ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

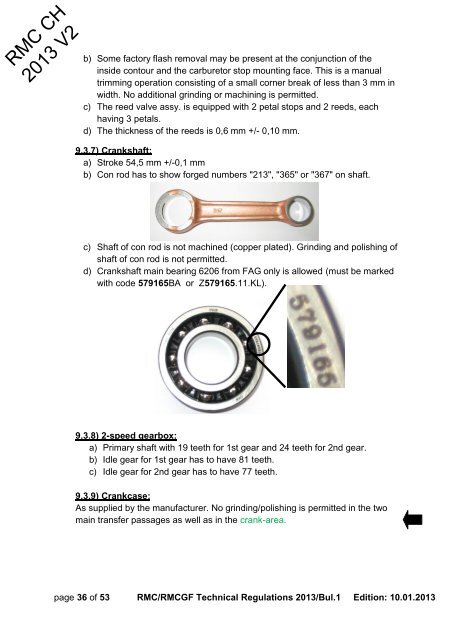

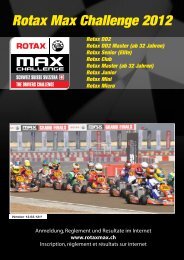

) Some factory flash removal may be present at the conjunction of theinside contour and the carburetor stop mounting face. This is a manualtrimming operation consisting of a small corner break of less than 3 mm inwidth. No additional grinding or ma<strong>ch</strong>ining is permitted.c) The reed valve assy. is equipped with 2 petal stops and 2 reeds, ea<strong>ch</strong>having 3 petals.d) The thickness of the reeds is 0,6 mm +/- 0,10 mm.9.3.7) Crankshaft:a) Stroke 54,5 mm +/-0,1 mmb) Con rod has to show forged numbers "213", "365" or "367" on shaft.c) Shaft of con rod is not ma<strong>ch</strong>ined (copper plated). Grinding and polishing ofshaft of con rod is not permitted.d) Crankshaft main bearing 6206 from FAG only is allowed (must be markedwith code 579165BA or Z579165.11.KL).9.3.8) 2-speed gearbox:a) Primary shaft with 19 teeth for 1st gear and 24 teeth for 2nd gear.b) Idle gear for 1st gear has to have 81 teeth.c) Idle gear for 2nd gear has to have 77 teeth.9.3.9) Crankcase:As supplied by the manufacturer. No grinding/polishing is permitted in the twomain transfer passages as well as in the crank-area.page 36 of 53 RMC/RMCGF <strong>Te<strong>ch</strong>nical</strong> Regulations 2013/Bul.1 Edition: 10.01.2013