Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

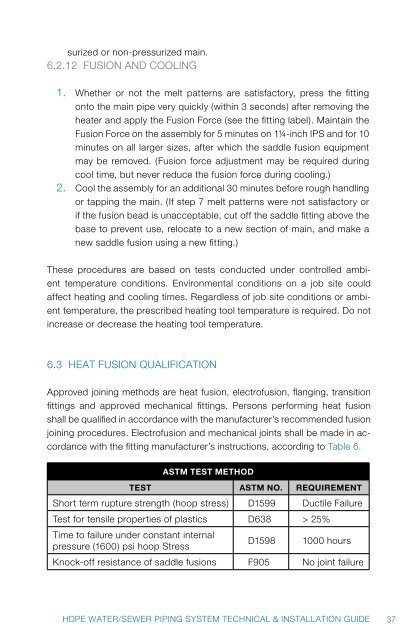

surized or non-pressurized main.6.2.12 Fusion and Cooling1. Whether or not the melt patterns are satisfactory, press the fittingonto the main pipe very quickly (within 3 seconds) after removing theheater and apply the Fusion Force (see the fitting label). Maintain theFusion Force on the assembly for 5 minutes on 1¼-inch IPS and for 10minutes on all larger sizes, after which the saddle fusion equipmentmay be removed. (Fusion force adjustment may be required duringcool time, but never reduce the fusion force during cooling.)2. Cool the assembly for an additional 30 minutes before rough handlingor tapping the main. (If step 7 melt patterns were not satisfactory orif the fusion bead is unacceptable, cut off the saddle fitting above thebase to prevent use, relocate to a new section of main, and make anew saddle fusion using a new fitting.)These procedures are based on tests conducted under controlled ambienttemperature conditions. Environmental conditions on a job site couldaffect heating and cooling times. Regardless of job site conditions or ambienttemperature, the prescribed heating tool temperature is required. Do notincrease or decrease the heating tool temperature.6.3 HEAT FUSION QUALIFICATIONApproved joining methods are heat fusion, electrofusion, flanging, transitionfittings and approved mechanical fittings. Persons performing heat fusionshall be qualified in accordance with the manufacturer’s recommended fusionjoining procedures. Electrofusion and mechanical joints shall be made in accordancewith the fitting manufacturer’s instructions, according to Table 6.ASTM Test MethodTEST ASTM NO. REQUIREMENTShort term rupture strength (hoop stress) D1599 Ductile FailureTest for tensile properties of plastics D638 > 25%Time to failure under constant internalpressure (1600) psi hoop StressD1598 1000 hoursKnock-off resistance of saddle fusions F905 No joint failureHDPE WATER/SEWER PIPING SYSTEM TECHNICAL & INSTALLATION GUIDE37