The Engineered Mist Eliminator - AMACS Process Tower Internals

The Engineered Mist Eliminator - AMACS Process Tower Internals

The Engineered Mist Eliminator - AMACS Process Tower Internals

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

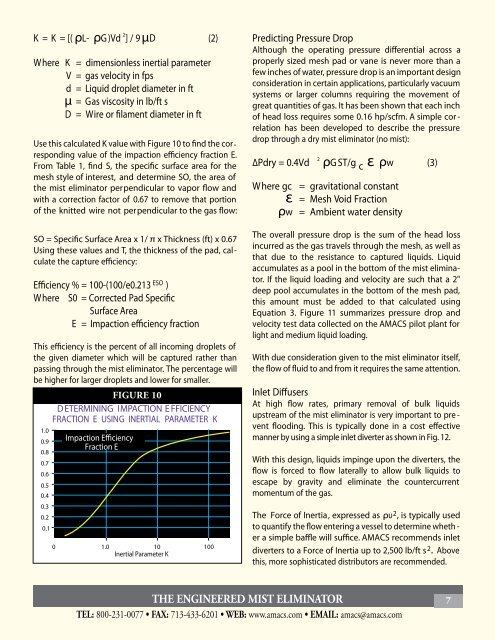

K = K = [( ρL- ρG )Vd 2 ] / 9 µD (2)Where K = dimensionless inertial parameterV = gas velocity in fpsd = Liquid droplet diameter in ftµ = Gas viscosity in lb/ft sD = Wire or filament diameter in ftUse this calculated K value with Figure 10 to find the correspondingvalue of the impaction efficiency fraction E.From Table 1, find S, the specific surface area for themesh style of interest, and determine SO, the area ofthe mist eliminator perpendicular to vapor flow andwith a correction factor of 0.67 to remove that portionof the knitted wire not perpendicular to the gas flow:SO = Specific Surface Area x 1/ π x Thickness (ft) x 0.67Using these values and T, the thickness of the pad, cal -culate the capture efficiency:Efficiency % = 100-(100/e0.213 ESO )Where S0 = Corrected Pad SpecificSurface AreaE = Impaction efficiency fractionThis efficiency is the percent of all incoming droplets ofthe given diameter which will be captured rather thanpassing through the mist eliminator. <strong>The</strong> percentage willbe higher for larger droplets and lower for smaller.FIGURE 10D ETERMINING IMPACTION E FFICIENCYFRACTION E USING INERTIAL PARAMETER K1.00.90.80.70.60.50.40.30.20.1Impaction EfficiencyFraction E0 1.0 10 100Inertial Parameter KPredicting Pressure DropAlthough the operating pressure differential across aproperly sized mesh pad or vane is never more than afew inches of water, pressure drop is an important designconsideration in certain applications, particularly vacuumsystems or larger columns requiring the movement ofgreat quantities of gas. It has been shown that each inchof head loss requires some 0.16 hp/scfm. A simple cor -relation has been developed to describe the pressuredrop through a dry mist eliminator (no mist):∆Pdry = 0.4Vd 2 ρG ST/g c ε ρw (3)Where gc = gravitational constantε = Mesh Void Fractionρw = Ambient water density<strong>The</strong> overall pressure drop is the sum of the head lossincurred as the gas travels through the mesh, as well asthat due to the resistance to captured liquids. Liquidaccumulates as a pool in the bottom of the mist eliminator.If the liquid loading and velocity are such that a 2"deep pool accumulates in the bottom of the mesh pad,this amount must be added to that calculated usingEquation 3. Figure 11 summarizes pressure drop andvelocity test data collected on the <strong>AMACS</strong> pilot plant forlight and medium liquid loading.With due consideration given to the mist eliminator itself,the flow of fluid to and from it requires the same attention.Inlet DiffusersAt high flow rates, primary removal of bulk liquidsupstream of the mist eliminator is very important to pre -vent flooding. This is typically done in a cost effectivemanner by using a simple inlet diverter as shown in Fig. 12.With this design, liquids impinge upon the diverters, theflow is forced to flow laterally to allow bulk liquids toescape by gravity and eliminate the countercurrentmomentum of the gas.<strong>The</strong> Force of Inertia, expressed as ρυ 2 , is typically usedto quantify the flow entering a vessel to determine wheth -er a simple baffle will suffice. <strong>AMACS</strong> recommends inletdiverters to a Force of Inertia up to 2,500 lb/ft s 2 . Abovethis, more sophisticated distributors are recommended.THE ENGINEERED MIST ELIMINATOR 7TEL: 800-231-0077 FAX: 713-433-6201 WEB: www.amacs.com EMAIL: amacs@amacs.com