Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1SMC Corporation1-16-4 Shimbashi, Minato-ku, Tokyo 105-8659, JAPANTel: 03-3502-2740 Fax: 03-3508-2480URL http://www.smcworld.com©2002 SMC Corporation All Rights Reserved1st printing Dec, 2002 D-DAD P-100 (YG) All specifications in this catalog are subject to change without notice.This catalog is printed on recycled paper with concern for the global environment.Printed in Japan<strong>Pneumatic</strong> <strong>Clean</strong> <strong>Series</strong> 3rd edition<strong>Pneumatic</strong> <strong>Clean</strong> <strong>Series</strong>Actuator, Rotary actuator, Air gripper, Directional control valve,Air line equipment, Air preparation equipment, Pressure switch,<strong>Clean</strong> regulator, <strong>Clean</strong> gas filter3rd edition

2SMC clean series isa pneumatic a system system that that can be selected according to the cleanliness (Class 10 to 1000) of the clean room.∗ Classification of cleanliness classes according to Fed. Std. 209D∗Dust is kept off from the clean room.• After inspection, the product is blownwith high purity air (of Class 100 cleanbench) in a clean environment.• Products are sealed and shipped inanti-static double bags. Within SMC clean series, the user can choose equipment that providesthe required level of cleanliness (Class 10 to Class 1000).Class10 Class100 Class1000Air cylinder<strong>Series</strong> 11-Air gripper<strong>Series</strong> 11- Four series of actuators are lined up, among which the customer can select themost suitable product according to the required clean level.SMC actuator (<strong>Clean</strong> <strong>Series</strong>)Pressure controlequipment<strong>Series</strong> 10-Rotary actuator<strong>Series</strong> 11-Dual packing type/Open to atmosphereBushingRelief portRod packingCylinder with guideRodless cylinderSingle packing type/Vacuum suctionVacuum port Bushing(Vacuum suction)Cylinder with guideRod packingRod packingAir preparation equipment<strong>Series</strong> 10-Air cylinder<strong>Series</strong> 10-Cylinder with guide<strong>Series</strong> 13-"Special treatment"Ball bush guideLinear guide"Special treatment"Cylinder tube"Special treatment"Ball bush guideLinear guideDirectional control valve<strong>Series</strong> 10-Fitting<strong>Series</strong> 10-Cylinder with guide<strong>Series</strong> 12-Rodless cylinder<strong>Series</strong> 12-<strong>Series</strong>10-<strong>Series</strong>12-<strong>Series</strong>11-<strong>Series</strong>13-Feature 1Feature 2

5PageAir Line Equipment 431Flow Control EquipmentFlow Control Equipment/Common Precautions ················································ 432<strong>Clean</strong> Speed Controller with One-touch Fittings Elbow Type AS-FPG/FPQ ································· 434Speed Controller with One-touch FittingsElbow Type/Universal Type 10-AS-F ······································ 438Speed Controller with One-touch FittingsStainless Steel Specifications (Elbow/Universal) 10-AS-FG ····································· 442Speed Controller with One-touch FittingsStainless Steel Specifications (Inline Type) 10-AS-FG ····································· 446Dual Speed Controller with One-touch Fittings 10-ASD ······································· 450Speed Controller for Low Speed Operationwith One-touch Fittings (Resin Body) 10-AS-FM ····································· 454Dual Speed Controller for Low Speed Control 10-ASD-FM ··································· 458Dual Speed Controller with One-touch FittingsStainless Steel Specifications 10-ASD-FG ··································· 462Speed Controller Cylinder Direct MountType Metal Elbow Type 10-AS1200 to 4200 ··························· 466Speed Controller/Inline Type 10-AS1000 to 5000 ··························· 468Air Filter/RegulatorAir Filter/Regulator/Common precautions ··············································· 472Air Filter 10-AF3000 to 6000 ··························· 474Mist Separator 10-AFM3000/4000 ···························· 478Micro Mist Separator 10-AFD3000/4000 ···························· 480Regulator 10-AR2000 to 6000 ··························· 482Direct Operated Precision Regulator 10-ARP3000 ·································· 488Regulator with Check Valve 10-AR2560/3060/4060 ······················· 490Filter Regulator 10-AW3000/4000 ····························· 494Mist Separator Regulator 10-AWM3000/4000 ··························· 498Micro Mist Separator Regulator 10-AWD3000/4000 ··························· 502Precision Regulator 10-IR1000/2000/3000 ························ 506Fittings & TubingFittings & Tubing/Common Precautions ················································· 512<strong>Clean</strong> One-touch Fittings for Blow KP ············································ 514<strong>Clean</strong> One-touch Fittings KPQ/KPG ····································· 520Miniature One-touch Fittings 10-KJ ········································· 524One-touch Fittings 10-KQ ········································ 532One-touch Fittings Stainless Specifications 10-KG ········································ 552Insert Fittings 10-KF ········································· 564Miniature Fittings 10-M ·········································· 570Stainless Miniature Fittings 10-MS ········································ 576Rectangular Multi-connector 10-KDM ······································· 580<strong>Clean</strong> Tubing/Polyolefin Tubing TPH ··········································· 584<strong>Clean</strong> Tubing/Soft Polyolefin Tubing TPS ··········································· 585Polyurethane Tubing 10-TU ········································· 586Polyurethane Coil Tubing 10-TCU ······································· 587Polyurethane Flat Tubing 10-TFU ······································· 588Air Preparation Equipment 589Air Preparation Equipment/Common Precautions ······································· 590Mist Separator 10-AM150 to 850 ····························· 592Micro Mist Separator 10-AMD150 to 850 ···························· 596Super Mist Separator 10-AME150 to 850 ···························· 600Odor Removal Filter 10-AMF150 to 850 ···························· 604Hollow Fiber Membrane Air Dryer 10-IDG ········································ 608Exhaust <strong>Clean</strong>er for <strong>Clean</strong> Room AMP220/320/420 ····························· 610Pressure Switch 615Pressure Switch/Common Precautions ················································· 616High Precision Remote Type Digital Pressure Switch 10-PSE ······································· 618High Precision Digital Pressure Switch 10-ZSE40/ISE40 ······························ 626Digital Pressure Switch with Backlight 10-ZSE5B/ISE5B ····························· 632Digital Pressure Switch with Backlight 10-ZSE6B/ISE6B ····························· 636<strong>Clean</strong> Regulator 639<strong>Clean</strong> Regulator SRH3000/4000 ······························· 640Precision <strong>Clean</strong> Regulator SRP1000 ····································· 644<strong>Clean</strong> Gas Filter 649<strong>Clean</strong> Gas Filter SFA/SFB/SFC ································ 650Front matter 3

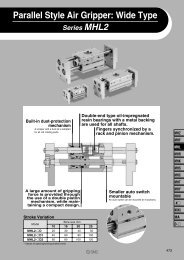

Rotary Actuator 187+1.40How to SearchThree types of search methods are available so that the desiredproduct can be found quickly as well as easily.61 How to Search from <strong>Clean</strong> <strong>Series</strong> Total Index (Product Name)<strong>Clean</strong> <strong>Series</strong> Total IndexFront matter 2<strong>Clean</strong> <strong>Series</strong> Total IndexPagePrior to Use ······························· Front matter 1/Supplement 1Index Guide ··················································· Front matter 1<strong>Clean</strong> <strong>Series</strong> Total Index ··································· Front matter 2/3How to Search ·············································· Front matter 4/5Safety Instructions ············································ Front matter 7<strong>Clean</strong> <strong>Series</strong>/Common Precautions ···················· Front matter 8 to 10<strong>Clean</strong> <strong>Series</strong> Basic Specifications ························· Front matter 11System Circuit in <strong>Clean</strong> Room ··························· Front matter 12/13How to Use <strong>Clean</strong> <strong>Series</strong> ··································· Front matter 14Particle Generation Measuring Method ···················· Front matter 16Index Guide ················································· Front matter 17Product <strong>Series</strong> Index (Alphabetical order) ··············· Supplement 1 to 3Actuator 1Actuator/Common Precautions ··························································· 2Auto Switch/Common Precautions ························································· 5Basic <strong>Series</strong>Air Cylinder CJ2/CJ2W/CJ2RA ·························· 8Air Cylinder CM2/CM2W/CM2R ························· 20Air Cylinder CG1/CG1W/CG1R ·························· 36Mini Free Mount Cylinder CUJ ········································· 48Free Mount Cylinder CU ·········································· 52Compact Cylinder CQS ········································· 56Compact Cylinder CQ2 ········································· 64End Lock Cylinder 10-CBM2 ······································ 72Sine Cylinder REC ········································· 78Cylinder With GuideDual Rod Cylinder/Compact Type CXSJ ········································ 84Dual Rod Cylinder CXSL ········································ 88Compact Cylinder With Guide MGPL ······································· 98Guide Table 10-MGF ······································· 102Air Slide TableAir Slide Table 11-MXP/11-MXPJ6 ··························· 106Air Slide Table 13-MXQ ······································· 116Air Slide Table 13-MXS ······································· 144Rodless Cylinder<strong>Clean</strong> Rodless Cylinder CYP ··········································· 166Magnetically Coupled Rodless Cylinder 12-CY1B ······································ 172Magnetically Coupled Rodless Cylinder (Direct Mount Type) 12-CY1R ······································ 176Sine Rodless Cylinder 12-REA ······································· 178Low Speed CylinderLow Speed Cylinder CQSX ······································· 180Low Speed Cylinder CQ2X ······································· 182Low Speed Cylinder CM2X ······································· 184Rotary Actuator/Common Precautions ························································ 188Vane Style Rotary Actuator 10-CRB1 ······································ 192Rack Pinion Style Rotary Actuator 11-CRA1 ······································ 204Rotary Table/Rack Pinion Style 11-MSQ ······································· 210Air Gripper 213Air Gripper/Common Precautions ······················································· 214Air Gripper 11-MHZ2 ······································ 216Rotary Actuated Air Gripper 2 Finger Type 11-MHR2 ····································· 220Rotary Actuated Air Gripper 3 Finger Type 11-MHR3 ····································· 226Wide Opening Air Gripper Parallel Style 11-MHL2 ····································· 230Directional Control Valve 2353/4/5 Port Solenoid Valve/Common Precautions ·················································· 2365 Port Solenoid Valve 10-SZ3000 ···································· 2405 Port Solenoid Valve 10-SQ1000/2000 ····························· 2544/5 Port Solenoid Valve 10-SY3000/5000/7000 ························ 2704/5 Port Solenoid Valve 10-SYJ3000/5000 ···························· 3103 Port Solenoid Valve 10-SY100 ····································· 3443 Port Solenoid Valve 10-SYJ300/500 ······························· 3525 Port Solenoid Valve 10-VQ1000/2000 ····························· 3683 Port Solenoid Valve 10-VQ100 ····································· 4184 Port Solenoid Valve 10-VQD1000 ·································· 428<strong>Series</strong>10-Air Cylinder <strong>Series</strong> 11-CM2/CM2W/CM2R 2010-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-11-12-11-12-12-13-10-11-10-11-10-11-10-11-Main TextCM2How to Order<strong>Clean</strong> series10 — Relief type11 — Vacuum suction typeBuilt-in magnetNil — NoD — With auto switch(Built-in magnet)MountingB — BasicL — Axial footF — Front flangeG — Rear flangeBZ — Boss-cut basicFZ — Boss-cut front flangeBore size (mm)Air Cylinder/ø20,ø25,ø32,ø4010 - C D M 2 L 40 - 150 A - C73Cylinder stroke (mm)CushionNil — Rubber bumperA — Air cushionModelType of auto switchReed switchC73Solid state switchH7BH7A1Number of auto switchesNil — 2S — 1n — nVacuum Reliefsuction type typeModel10-CM22010-CM22510-CM23210-CM24011-CM22011-CM22511-CM23211-CM240Bore size PortStandard strokeLubrication Action(mm) size(mm)2025 Rc1/83240 Rc1/4Double acting 25, 50, 75, 100, 125,Non-lube20single rod150, 175, 200, 250, 30025 Rc1/83240 Rc1/4Auto switchmountingAvailableCushionRubber AirAvailable AvailableSpecificationsBore size (mm)ItemProof pressureMax. operating pressureMin. operating pressureAmbient and fluid temperaturePiston speedStroke length toleranceMounting20,25,32,401.5MPa1.0MPa0.05MPaWithout auto switch : –10°C to 70°C, With auto switch: –10°C to 60°C (With no condensation)30 to 400mm/sBasic,Axial foot,Front flange,Rear flange20Front matter 4

Air Cylinder<strong>Series</strong> CJ2Air Cylinder<strong>Series</strong> CM2Air Cylinder<strong>Series</strong> CG1Mini Free Mount Cylinder<strong>Series</strong> CUJFree Mount Cylinder<strong>Series</strong> CUVane Style<strong>Series</strong> CRB1Parallel Type<strong>Series</strong> MHZ25 PortSZ30005 PortSQ1000/2000<strong>Clean</strong> Speed Controller<strong>Series</strong> ASSpeed Controller<strong>Series</strong> ASMist Separator<strong>Series</strong> AMMicro Mist Separator<strong>Series</strong> AMDHigh Precision Separate TypeDigital Pressure Switch<strong>Clean</strong> RegulatorSRH3000•4000<strong>Clean</strong> Gas Filter<strong>Series</strong> SFA•SFB•SFCCompact Cylinder<strong>Series</strong> CQSCompact Cylinder<strong>Series</strong> CQ2End Lock Cylinder<strong>Series</strong> CBM2Sine Cylinder<strong>Series</strong> RECRack Pinion Style<strong>Series</strong> CRA1Rotary Actuated<strong>Series</strong> MHR25 PortSY3000/5000/70004/5 PortSYJ3000·5000Super Mist Separator<strong>Series</strong> AMEOdor Removal Filter<strong>Series</strong> AMFHigh PrecisionDigital Pressure SwitchAir Filter<strong>Series</strong> AFRegulator<strong>Series</strong> AR10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-10-11-Dual Rod Cylinder/Compact Type<strong>Series</strong> CXSJDual Rod Cylinder<strong>Series</strong> CXSCompact (Type) Cylinder with Guide<strong>Series</strong> MGPLGuide Cylinder Table<strong>Series</strong> MGFRotary Table/Rack Pinion Style<strong>Series</strong> MSQRotary Actuated<strong>Series</strong> MHR33 PortSY1003 PortSYJ300·500Filter Regulator<strong>Series</strong> AWAir Slide Table<strong>Series</strong> MXP/MXPJ6Air Slide Table<strong>Series</strong> 13-MXQAir Slide Table<strong>Series</strong> 13-MXSWide Opening Parallel Type<strong>Series</strong> MHL25 PortVQ1000·20003 PortVQ100Precision Regulator<strong>Series</strong> IRHollow Fiber Membrane Air Dryer<strong>Series</strong> IDGExhaust <strong>Clean</strong>er for <strong>Clean</strong> Room<strong>Series</strong> AMPDigital Pressure SwitchWith Back LightPrecision <strong>Clean</strong> RegulatorSRP1000Digital Pressure SwitchWith Back Light<strong>Clean</strong> Rodless Cylinder<strong>Series</strong> CYPMagnetically Coupled Rodless Cylinder<strong>Series</strong> CY1BMagnetically Coupled Rodless Cylinder<strong>Series</strong> 12-CY1RSine Rodless Cylinder<strong>Series</strong> REA4 PortVQD1000Fitting & Tubing<strong>Series</strong> KLow Speed Cylinder<strong>Series</strong> CQSXLow Speed Cylinder<strong>Series</strong> CQ2XLow Speed Cylinder<strong>Series</strong> CM2X592Air Cylinder<strong>Series</strong> CJ2Air Cylinder<strong>Series</strong> CM2Air Cylinder<strong>Series</strong> CG1Mini Free Mount Cylinder<strong>Series</strong> CUJFree Mount Cylinder<strong>Series</strong> CUCompact Cylinder<strong>Series</strong> CQSCompact Cylinder<strong>Series</strong> CQ2End Lock Cylinder<strong>Series</strong> CBM2Sine Cylinder<strong>Series</strong> RECDual Rod Cylinder/Compact Type<strong>Series</strong> CXSJDual Rod Cylinder<strong>Series</strong> CXSCompact Cylinder with Guide<strong>Series</strong> MGPLGuide Table<strong>Series</strong> MGFAir Slide Table<strong>Series</strong> MXP/MXPJ6Air Slide Table<strong>Series</strong> 13-MXQAir Slide Table<strong>Series</strong> 13-MXS<strong>Clean</strong> Rodless Cylinder<strong>Series</strong> CYPMagnetically Coupled Rodless Cylinder<strong>Series</strong> CY1BMagnetically Coupled Rodless Cylinder<strong>Series</strong> 12-CY1RSine Rodless Cylinder<strong>Series</strong> REALow Speed Cylinder<strong>Series</strong> CQSXLow Speed Cylinder<strong>Series</strong> CQ2XLow Speed Cylinder<strong>Series</strong> CM2X72 How to Search From Index GuideIndex GuideMiddle Cover<strong>Clean</strong> <strong>Series</strong>Index Guide<strong>Clean</strong> <strong>Series</strong>ActuatorBasic <strong>Series</strong> Cylinder with Guide Air Slide Table Rodless Cylinder Low Speed CylinderBasic <strong>Series</strong> Cylinder with Guide Air Slide Table Rodless Cylinder Low Speed CylinderCJ2 P.8CUJ P.4810-11-10-11-10-11-CUP.52CQS P.56REC P.7811-12-11-12-CXSJ10-11-CU10-11-10-11-P.84CXSL P.8810-11-10-11-12-13-CQ2XCM2 P.2010-11-CG1 P.3610-11-10-11-MGPL P.9810-MGF P.102CQ2 P.6410-CBM2 P.7211-MXP/MXPJ6 P.10613-MXQ P.11613-MXS P.144CYPP.16612-CY1B P.17212-CY1R P.17612-REA P.178CQSX P.18010-11-CM2XP.182P.184ActuatorCJ2 P.8P.52CQS P.56REC P.7811-12-11-12-CXSJ P.8410-11-10-11-10-11-10-11-CXSL P.8812-13-MGPL P.9810-MGF P.102CQ2 P.6410-CBM2 P.7211-MXP/MXPJ6 P.10613-MXQ P.11613-MXS P.144CYPP.16612-CY1B P.17212-CY1R P.17612-REA P.178CM2 P.2010-11-CG1 P.3610-11-CUJ P.4810-11-10-11-CQSX P.18010-11-CQ2XP.18210-11-CM2X P.184ActuatorP.204P.210Rotary ActuatorP.220P.22610-CRB1 P.19211-CRA111-MSQ11-MHR211-MHZ2 P.21611-MHR311-MHL2P.230Air GripperP.240P.254P.270P.31010-VQD P.42810-SY10-SYJP.344P.35210-SY10-SYJ10-SZ10-SQ10-VQ10-VQP.368P.418Direction ControlValveFlow Control Equipment Air Filter/Regulator Fitting & TubingP.434P.438P.592P.596P.474P.48210-K10-AF10-AR10-AW10-IRP.494P.506P.514Air Line EquipmentAir PreparationEquipmentP.61810-ZSE5BISE5B10-ZSE40(F)ISE40P.62610-ZSE6BISE6BP.63210-P.600 IDG P.608AMPP.604P.610AS10-AS10-AM10-AMD10-AME10-AMF10-PSEP.636Pressure SwitchSRHSFP.640P.650SRPP.644<strong>Clean</strong> Gas Filter <strong>Clean</strong> RegulatorFront matter 113 How to Search by Type and Model (in Alphabetical Order)INDEX in the Alphabetical OrderAlphabet IndexProduct <strong>Series</strong> Index (Alphabetical Order)ACIAMPAS-FPGAS-FPQ10-AF3000 to 600010-AFD3000/400010-AFM3000/400010-AM150 to 85010-AMD150 to 85010-AME150 to 85010-AMF150 to 85010-AR2000 to 600010-AR2560 to 406010-ARP300010-AS1200 to 420010-AS1000 to 500010-AS-F10-AS-FG10-AS-FG10-AS-FM10-ASD-F10-ASD-FG10-ASD-FM10-AW3000/400010-AWD3000/400010-AWM3000/400010-CBM2CG1CG1RCG1WCJ2CJ2RACJ2WCM2CM2RCM2WCM2XCQ2CQ2XCQSCQSX11-CRA110-CRB1CUCUJCXSJCXSL12-CY1B12-CY1R10-IDG10-IR10-ISE4010-ISE5B10-ISE6BPageExhaust <strong>Clean</strong>er for <strong>Clean</strong> Room ········································ 610<strong>Clean</strong> Speed Controller With One-touch Fittings/Stainless Specification ··· 434<strong>Clean</strong> Speed Controller With One-touch Fittings/Nickel Plated Specification ···· 434Air Filter ································································· 474Micro Mist Separator ····················································· 480Mist Separator ··························································· 480Mist Separator ··························································· 592Micro Mist Separator ····················································· 596Super Mist Separator ···················································· 600Odor Removal Filter ···················································· 604Regulator ································································ 482Regulator With Check Valve ············································· 490Direct Operated Precision Regulator ···································· 488Speed Controller Cylinder Direct Mount Type Metal Elbow Type ······ 466Speed Controller/Inline Type ············································ 468Speed Controller With One-touch Fittings Elbow Type/Universal Type ······ 438Speed Controller With One-touch Fittings Stainless specifications (Elbow/Universal) ····· 442Speed Controller With One-touch Fittings Stainless Specifications (Inline Type) ···· 446Speed Controller for Low Speed Operation With One-touch Fittings (Resin Body) ····· 454Dual Speed Controller With One-touch Fitting ··························· 450Dual Speed Controller With One-touch Fitting Stainless <strong>Series</strong> ········ 462Dual Speed Controller For Low Speed Operation ······················· 458Filter Regulator ·························································· 494Micro Mist Separator Regulator ········································· 502Mist Separator Regulator ················································ 498End Lock Cylinder ······················································· 72Air Cylinder ······························································ 36Direct Mount Cylinder ··················································· 46Double Rod Cylinder ···················································· 42Air Cylinder ······························································ 8Direct Mount Cylinder ··················································· 18Double Rod Cylinder ···················································· 14Air Cylinder ······························································ 20Direct Mount Cylinder ···················································· 32Double Rod Cylinder ···················································· 28Low Speed Cylinder Double Acting Single Rod ·························· 184Compact Cylinder ······················································· 64Low Speed Cylinder ····················································· 182Compact Cylinder ······················································· 56Low Speed Cylinder ····················································· 180Rack Pinion Style Rotary Actuator ······································· 204Vane Style Rotary Actuator ·············································· 192Free Mount Cylinder ····················································· 52Mini Free Mount Cylinder ················································ 48Dual Rod Cylinder/Compact Type ······································· 84Dual Rod Cylinder ······················································· 88Magnetically Coupled Rodless Cylinder ································· 172Magnetically Coupled Rodless Cylinder (Direct Mount Type) ············ 17610-AM150 to 850····················592Hollow Fiber Membrane Air Dryer ······································· 608Precision Regulator ······················································ 506High Precision Digital Pressure Switch ·································· 626Digital Pressure Switch With Back Light ································· 632Digital Pressure Switch With Backlight ·································· 636Main Text<strong>Series</strong> 10-AMHow to Order<strong>Clean</strong> seriesBody size150— 1/8250— 1/4350— 3/8450— 1/2550— 3/4650— 1850—1 1 /2Mist Separator10 - AM 250 - 03 B - JPort size01—1/802—1/403—3/804—1/206—3/410—114—1 1/220—2OptionNil—NoB —BracketWith drain guideModelModel10-AM150 10-AM250 10-AM350 10-AM450 10-AM550 10-AM650 10-AM850Air flow capacity l/min (ANR) 300 750 1500 2200 3500 6000 12000Pressure drop (MPa) 0.025 0.025 0.02 0.027 0.025 0.029 0.025Port size Rc1/8,1/4,3/8 Rc1/4,3/8,1/2 Rc3/8,1/2,3/4 Rc1/2,3/4,1 Rc3/4,1 Rc1,1 1/2 Rc1 1/2,2SpecificationsMax. operating pressure1.0MPaMin. operating pressure0.05MPaFluidAirFiltration0.3µm (95% scavenging particle diameter)Ambient and fluid temperature5 to 60°COil mist density on secondary side∗Max.1.0mg/m 3 (ANR) (≅0.8ppm)Element life2 years or when the pressure drop reaches 0.1 MPa∗At compressor projection oil mist density of 30 mg/m3 (ANR)Replacement PartsKKPKPGKPQ10-KDM<strong>Clean</strong> One-touch Fittings For Blowing ··································· 514<strong>Clean</strong> One-touch Fittings/Stainless ······································ 520<strong>Clean</strong> One-touch Fittings/Nickel Plated ·································· 520Rectangular Multi-connector ············································ 580ModelDescription Material10-AM150 10-AM250 10-AM350 10-AM450 10-AM550 10-AM650 10-AM850Element Glass fiber10-AM-EL150 10-AM-EL250 10-AM-EL350 10-AM-EL450 10-AM-EL550 10-AM-EL650 10-AM-EL850assembly NBR∗Gasket, with O-ringSupplement 2Front matter 5

Front matter 68

9Safety InstructionsThese safety instructions are intended to prevent hazardous situations and/or equipmentdamage. These instructions indicate the level of potential hazard by labeling "Caution","Warning" or "Danger". To ensure safety, be sure to observe ISO4414 Note 1) , JIS B 8370Note 2) and other safety practices.Caution:Warning:Danger:Operator error could result in injury or equipment damage.Operator error could result in serious injury or loss of life.In extreme conditions, there is a possibility of serious injury or loss of life.Note 1) ISO 4414: <strong>Pneumatic</strong> fluid power-General rules relating to systems.Note 2) JIS B 8370: <strong>Pneumatic</strong> system axiom.Warningq The compatibility of pneumatic equipment is the responsibility of the person who designsthe pneumatic system or decides its specifications.Since the products specified here are used in various operating conditions, their compatibility with thespecific pneumatic system must be based on specifications or after analysis and/or tests to meet yourspecific requirements.w Only trained personnel should operate pneumatically operated machinery and equipment.Compressed air can be dangerous if an operator is unfamiliar with it. Assembly, handling or repair ofpneumatic systems should be performed by trained and experienced operators.e Do not service machinery/equipment or attempt to remove components until safety isconfirmed.1. Inspection and maintenance of machinery/equipment should only be performed after confirmation ofsafe locked-out control positions.2. When equipment is to be removed, confirm the safety process as mentioned above. Cut the supplypressure for the equipment and exhaust all residual compressed air in the system.3. Before machinery/equipment is re-started, take measures to prevent quick extensions of the cylinderpiston rod etc.r Contact SMC if the product is to be used in any of the following conditions:1. Conditions and environments beyond the given specifications, or if product is used outdoors.2. Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles, medicalequipment, food and beverage, recreation equipment, emergency stop circuits, press applications. orsafety equipment.3. An application which has the possibility of having negative effects on people, property, or animals,requiring special safety analysis.Front matter 7

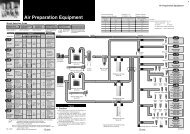

<strong>Clean</strong> <strong>Series</strong>/Common Precautions 1Be sure to read before handling.Refer to the main text for precautions for each series.10CautionAir Supplyq System configurationRefer to Compressed Air <strong>Clean</strong> System below for the quality of compressed air to configure the system.Main Line Sub-Line Local LineReciprocatingair compressorAfter cooler(Air-cooled)<strong>Series</strong> HAAAfter cooler(Air-cooled)<strong>Series</strong> HAAAfter cooler (water-cooled)<strong>Series</strong> HAWAir tank<strong>Series</strong> ATMain line filter<strong>Series</strong> AFF<strong>Series</strong> AM <strong>Series</strong> AMDRefrigeratedair dryer<strong>Series</strong> IDFIDG1Air tank<strong>Series</strong> AT<strong>Series</strong> AMMoisture(Pressuredew point)10°CImpurity in compressed airSolid matter Oil mist concentration0.3µm 0.01100 pcs/ft 3 mg/m 3or less (ANR)OdorLittleodorof oil<strong>Series</strong>AMEScrewair compressorw PipingAfter cooler (water-cooled)<strong>Series</strong> HAWq Provide an inclination of 1cm per meter in the direction of the airflow to the main piping.w If there is a line branching from the main piping, provide an outlet ofcompressed air on top using a tee so that drainage accumulated inthe piping will not flow out.e Provide a drainage mechanism at every recessed point or deadend to prevent drain accumulation.r For future extension of piping, plug the end of the piping with atee.t Preparation before connecting the pipingUse an air blower to thoroughly flush the piping or wash thepiping to remove any cutting chips, cutting oil, or debris frominside the piping before connecting them.y Wrapping the seal tapeWhen screwing in the pipes or fittings, be sure to prevent cuttingchips or sealing material on the threaded portion of the pipefrom entering the piping.WrappingdirectionLeave 2 ridgesexposed.Seal tapee MaintenanceIf the heatless air dryer <strong>Series</strong> ID is left unused for a long period,the absorbent may be moistened. Prior to use, stop the valve onthe secondary side of the dryer for regeneration and drying.r Blow systemEven a small amount of dust can cause problems in a blow system.Install a clean gas filter series SF at the end of the blow line.Refrigerated air dryer<strong>Series</strong> IDFRefrigerated air dryer<strong>Series</strong> IDUt Precautions on designAdopt a safety design to prevent occurrence of unexpectedaccidents as listed below.Warningq Design a layout so that high pressure compressed air willnot flow over to the secondary side.If the coolant water of a water-cooled after cooler or the fanmotor of an air-cooled after cooler stops, high temperaturecompressed air will flow over to the secondary side, which maycause the secondary side equipment (AFF, AM, AD, IDF, etc.) tomalfunction or be damaged.w Consider possible failure in supply of compressed air whendesigning the system.Freezing in a refrigerated air dryer or malfunction of a switchingvalve (In case of a heatless dryer) may hinder flow ofcompressed air.Caution<strong>Series</strong> AME<strong>Series</strong> ID +<strong>Series</strong> AMFImpurity in compressed airMoisture Solid matter Oil mist concentration OdorAtmosphericpressure 0.01µm 0.004No odordew point 1 pcs/ft 3 mg/m 3 of oil-50°C or less (ANR)or less<strong>Series</strong>SFq Design a layout in consideration of possible leakage ofcoolant water or water dripping due to condensation.Water leakage may be caused by freezing on a water-cooledafter cooler using coolant water while condensation andconsequent water dripping may be caused by overcoolingdepending on the operating conditions in case of a refrigeratedair dryer and its downstream piping.w Design a layout which will prevent occurrence ofreverse pressure and reverse flow.Reverse pressure or reverse flow will cause malfunction ordamage to equipment. Implement safety measures includingthose for handling procedures.Front matter 8

<strong>Clean</strong> <strong>Series</strong>/Common Precautions 2Be sure to read before handling.Refer to the main text for precautions for each series.11Cautionq Do not make the piping for the air cylinder relief portand regulator breathing vent piping common withsolenoid valve exhaust piping.It can cause malfunction of air cylinder or regulator pressurechange.w Arrange the piping to allow exhaust air of the solenoidvalve to be exhausted outside the clean room.e Air filter drain pipingExhaust drainage outside the clean room through piping fromthe drain guide of the air filter.Piping Inside <strong>Clean</strong> Roomr Arrange membrane dryer air purge piping to exhaustair outside the clean room using a standard sizetubing.t Take precautions so that the threaded portion ofpiping connection or tubing connection will not beloosened.Take enough precautions if the piping is shaking along with thevibration of the equipment.y Use polyurethane tubing containing no plasticizer.Inside <strong>Clean</strong> RoomRelief port pipingSolenoid valveexhaust pipingBreathing ventpiping ofregulatorPurge air pipingfor membraneair dryerDrain pipingCautionHandlingq The inner bag of a double packed clean seriespackage should be opened in a clean room or cleanenvironment.w When standard pneumatic equipment is brought intoa clean room, spray high purity air upon it and cleardust thoroughly by wiping the external surfaces ofcylinder tubing, solenoid valves and air lineequipment with alcohol.e To replace parts or disassemble the product in aclean room, first exhaust compressed air inside thepiping to outside of the clean room before the work.r Do not use rotation type mounting brackets such asclevis and trunnion. They will generate aconsiderable amount of particles due to slidingfriction between metal parts.WarningBe sure to wash your hands after handling fluoro resin grease.The grease is not hazardous but it can produce hazardous gasunder a temperaruter exceeding 260°C.Cautionq Do not use grease except for those specified by SMC.Use of grease not in the specification will causemalfunction or particle generation.w Do not lubricate since the product is of a nonlubricant type.As the clean series actuator is lubricated at the factorywith fluororesin grease, it may not satisfy the productspecifications if turbin oil is applied.CautionLubrication/ActuatorPiston SpeedIn order to retain the particle generation grade, set astandard limit of 400 mm/s of travel distance.Front matter 9

<strong>Clean</strong> <strong>Series</strong>/Common Precautions 3Be sure to read before handling.Refer to the main text for precautions for each series.12CautionIn case of a vacuum type (<strong>Series</strong> 11- / <strong>Series</strong> 13-), performvacuum suction at the vacuum port to retain the particlegeneration grade.The optimum suction rate varies among series and sizes. Refer tothe following table for guidelines. (The vacuum pressure may beapproximately -13kPa to -27kPa around the vacuum port.) ConsultSMC for other types and models.Vacuum Flow Rate of Vacuum Types(Reference value)<strong>Series</strong> Model Bore size (mm) Suction flow rate (l/min(ANR))Air cylinderCompact cylinderMini free mountcylinderFree mountcylinderSine cylinderDual rod cylinder(Compact type)Dual rodcylinderCompactcylinder with guideRotary actuatorRotary tableAir gripperAir slide table11-CJ211-CM211-CG111-CQS11-CQ211-CUJ11-CU11-REC11-CXSJ11-CXSL13-MGPL11-CRA111-MSQ11-MHZ211-MHR2Æ311-MHL213-MXS,MXQ11-MXP,MXPJ6¿10, ¿16¿20 to ¿40¿20 to ¿40¿50, ¿63¿12 to ¿25¿32, ¿40¿50, ¿63¿6, ¿8¿10¿6¿10¿16 to ¿25¿20¿25 to ¿40¿6¿10¿6¿10¿15¿20, ¿25¿32¿12 to ¿25¿32, ¿40¿50 to ¿63size30size50Size10 to Size50¿10¿16¿20¿25Size10 to Size30¿10 to ¿32¿6 to ¿12¿16¿20¿25¿6¿10¿12¿16121020551023610121271525101520510101511122102512351346Front matter 10

131 <strong>Clean</strong> <strong>Series</strong> Basic SpecificationsDischarges Particles Out ofThe <strong>Clean</strong> RoomAir Cylinder/Rotary Actuator/Air GripperAny external leakage is exhausted outside theclean room through the relief port.Prevents Particle GenerationCylinder with Guide/Rodless CylinderSpecial treatment on the guide and sliding partprevents grease scattering.Relief portSpecial treatmentSpecial treatmentActuatorRelief portSpecial treatmentSolenoidValveSolenoid ValveCommon exhaust mechanismallows air from the pilot valveto be exhausted outsidethe clean room.RegulatorBreathing air is exhaustedoutside the clean roomthrough the relief port.Reliefport<strong>Clean</strong> RegulatorExcellent corrosion resistance dueto use of stainless steel for all fluidcontact parts and electrolyticaluminum on external metal parts.Air LineEquipmentAir FilterDrainage is exhaustedoutside the clean roomthrough the drain guide.<strong>Clean</strong> Gas FilterThe PTFE membraneelement enablesprecision filtering.Drain guideFittings&Tubing<strong>Clean</strong> One-touch FittingsPrevents sliding and reduces particle generationby holding cushion and fixing packing. Blow typeis completely oil free and uses non-metal materialfor fluid contact areas.<strong>Clean</strong> TubingPolyolefine resinFront matter 11

142 System Circuit in <strong>Clean</strong> RoomFollowing are the actuator driving system and circuit configuration of blow system employed toreduce particle generation when using pneumatic equipment in a clean room.Actuator driving system<strong>Clean</strong> blowing systemInside clean roomInside clean roomRelief port pipingSolenoid valveexhaust pipingBreathing vent Drain pipingpiping of regulatorSupermistseparator10-AMEOdorremovalfilter10-AMF<strong>Clean</strong>regulatorSRH2 port airoperatedvalveLV<strong>Clean</strong> gasfilterSFA<strong>Clean</strong> blowAir micro meterActuatorFlow controlequipmentAir filter/RegulatorSFBPressure feed ofclean liquidSFCAir cylinderAir cylinder10- <strong>Series</strong> 11-CJ2/CJ2W/CJ2RAAir cylinder10- <strong>Series</strong> 11-CM2/CM2W/CM2RAir cylinder10- <strong>Series</strong> 11-CG1CG1W/CG1RMini free mount cylinder10- <strong>Series</strong> 11-CUJFree mount cylinder10- <strong>Series</strong> 11-CUCompact cylinder10-<strong>Series</strong> 11-CQSCompact cylinder10-<strong>Series</strong> 11-CQ2End lock cylinder<strong>Series</strong> 10-CBM2Sine cylinder10-<strong>Series</strong> 11-RECDual rod cylinder/Compact11-<strong>Series</strong> 12-CXSJDual rod cylinder11-<strong>Series</strong> 12-CXSLCompact cylinder with guide12-<strong>Series</strong> 13-MGPLGuide table<strong>Series</strong> 10-MGFAir slide table<strong>Series</strong> 11-MXP/MXPJ6Air slide table<strong>Series</strong> 13-MXQAir slide table<strong>Series</strong> 13-MXS<strong>Clean</strong> rodless cylinder<strong>Series</strong> CYPMagnetically coupled rodless cylinder<strong>Series</strong> 12-CY1BMagnetically coupled rodless cylinder<strong>Series</strong> 12-CY1RSine rodless cylinder<strong>Series</strong> 12-REALow speed cylinder10-<strong>Series</strong> 11-CQSXLow speed cylinder10-<strong>Series</strong> 11-CQ2XLow speed cylinder10-<strong>Series</strong> 11-CM2XRotary actuatorRotary actuator/Vane type<strong>Series</strong> 10-CRB1Rotary actuator/Rack pinion type<strong>Series</strong> 11-CRA1Rotary table/Rack pinion type<strong>Series</strong> 11-MSQAir gripperParallel type air gripper11-MHZ2Rotary type air gripper11-MHR2Rotary type air gripper11-MHR3Wide opening parallel type air gripper11-MHL2<strong>Clean</strong> speed controllerAS-FPG/FPQWith One-touch fitting(Elbow/Universal)10-AS-FWith One-touch fitting stainless steel specifications(Elbow/Universal)10-AS-FGWith One-touch fitting stainless steel specifications(In-line)10-AS-FGWith One-touch fitting dual type10-ASDWith One-touch fitting low speed specifications10-AS-FMWith One-touch fitting low speed/dual type10-ASD-FMWith One-touch fitting stainless steel/dual type10-ASD-FGCylinder direct mount type metal elbow10-AS1200 to 4200Inline type10-AS1000 to 5000Directional control valve5 port solenoid valve10-SZ30005 port solenoid valve10-SQ1000/20004/5 port solenoid valve10-SY3000/5000/70004/5 port solenoid valve10-SYJ3000/50003 port solenoid valve10-SY1003 port solenoid valve10-SYJ300/5005 port solenoid valve10-VQ1000/20003 port solenoid valve10-VQ1004 port solenoid valve10-VQD1000Air filter/Modular type10-AF3000 to 6000Mist separator/Modular type10-AFM3000/4000Micromist separator/Modular type10-AFD3000/4000Regulator/Modular type10-AR2000 to 6000Direct operated precision regulator/Modular type10-ARP3000Regulator with check valve/Modular type10-AR2560/3060/4060Filter regulator/Modular type10-AW3000/4000Mist separator regulator/Modular type10-AWM3000/4000Micro mist separator regulator/Modular type10-AWD3000/4000Precision regulator10-IR1000/2000/3000Fittings & Tubing<strong>Clean</strong> One-touch fittings (for blow)<strong>Series</strong> KP<strong>Clean</strong> One-touch fittings (for air piping of driving system)<strong>Series</strong> KPQ/KPGOne-touch mini10-KJOne-touch fittings10-KQOne-touch fittings stainless specifications10-KGInsert fittings10-KFMiniature fittings10-MStainless steel miniature fittings10-MSRectangular multi-connector10-KDM<strong>Clean</strong> tubing/Polyolefin<strong>Series</strong> TPH<strong>Clean</strong> tubing/Soft polyolefine<strong>Series</strong> TPSPolyurethane tubing10-TUPolyurethane coil tubing10-TCUPolyurethane flat tubing10-TFUN2Gas<strong>Clean</strong> regulatorExcellent corrosion resistance due to use of stainlesssteel for all fluid contact parts and electrolytic aluminumon external metal parts.<strong>Clean</strong> room regulatorSRH 3000/4000Air preparation equipmentMist separator 10-AM150 to 850Micromist separator 10-AMD150 to 850Super mist separator 10-AME150 to 850Order removal filter 10-AMF150 to 850Fittings & TubingApproved<strong>Clean</strong> One-touch fittingKP<strong>Clean</strong> tubingTPH/TPS<strong>Clean</strong> gas filterN2 blowAll products undergo consistent manufacturing process in a clean room(of CLASS 100 atmosphere) including ultrasonic pure water cleaning,assembly, inspection and double bag sealing.Cartridge typeDisc typeSFA100/200/300Straight typeSFB100Disposable typeStraight typeSFB300Multiple disc typeSFC100Front matter 12Front matter 13

153 How to Use <strong>Clean</strong> <strong>Series</strong>The position of the pneumatic equipment in relation to the workpiece is determined by the degree of particle generation.The grade number of the pneumatic equipmentor moreThe grade number of the particle density around the workpieceClassification of particlegeneration gradesSelection procedureqParticle density(particles/ft 3 )10 410 310 21010.1Particle density(particles/m 3 )10 510 410 310 210(Equivalent to Class 1000)Grade 4(Equivalent to Class 100)Grade 3Grade 2(Equivalent to Class10)Grade 1(Equivalent to Class 1)10.1 0.5 1Particle diameter (µm)∗ The grading in the left figure is based on SMCoriginal representation. The grade numberdecreases with the amount of particle generation.(For particle generation measurement method,please refer to Item 4 particle generationmeasurement method.)What is the cleanliness of the clean room? Class10 or Class100 or Class1000 ?wHow does the air currents to theworkpiece flow? (Refer to Diagram 1.)Diagram 1 Condition of air currentsWorkpiece AThe air current is blockedbefore the workpiece.Workpiece BConvection currents are frequentlygenerated around the workpiece.eWhere is the pneumatic equipmentused? (Refer to Diagram 2.)Workpiece CThe air current flows freely.Workpiece DThe air is suctioned forcedlybelow the workpiece.rFrom the above 3 items, decide thegrade number of the particle densityaround the workpiece (Table 1).Diagram 2 Point of useCurrentAbove the workpieceWorkpieceUnstable areaBelow the workpiecerSelect the equipment to be usedfrom Table 2.Stable areaTable 1 Grades of particle density around the workpiecew Workpiece A, B Ce Position of the equipmentto be usedUpstream tothe workpieceDownstream to the workpieceUnstable area Stable areaUpstream tothe workpieceDownstream to the workpieceUnstable area Stable areaUpstream tothe workpieceDDownstream to the workpieceUnstable area Stable areaClass 10Grade 1Grade 2 Grade 1 Grade 2q <strong>Clean</strong>linessClass 100Grade 2 Grade 3Grade 3Class 1000Grade 1 Grade 2 Grade 3 Grade 2Grade 3 Grade 4Grade 2Grade 3 Grade 4The cleanliness of Class 10 and 1000 is not available for the sections indicated withbecause of dust accumulation and flotation.Front matter 14

16Table 2 Grading of Particle Generation for <strong>Pneumatic</strong> EquipmentAir cylinderModelCJ2CM2CG1Standard product <strong>Series</strong> 10- <strong>Series</strong> 11- <strong>Series</strong> 12- <strong>Series</strong> 13-Compact cylinderCQSCQ2Mini freemount cylinderCUJGrade 3Grade 2 Grade 1Free mount cylinderCUEnd lock cylinderCBM2Sine cylinderRECDual rod cylinderCompact typeCXSJLCXSJMGrade 3Grade 4Grade 1Grade 1Grade 2Dual rod cylinderCXSLCXSMGrade 3Grade 4Grade 1 Grade 2Compact cylinderwith guideMGPLGrade 4Grade 3Grade 2Air slide tableWithout adjusterMXSRubber stopperMXQMetal stopperMXP(J)Without adjuster∗Rubber stopperMetal stopper∗ The option without adjusteris not available for 11-MXP6.Grade 1Grade 2Grade 4Grade 3Grade 4<strong>Clean</strong> rodless cylinder CYP Grade 2Magnetically coupledrodless cylinderCY1BCY1RGrade 4Grade 3Sine rodless cylinderREAGuide tableMGFGrade 4Grade 2Rotary actuatorMSQCRA1CRB1Grade 3Grade 4Grade 2Grade 1Grade 2Air gripperMHRMHL2MHZ2Grade 4Grade 1Grade 2Grade 2Speed controllerStandard typeWith one-touch fittingsGrade 1Grade 3<strong>Clean</strong> one-touchfittingsFittingsInsertMiniatureOne-touchSolenoid valveFor blowing/KPFor piping of driving air/KPQKFM, MSKQ, KJ, KGVQSY/SXGrade 1Grade 3(Rubber seal)RegulatorFilterARAFGrade 3Grade 3<strong>Clean</strong> regulatorSRHGrade 1Precision clean regulator SRPGrade 3<strong>Clean</strong> exhaust cleaner AMP Grade 3Grade 1Grade 3Grade 1Grade 1Grade 1Indicates that production is possible.Please contact SMC for details.Note) With one-touch fittings (KQ/KG, solenoidvalve manifold with built-in one-touchfittings and speed controller with onetouchfittings), changes in internalpressure may cause the collet chuck tomove slightly, which can result in particlegeneration.Therefore, please avoid using theabove-mentioned products in the Grade1 and Grade 2 areas. This will nothappen with insert fittings (KF) andminiature fittings (M, MS).Front matter 15

174 Particle Generation Measuring MethodThe particle generation data for the SMC CLEAN SERIES are measured in the following test method.[Test method 1] (Example)Put the specimen in the acrylic resin chamber and operate it while supplying the same flow rate of clean air asthe suction flow rate of the measurement equipment (15 l/min). Measure the chronological changes of theparticle density until the number of cycles reaches the specified point.The chamber is located in a Class 100 clean bench.[Measurement conditions]Unobstructed 15lChamberQuality of supply air Same as the supply air for driving.ModelTS-1500Measuring Minimum measurableinstrument0.17µmparticle diameterInlet flow rate 15l/minManufacturerHitachi electronicengineering Co. Ltd.SettingconditionsNameSampling timeInterval timeSampling air flowLaser dust monitor(automatic particle counterby light scattering method)5min55min75l<strong>Clean</strong> system<strong>Clean</strong> gasfilter<strong>Clean</strong> gasfilter<strong>Clean</strong> bench (Class 100)Supply rate 15l/minExhaustedfrom relief portLaser dust monitor(Suction amount15l/min)Generated output measuring circuit[Evaluation method]To obtain the measured value of particle density, the accumulated value Note 1) of particles captured by the laser dustmonitor every 5 minutes is converted into the particle density in every 1m 3 .The value used to determine the particle generation grade Note 2) is considered to be 100% against the percentage of theaverage of actually measured particle density value assumed as 95%.The extra 5% is added to ensure cleanliness in the actual operation.The graphs are plotted based on the value considered to be 100% against the percentage of the average particelddensity as 95%. The extra 5% is added to ensure cleanliness in the actual operation.Note 1) Sampling air: Number of particles contained in 75l of airNote 2) Actuator: 1 million cyclesSolenoid valve: 20 million cycles Particle generationcharacteristics of CM2 Particle generationcharacteristics of CXSL Particle generationcharacteristics of CY1BParticle density (particles/m 3 )10 610 510 410 310 210Standardproduct10-CM211-CM2Particle density (particles/m 3 )10 610 510 410 310 210Standardproduct12-CXSL11-CXSLParticle density (particles/m3)10 610 510 410 310 210Standardproduct12-CY1B1 110.1 0.5 10.1 0.5 10.1 0.5 1Particle diameter (µm) Particle diameter (µm) Particle diameter (µm)Front matter 16

<strong>Clean</strong> <strong>Series</strong>Index Guide18Basic <strong>Series</strong> Cylinder with Guide Air Slide Table Rodless Cylinder Low Speed Cylinder10-11-CJ210-11-CM210-11-CG110-11-CUJ10-11-CUAir Cylinder<strong>Series</strong> CJ2P.8Air Cylinder<strong>Series</strong> CM2P.20Air Cylinder<strong>Series</strong> CG1P.36Mini Free Mount Cylinder<strong>Series</strong> CUJP.48Free Mount Cylinder<strong>Series</strong> CUP.5210-11-CQS10-11-CQ2Compact Cylinder<strong>Series</strong> CQSP.56Compact Cylinder<strong>Series</strong> CQ2P.64End Lock Cylinder10- <strong>Series</strong> CBM2CBM2 P.7210-11-RECSine Cylinder<strong>Series</strong> RECP.7811-12-CXSJDual Rod Cylinder/Compact Type<strong>Series</strong> CXSJP.8411- Dual Rod Cylinder12- <strong>Series</strong> CXSLCXSL P.8812- Compact (Type) Cylinder with Guide13- <strong>Series</strong> MGPLMGPL P.9810-MGFGuide Cylinder Table<strong>Series</strong> MGFP.10211-MXP/MXPJ613-MXQ13-MXSAir Slide Table<strong>Series</strong> MXP/MXPJ6P.106Air Slide Table<strong>Series</strong> 13-MXQP.116Air Slide Table<strong>Series</strong> 13-MXSP.144CYP12-CY1B12-CY1R12-REA<strong>Clean</strong> Rodless Cylinder<strong>Series</strong> CYPP.166Magnetically Coupled Rodless Cylinder<strong>Series</strong> CY1BP.172Magnetically Coupled Rodless Cylinder<strong>Series</strong> 12-CY1RP.176Sine Rodless Cylinder<strong>Series</strong> REAP.17810- Low Speed Cylinder11- <strong>Series</strong> CQSXCQSX P.18010- Low Speed Cylinder11- <strong>Series</strong> CQ2XCQ2X P.18210- Low Speed Cylinder11- <strong>Series</strong> CM2XCM2X P.184ActuatorVane Type10- <strong>Series</strong> CRB1CRB1 P.192Rack Pinion Type11- <strong>Series</strong> CRA1CRA1 P.204Rotary Table/Rack and Pinion Type11- <strong>Series</strong> MSQMSQ P.210Rotary Actuator11-MHZ2Parallel Type<strong>Series</strong> MHZ2P.216Rotary Actuated11- <strong>Series</strong> MHR2MHR2 P.220Rotary Actuated11- <strong>Series</strong> MHR3MHR3 P.22611-MHL2Wide Opening Parallel Type<strong>Series</strong> MHL2P.230Air Gripper10-SZ10-SQ5 PortSZ3000P.2405 PortSQ1000/2000P.25410-SY10-SYJ5 PortSY3000/5000/7000P.2704/5 PortSYJ3000/5000P.31010-SY10-SYJ3 PortSY100P.3443 PortSYJ300/500P.35210-VQ10-VQ5 PortVQ1000/2000P.3683 PortVQ100P.41810-VQD4 PortVQD1000P.428DirectionalControl ValveFlow Control Equipment Air Filter/Regulator Fittings & TubingAS10-AS<strong>Clean</strong> Speed Controller<strong>Series</strong> ASP.434Speed Controller<strong>Series</strong> ASP.43810-AF10-ARAir Filter<strong>Series</strong> AFP.474Regulator<strong>Series</strong> ARP.48210-AW10-IRFilter Regulator<strong>Series</strong> AWP.494Precision Regulator<strong>Series</strong> IRP.50610-KFittings & Tubing<strong>Series</strong> KP.514Air Line Equipment10-AMMist Separator<strong>Series</strong> AMP.592Micro Mist Separator10- <strong>Series</strong> AMDAMD P.596Super Mist Separator10- <strong>Series</strong> AMEAME P.60010-AMFOdor Removal Filter<strong>Series</strong> AMFP.60410-IDGHollow Fiber Membrane Air Dryer<strong>Series</strong> IDGP.608Exhaust <strong>Clean</strong>er for <strong>Clean</strong> RoomAMP <strong>Series</strong> AMPP.610Air PreparationEquipment10-PSEHigh Precision Separate TypeDigital Pressure SwitchP.61810-ZSE40(F)ISE40High PrecisionDigital Pressure SwitchP.62610-ZSE5BISE5BDigital Pressure SwitchWith BacklightP.63210- Digital Pressure SwitchZSE6B With BacklightISE6B P.636Pressure Switch<strong>Clean</strong> RegulatorSRH SRH3000•4000P.640SRPPrecision <strong>Clean</strong> RegulatorSRP1000P.644<strong>Clean</strong> Regulator<strong>Clean</strong> Gas FilterSF <strong>Series</strong> SFA,SFB,SFCP.650<strong>Clean</strong> Gas FilterFront matter 17

Front matter 1819

<strong>Clean</strong> <strong>Series</strong>Actuator20Basic <strong>Series</strong> Cylinder with Guide Air Slide Table Rodless Cylinder Low Speed Cylinder10-11-CJ210-11-CM210-11-CG110-11-CUJ10-11-CUAir Cylinder<strong>Series</strong> CJ2P.8Air Cylinder<strong>Series</strong> CM2P.20Air Cylinder<strong>Series</strong> CG1P.36Mini Free Mount Cylinder<strong>Series</strong> CUJP.48Free Mount Cylinder<strong>Series</strong> CUP.5210-11-CQS10-11-CQ2Compact Cylinder<strong>Series</strong> CQSP.56Compact Cylinder<strong>Series</strong> CQ2P.64End Lock Cylinder10- <strong>Series</strong> CBM2CBM2 P.7210-11-RECSine Cylinder<strong>Series</strong> RECP.7811-12-CXSJDual Rod Cylinder/Compact Type<strong>Series</strong> CXSJP.8411- Dual Rod Cylinder12- <strong>Series</strong> CXSCXSL P.8812-13-MGPL10-MGFCompact Cylinder with Guide<strong>Series</strong> MGPLP.98Guide Table<strong>Series</strong> MGFP.10211-MXP/MXPJ6Air Slide Table<strong>Series</strong> MXP/MXPJ6P.106Air Slide Table13- <strong>Series</strong> 13-MXQMXQ P.11613-MXSAir Slide Table<strong>Series</strong> 13-MXSP.144CYP12-CY1B12-CY1R12-REA<strong>Clean</strong> Rodless Cylinder<strong>Series</strong> CYPP.166Magnetically Coupled Rodless Cylinder<strong>Series</strong> CY1BP.172Magnetically Coupled Rodless Cylinder<strong>Series</strong> 12-CY1RP.176Sine Rodless Cylinder<strong>Series</strong> REAP.17810- Low Speed Cylinder11- <strong>Series</strong> CQSXCQSX P.18010- Low Speed Cylinder11- <strong>Series</strong> CQ2XCQ2X P.18210- Low Speed Cylinder11- <strong>Series</strong> CM2XCM2X P.184Actuator1

21Actuator/Common Precautions 1Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.WarningPrecautions on DesignqThere is a possibility of dangerous sudden action by air cylinders ifthe sliding parts of machinery are twisted due to external forces, etc.In such cases, it may cause human injury by catching in human handsor feet or damage the machinery. Adjust the equipment for smoothmovement and design a system that can prevent human injury.wInstall a protective cover to minimize the risk of injury incase it is especially likely that human injury may be caused.If the driven object or the movable part of the cylinder cancause danger to the human body, design a configuration thatwill not allow human body to contact these parts directly.eSecurely tighten all stationary parts and joints sothat they will not become loose.Adopt a secure fastening method when the cylinder operates ata high frequency or is installed in a place with a lot of vibration.rA deceleration circuit may be required.If the driven object moves at a high speed or has a heavy weight, thecylinder cushion alone may not be able to absorb the impact. Install acircuit for deceleration before cushioning to moderate the impact.In this case, the rigidity of the machinery should also be examined.tConsider possible drops in circuit pressure due topower failure or some other factors.In case the cylinder is used in a clamping mechanism, a drop incircuit pressure may result in decrease of the clamping forceand consequently dropping of the work piece.Install safety equipment to protect the human body ormachinery against injury or damage. Suspension mechanismand lifting devices also need measurement against dropping.yConsider a possible loss of power source.If the product is controlled by pneumatic pressure, electricity or hydraulicpressure, take measures against possible failure of the power source sothat the failure will cause no human injury or damage to equipment.uDesign circuitry to prevent sudden lurching of the driven object.When the cylinder is driven with an exhaust center directional controlvalve or is started after the residual pressure is exhausted from thecircuit, the pressure is applied to one side of the piston in the absenceof air inside the cylinder. Therefore, the driven object will lurch at ahigh speed, which can cause human injury by catching in hands andfeet or damage to equipment. Select equipment and design circuit sothat lurching will be prevented.iConsider the behavior at an emergency stop.Design a system that will prevent human injury or equipment damagecaused by the cylinder movement when the machine is halted by amanual emergency stop or by a safety device detecting abnormalitysuch as power failure.oConsider the behavior on restart after an emergencystop or abnormal stop.Design a system so that no damage to human or equipment willbe caused on restart of operation.When the cylinder has to be reset at the start position, installmanual safety equipment.WarningSelectionqConfirm the specifications.The products in this catalog are designed to be used inindustrial compressed air systems only. If the products areused in an environment where pressure, temperature, etc. areout of the specified range, damage and/or malfunction may becaused. Do not use under such conditions. (Refer to thespecifications).Consult SMC in case any fluid other than compressed air is tobe used.wIntermediate stopWhen the cylinder piston is stopped at an intermediate positionwith a 3 position closed center directional control valve, it isdifficult, due to air compressibility, to achieve a stop position asprecisely and accurately as in cases using hydraulic pressure.Furthermore, since valves and cylinders are not guaranteed forzero air leakage, they may not be able to hold a stop positionfor an extended period of time. Consult SMC in case it isnecessary to hold a stopped position for an extended period.CautionqDo not exceed the maximum applicable stroke.Operation at a stroke exceeding the maximum stroke maydamage the piston rod. Refer to the model selection procedurefor information about the maximum applicable stroke.wOperate the piston within the proper range so thatcollision damage will not occur at the stroke end.Operate within a range that will not cause any damage whenthe piston having inertial force stops by striking the cover at thestroke end. Refer to the cylinder selection procedures for therange within which damage will not be caused.eUse a speed controller to adjust the driving speed ofthe cylinder, gradually increasing it from a smallvalue to the desired speed setting.rProvide an intermediate support for a cylinder with along stroke.If the cylinder has a long stroke, provide an intermediatesupport to prevent rod sagging and tube flexing, as well as toprevent damage to the rod due to vibrations or external loads.2

22Actuator/Common Precaution 2Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.CautionMountingqBe sure to connect the rod and the load so that theiraxial centers and movement directions match.If the cylinder is not properly aligned, the rod and tube may betwisted. This can wear out the inner surface of the tube,bushings, rod surface and seals, causing damage to these parts.wWhen using an external guide, connect the rod endand the load in such a way that there is nointerference at any point within the stroke.eDo not scratch or gouge the sliding parts of thecylinder tube or piston rod by striking them withother objects or holding them in your mouth.Cylinder bores are manufactured to precise tolerances, so thateven a slight deformation may cause malfunction. Also,scratches or gouges on the sliding part of the piston rod maydamage seals and cause air leakage.rWhen using an external guide, connect the rod endand the load in such a way that there is nointerference at any point within the stroke.After mounting, repair or modification, etc., connect the airsupply and electric power and conduct appropriate function andleakage inspections to confirm proper installation.tThe operation manualMount and operate the product after reading the manualcarefully and understanding its contents.Also keep the manual where it can be referred to as necessary.WarningAir SupplyqUse clean air.Do not use compressed air that contains synthetic oil, salt, andcorrosive gases in which chemicals and organic solvents arepresent, because it could cause equipment damage ormalfunction.CautionqMount the air filter.Install an air filter close to and upstream of the valve. Select afiltering degree of 5µm or smaller.wTake measures such as installation of after cooler,air dryer or drain catch.Compressed air containing excessive condensate may causethe valve or other pneumatic equipment to malfunction. Takecountermeasures such as installation of an after cooler, airdryer or drain catch.eUse the product within the specified range of fluidand ambient temperature.Take freeze proof measures when the temperature is 5°C orbelow. Otherwise the moisture in the circuit may freeze tocause damage to the packing or malfunction.For detailed information regarding the quality of thecompressed air descried above, refer to pages 8 to 9 of FrontMatter.ActuatorCautionCushionqReadjust with a cushion needle.Though the cushion is adjusted at the time of shipment,readjust the cushion needle on the cover according to the sizeof the load and operating speed before operating the actuator.Turn the cushion needle clockwise and meter in the throttle toimprove the cushion effect. After completing the adjustment,fasten the lock nut firmly.wDo not operate the product with the cushion needlefully closed.Otherwise the packing may be damaged.3

23Actuator/Common Precautions 3Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.WarningEnvironmentqDo not use in environments where there is danger ofcorrosion.Refer to the construction drawings regarding cylinder materials.wInstall a cover over the rod if it is used in an areathat is dusty, or in an environment in which water orwashing solvent splashes on the cylinder.WarningMaintenanceqMaintenance should be conducted according toprocedures described in the operation manual.Improper handling may result in malfunction and damage ofmachinery or equipment.wMachine maintenance and supply/exhaust of compressedairWhen machine is to be serviced, first check for removal ofwork pieces and run-away of equipment, etc. Then, shut off thesupply pressure and power and exhaust compressed air in thesystem through residual pressure release mechanism.When machinery is restarted, confirm that a lurch preventionmeasure is taken.CautionqDrainRemove condensate from air filters regularly.4

24Auto Switch/Common Precautions 1Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.WarningqConfirm the specifications.The product may be damaged or malfunction if it is used outsidethe specified range of current load, voltage, temperature or impact.wTake precautions when multiple cylinders are usedclose together.When multiple auto switch cylinders are used in closeproximity, magnetic field interference may cause the switchesto malfunction. Design a minimum interval of 40mm betweenthe cylinder tubes. (When the allowable interval is indicated foreach cylinder series, use the specified value.)ePay attention to the length of period when the switchis ON at an intermediate stroke position.In case an auto switch is placed at an intermediate position ofthe stroke and the load is supposed to be driven while thepiston passes, an excessively high piston speed may not allowenough time for the load to operate, even though the autoswitch will operate. The maximum detectable piston speed isV (mm/s)=Auto switch operation range (mm)X 1000Load operation time (ms)For a high piston speed, auto switches with built-in off delaytimer (approx. 200ms) (D-F5NT, F7NT, G5NT and M5T) canbe used to extend the load operation time.rKeep the wiring as short as possible.The rush current at the time of switching ON increases with thelength of wiring to the load, which may shorten the product's life(The switch will stay ON all the time).1)For an auto switch without a contact protection circuit, use acontact protection box when the wire length is 5m or longer.2)Even when an auto switch has a built-in contact protectioncircuit, with a lead wire length of 30m or longer, the rush currentmay not be adequately absorbed and the life of the switch maybe shortened. Contact SMC in such a case, as it will benecessary to connect a contact protection box to extend the lifeof the switch.3)Although the length should not affect the switch function, usea wire of 100m or shorter.tWatch for internal voltage drops of the switch.1)Switches with indicator light (Not including Models D-A56,A76H, A96, A96V, C76, E76A and Z76).If auto switches are connected in series as shown below,take note that there will be a large voltage drop because ofinternal resistance of the light emitting diode. (Refer to theinternal voltage drop in the auto switch specifications.)[If n pieces of auto switches are connected, the pressure dropwill be n times as large.]Although the auto switch may operate normally, the load mayLoadDesign • SelectionIn the same way, when operating below the specifiedvoltage, although an auto switch may operate normally, theload may not operate. Therefore, the formula below should besatisfied after confirming the minimum operating voltage ofthe load.Supplyvoltage–Internal voltagedrop of switchMinimum operatingvoltage of load2)If the internal resistance of the light emitting diode causes aproblem, select a switch without an indicator light (Models: D-A6, A80, A80H, A90, A90V, C80, R80, 90, E80A, Z80).3)Generally, the internal voltage drop will be greater with a 2wire solid state auto switch than with a reed switch. Take thesame precautions as in 1).Also, note that a 12VDC relay is not applicable.yTake precautions against leakage current.With a 2 wire solid auto switch, current (leakage current) flowsto the load to operate the internal circuit even when the switchis OFF.Operating current of load> Leakage current(Input OFF current of controller)If the above condition is not met, the switch will not be resetproperly (will stay ON). Use a 3 wire switch if the specificationis not satisfied.The leakage current flow to the load will be "n" times as largewhen "n" pieces of auto switches are connected in parallel.uDo not use a load that generates surge voltage.When driving a load that generates a surge voltage, such as arelay, use a switch with a built-in contact protection circuit oruse a contact protection box.Although a zener diode for surge protection is connected at theoutput side of a solid state auto switch, damage may still becaused if the surge is applied repeatedly. When a load, such asa relay or solenoid, which generates surge is driven directly,use a switch with a built-in surge absorbing element.iCaution for use in an interlocking circuitWhen an auto switch is used for an interlock signal requiringhigh reliability, devise a double interlock system to avoid troubleby providing a mechanical protection function or by also usinganother switch (sensor) together with the auto switch.At the same time, perform periodic inspections to confirmproper operation.oEnsure sufficient clearance for maintenance activities.When designing an application, be sure to allow sufficient clearancefor maintenance and inspections.>Actuator5

25Auto Switch/Common Precautions 2Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.WarningMounting • AdjustmentqDo not drop or bump.Do not drop, bump or apply excessive impacts (300m/s 2 ormore for reed switches and 1000m/s 2 or more for solid stateswitches) while handling. Although the body of the switch maynot be damaged, the internal parts could be damaged andcause a problem.wDo not carry a cylinder by the auto switch lead wires.It may not only cause the lead wires to be cut off but also causeinternal elements of the switch to be damaged by stress appliedto the internal parts of the switch.eWhen installing the product, observe the prescribedtightening torque specifications.When a switch is tightened with a force larger than thetightening torque range, the mounting screws, mountingbrackets or switch may be damaged.On the other hand, tightening with a force below the tighteningtorque range may allow the switch to slip out of position.rMount the switch at the center of the operatingrange.Adjust the mounting position of the auto switch so that thepiston will stop at the center of the operating range (the rangein which the auto switch is ON). (The catalog shows theoptimum mounting position at the stroke end.) If mounted onthe edge of the operating range (around the border betweenON and OFF ranges), the operation may be unstable.WarningWiringqDo not apply repeated bending stress or stretchingforce to the lead wire.Disconnection may result from wiring that applies repeatedbending stress or stretching force to lead wires.wBe sure to connect the load before power is applied.The switch will be instantly damaged by an overcurrent if it isturned on without any load connected.eConfirm proper insulation of wiring.Make sure that there is no faulty wiring insulation (contact withother circuits, ground fault, improper insulation betweenterminals, etc.). Damage may be caused due to excess currentflow into the auto switch.rDo not wire with power lines or high voltage lines.Wire separately from power lines or high voltage lines, avoidingparallel wiring or wiring in the same conduit with these lines.Control circuits, including auto switches, may malfunction dueto noise from these other lines.WiringtDo not allow short circuits of loads.If the power is turned ON while the load is short circuited, theswitch will be instantly damaged because of excess currentflow into the switch.Models D-F9(V), F9W(V), J51, G5NB and all models ofPNP output switches do not have built-in short circuitprevention circuits. If loads are short circuited, the switches willbe instantly damaged.Take special care to avoid reverse wiring of the power supplyline (brown) and the output line (black) with 3 wire typeswitches.yAvoid incorrect wiring.A 24VDC switch with indicator light has polarity. The brownlead wire or terminal No.1 is (+), and the blue lead wire orterminal No.2 is (-).[In the case of model D-97, the side without indicator is (+) andthe black line side is (-).]1)If connections are reversed, the switch will operate, however,the light emitting diode will not light up.Also, not that a current larger than that specified will damagethe light emitting diode, making it unable to operate again.Applicable modelsD-A73, A73H, A73C, C73, C73C, E73A, Z73, R73D-97, 93A, A93, A93VD-A33, A34, A33A, A34A, A44, A44AD-A53, A54, B53, B542)However, when using a 2 color indication auto switch (D-A79W, A59W, B59W), be aware that the switch willconstantly remain ON if the connections are reversed.1)If connections are reversed on a 2 wire type switch, theswitch will not be damaged when protected by a protectioncircuit, but it will always stay ON. However, it is stillnecessary to avoid reverse connections since they willdamage the switch when the load is short circuited.2)If connections are reversed (power supply line + and powersupply line -) on a 3 wire type switch, the switch will beprotected by a protection circuit. However, if the powersupply line (+) is connected to the blue (black) wire and thepower supply line (-) to the black (white) wire, the switch willbe damaged.uProcess the terminal before carrying the auto switchinto the clean room.Some lead wires contain white powder to prevent anastomosisof the sheath and the core wires. If this powder can possibly bea problem, before carrying it into the clean room, cut the leadwire, remove the powder adhering to the insulator and coat thesheath sectional area with an insulation tape to prevent powderfrom leaking out.6

26Auto Switch/Common Precautions 3Be sure to read before handling. Refer to pages 7 to 16 of Front matter for safety instructions andcommon precautions for clean series. Refer to the main text for precautions for each series.WarningEnvironmentqNever use in an atmosphere with explosive gases.The construction of auto switches is not designed to preventexplosion. Never use in an atmosphere with explosive gasessince it may cause a serious explosion.wDo not use in an area where a magnetic field isgenerated.It can cause the auto switch to malfunction or demagnetize themagnet inside the cylinder. (Consult SMC regarding theavailability of magnetic field resistant auto switches.)eDo not use switches in applications where theswitch is continually exposed to water splash orspray.Although switches except D-A3, A44, G39, K39 satisfy theIEC standard IP67 enclosure (JIS C 0920: anti-immersionenclosure), do not use switches in applications where they arecontinually exposed to water splash or spray. Poor insulation orswelling of the potting resin inside switches may cause malfunction.rDo not use in an environment with oil or chemicals.Consult SMC if auto switches will be used in an environmentwith coolant, washing solvent, various oils or chemicals. If autoswitches are used under these conditions for even a short time,they may be adversely affected, resulting in poor insulation,malfunction due to swelling of the potting resin or hardening ofthe lead wires.tDo not use in an environment where there isexcessive impact shock.Consult SMC if switches are used where there are temperaturecycles other than normal temperature changes, as they may beadversely affected by improper insulation, malfunction due toswelling of the potting resin, or hardening of the lead wires.yDo not use in an environment where there isexcessive impact shock.When excessive impact (300m/s 2 ) is applied to a reed switch duringoperation, the contact point will malfunction and turn the signal on oroff momentarily (for 1ms or shorter). Consult SMC regarding theneed to use a solid state switch depending upon the environment.uDo not use in an environment where surges aregenerated.Where there are units (Solenoid lifter, high frequency inductionfurnace, motor, etc.) which generate a large amount of surge inthe area around cylinders with solid state auto switch, theswitch may deteriorate or be damaged. Avoid sources of surgegeneration and disorganized lines.iAvoid close contact with magnetic substances.When a magnetic substance (an object that can be attracted bymagnets) is brought into close proximity with an auto switchcylinder, it may absorb the magnetic force inside the cylinder,causing the auto switch to malfunction.WarningMaintenanceqPerform the following maintenance periodically inorder to prevent possible danger due to unexpectedauto switch malfunction.1)Secure and tighten switch mounting screws.If screws become loose or the mounting position isdislocated, retighten them after readjusting the mountingposition.2)Confirm that there is no damage to lead wires.To prevent faulty insulation, replace switches or repair leadwires, etc. when damage is discovered.3)Confirm that the green LED on the 2 color indicator lights up.Confirm that the green LED is on when the piston is stoppedat the established position. If the red LED is on, the mountingposition is not appropriate. Readjust the mounting positionuntil the green LED lights up.WarningOtherqConsult SMC concerning water resistance, elasticityof lead wires, etc.∗Lead Wire Color ChangesLead wire colors of SMC switches and related products have been changedin order to meet NECA (Nippon Electric Control Equipment IndustriesAssociation) Standard 0402 for production beginning September, 1996and thereafter.Special care should be taken regarding wire polarity during the time thatthe old colors still coexist with the new colors.2–wire systemOld New3–wire systemOld NewOutput (+) Red Brown Power supply + Red BrownOutput (–) Black BluePower supply GND Black BlueOutput White BlackSolid state with diagnostic output Solid state with latch diagnostic outputOld NewOld NewPower supply + Red BrownPower supply + Red BrownPower supply GND Black BluePower supply GND Black BlueOutput White Black Output White BlackDiagnostic output Yellow Orange Latch typeYellowdiagnostic outputOrangeActuator7

<strong>Series</strong>How to Order10-11-CJ2Air Cylinder/ø6,ø10,ø1627<strong>Clean</strong> <strong>Series</strong>10 — Relief type11 — Vacuum suction typeBuilt-in magnetNil — NoD — With auto switch(Built-in magnet)MountingB — BasicL — Axial footF — Front flangeBore size (mm)10 - C D J 2 L 16 - 60 A R - C73ModelCylinder stroke (mm)CushionNil — Rubber bumper (Standard)A — Air cushion (Not including ø6)Head cover port locationBore size(mm) 6SymbolNilR10,16— PerpendicularAxial Axialdirection directionType of auto switchReed switchC73Solid state switchH7BH7A1∗Band mounting onlyNumber of auto switchesNil —2S —1n —nRelieftypeVacuumsuction typeModel10-CJ2610-CJ21010-CJ21611-CJ2611-CJ21011-CJ216Bore size(mm)6101661016PortsizeLubricationActionStandard stroke(mm)15,30,45,6015,30,45,60,75,100,125,150Double15,30,45,60,75,100,125,150,175,200M5 X 0.8 Non-lube acting15,30,45,60single rod15,30,45,60,75,100,125,15015,30,45,60,75,100,125,150,175,200Auto switchmountingAvailableCushionRubber AirAvailable Available(Standard) (Not includingø6)Specifications8Bore size (mm)Item610,16Proof pressureMax. operating pressure1.05MPa0.7MPaMin. operating pressure0.14MPa0.08MPa (Air cushion 0.1MPa )Ambient and fluid temperaturePiston speedStroke length toleranceWithout auto switch : -10°C to 70°C, With auto switch -10°C to 60°C (With no condensation)50 to 400mm/s+1.00MountingBasic,Axial foot,Front flange

Auto Switch SpecificationsAir Cylinder 10-CJ2/11-CJ2(Refer to page 1.3-2 of Best <strong>Pneumatic</strong>s No.w for detailed specifications and auto switches not in the following table.)28StyleReed switch2-wiresystemSolid stateswitch3-wiresystemAuto switch part no.D-C73D-H7BD-H7A1∗Auto switch mounting method is band mounting only.Load voltage24VDC100VAC24VDC (10 to 28VDC)28VDC or lessLoad current range5 to 40mA5 to 20mA5 to 150mA150mA or lessIndicator lightYesYesYesApplicationRelay, PLC24VDC relay, PLCIC circuit, Relay, PLCActuatorAuto Switch/Proper Mounting Positions for Stroke End DetectionD-C73D-H7A1/H7BAuto switchAuto switch1616≅HsA 26 B≅HsA 29 BBore sizeD-C73D-H7A1/H7BA B Hs A B Hs62 2 15 1 1 15102.5 2.5 17 1.5 1.5 1716 3 3 20.5 2 2 20.5(mm)Mounting Bracket/Part No.Mounting bracketFoot bracketFlangeBore size (mm)6 10 16CJ-L010B CJ-L016B CJK-L016BCJ-F010B CJ-F016B CJK-F016BSpecific Product PrecautionsBe sure to read before handling.Refer to pages 7 to 16 of Front matter for safety instructions and common precautions for clean series andpages 2 to 7 for common precautions for actuators.CautionqWhen installing the cylinder, secure the rod cover and tighten byapplying an appropriate tightening torque to the retaining nut ortighten the body of the rod cover by applying proper tighteningtorque. Fixing the head cover or tightening the body of the headcover may lead to a deviation due to rotation of the head cover.MountingwApply proper screw tightening torque within the followingranges.ø6 : 5.9 to 6.4Nmø10 : 10.8 to 11.8Nmø16 : 20.0 to 21.0Nm9