Griffon 2000TDX Hovercraft - HovercraftModels.com

Griffon 2000TDX Hovercraft - HovercraftModels.com

Griffon 2000TDX Hovercraft - HovercraftModels.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

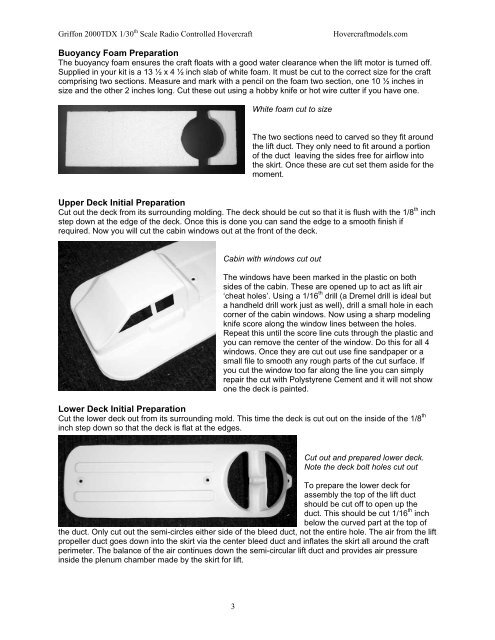

<strong>Griffon</strong> <strong>2000TDX</strong> 1/30 th Scale Radio Controlled <strong>Hovercraft</strong><strong>Hovercraft</strong>models.<strong>com</strong>Buoyancy Foam PreparationThe buoyancy foam ensures the craft floats with a good water clearance when the lift motor is turned off.Supplied in your kit is a 13 ½ x 4 ½ inch slab of white foam. It must be cut to the correct size for the craft<strong>com</strong>prising two sections. Measure and mark with a pencil on the foam two section, one 10 ½ inches insize and the other 2 inches long. Cut these out using a hobby knife or hot wire cutter if you have one.White foam cut to sizeThe two sections need to carved so they fit aroundthe lift duct. They only need to fit around a portionof the duct leaving the sides free for airflow intothe skirt. Once these are cut set them aside for themoment.Upper Deck Initial PreparationCut out the deck from its surrounding molding. The deck should be cut so that it is flush with the 1/8 th inchstep down at the edge of the deck. Once this is done you can sand the edge to a smooth finish ifrequired. Now you will cut the cabin windows out at the front of the deck.Cabin with windows cut outThe windows have been marked in the plastic on bothsides of the cabin. These are opened up to act as lift air‘cheat holes’. Using a 1/16 th drill (a Dremel drill is ideal buta handheld drill work just as well), drill a small hole in eachcorner of the cabin windows. Now using a sharp modelingknife score along the window lines between the holes.Repeat this until the score line cuts through the plastic andyou can remove the center of the window. Do this for all 4windows. Once they are cut out use fine sandpaper or asmall file to smooth any rough parts of the cut surface. Ifyou cut the window too far along the line you can simplyrepair the cut with Polystyrene Cement and it will not showone the deck is painted.Lower Deck Initial PreparationCut the lower deck out from its surrounding mold. This time the deck is cut out on the inside of the 1/8 thinch step down so that the deck is flat at the edges.Cut out and prepared lower deck.Note the deck bolt holes cut outTo prepare the lower deck forassembly the top of the lift ductshould be cut off to open up theduct. This should be cut 1/16 th inchbelow the curved part at the top ofthe duct. Only cut out the semi-circles either side of the bleed duct, not the entire hole. The air from the liftpropeller duct goes down into the skirt via the center bleed duct and inflates the skirt all around the craftperimeter. The balance of the air continues down the semi-circular lift duct and provides air pressureinside the plenum chamber made by the skirt for lift.3