The Engineered Mist Eliminator - AMACS Process Tower Internals

The Engineered Mist Eliminator - AMACS Process Tower Internals

The Engineered Mist Eliminator - AMACS Process Tower Internals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

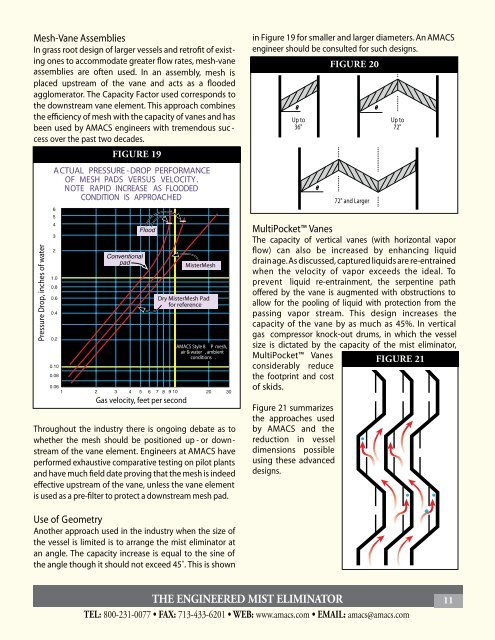

Mesh-Vane AssembliesIn grass root design of larger vessels and of existingones to accommodate greater rates, mesh-vaneassemblies are often used. In an assembly, mesh isplaced upstream of the vane and acts as aagglomerator. <strong>The</strong> Capacity Factor used corresponds tothe downstream vane element. This approach combinesthe e ciency of mesh with the capacity of vanes and hasbeen used by <strong>AMACS</strong> engineers with tremendous suc -cess over the past two decades.FIGURE 19ACTUAL PRESSURE - DROP PERFORMANCEOF MESH PADS VERSUS VELOCITY .NOTE RAPID INCREASE AS FLOODEDCONDITION IS APPROACHEDin Figure 19 for smaller and larger diameters. An <strong>AMACS</strong>engineer should be consulted for such designs.Up to36"FIGURE 2072" and LargerUp to72"Pressure Drop, inches of water<strong>Mist</strong>erMeshDry <strong>Mist</strong>erMesh Padfor referenceGas velocity, feet per second<strong>AMACS</strong> Style 8 P mesh,air & water , ambientconditions .Throughout the industry there is ongoing debate as towhether the mesh should be positioned up - or downstreamof the vane element. Engineers at <strong>AMACS</strong> haveperformed exhaustive comparative testing on pilot plantsand have much date proving that the mesh is indeede ective upstream of the vane, unless the vane elementis used as a to protect a downstream mesh pad.MultiPocket Vanes<strong>The</strong> capacity of vertical vanes (with horizontal vaporow) can also be increased by enhancing liquiddrainage. As discussed, captured liquids are re-entrainedwhen the velocity of vapor exceeds the ideal. Toprevent liquid re-entrainment, the serpentine patho ered by the vane is augmented with obstructions toallow for the pooling of liquid with protection from thepassing vapor stream. This design increases thecapacity of the vane by as much as 45%. In verticalgas compressor knock-out drums, in which the vesselsize is dictated by the capacity of the mist eliminator,MultiPocket Vanes FIGURE 21considerably reducethe footprint and costof skids.Figure 21 summarizesthe approaches usedby <strong>AMACS</strong> and thereduction in vesseldimensions possibleusing these advanceddesigns.Use of GeometryAnother approach used in the industry when the size ofthe vessel is limited is to arrange the mist eliminator atan angle. <strong>The</strong> capacity increase is equal to the sine ofthe angle though it should not exceed 45˚. This is shownTHE ENGINEERED MIST ELIMINATOR 11TEL: 800-231-0077 • FAX: 713-433-6201 • WEB: www.amacs.com • EMAIL: amacs@amacs.com