Wadkin ECA Tenoner Manual and Parts List

Wadkin ECA Tenoner Manual and Parts List

Wadkin ECA Tenoner Manual and Parts List

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

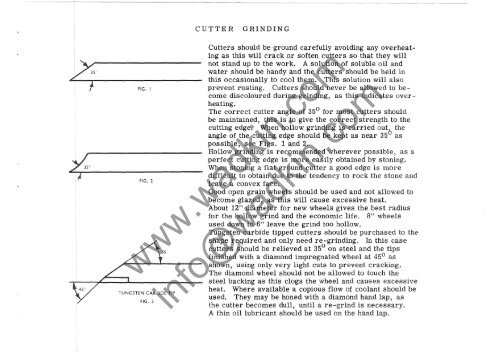

CUTTER GRINDINGFIG. 2TUNGSTEN CARBIDE TIPFIG. 3Cutters should be ground carefully avoiding any overheatingas this will crack or soften cutters so that they willnot st<strong>and</strong> up to the work. A solution of soluble oil <strong>and</strong>water should be h<strong>and</strong>y <strong>and</strong> the cutters should be heldthis occasionally to cool them. This solution will alsoprevent rusting, Cutters should never be allowed to becomediscoloured during grinding, as this indicates overheating.The correct cutter angle of 35 0 for most cutters shouldbe maintained, this is to give the correct strength to thecutting edge. When hollow grinding is carried outangle of the cutting edge should be kept as near 35° aspossible, see Figs. 1 <strong>and</strong> 2.Hollow grinding is recommended wherever possible, as aperfect cutting edge is more easily obtained by stoning.When stoning a flat ground cutter a good edge is moredifficult to obtain due to the tendency to rock the stoneleave a convex face.Good open grain wheels should be used <strong>and</strong> not allowedbecome glazed, as this will cause excessive heat.About 12" (iiameter for new wheels gives the best radiusfor the hollow grind <strong>and</strong> the economic life. ' wheelsused down to 6" leave the grind too hollow.Tungsten carbide tipped cutters should be purchased to theshape required <strong>and</strong> only need re-grinding, In this casecutters should be relieved at 35 0 on steel <strong>and</strong> the tipsfinished with a diamond impregnated wheel at 45 0 asshown, using only very light cuts to prevent cracking.The diamond wheel should not be allowed to touch thesteel backing as this clogs the wheel <strong>and</strong> causes excessiveheat. Where available a copious flow of coolant should beused. They may be honed with a diamond h<strong>and</strong> lap, aswww.wadkin.cominfo@wadkin.comthe cutter becomes dull, until a re-grind is necessary.A thin oil lubricant should be used on the h<strong>and</strong> lap.