ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

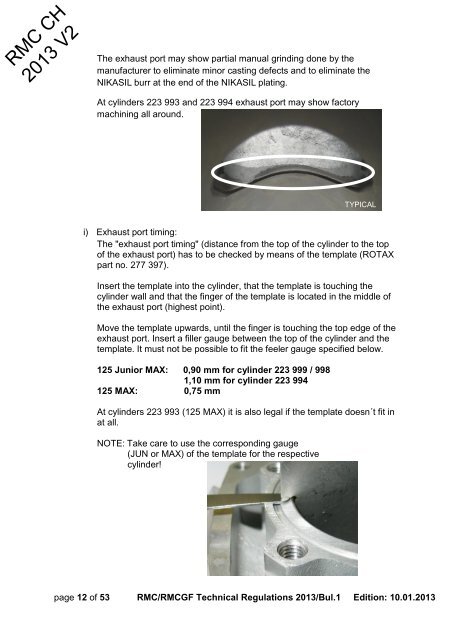

The exhaust port may show partial manual grinding done by themanufacturer to eliminate minor casting defects and to eliminate theNIKASIL burr at the end of the NIKASIL plating.At cylinders 223 993 and 223 994 exhaust port may show factoryma<strong>ch</strong>ining all around.TYPICALi) Exhaust port timing:The "exhaust port timing" (distance from the top of the cylinder to the topof the exhaust port) has to be <strong>ch</strong>ecked by means of the template (<strong>ROTAX</strong>part no. 277 397).Insert the template into the cylinder, that the template is tou<strong>ch</strong>ing thecylinder wall and that the finger of the template is located in the middle ofthe exhaust port (highest point).Move the template upwards, until the finger is tou<strong>ch</strong>ing the top edge of theexhaust port. Insert a filler gauge between the top of the cylinder and thetemplate. It must not be possible to fit the feeler gauge specified below.125 Junior <strong>MAX</strong>: 0,90 mm for cylinder 223 999 / 9981,10 mm for cylinder 223 994125 <strong>MAX</strong>: 0,75 mmAt cylinders 223 993 (125 <strong>MAX</strong>) it is also legal if the template doesn´t fit inat all.NOTE: Take care to use the corresponding gauge(JUN or <strong>MAX</strong>) of the template for the respectivecylinder!page 12 of 53 RMC/RMCGF <strong>Te<strong>ch</strong>nical</strong> Regulations 2013/Bul.1 Edition: 10.01.2013