Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

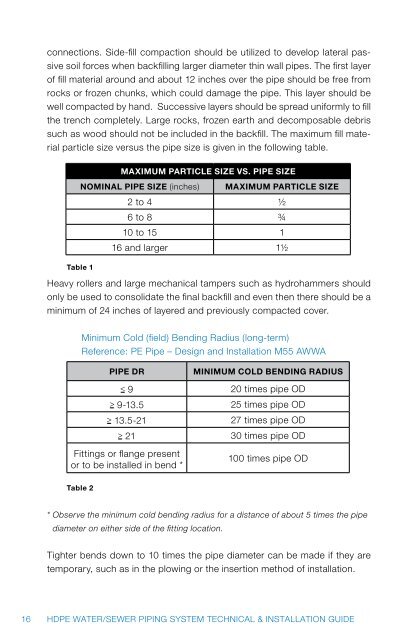

connections. Side-fill compaction should be utilized to develop lateral passivesoil forces when backfilling larger diameter thin wall pipes. The first layerof fill material around and about 12 inches over the pipe should be free fromrocks or frozen chunks, which could damage the pipe. This layer should bewell compacted by hand. Successive layers should be spread uniformly to fillthe trench completely. Large rocks, frozen earth and decomposable debrissuch as wood should not be included in the backfill. The maximum fill materialparticle size versus the pipe size is given in the following table.Maximum Particle Size vs. Pipe SizeNOMINAL PIPE SIZE (inches) Maximum Particle Size2 to 4 ½6 to 8 ¾10 to 15 116 and larger 1½Table 1Heavy rollers and large mechanical tampers such as hydrohammers shouldonly be used to consolidate the final backfill and even then there should be aminimum of 24 inches of layered and previously compacted cover.Minimum Cold (field) Bending Radius (long-term)Reference: PE Pipe – Design and Installation M55 AWWAPIPE DRMinimum Cold Bending Radius9 20 times pipe OD9-13.5 25 times pipe OD13.5-21 27 times pipe OD21 30 times pipe ODFittings or flange presentor to be installed in bend *100 times pipe ODTable 2* Observe the minimum cold bending radius for a distance of about 5 times the pipediameter on either side of the fitting location.Tighter bends down to 10 times the pipe diameter can be made if they aretemporary, such as in the plowing or the insertion method of installation.16 HDPE WATER/SEWER PIPING SYSTEM TECHNICAL & INSTALLATION GUIDE