Solar Heat: for My Maine Workshop - Home Power Magazine

Solar Heat: for My Maine Workshop - Home Power Magazine

Solar Heat: for My Maine Workshop - Home Power Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

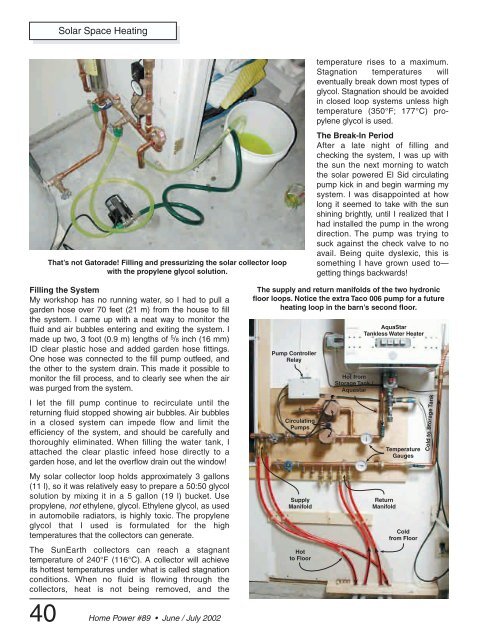

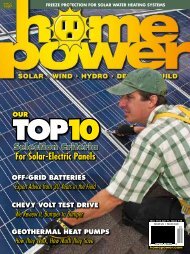

<strong>Solar</strong> Space <strong>Heat</strong>ingThat’s not Gatorade! Filling and pressurizing the solar collector loopwith the propylene glycol solution.temperature rises to a maximum.Stagnation temperatures willeventually break down most types ofglycol. Stagnation should be avoidedin closed loop systems unless hightemperature (350°F; 177°C) propyleneglycol is used.The Break-In PeriodAfter a late night of filling andchecking the system, I was up withthe sun the next morning to watchthe solar powered El Sid circulatingpump kick in and begin warming mysystem. I was disappointed at howlong it seemed to take with the sunshining brightly, until I realized that Ihad installed the pump in the wrongdirection. The pump was trying tosuck against the check valve to noavail. Being quite dyslexic, this issomething I have grown used to—getting things backwards!Filling the System<strong>My</strong> workshop has no running water, so I had to pull agarden hose over 70 feet (21 m) from the house to fillthe system. I came up with a neat way to monitor thefluid and air bubbles entering and exiting the system. Imade up two, 3 foot (0.9 m) lengths of 5 /8 inch (16 mm)ID clear plastic hose and added garden hose fittings.One hose was connected to the fill pump outfeed, andthe other to the system drain. This made it possible tomonitor the fill process, and to clearly see when the airwas purged from the system.I let the fill pump continue to recirculate until thereturning fluid stopped showing air bubbles. Air bubblesin a closed system can impede flow and limit theefficiency of the system, and should be carefully andthoroughly eliminated. When filling the water tank, Iattached the clear plastic infeed hose directly to agarden hose, and let the overflow drain out the window!<strong>My</strong> solar collector loop holds approximately 3 gallons(11 l), so it was relatively easy to prepare a 50:50 glycolsolution by mixing it in a 5 gallon (19 l) bucket. Usepropylene, not ethylene, glycol. Ethylene glycol, as usedin automobile radiators, is highly toxic. The propyleneglycol that I used is <strong>for</strong>mulated <strong>for</strong> the hightemperatures that the collectors can generate.The SunEarth collectors can reach a stagnanttemperature of 240°F (116°C). A collector will achieveits hottest temperatures under what is called stagnationconditions. When no fluid is flowing through thecollectors, heat is not being removed, and theThe supply and return manifolds of the two hydronicfloor loops. Notice the extra Taco 006 pump <strong>for</strong> a futureheating loop in the barn’s second floor.Pump ControllerRelayCirculatingPumpsSupplyManifoldHotto FloorHot fromStorage Tank /AquastarAquaStarTankless Water <strong>Heat</strong>erReturnManifoldTemperatureGaugesColdfrom FloorCold to Storage Tank40 <strong>Home</strong> <strong>Power</strong> #89 • June / July 2002