent (lowering) of the platform. The alarm signal is activated by theholding valve circuit, which is energized when lowering the platform.MOTION ALARM (OPTION)This option indicates forward or reverse drive, and raising or lowering of the platform. The alarmsignal is activated from two different circuits; one energizes the pump motor contactor, and the otherenergizes the holding valve for platform lowering (pump not running). A diode is used in each circuitto prevent unintended feedback.HOUR METER (OPTION)This option is to record the "run time" of the machine for maintenance scheduling, rental usage,etc.. The meter runs only when the pump motor contactor is energized (pump running); therefore, themeter does not run when the machine is sitting idle, or when the platform is being lowered.MANUAL 92370-002November 1997

~3 ______________________________________________ ~H~NElectrical Schematic•r3~ _________________________________________________________ Rrn--{5·}-B_~ ______ ~14 WHTSLoPE SENSOR OPTIONSLOPE ALARIA oPTION3 .f.. WH1~2. BUT. SEE NOTE 3t=-----3~------~----------------~A~----~3-POSSELECTOR+,3,,-_...:U1';;..;,.;PE:;;R'-J> (~ SD..l.-,SDLOWERSIGNAL oPTIONLOW VOLT OPTION (SENSOR)STROBE LIGHT oPTIONSA TTERY CONDITIONINDICA TOR oPTIONSA TTERY DISCONNECTKEY SWITCH OPTIONfOUR 6VOC SA TTERIESPLAlFORM6C· ~ B UPPUMP MOTORPUMP MOTOR CONTACTOR5CI PLA~=~9~ ___ ~_~-+ _____ ~ _______ ~_~~_~BCHOUR METER OPTIONMOTION ALARM oPTIONVALVE ON LIFT en7DESCEND ALARU OPTIONRIGHT(STEER VALVE)LEftFORWA.RD(DRIVE VALVE)REVERSEGREEN.f..~ PLA ~g"W::3A ENAB~: :LArr~U8D3C ~ 8 uP~--------~----------~----------~~~3B 10,3-POSSPEroSELECTOR,I3B I 11~W~ ____ ~~~~~~~ ____ ~+{~2'H-__________ ~III1fAS££ NOTE 1TRAVEL ALARM OPTIONDECELERATION VALVEun PLATFORM.(SELECTOR VALVE)fAST DRIVE SPEEDCREEP DRIVE SPEED VAL 'IE3B "--"""-'12"-________________________________________________ -o.J/r __

•BATTERY SERVICING TOOLSUse proper tools when performing battery service to prevent damage to battery, cables, terminalsand hold-downs, and to save time and energy.BATTERY SERVICESuggested battery tools and their use are described below.FILLING DEVICESOne of the most important routine battery service for conventional batteries is to maintain thecorrect electrolyte level. Two devices are available for this purpose, a self-leveling filler which fills thebattery to a predetermined level automatically, and the syringe type. Battery cells should never be filledabove the level indicator. Do not squeeze the syringe so hard that the water splashes acid from thecell opening.SCRAPER AND WIRE BRUSHThe scraper and wire brush can be used for removing dirt, corrosion and rust from various partssuch as the battery posts, battery tray, the hold-down and the hold-down bolts.BATTERY CARRIERA battery carrier should not place any undue strain on the battery terminals or the container. Anexcellent carrier for plastic cased batteries is a clamp ("ice tong") type carrier with rubber pads which gripthe SIDE WALLS of the container just below the lip ofthe cover. It is used on the side walls rather thanthe end walls, since the side walls have additional strength from the inner cell partitions. Gripping theflexible end walls of plastic containers could cause electrolyte to spew from some of the cells.SERVICE PROCEDURESThe user should realize that the battery is a perishable item and requires periodic attention. With areasonable amount of care, the life of the battery can be appreciably extended. Neglect and abuse willinvariably cause shorter life.CAUTIONLow battery voltage ( discharged) requires higher current draw to do the samework. This high current draw WILL DAMAGE the electric motor, relaycontacts and the batteries. DO NOT OPERATE the CONDOR® with abattery DISCHARGED or that has a specific gravity of 1.130 or LESS.Routine servicing ofthe battery should proceed as follows:First, make a visual inspection for defective cables, loose connections, corrosion, cracked casesor covers, loose hold-downs and deformed or loose terminal posts. If any parts such as cables, hold-downsor the battery appear to be unserviceable, it is recommended that they be replaced.When there is corrosion on the terminal posts or hold-down, the tray or hold-down parts are rusty,or the battery is very dirty, it is recommended that time be taken to clean the parts. A wire brush can beused to remove dirt, corrosion or rust from parts. Clean dirt from the battery top with a cloth wetted withammonia or baking soda in water.MANUAL 92370-002November 1997

Next, wipe with a cloth with clear water. After rust is removed from a part with a wire brush,rinse with clear water, dry and paint with an acid-resistant paint.If corrosion is found on the terminal posts, remove the cable terminals from the battery (groundcable first), using the proper end wrench. A wire cleaning brush can be used to clean the posts and themating surfaces of the cable clamps. Connect the cables to the terminal posts (ground cable last). Coatthe terminal connections with a spray corrosion inhibitor or high temperature grease.The second item in routine servicing of conventional batteries is to check the electrolyte level inall cells. Ifnecessary, add clear, odorless, mineral free water to bring the liquid level to the level indicatorin all cells. If the battery does not have a level indicator, bring the level to 112" (13mm) above the topsof the separators. Do not overfill any cell. When a cell is overfilled, the excess electrolyte may beforced from the cell by the gas formed in the battery. This will cause excessive corrosion of adjacentmetal parts, reduced performance and shorter life.BATTERY TESTINGBattery testing should be considered an integral part of periodic equipment maintenance and should beperformed whether or not a starting problem has occurred. Servicing the battery in the equipment asdescribed will help prevent premature battery failure from external causes and periodic battery failurefrom both external and internal causes or merely from the battery reaching the end of its useful life.STEP 1-VISUAL INSPECTIONFor protection, wear a face shield. First, visually inspect the battery. Check for container,cover or terminal damage that might cause leakage of electrolyte or internal damage. If serious damageis found, replace the battery. Check the electrolyte level in each cell. If below the tops of the plates inany cells, fill all cells with water to just above the tops of the separators and charge for 15 minutes at 15-25 amps to mix the water with the electrolyte. If electrolyte levels are above the tops of the plates,continue to Step 2.STEP 2 -HYDROMETER TESTUsing the hydrometer, measure and record the specific gravity (sp. gr.), corrected to 80 degreesF (26.7 C) of the electrolyte in each cell. Iftherange (highest-lowest) is 50 points (0.050 sp. gr.) or greaterorthe lowest is less than 1.225 sp.gr., charge the battery atthe recommended rate or until all cells are 1.225sp.gr. or greater and the range is less than 50 points. If no amount of charging will achieve theseI,DANGERLead acid batteries generate highly explosive hydrogen gas especially during thecharging cycle. To AVOID the possibility of an explosion, charge batteries ONLYin a well VENTILATED AREA. Keep fire, sparks, and burning material away fromthe charging area. Do Not smoke near a battery, and always shield the eyes whenworking near a battery.MANUAL 92370-002November 1997

The average state of charge ofthe cells in a battery can be determined by measuring the stabilized favoltage of the battery. The voltage is stabilized if the battery has been on open circuit overnight or fora period of several hours. A voltage reading of 12.4 (6.2 on a 6 volt battery) is equivalentto a specificgravity of 1.225. The disadvantage of measuring the open circuit voltage is that a lower voltage cell canbe masked by the remaining cells. Ifthe cell connectors are accessible for voltage measurements, a rangeof 0.05 volts between the highest and lowest cells corresponds to a 50 point variation in specific gravity.A cell voltage of2.07 is equivalent to a specific gravity of 1.225.STEP 3 -ADJUSTABLE LOAD TESTThe following instructions are intended as guidelines. When available, the instrumentmanufacturer's instructions should be followed. Follow all precautions.A. Disconnect battery cables starting with ground cable.B. Measure temperature of a center cell. If instrument has an integral temperaturecompensator, use attached probe.C. Connect voltmeter and load test leads to appropriate battery terminals, make certainterminals are free of corrosion.D. Connect current transducer (if necessary) to appropriate lead.E. Apply test load equivalent to 50% of Cranking Performance rating of battery for 15seconds. If Cranking Performance is unavailable, use 3 times the 20 ampere-hourcapacity.F. Read the voltage at 15 seconds, then remove the load.G. Determine minimum voltage required at electrolyte test temperature from chart inFigure X.H. If test voltage is above minimum, return battery to service.I. Iftest voltage is below minimum, replace battery.TESTING WITH FIXED LOAD TESTER AND OPEN CIRCUITFor testing batteries with a fixed load tester and an open circuit voltmeter, refer to "Battery Testing Chart"Figure Y.STEP 1 -VISUAL INSPECTIONFirst, visually inspectthe battery and check the electrolyte levels as described in Step 1 of "Testingwith Adjustable Load Tester and Hydrometer"; take the same corrective actions. Continue to Step 2.MANUAL 92370-002November 1997

.STEP 2 -FIXED LOAD TESTSome commercial battery testers do not have an adjustable load but measure the battery voltageunder a heavy fixed load. The tester should include a selector switch or meter scale to choose among avariety of battery sizes. It should include some means of correcting for the battery temperature, eitherin automatic sensing circuit or a manually selectable one.The following instructions are intended as guidelines. When available, the instrument manufacturersinstructions should be followed.A. Disconnect battery cables starting with ground cable.B. Measure temperature of a center cell and set temperature dial on tester or insertautomatic temperature corrector probe in center cell. Cover battery with a damp cloth.C. Set battery size selector to a range or select range on meter which will include 50%of the Cranking Performance rating or 3 times to 20 ampere-hour capacity of the battery.D. Connect voltmeter and load test leads to appropriate battery terminals, make certainterminals are free of corrosion.E. Apply test load for 15 seconds.F. Read battery performance from instrument meter at 15 seconds, then remove the load.G. If the battery passed the load test, return it to service.H. If the battery failed the load test, continue to Step 3.STEP 3 -OPEN CIRCUIT VOLTAGE TESTIf the battery failed the load test, the state of charge must be checked. If a hydrometer is notavailable, the stabilized open circuit voltage can be used to indicate the state of charge. Allow at least10 minutes after the load test for the voltage to stabilize, then measure and record the open circuit voltage.Determine the approximate state of charge from the following chart (Battery temperature 60-1 00 degreesF.)OPEN CIRCUIT VOLTS12.6 or greater12.4 - 12.612.2 - 12.412.0 - 12.211.7 - 12.011.7 or lessPERCENT CHARGE100%75-100%50-75%25-50%0-25%0%The change of voltage with state of charge is small and must be measured accurately using adigital meter or an analog meter with an expanded scale. If the state of charge is 75% or greater and thebattery failed the load test, it should be replaced. Ifthe state of charge is less than 75%, the battery shouldbe charged at the recommended rate and time, and the load test repeated. If the battery passes the loadtest, return it to service. If it fails the load test again, replace it and refer to the next chapter to determinethe cause of failure.MANUAL 92370-002November 1997

DETERMINING CAUSES OF BATTERY FAILURE•Whether the battery passes or fails either of the above tests, the results must be believed. If the batterypassed the load test only after a recharge, the cause of the discharge condition should be determined.Ifthe battery has been returned previously or is otherwise still questionable, one final test should be made.Fully charge the battery and place it on open circuit stand for three days. If the loss in specific gravityof any cell is greater than 35 points or the open circuit voltage drops by more than 0.20 volts, replace thebattery. If not, return the battery to service and determine the cause for the discharged condition.The following should be checked:1. Corroded Battery Terminals or ConnectorsA corrosion layer between the battery terminals and the cable connectors can prevent goodelectrical contact even when the connectors are tight. The cables should always be removedbefore testing a battery and any corrosion cleaned from the terminals.2. Electrical Circuit LeakageThere may be a fault in the equipment's electrical system that can discharge the battery even whenall the accessories are turned off. To check for such leakage, turn off all accessories in the equipment.Check for leakage using one of the following methods.A. Ammeter - Cover battery with a damp cloth. Disconnect the ground cable. Using a DCammeter with a resolution of at least 0.1 amp, measure the current between thedisconnected cable and the battery terminal. (DO NOT CONNECT AMMETERACROSS BATTERY TERMINALS!) A leakage current measurement of 0.1 amp ormore indicates the equipment electrical system should be tested and repaired.B. Ohmmeter - Disconnect the positive cable at the battery. Connect an ohmmetertothedisconnected cable end and to the chassis. A resistance measurement of under 100 ohmindicates a load of 0 .1 amp or more and indicates the equipment electrical system shouldbe tested and repaired.C. Voltmeter - Disconnect the ground cable (negative) at the battery. Connect a lowresistance voltmeter (100 ohms - see Note 1) between the disconnected battery postand the chassis. A voltage measurement of 6 volts or more indicates a leak of 0.1 ampor more and the equipment electrical system should be tested and repaired.3. Charging SystemNote 1: The voltmeter test cannot be made with high resistance voltmeters.To complete the determination of the cause for the battery's discharged condition, check theequipment's charging system.MANUAL 92370-002November 1997

•ST EP1I OBVIOUS DAMAGE IIREPLACEBATTERVIBELOW TOP OF PLATES IN ONE ORMORE CELLSADD WATER TO JUST ABOVE SEPA-RA TORS. CHARGE FOR 15 MINUTESAT 15-25AMPS. PROCEED TO STEP 2FIGURE: XBATTERY TESTING CHARTVISUAL INSPECTIONCHECK FOR OBVIOUS DAMAGE SUCH ASCRACKED OR BROKEN CASE THAT SHOWSlOSS OF ELECTROLYTE. ALSO CHECK FORTERMINAL DAMAGE.lII NO OBVIOUS DAMAGE I: CHECK ELECTROLYTE LEVEL IELECTROLYTE lEVEL ABOVE TOP OFPLATES IN ALL CELLS - PROCED TOSTEP 2ST EP2I HVDROMETERTEST IIISPECIFIC GRAVITY LESS THAN 1.225SPECIFIC GRAVITY 1.225 OR GREATEROR CELL VARIATION 50 POINTS OR OR CELL VARIATION LESS THAN 50GREATER.POINTS.III RECHARGEI DISCHARGE AT 150 AMPS FOR 15\SECONDSISPECIFIC GRAVITY LESS THAN 1.225OR CELL VARIATION 50 POINTS ORGREATER.STEP 3II REPLACE BATTERV II LOAD TEST II1. PLACE THERMOMETER IN CENTER CELL.COVER BATTERVWlTH A DAMP CLOTH.2. CONNECT VOLTMETER AND AMPERE LOADEQUAL TO 1/2THE COLDCRANKINGAMPERESAT O°F (-18°C) RATING OF THE BATTERV FOR15 SECONDS.3. OBSERVE VOLTAGE AT 15 SECONDS WITHLOAD ON.4. REFER TO VOLTAGE CHART BELOW.II CONTINUE TO STEP 3 IIIII VOLTAGE EQUAL TO OR ABOVE CHART II VALUE - RETURN TO SERVICEIREPLACEBATTERVII VOLTAGE BELOW CHART VALUE IVOLTAGE CHARTESTIMATED ELECTROLYTE TEMPERATURE70°F (21°C) & ABOVE60°F (16°C)50°F (10°C)40°F (4°C)30°F (-1°C)20°F (-7°C)10°F (-12°C)O°F (-18°C)MINIMUM REQUIRED VOLTAGE UNDER 15 SEC. LOAD(USE 1/2 THESE VALVES FOR 6-VOL T BATTERIES)9.69.59.49.39.18.98.78.5MANUAL 92370"()()2November 1997

STEP 1STEP 2II OBVIOUS DAMAGE III REPLACE BATTERY IFIGURE:YSA TTERY TESTING CHARTVISUAL INSPECTIONCHECK FOR OBVIOUS DAMAGE SUCH ASCRACKED OR BROKEN CASE THAT SHOWSLOSS OF ELECTROLYTE. ALSO CHECKFOR TERMINAL DAMAGE.I FIXED LOAD TEST IIIINO OBVIOUS DAMAGE IICHECK ELECTROLYTE LEVEL. ADDWATER IF NECESSARY. PROCEEDTO STEP 2.1. ATTACH TESTER CLAMPS TO BATTERY TERMINALS IN CORRECTPOLAITY - USUALLY RED TO POSITIVE (+) AND BLACK TO NEGATIVE (-).2. SET SELECTOR SWITCH ON LOAD TESTER TO 1/2 CRANKING AMPERAGERATING OF BATTERY (AT O·F, -1S·C).3. IF TESTER DOES NOT HAVE AN AUTOMATIC BATTERY TEMPERATURECOMPENSATOR, PLACE A THERMOMETER IN CELL, READ AND SET TEMPERATURE DIAL ON TESTER. WITHOUT ANY TEMPERATURE CORRECTION,MAKE LOAD TESTS ONLY ON BATTERIES ABOVE 60·F (16·C).4. APPLY LOAD FOR 15 SECONDS AND READ LOAD TESTER JUST BEFORERELEASING THE LOAD.JI BATTERY FAILS LOAD TEST III PROCEED TO STEP 3 IIIIBATTERY PASSES LOAD TEST IRETURN TO SERVICE.I•STEP 3I OPEN CIRCUIT VOLTAGE TEST II1. ALLOW 10 MINUTES FOR BATTERY VOLTAGE TO STABILIZEAFTER LOAD TEXT.2. READ OPEN CIRUITVOLTAGE.IIUNDER 12.4 VOLTS-BATTERY SHOULD12.4 VOLTS OR ABOVE - IF BATTERYBE CHARGED AND LOAD TESTED AGAI NDID NOT PASS THE LOAD TEST, IT(REPEAT STEP2). IF BATTERY AGAINSHOULD BE REPLACED - THEN PRO-FAILS THE LOAD TEST, REPLACE IT. IF IT CEED TO STEP 4.PASSES, RETURN TO SERVICE AFTERPROCEEDING TO STEP 4.STEP 4CAUSES OF BATTERY FAILURE:1. CORRODED BATTERY POSTS OR CONNECTORS - ALWAYS CLEAN THE BATTERY POSTS ORSIDE TERMINALS AND THE BATTERY CABLE CONNECTIONS WHEN CHARGING OR REPLACINGA BATTERY.2. ELECTRICAL LEAKAGE - CHECK FOR ELECTRICAL LEAKAGE WITH ALL ACCESORIES TURNEDOFF:A) DISCONNECT THE BATTERY GROUND CABLE AND CONNECT A SUITABLE VOLTMETERBETWEEN DISCONNECTED BATTERY POST AND GROUND (A READING OVER 6 VOLTSINDICATES AN EXCESSIVE LEAK).ORB) DISCONNECT THE BATTERY CABLE THAT GOES TO THE STARTER AND CONNECT ANOHMMETER BETWEEN THE CABLE AND THE GOUND (A RESISTANCE OF UNDER 100 OHMSWILL DRAIN THE BATTERY).3. CHARGING SYSTEM SHOULD ALWAYS BE CHECKED AFTER CHARGING OR REPLACING ABATTERY.MANUAL 92370..002November 1997

•NOTESMANUAL 92370-002November 1997

PREVENTIVE MAINTENANCE•In conjunction with the pre-operation inspection, a good preventive maintenance program will ensurea properly operating CONDOR®. This section is directed toward those items of maintenance whichthe operator should be aware of, and which may be accomplished prior to the operation of the equipment.Refer to the "Preventive Maintenance Daily Inspection" and the "Preventive Maintenance 50Hour Inspection" for detailed inspection procedures. Included in this section are checklists, for theDaily and 50 Hour Inspections, to assist in maintaining the CONDOR®. Please note that on the 50Hour Inspection, some items may be stated as 500 Hours, where applicable.LUBRICATIONNOTE:Recommended lubrication intervals are based on normal use innormal environmental conditions. The operator is cautioned toadjust the lubricating interval accordingly to meet each individualcondition and usage. The recommended lubricants are generallythe best choice. Should these lubricants be unavailable in your area,consult your local supplier for an equivalent.1. Wheel BearingsLubricant:Time Interval:Procedure:Wheel bearing grease.Every 500 hours of operation or yearly, whichever comes first--or upon disassembly.Raise chassis and support. Remove fixed axle wheels. Removeouter dust cap, spindle nut, and washer. Remove outer conebearing, hub, dust seal and inner cone bearing. Clean conebearings and races, and inspect both for physical damage(pitting, etc). Inspect spindle for bending, cracked welds, orother physical damage.IMPORTANT: If damage is evident, remove the CONDOR®from service until the spindle assembly is replaced, and contactthe Condor Div. Service Department to report the damage.Repack cone bearings using fresh wheel bearing grease, installnew dust seal, then reassemble components in reverse order ofdisassembly. Tighten spindle nut until hub will not tum, tumspindle nut counterclockwise one castellation, or until cotterpin will pass through spindle and spindle nut. Secure cotterpin, ensure that hub will rotate. Reinstall wheel assembly;torque wheel nuts to 120 ft lbs.MANUAL 92370-002November 1997

•2.Hydraulic SystemFluid Level:Check level daily. Maintain fluid level so that it is visiblebetween the marks on the sight glass with platform all theway down.Return Filter:Replace filter element after first 50 hours of operation. Thereafter,replace filter element every 500 hours of operation.Tank Breather:Clean every 50 hours of operation. Remove from tank and cleanwith solvent; air blow-dry.Hydraulic Tank:Drain fluid from tank and replace annually. Add hydraulic fluidto required level using only Shell Tellus T-32 or equivalent.3. Battery ServicingDO NOT MIX DIFFERENT HYDRAULIC FLUIDSFOR PROTECTION WHEN SERVICING BATTERIES,ALWAYS WEAR A FACE SHIELD AND DO NOT SMOKE!Visual Inspection:Cleaning:Electrolyte Level:Inspect for defective cables, loose connections, corrosion,cracked or swelling cases or covers, loose hold downs, and looseor deformed terminal posts.When needed, a wire brush can be used to remove rust, corrosion, or dirt from terminal ends or posts. The battery top can becleaned with a cloth wetted with ammonia, or baking soda withwater, then wiped with a cloth and clear water.Check electrolyte level daily in each cell. If necessary, add clear,odorless, mineral free water to bring the level to 112" above thetop of the separators, or to the level indicator (if equipped), ineach cell. Only add water after the charging cycle is complete.MANUAL 92370-002November 1997

•PREVENTIVE MAINTENANCE INSPECTIONThis field inspection list provides for a systematic inspection ofthe CONDOR®. The items listed to beinspected or checked daily will ensure proper unit performance prior to operation. By following the daily inspectionprocedure on a regular basis, any potential malfunction will be identified before it can become a majorproblem. The 50 Hour Inspection will detect any defective, damaged, or improperly secured part. The 50 hourInspection also includes items requiring attention at 500 hours or yearly which, are indicated where applicable.The time interval of 50 hours applies to normal operation under normal conditions. Should the unit be subjectedto extensive use or abnormal environmental conditions, the inspections should be made more frequently. CondorDiv. recommends that a maintenance log be maintained, and that abnormal conditions of any kind be recorded.To help assist in starting a maintenance log, there are inspection checklists included after each inspection list.These are intended to be used with the field inspection lists to help gain familiarity with the repetitive tasks.A. VISUAL INSPECTIONDAILY INSPECTIONOverall Condition:Tire Condition:Battery CableConnections:Hydraulic FluidLeaks:Inspect platform, armstack, and carriage to make certain that no physicaldamage is evident. Look for missing components and hardware, loosecomponents, etc.Inspect tires for wear, cuts, and abrasions.For protection, wear a faceshield. Inspect for swelling of battery sides,tightness and corrosion ofterminals. If corrosion is present, remove cablesfrom the battery (ground cable first). Clean terminals and posts with a wirebrush and reconnect to battery (ground cable last). Coat the terminalconnections with a spray corrosion inhibiter, or high temperature grease.Inspect to ensure that there is no evidence of leaking hoses or fittings.Decals and Placards:Verify that all decals and placards are in place and are legible. It is recommended that any decals or placards which are torn, damaged, missing, orpainted over, be replaced. Essential decals must be legible, or must bereplaced.B. FLUID LEVEL CHECKHydraulic TankLevel:Check level daily. Maintain fluid level so that it is visible between themarks on the sight glass with platform all the way down.Battery ElectrolyteLevel:For protection, wear a faceshield. Check electrolyte level in each cell.If necessary add electrolyte or clear, odorless, mineral free water as requiredto bring the level to 112" above the tops of the separators or to the levelindicators (if equipped), in each cell. Add only after the charging cycle iscomplete.MANUAL 92370-002November 1997

•C.OPERATIONAL TESTInstrument CheckHour Meter:Battery Condition Indicator:Ensure that meter is recording properly.Ensure that indicator is monitoring the batteries state-ofchargeproperly.Lower ControlsOperation CheckEmergency Stop Button:Control Selector Switch:Lift Control Buttons:Ensure that machine will not operate with button pushed in.Check that button maintains its in or out position.Ensure that switch controls the selection of "UPPER orLOWER" properly. Make certain that machine will notoperate with switch in its center position.Check that buttons and toggle switch return to their normalposition when released, and that buttons and toggle switchproperly operate the lift function.Upper ControlsOperation CheckEmergency Stop Button:Lift Control Buttons:Drive/Steer Functions:Drive Speed Selector:Positraction Button:Slope Alarm:Ensure that machine will not operate from upper controls withbutton pushed in. Check that button maintains its in or outposition.Check that buttons return to their normal position whenreleased, and that buttons properly operate the lift function.Make certain that lift function does not operate unless greenpower button is depressed.Squeeze handle grip and operate drive and steer functions.Ensure that each speed selection works properly while driving.Ensure that speed shifts to low when button is depressed(platform below seven feet), regardless of speed selectorposition.Tilt sensor more than 5° (located in belly pan), and check foraudible alarm at platform control box. Selector switch must bein "UPPER" position.MANUAL 92370-002November 1997

PREVENTIVE MAINTENANCEDAILY INSPECTION•MON TUBSZ V ITEM IHOURSVISUAL INSPECTIONWEDV /THURS FRI/ /SAT SUN/ /Overall ConditionTire ConditionBattery Cable ConnectionsHydraulic Fluid LeaksBattery Electrolyte LevelVerify Legibility of Decals & PlacardsOPERATIONAL TESTHour MeterBattery Condition IndicatorLOWER CONTROLSEmergency Stop ButtonControl Selector SwitchLift Control ButtonsUPPER CONTROLSEmergency Stop ButtonLift Control ButtonsDrive/Steer FunctionsDrive Speed Selector SwitchPositraction ButtonSlope Alarm(MANUAL 92370-002. November 1997