Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

Polyethylene Water/Sewer - JM Eagle

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

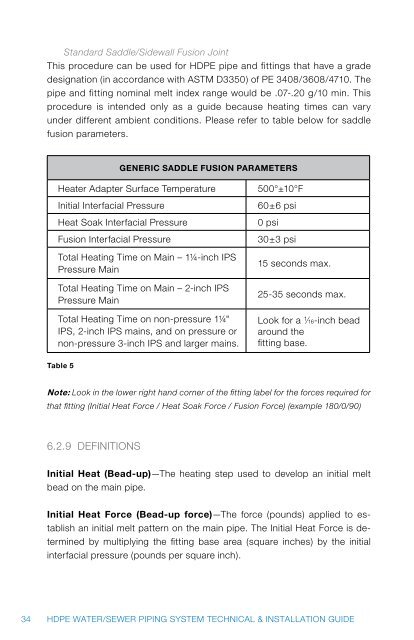

Standard Saddle/Sidewall Fusion JointThis procedure can be used for HDPE pipe and fittings that have a gradedesignation (in accordance with ASTM D3350) of PE 3408/3608/4710. Thepipe and fitting nominal melt index range would be .07-.20 g/10 min. Thisprocedure is intended only as a guide because heating times can varyunder different ambient conditions. Please refer to table below for saddlefusion parameters.Generic Saddle Fusion ParametersHeater Adapter Surface TemperatureInitial Interfacial PressureHeat Soak Interfacial PressureFusion Interfacial PressureTotal Heating Time on Main – 1¼-inch IPSPressure MainTotal Heating Time on Main – 2-inch IPSPressure MainTotal Heating Time on non-pressure 1¼"IPS, 2-inch IPS mains, and on pressure ornon-pressure 3-inch IPS and larger mains.500°±10°F60±6 psi0 psi30±3 psi15 seconds max.25-35 seconds max.Look for a 1 /16-inch beadaround thefitting base.Table 5Note: Look in the lower right hand corner of the fitting label for the forces required forthat fitting (Initial Heat Force / Heat Soak Force / Fusion Force) (example 180/0/90)6.2.9 DefinitionsInitial Heat (Bead-up)—The heating step used to develop an initial meltbead on the main pipe.Initial Heat Force (Bead-up force)—The force (pounds) applied to establishan initial melt pattern on the main pipe. The Initial Heat Force is determinedby multiplying the fitting base area (square inches) by the initialinterfacial pressure (pounds per square inch).34 HDPE WATER/SEWER PIPING SYSTEM TECHNICAL & INSTALLATION GUIDE